Craftsman 22 gallon air compressor is a powerful and essential tool for professionals and DIY enthusiasts. It can use for several applications, from powering air tools to inflating tires.

However, if you have never used an air compressor before, it can be daunting to figure out how to use the craftsman 22 gallon. Fear not, as this blog post guides you through the process step-by-step. We will cover everything you need to know about using the 22 gallon air compressor. From setting up the compressor to troubleshooting common issues, this guide will provide you with all the necessary information to get the most out of your air compressor.

We will also discuss the different types of air tools that you can use with the compressor and how to maintain the compressor to ensure its longevity. Whether you are a seasoned professional or a beginner, this guide is perfect for anyone learning to use the Craftsman.

How To Use Craftsman 22 Gallon Air Compressor – [Step By Step]

![How To Use Craftsman 22 Gallon Air Compressor - [Step By Step]](https://topchooser.com/wp-content/uploads/2023/07/How-To-Use-Craftsman-22-Gallon-Air-Compressor-Step-By-Step.jpg)

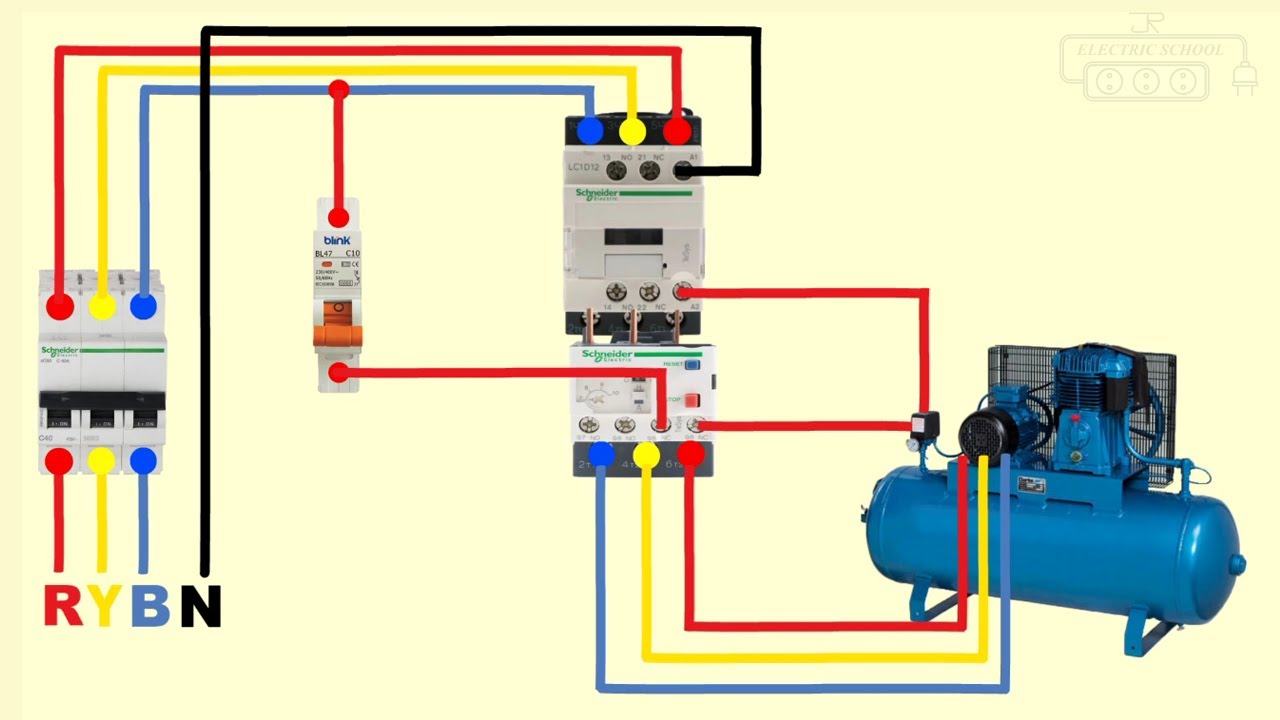

Craftsman 22 gallon air compressor is a powerful and reliable tool for various tasks. First, place the compressor on a level surface and connect it to a power source to start using it. Then, check the oil level and add oil if necessary. The compressor should also have an air filter and a pressure regulator.

Turn the compressor on by flipping the switch and allowing it to build up pressure. Once the pressure reaches the desired level, attach the air hose to the compressor and use the tool. The compressor can use for various tasks, including inflating tires, powering air tools, and spraying paint.

Checking and changing the oil level regularly is important to maintain the compressor. It’s also important to clean the air filter and check for any leaks in the system. With proper maintenance, the Craftsman 22 gallon can provide reliable performance for years. To use a Craftsman 22-gallon air compressor, follow these step-by-step instructions:

1. Set Up The Compressor

Setting up the compressor is essential to ensure optimal performance and longevity of the equipment. Firstly, identify a suitable location for a well-ventilated compressor free from moisture and dust. Once the location is determined, ensure the compressor is placed flat to prevent any vibration during operation.

The next step is to connect the air intake filter to the compressor using the provided fittings. This filter is crucial in preventing dust and debris from entering the compressor and causing damage to the internal components. After connecting the filter, checking the oil level and refilling if necessary is essential.

2. Power Connection

Using a Craftsman 22 gallon air compressor can be a game-changer for those who work with compressed air tools. However, ensuring you have a proper power connection is important before using it. Check the voltage and amperage requirements of the compressor, which can be found in the manual or on the manufacturer’s website, as the first step. You’ll also need to have a compatible outlet and circuit breaker.

To connect the air compressor to a power source, unplug it and turn the pressure switch off. Next, plug the power cord into the outlet and turn on the circuit breaker. Finally, turn the pressure switch back on and listen to the compressor’s sound filling up with air. Once it reaches the desired pressure, you can use your compressed air tools.

3. Check Oil Level

Firstly, plug the compressor into a power source. Then, check the oil level in the compressor before using it. This is important, as an insufficient amount of oil can cause damage to the machine. To check the oil level, locate the oil fill cap on the compressor and remove it. Use a dipstick to check the oil level in the tank – if it’s low, add more oil until it reaches the correct level.

Once you’ve checked the oil level, you can use the compressor. To do so, turn the on/off switch to the “on” position. You’ll hear the compressor motor start to run, and the tank will begin to fill with air. Once the tank reaches maximum pressure, the compressor will automatically shut off.

4. Connect Air Hose

Fortunately, it’s not too difficult. First, plug in and turn on the compressor. Then, connect the air hose to the compressor’s output port. You’ll want to ensure the hose is securely fastened to the port so air doesn’t leak out. Once the hose is attached, you can start using the compressor.

To do this, simply turn on any tool or accessory you want to use, such as an air wrench or spray gun. The compressor will automatically start pumping air into the tool or accessory, allowing you to use it effectively.

It’s important to note that you should never exceed the maximum pressure rating for your tools or accessories. This information is usually found in the owner’s manual or the tool. Additionally, you may want to consider using safety goggles or other protective gear, especially if you’re using high-pressure tools.

5. Connect Tools

A Craftsman 22 gallon air compressor can be a great addition to your home or workshop. To get started, ensure the compressor is set up in a safe and stable location with plenty of room for airflow. Connect the compressor to a power source and plug it in.

Next, attach your tools to the compressor using the appropriate fittings. It’s important to use the correct size hose and fittings for your tools to ensure maximum efficiency. You can also add a regulator to control the air pressure and prevent damage to your tools. Once you have connected everything, turn on the compressor and allow it to build pressure. With adequate pressure, you can begin using your tools.

6. Pressure Adjustment

It’s essential to understand how to adjust the pressure. First, locate the pressure adjustment knob on the compressor’s regulator. Turn the knob clockwise to increase the pressure and counterclockwise to decrease it. Adjust the pressure before using the compressor to ensure the proper air pressure is supplied to your tools.

Once you have adjusted the pressure, you’re ready to use the compressor. Attach your air hose to the compressor’s outlet and connect the other end to your tool or accessory. Turn on the compressor and allow it to fill the tank, which will take a few minutes. Once the tank is full, the compressor will automatically shut off. You can now use your tool or accessory.

It’s important to check the pressure periodically while using the compressor to ensure it remains at the desired level. If the pressure drops below the desired level, the compressor may need to refill the tank before continuing use.

7. Turn On The Compressor

Make sure the compressor is properly grounded and that the air filter is clean. Once you’ve done that, you’re ready to turn on the compressor.

To turn on the Craftsman 22 gallon air compressor, locate the power switch on the side of the unit. Flip the switch to the “on” position and wait for the compressor to build up pressure. You’ll know it’s ready to use when the pressure gauge reaches the desired level.

Now that your compressor is up and running, it’s time to put it to use. Whether you’re using it for DIY projects or professional applications, there are countless ways to use an air compressor.

8. Monitor The Pressure

With its powerful motor and high-capacity tank, you can easily operate various air-powered tools. However, before using it, you must know how to correctly use the Craftsman 22-gallon air compressor. First, ensure it’s plugged into a grounded outlet and off position.

Then, connect the air hose to your tool and the compressor. Next, turn on the compressor and let it fill the tank until it reaches the recommended pressure. Monitoring the pressure while using the compressor is crucial to avoid overloading it.

You can do this by checking the pressure gauge on the compressor’s control panel regularly. If the pressure drops below the recommended level, turn off the compressor and let it refill the tank.

9. Compressor Maintenance

It’s actually quite simple. First, make sure the compressor is plugged in and turned on. Then, attach the air hose to the compressor and the tool you plan on using. Adjust the regulator to the desired pressure and turn the compressor on.

The compressor will automatically turn off once it reaches the desired pressure, but turn it off manually when you finish using it. As for compressor maintenance, it’s important to keep your unit clean and well-oiled. Check the oil level regularly and add more as needed.

You should also drain the tank after each use to prevent moisture buildup, which can lead to rust and damage. It’s recommended to replace the air filter every 6 months to a year, depending on usage. Additionally, inspect all hoses and connections for any signs of wear or damage, and replace them if necessary.

10. Shutting Down The Compressor

Knowing how to use a Craftsman 22 gallon air compressor is essential for anyone working with pneumatic tools or equipment. Firstly, ensuring the compressor is correctly set up and connected to a power source is important.

Once connected, turn the pressure regulator knob to the desired pressure level and switch the compressor on. As the compressor is in use, monitoring the pressure level and adjusting it as necessary is important. The compressor also has safety features, such as an automatic shut-off switch that turns off the compressor when it reaches maximum pressure.

When shutting down the compressor, it is important to follow the correct procedure to avoid any damage to the machine or injury to the user. Begin by turning off the regulator knob and allowing all the air to escape from the hose. Then, switch off the compressor and unplug it from the power source.

Conclusion

The Craftsman 22 gallon air compressor is a powerful tool that can help you easily complete various tasks. Learning how to use it properly is essential to ensure your safety and maximize its efficiency.

By following the manufacturer’s instructions and using the right accessories, you can operate this air compressor like a pro and accomplish any project you have in mind. Remember to maintain it regularly and keep it clean to prolong its lifespan and enjoy its benefits for years.

FAQ’s

[rank_math_rich_snippet id=”s-ac6dea73-5f14-4225-9e94-290f9dda2a05″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.