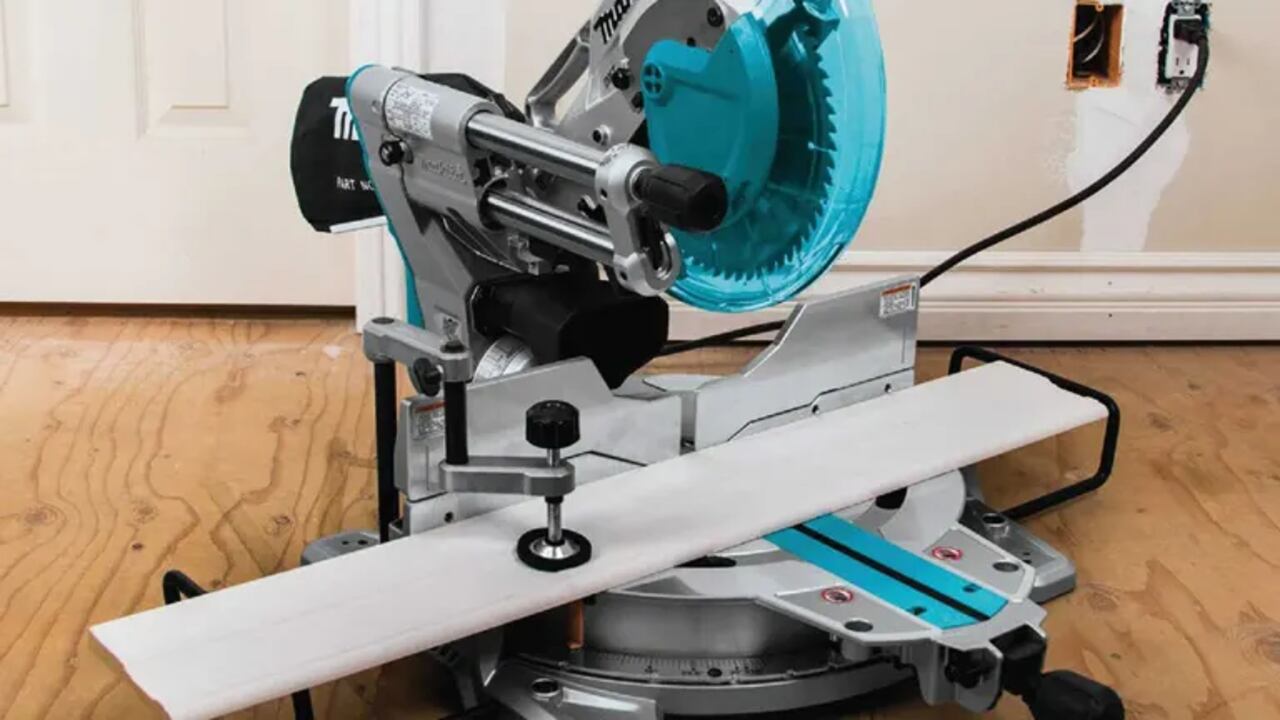

The Makita LS1219L is a highly capable and versatile power tool that boasts an impressive range of features. One of its standout characteristics is its large cutting capacity, allowing users to tackle various projects easily.

However, like any other tool, it can experience problems over time, ranging from minor problems to significant errors. These issues can cause frustration and delays in your work, resulting in decreased productivity and increased costs. Consequently, it is essential to identify these problems early and find appropriate solutions to avoid costly repairs or replacements.

We will discuss practical solutions to common Makita LS1219L problems you may encounter while using this tool. We have compiled information from various sources, including user reviews, forums, and technical manuals, to provide the most solutions you may encounter with your Makita LS1219L.

About Makita Ls1219l

The LS1219L also offers impressive speed, allowing for efficient and precise cuts. This saw can handle it all, whether you’re working with wood, metal, or other materials. Its crosscut capacity further enhances its versatility, enabling users to make accurate cuts at various angles.

One of the positive features of the LS1219L is its smooth and user-friendly operation. Thanks to its well-designed detent plate, users can easily set and lock the desired cutting angles, ensuring consistent and precise results every time. Additionally, the ergonomic design of this tool provides comfort during extended use, reducing fatigue and improving overall productivity.

Pros:

- Powerful motor for efficient cutting

- Large cutting capacity for versatility

- Smooth and accurate cuts

- Durable construction for long-lasting use

- Easy to use and adjust

- Good dust collection system

Cons:

- Relatively expensive compared to other models

- Heavy and bulky, making it less portable

10 Common Makita Ls1219l Problems And Solutions

The Makita LS1219L, despite being a popular choice, has encountered some major issues. The original blade is one of the main concerns, as it wears out quickly and requires frequent replacements. Additionally, bevel adjustments on this model are somewhat challenging and not as precise as expected.

However, customers have praised Makita’s customer service for their quick responses and helpful solutions. They have a reliable service center for more complicated issues that can assist with repairs and provide necessary replacements.

On a positive note, the capacity of the baseboard is impressive, allowing for larger projects without any limitations. Here are some common problems that users may encounter with the Makita ls1219l problems and their corresponding solutions:

1.Alignment Issues

Alignment issues can be a common problem with the Makita LS1219L. Sometimes, you may not properly align the blade with the cutting line. A misaligned fence, miter gauge, or worn-out or damaged blade can cause this.

To fix this problem, it is important to check and adjust the alignment of the fence and miter gauge according to the manufacturer’s instructions. Sometimes, you might need to replace or professionally sharpen the blade. Regular maintenance and cleaning of the saw can also help prevent alignment issues. Another common problem is motor overheating, caused by prolonged use or a clogged air vent.

2.Dust Collection

One common issue users encounter with the Makita LS1219L is ineffective dust collection. Ensuring the dust bag or collector is properly attached and free from blockages is important to improve dust collection. Regularly cleaning or replacing the dust bag or filter can also help enhance dust collection efficiency.

Another solution is to use a shop vacuum or dust extraction system alongside the saw to capture the dust particles effectively. Remember to follow proper safety precautions, such as wearing a dust mask when working with power tools and inadequate dust collection.

3.Motor Burnout

Motor burnout is a common problem with the Makita LS1219L model. It usually happens due to overheating or excessive use. Following the recommended limits and avoiding overloading the saw is essential to prevent motor burnout.

Regular maintenance, such as cleaning the motor and ensuring proper lubrication, can also help prevent this issue. A professional technician must replace or repair the motor if it burns out. Refer to the manufacturer’s instructions for troubleshooting and resolving motor burnout problems.

4.Fence Accuracy Issues

The Makita LS1219L may misalign the fence, causing inaccurate cuts. To address this problem, we recommend checking the alignment of the fence and making any necessary adjustments. A square or straight edge can also help ensure the fence is parallel to the blade.

If the fence continues to be inaccurate, we may need to replace it. Regular maintenance and cleaning of the fence can help prevent accuracy issues, while using a high-quality blade can improve cutting precision. Despite these potential challenges, the reduced footprint of the Makita LS1219L makes it a great choice for those with limited workshop space.

5.Blade Wobble

Blade wobble is a common issue users may encounter with the Makita LS1219L. It can occur if you don’t properly tighten or damage the blade. To resolve this problem, tighten the blade and securely ensure proper alignment. Replacing a damaged blade with a new one is recommended to eliminate wobble.

Additionally, regular maintenance and cleaning of the saw can help prevent blade wobble in the future. In some cases, users have also found that utilizing the adjustable lasers and performing operation flush can enhance accuracy. With proper maintenance and attention to detail, you can overcome these issues and enjoy precise bevel cuts with this saw.

6.Laser Accuracy Issues

Laser accuracy issues are a common problem with the Makita LS1219L. Users may experience the laser not aligning properly with the cutting line or the laser being dim or difficult to see.

To address these issues, we recommend checking and adjusting the laser alignment using the adjustment screws on the tool. Also, cleaning the laser lens can help improve accuracy by removing dirt or debris. If these solutions do not work, contacting Makita customer support or seeking professional repair may be necessary. Regular maintenance and cleaning can also prevent laser accuracy problems.

7.Durability Issues

Some users have experienced durability issues with the Makita LS1219L. They have reported problems such as parts breaking or wearing out quickly. To address these concerns, it is important to ensure proper maintenance and care of the saw. This includes regular cleaning and lubrication. If a specific part is consistently breaking or wearing out, it is advisable to contact Makita for a replacement or repair.

Additionally, using the saw within its recommended limits and avoiding excessive force can help prevent durability issues. Remember that not all users face durability problems, so proper usage and maintenance can greatly reduce the likelihood of encountering such issues.

8.Poor Sliding Function

The Makita LS1219L is a powerful and versatile sliding compound miter saw that offers a range of features to enhance your woodworking experience. However, some users have reported issues with the sliding function, which can affect the accuracy of their cuts.

One common problem is the poor sliding function, which can be attributed to issues with the glide mechanism. To address this, cleaning and lubricating the glide mechanism regularly is recommended to ensure smooth operation. To improve the sliding action, adjust the blade guard and ensure proper alignment of the dual dust collection ports.

9.The Issue With Getting Square Cuts

One common problem users may encounter with the Makita Ls1219l is achieving square cuts. This issue can be frustrating, especially when precision is important. However, there are a few possible fixes to improve the accuracy of your cuts. First, ensure that you properly align the saw blade and check for any dullness or damage.

Also, double-check that you securely clamp the material being cut to avoid shifting. Lastly, take your time and use a steady hand to guide the saw smoothly through the material. By implementing these fixes, you can overcome the problem of getting square cuts with the Makita Ls1219l.

10.Motor Burns Out

One common problem with the Makita LS1219L is the motor burning out. This can happen for various reasons, such as overuse or lack of proper maintenance. However, some quick adjustments can help prevent this issue.

Firstly, ensure the saw is properly lubricated to reduce friction and heat buildup. Secondly, use a high-quality tooth blade suitable for accurate cutting and can handle compound cuts. By taking these precautions, you can extend the life of your motor and avoid potential burnout.

Conclusion

The Makita LS1219L is an excellent sliding compound miter saw, but like any tool, it can experience problems from time to time. The Makita LS1219L, despite being a popular choice, has encountered some major issues. Identifying the common Makita ls1219l problems makes it possible to address them quickly and effectively.

From blade wobbling to inaccurate cuts, solutions are available to ensure that the LS1219L continues to deliver precise and reliable performance. With proper maintenance and attention to detail, this saw can be an essential part of any professional’s toolkit for years. Remember always to follow safety guidelines and manufacturer recommendations to ensure the longevity and reliable performance of your Makita LS1219L.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-33373330-0022-4180-b522-a51bf6a7b2f3″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.