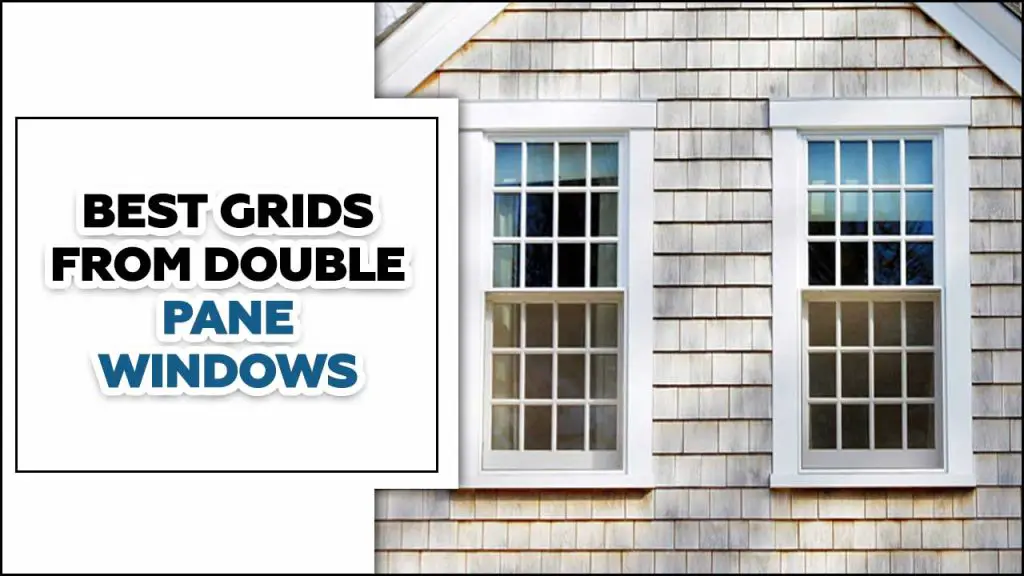

Best Grids From Double Pane Windows: Match Your Home

Double-pane windows have long been appreciated for their ability to provide insulation and energy efficiency in homes and buildings. However, in recent years, the focus has shifted towards the functionality of these windows and their aesthetic appeal. This is where grids come into play. These decorative patterns, also known as muntins or grilles, add a …

Best Grids From Double Pane Windows: Match Your Home Read More »