Choosing the right type of lumber is a critical decision regarding building or renovating a structure. Two of the most commonly used types of lumber are framing lumber and pressure-treated lumber.

While both may seem similar at first glance, significant differences between the two can impact your project’s overall quality and durability. We will explore the characteristics and uses of framing lumber vs pressure-treated lumber, as well as the pros and cons of each.

By understanding the key differences between these two types of lumber, you can decide which is the best option for your specific construction needs. So, let’s delve into the world of framing and pressure-treated lumber and find the right fit for your construction needs.

What Is Framing Lumber?

Framing lumber is an indispensable element in construction, as it supports buildings. It comes from softwoods such as pine or Douglas fir in different sizes and grades. The #2 grade is most commonly handy in residential projects due to its high strength and affordability. Proper installation and maintenance of framing lumber can significantly extend its lifespan.

This includes protecting it from moisture, pests, and fire hazards through appropriate coatings, treatments, and building practices. Building codes also specify the minimum standards for framing lumber to ensure safety and quality in construction projects.

What Is Pressure-Treated Lumber?

Pressure-treated lumber refers to wood that has undergone a treatment process to safeguard against decay, rot, and insects. This involves placing the wood in a vacuum chamber and introducing preservatives into its fibers. Compared to regular framing lumber, pressure-treated lumber offers enhanced durability and longevity, making it an excellent choice for outdoor structures like decks, fences, and retaining walls.

Although pressure-treated lumber may be initially more expensive, its long-term durability makes it a valuable investment. With its resistance to pests and decay, pressure-treated lumber ensures structural stability and longevity.

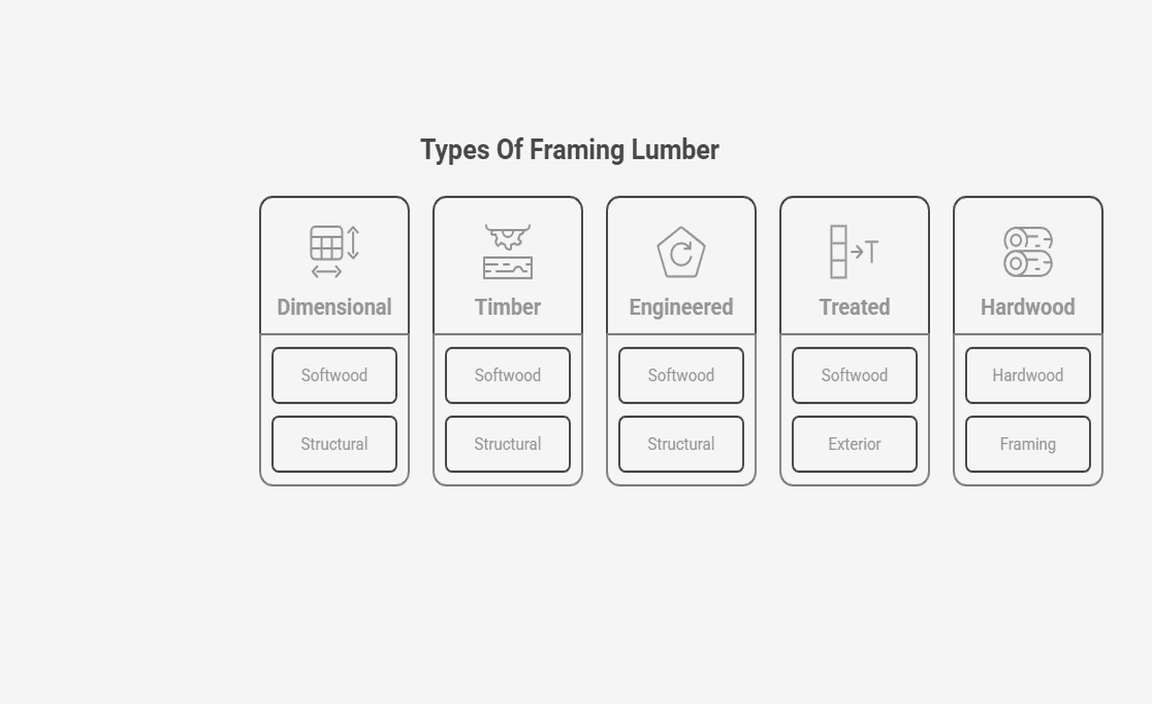

Types Of Framing Lumber

Softwood, specifically Douglas fir and spruce pine fir (SPF), is the most commonly used type of framing lumber in construction. While hardwood can also be handy for framing, it is less popular due to cost and availability.

Softwood lumber, like plywood, is a popular building material known for its strength and dimensional stability. It is often handy for structural support, such as studs and joists, and for exterior use, including decks and railings.

- Dimensional Lumber

- Timber

- Engineered Lumber

- Treated Lumber

- Hardwood Lumber

Types Of Pressure-Treated Lumber

Different types of pressure-treated lumber are available for various applications. One common type is ACQ (Alkaline Copper Quaternary) treated lumber, which offers protection against rot and decay. Additionally, there are other options, such as CA-C (Copper Azole with co-biocide) and MCQ (Micronized Copper Quaternary) treated lumber. The pressure-treated lumber choice depends on the protection required for specific projects.

- Above Ground Contact (AG)

- Ground Contact (GC)

- Marine Treated

- Fire Retardant Treated (FRT)

Comparison Between Framing Lumber Vs Pressure-Treated Lumber

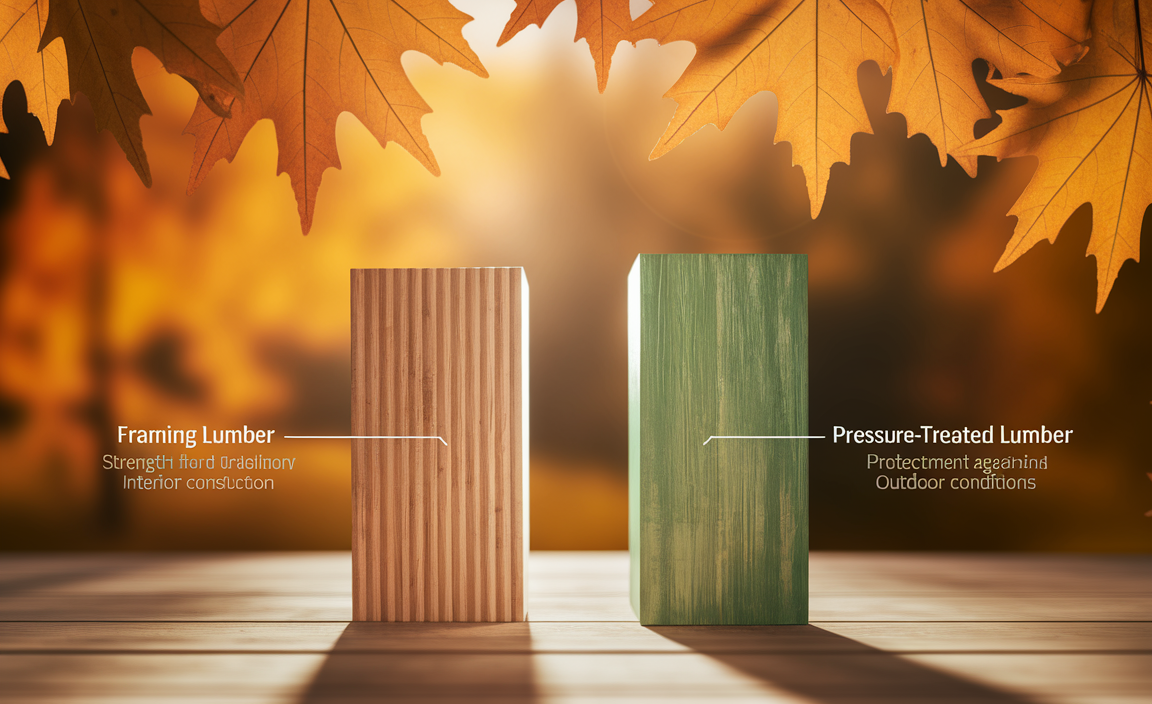

There are a few key differences when choosing between framing and pressure-treated lumber. Framing lumber is typically handy for interior construction projects, such as framing walls and building structures. It is strong and durable, making it a reliable choice for these applications.

On the other hand, pressure-treated lumber has specific designs to resist decay and insect damage. It is often handy for outdoor projects like decks, fences, and landscaping. The treatment involves injecting chemicals into the wood to protect it from moisture and pests. Scroll down to head in detail on framing lumber vs pressure-treated lumber.

Durability Comparison

When comparing untreated lumber’s and pressure-treated lumber’s durability for wood structures, it is essential to consider the wood species used. However, initially more cost-effective, untreated lumber may not withstand environmental elements as well as pressure-treated lumber.

Pressure-treated lumber, treated with preservatives to resist decay and pests, offers greater longevity and protection for wood structures, making it a preferred choice for long-lasting construction projects.

Installation And Maintenance

Choosing between untreated and pressure-treated lumber is important for installing and maintaining structures. Though more affordable, untreated lumber may lack the durability of pressure-treated options.

The latter, identifiable by a lumber stamp, is a reliable choice for wood structures as it is treated to be resistant to decay and pests. Consider the longevity and strength of pressure-treated lumber for your next project.

Environmental Impact

Wood planks are commonly handy in construction, particularly for building fences. When considering the environmental impact, it is essential to differentiate between framing and pressure-treated lumber.

While framing lumber is primarily handy in constructing wooden fences, pressure-treated lumber involves treating the wood in contact with the ground to prevent rot and decay. This distinction is crucial in assessing the sustainability of wood fencing materials.

Resistance To Decay And Insects

Framing and pressure-treated lumber present distinct advantages when considering resistance to decay and insects. Framing lumber, such as wood planks, offers natural durability but may be more susceptible to decay and pest damage over time.

Conversely, pressure-treated lumber, including aboveground wood, undergoes a treatment process that enhances its resistance to decay and insects, making it a preferred choice for long-lasting structures.

Cost-Effectiveness

The average price of framing lumber is typically lower than pressure-treated lumber. Framing lumber is often used for structural purposes in building construction and usually comes from softwood species like pine or spruce. On the other hand, pressure-treated lumber is treated with chemicals to resist decay, rot, and insect damage, making it more expensive.

The cost difference between the two types of lumber can vary depending on market conditions, demand, and availability of raw materials. Framing lumber is a more affordable option for basic construction projects. In contrast, pressure-treated lumber is more durable and long-lasting for outdoor structures or projects in damp or humid environments.

Applications Of Framing Lumber And Pressure-Treated Lumber

People commonly use framing and pressure-treated lumber in construction projects because of their durability and strength. People often employ framing lumber in structural applications, such as framing walls and roofs, while they consider pressure-treated lumber ideal for outdoor projects like decks and fences.

When selecting lumber for specific projects, factors such as moisture exposure and load-bearing capacity must be carefully considered to ensure optimal performance and longevity.

Advantages And Disadvantages Of Framing Lumber

Framing lumber offers numerous advantages, such as affordability, availability, and ease of installation. It is versatile and can be handy for various construction projects. However, it also has disadvantages, including susceptibility to warping, splitting, and moisture damage, requiring proper maintenance and treatment to ensure durability and longevity.

advantage

- Cost-effective compared to other building materials

- Widely available in various sizes and types

- Easy to work with and install for construction projects

- Renewable and sustainable resources, if sourced responsibly

disadvantages

- Prone to warping, twisting, and shrinking over time

- Limited in loadbearing capacity compared to steel or concrete

Advantage And Disadvantages Of Pressure Treated Lumber

Pressure-treated lumber offers durability and resistance to decay, making it ideal for outdoor construction projects. However, it can be more expensive than untreated wood and may contain harmful chemicals to health and the environment. Proper handling and disposal are essential to mitigate these risks.

Advantages

- Increased resistance to rot and decay

- Protection against insect damage

- Longer lifespan compared to untreated wood

- Suitable for outdoor applications

Disadvantages

- The initial cost can be higher than untreated lumber

- Limited color options compared to untreated wood

Safety Considerations

Safety is paramount when working with pressure-treated lumber. To protect yourself, always wear gloves and safety goggles to shield your hands and eyes from any potential harm. Additionally, work in a well-ventilated area when cutting or sanding pressure-treated wood to prevent inhaling sawdust particles.

It’s important to note that we do not recommend burning this type of lumber as it can release toxic fumes. To minimize direct skin contact, consider wearing long sleeves and pants. Lastly, adhere to manufacturer guidelines for selecting the appropriate fasteners and hardware when using pressure-treated lumber.

Conclusion

Both framing and pressure-treated lumber have their advantages and considerations. Framing lumber is a versatile and cost-effective option for various construction projects. On the other hand, pressure-treated lumber offers enhanced resistance to moisture, insects, and rot, making it ideal for outdoor applications.

When deciding between the two, it’s important to consider cost, durability, installation, maintenance, environmental impact, and safety. Ultimately, your choice should align with your specific project requirements and budget.

Whether you opt for framing or pressure-treated lumber, ensure that you follow the recommended guidelines for installation and maintenance to maximize their durability and longevity. We hope you know the difference between framing lumber and pressure-treated lumber.

Frequently Asked Questions

What Is Framing Lumber Called?

People commonly refer to framing lumber as dimensional lumber or construction lumber. This type of lumber is specifically designed and processed to be used in the structural framing of buildings, including homes, offices, and commercial structures.

How Long Does Pressure-Treated Framing Last?

Pressure-treated framing typically lasts 20-30 years, depending on environmental conditions and maintenance. Regular inspections and proper care can help extend the lifespan of the framing.

What Is The Most Common Wood Used In Framing?

The most common wood used in framing is pine, specifically Southern Yellow Pine, due to its strength, durability, and cost-effectiveness. It is widely available and ideal for structural framing in construction projects.

Is Pressure-Treated Lumber Safe?

Pressure-treated lumber is generally safe for outdoor projects where it may be exposed to moisture or insects, as the treatment process helps prevent decay and damage.

What Size Is Framing Lumber?

Framing lumber typically comes in standard sizes such as 2×4, 2×6, 2×8, etc., with the actual dimensions being slightly smaller due to milling processes. These sizes are commonly used in construction for framing walls, floors, and roofs.

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.