Fuel tanks play a crucial role in the functioning of various vehicles and machines. They store vital liquid fuels such as gasoline, diesel, and jet fuel, essential for powering engines and providing energy. However, the operation of fuel tanks is not as simple as just storing fuel. One of the essential aspects of fuel tank design is venting.

We will cover everything you need to know about fuel tank venting. We will explain why fuel tanks must be vented and the dangers of venting them properly. Then, we will dive into the various types of fuel tank vents available, including pressure vacuum vents, rollover vents, flapper vents, emergency vents, flame arrestor vents, excess flow vents, flameproof vents, positive pressure vents, non-pressure vents, and combination vents.

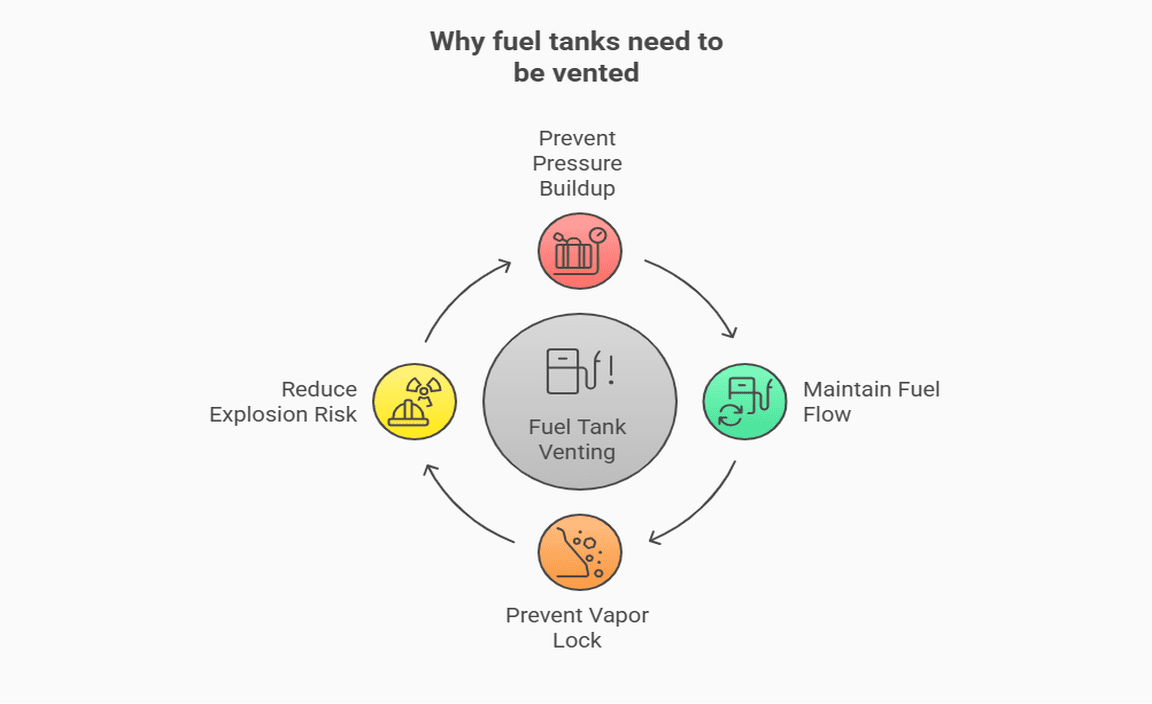

Why fuel tanks need to be vented

Venting fuel tanks is crucial to prevent pressure buildup and potential explosions. Proper venting allows for the release of harmful vapors and fumes, ensuring the system’s safety.

Additionally, venting helps maintain proper fuel flow and combustion efficiency. It also prevents damage caused by vacuum or excessive pressure, ensuring the smooth operation of the fuel system. Here are some reasons why fuel tanks need to be vented:

– Prevents pressure build-up within the tank

– Helps in maintaining fuel flow

– Prevents vapor lock issues

– Reduces the risk of explosion due to fuel vapor buildup

The dangers of not properly venting fuel tanks

Improper venting of fuel tanks can have detrimental consequences. Fuel tanks risk collapsing or expanding due to pressure variations without proper venting. This can lead to fuel leakage, environmental contamination, and even fuel pump failure, resulting in reduced engine performance. Additionally, the absence of vents can make fuel tanks susceptible to moisture accumulation and corrosion. Inadequate venting also increases the danger of fuel system fires and explosions. To mitigate these risks, it’s crucial to ensure fuel tanks are properly vented.

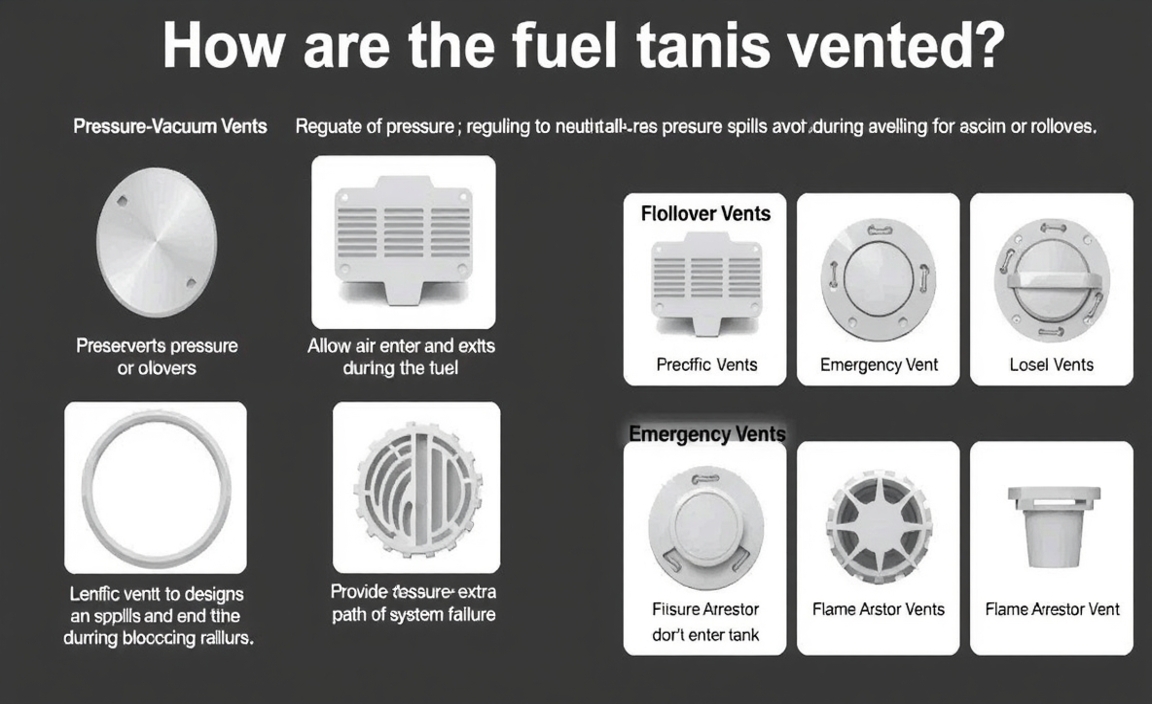

How are the fuel tanks vented? Different types?

Pressure Vacuum Vents regulate the pressure in fuel tanks, preventing excessive pressure or vacuum. Rollover Vents have specific designs to avoid spills during vehicle rollovers. Flapper Vents allow air to enter and exit the tank while blocking fuel. Emergency Vents provide an extra path in case of system failure. Flame Arrestor Vents ensure flames don’t enter the tank. These different types of vents help maintain safe conditions and efficient operation.

Pressure Vacuum Vents

Pressure Vacuum Vents are essential to fuel tank systems as they help regulate pressure changes. These vents allow air to enter or escape the tank in response to its needs, preventing over-pressurization or collapse. They have specific designs with valves or diaphragms that help control airflow and maintain the right pressure balance within the fuel system. Pressure Vacuum Vents play a crucial role in preventing accidents and maintaining optimal fuel efficiency by ensuring fuel integrity and safety. Choosing the right type of vent for your fuel tank system is important, considering factors such as tank size, pressure requirements, and environmentally dangerous conditions.

Rollover Vents

Rollover Vents, located at the highest point of the tank, play a crucial role in fuel tank venting systems. These vents allow air to enter and exit the tank during rollover events, preventing fuel spillage and maintaining a sealed tank. Normally closed, they open during rollovers to equalize pressure and prevent leakage. Rollover Vents, made of brass with in-line vent hose clamps, enhance safety by preventing fuel system damage and maintaining atmospheric pressure.

Flapper Vents

Flapper vents, commonly used in marine and off-road vehicle applications, utilize a hinged flap to control airflow in and out of the fuel tank. These vents ensure proper ventilation while blocking fuel escape. The flap opens under pressure changes, allowing air to enter or escape, and closes when pressure stabilizes. Flapper vents provide reliable venting without compromising safety, maintaining fuel system integrity and preventing over-pressurization or collapse.

Emergency Vents

In the event of a primary venting system failure, emergency vents serve as backup vents, providing an alternative path for pressure relief. Typically featuring a pressure-actuated valve or rupture disc, these vents activate only when pressure reaches a critical tank level. By safeguarding against excessive pressure and potential tank failure, emergency vents play a crucial role in maintaining the integrity of the fuel filler tank.

Flame Arrestor Vents

Flame Arrestor Vents, found in boats, off-road vehicles, and industrial equipment, prevent flames or sparks from entering the fuel tank. These vents have specific designs with a mesh or screen that traps and extinguishes potential ignition sources. Flame Arrestor Vents enhance safety in environments with flammable vapors by mitigating the risk of fuel tank explosions. Their utilization ensures a higher fuel level of safety by providing additional protection against potential fuel tank explosions.

Excess Flow Vents

Excess Flow Vents have specific designs to control the fuel flow rate into the tank, particularly during refueling. These vents serve an important purpose in preventing spillage by limiting the flow rate and automatically closing if the rate exceeds a certain threshold. By protecting against overfilling and reducing environmental hazards, Excess Flow Vents promote safe refueling practices and prevent unnecessary fuel wastage. Their presence ensures fuel is efficiently and safely transferred into the tank without any potential risks or dangers.

Flameproof Vents

Flameproof Vents act as a flame barrier within the fuel tank. These vents have specific designs to withstand direct exposure to flames without igniting. They ensure safe operation in potentially hazardous environments. Flameproof Vents are commonly handy in industrial and military applications, providing enhanced protection against fire and explosion risks. Their ability to resist flames makes them essential for maintaining safety in fuel tanks.

Positive Pressure Vents

Positive pressure vents are a crucial component of fuel tank venting systems. These vents maintain a higher pressure inside the fuel tank, preventing the formation of vacuum and fuel starvation. Positive pressure vents help reduce the risk of fuel leakage by ensuring a constant fuel supply to the engine. They employ a valve to regulate the pressure inside the tank, effectively maintaining a balanced and controlled system. Positive pressure vents are essential for the safe and efficient operation of fuel tanks.

Non-Pressure Vents

Non-pressure vents allow the fuel tank to breathe without building up pressure. They release excess vapor to prevent overpressurization and minimize the risk of explosions. These vents ensure air can enter and exit the tank, preventing vacuum or pressure buildup. Non-pressure vents use a vent line to release vapors into the atmosphere. This helps to maintain atmospheric pressure within the tank, ensuring safe and efficient operation.

Combination Vents

Combination vents have specific designs to provide a balanced approach to venting fuel tanks. By combining the features of positive pressure and non-pressure vents, they offer both pressure relief and pressure control. This helps to maintain the proper fuel-to-air ratio for optimal engine performance. Combination vents achieve these results through a combination of valves and vent lines. They ensure that the highest point of the tank is properly vented without allowing fuel leakage or the buildup of enough pressure to cause safety concerns. These vents typically utilize hose clamps, hoses, and in-line valves, often made of brass, to regulate the release of vapors by atmospheric pressure.

Open vent systems and their benefits and drawbacks

Open vent systems are commonly handy to vent fuel tanks in various industries. These systems have benefits and drawbacks, which are important to consider when designing or implementing a fuel tank venting system. Here are some key points to know about open vent systems:

Benefits:

Allows for pressure release: Open vent systems provide a pathway to release pressure that can build up inside the fuel tank. This helps to prevent damage to the tank and potential safety hazards.

Reduces the risk of vacuum formation: By allowing air to enter the tank through the vent, open vent systems help prevent a vacuum’s formation. Vacuums can lead to fuel starvation and engine performance issues.

Drawbacks:

Potential for environmental contamination: Open vent systems can allow fuel vapors and potentially liquid fuel to escape into the environment. This can contribute to air pollution and pose a risk to nearby ecosystems.

How fuel tank vents prevent pressure buildup and fuel leakage

Fuel tanks are vented to prevent pressure buildup and leakage, which can be dangerous and lead to accidents. Overall, fuel tank vents play a critical role in maintaining the safety and integrity of fuel systems by preventing pressure buildup and fuel leakage. Manufacturers and vehicle owners must ensure these vents are maintained and functioning correctly. Here are some key points about how fuel tank vents work:

- Fuel tank vents allow air to flow in and out of the tank, balancing the pressure inside with the atmospheric pressure outside. This prevents pressure buildup that could cause the tank to rupture or leak.

- Vents typically consist of small valves or openings on the fuel tank’s top. These openings allow air to enter and exit the tank as needed.

- The design of fuel tank vents is crucial in preventing fuel leakage. They are often equipped with special features such as check valves or filters to ensure that only air can pass through while preventing any fuel from escaping.

- Fuel tank vehicles are also equipped with rollover valves, which further enhance safety by preventing fuel from spilling out in the event of a rollover or collision.

Common problems with fuel tank venting systems and how to troubleshoot them

Common problems with fuel tank venting systems can include clogs or blockages, fuel leaks or cracks in the vent lines, and malfunctioning valves. If you are experiencing issues with your fuel tank venting system, here are some troubleshooting steps to consider:

- Check for clogs or blockages in the vent lines. Use a flashlight to inspect the lines for debris or obstructions preventing proper airflow.

- Inspect the vent valve for leaks or cracks. If you notice any signs of damage, such as fuel leaking from the valve, you may need to replace it.

- Test the functionality of the vent valve. You can do this by applying vacuum pressure to the valve and checking if it opens and closes properly.

- Ensure that all connections are secure and tight. Loose connections can contribute to fuel tank venting issues.

- Consult a professional mechanic if you cannot independently identify or resolve the problem. They will have the expertise and tools necessary to diagnose and repair any issues with your fuel tank venting system.

Upgrading or replacing a fuel tank venting system

When upgrading or replacing a fuel tank venting system, there are a few key considerations to remember. First and foremost, it is important to ensure that the new venting system meets all relevant safety regulations and standards. This may include requirements for pressure relief, flame resistance, and anti-siphoning capabilities. Additionally, it is important to consider the specific needs of your application when selecting a venting system.

Factors such as fuel type, tank size, and operating conditions can all impact the performance and effectiveness of the venting system. Lastly, proper installation and maintenance are crucial for ensuring the venting system’s continued safe and efficient operation. It is recommended to consult with a qualified professional or manufacturer to determine the best venting solution for your specific needs.

Safety precautions when working with fuel tanks and venting systems

When working with fuel tanks and venting systems, it is crucial to take proper safety precautions. Following these safety precautions and guidelines can minimize the risks of handling fuel tanks and venting systems. Always prioritize safety when working with potentially hazardous materials like fuel. Here is a step-by-step guide to ensure safe handling:

- Wear appropriate protective gear such as gloves, goggles, and respirators to protect yourself from harmful fumes.

- Before starting any work on the fuel tank, relieve the pressure by slowly opening the vent valve.

- Ensure that you ventilate the area around the fuel tank well to prevent the accumulation of flammable vapors.

- Use caution when removing or installing vent lines to avoid damaging them or causing leaks.

- Regularly inspect vent lines for signs of wear or damage and replace them if necessary.

- Always follow manufacturer guidelines and local safety regulations when working with fuel tanks.

- In case of an emergency or suspected leak, immediately shut off all ignition sources and evacuate the area.

Frequently Asked Questions

Do fuel tanks need to be vented?

You must vent fuel tanks to prevent pressure buildup and ensure proper broken fuel flow. Without venting, tanks can collapse or rupture due to pressure changes. Regular inspection and maintenance of fuel tank vents are crucial for safe operation.

Where does the fuel tank vent go?

The charcoal canister or evaporative emissions control system directs the fuel tank vent. Its purpose is to prevent pressure buildup in the tank. The charcoal vapor canister filters vented gas vapors before releasing them into the atmosphere.

What is a fuel tank vent valve?

A fuel tank vent valve is a crucial component that regulates air flow in and out of the fuel tank. It helps prevent pressure buildup, avoiding potential leaks or other issues. Typically made of durable materials like plastic or metal, a qualified mechanic must inspect the vent valve if any problems arise.

What About Vented Gas Caps?

Vented gas caps play a crucial role in fuel tank venting. They allow air to enter the tank as gasoline is handy and prevents pressure buildup caused by expanding gasoline. Using your vehicle’s correct type of gas cap is important to ensure proper venting and prevent damage.

Would the diesel and gasoline vents be compatible?

Diesel and gasoline venting systems are not compatible. Using the wrong type of vent can cause damage to your fuel tank or engine. It is crucial to use the correct vent for your fuel type. If unsure, consult with a professional to ensure proper compatibility.

Conclusion

Proper venting of fuel tanks is crucial for maintaining safety and preventing potential hazards. Understanding the different types of fuel tank vents and their functions is essential to ensure the smooth operation of your fuel system. Whether you have an open vent system or a closed vent system, each has its benefits and drawbacks that need to be considered. Fuel tank vents are vital in preventing pressure buildup and fuel leakage. They help maintain the right balance of pressure inside the tank, allowing fuel to flow smoothly without any disruptions. However, fuel tank vents can encounter problems like any other system over time. It is important to be aware of common issues and troubleshoot them promptly to avoid any safety risks. We’ve discussed how the fuel tanks are vented.

Resource:

Combustion Safety in Tanks: https://www.osha.gov/fire-safety/fuel-storage

Evaporative Emission Systems Overview: https://www.epa.gov/vehicles-and-engines

Understanding Tank Pressure and Vacuum: https://www.engineeringtoolbox.com/pressure-vacuum-d_912.html

Fuel System Maintenance Tips: https://www.ase.com/tools-resources/resource-center/fuel-system-maintenance-tips

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.