Air compressors are one of the most vital tools in any garage or workshop. They’re used to air tools, such as drills and saws, ensuring that air is compressed for faster air delivery. The oil-less air compressor tanks are a huge relief for air compressors with low air capacity. They function without the need for oil to ensure air compression, which saves time and money.

Besides, they’re convenient as they don’t require frequent refills or draining of air. Most air compressors use oil as their source of air. While this isn’t a problem in general, there are some instances where using an oil-less air compressor tank can be beneficial. Let’s look at all the benefits and factors to consider when buying an oil-less air compressor tank. Without further ado, let’s discuss the wonders of oil-less air compressor tanks and get you started in your journey to an oil-less air compressor tank of your own!

What You Should Know About Oil-Less Air Compressor Tanks

Oil-free air compressors have become popular in industries such as pharmaceutical, laboratory, and electronic for the same reasons as their oil-based counterparts. However, they are considered environmentally friendly, low noise, and low maintenance operations.

With an oil-free compressor, no oil is required to operate it. This means there is a reduction in waste and a lesser impact on the environment. Moreover, oil free compressors don’t require any lubrication to function properly. This also minimizes contaminants and zero risk of contamination.

These benefits make them a good option for sensitive applications where contaminants must be kept to minimum. Besides, having an oil free compressor reduces maintenance expenses and overall running cost of the compressor.

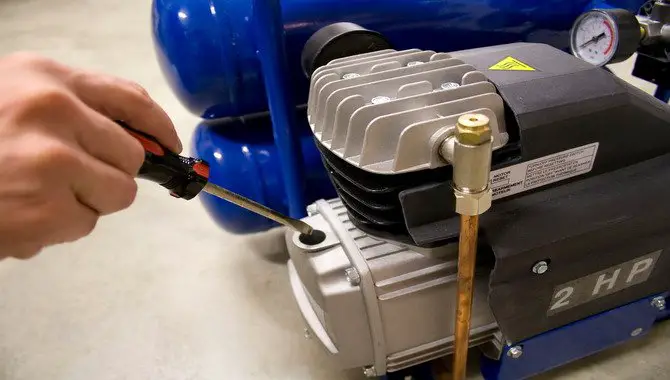

An oil-less air compressor tank is an essential component of any air compressor system. These tanks are designed to store compressed air and release it when needed. They can be mounted on the floor or on a wall and have a valve that allows for the flow of air into the tank from a source.

The tank is filled with compressed air at one end, and it has a valve that allows for the flow of air into the tank from a source. The other end of the tank is connected to an outlet port on the machine or another component in the system.

When you turn on the machine, compressed air flows out of the tank and into your workplace, where it takes care of all of your air needs. These tanks are made from different materials, such as stainless steel, polyethylene terephthalate (PET), and polypropylene (PP).

They are also available in various sizes, depending on your specific needs. One important aspect to consider when purchasing an oil-less air compressor tank is its durability. You should purchase a tank withstanding heavy use due to its long life expectancy.

Also, pay attention to the quality of welding used in its construction. Overall, an oil-less air compressor tank plays an essential role in ensuring an efficient and effective air supply throughout your business or home.

Benefits Of Using Oil-Less Air Compressor Tanks

Oil-less air compressors are a popular choice for homeowners and businesses for a variety of reasons. They require less maintenance, are more energy efficient, and are quieter than oil-based models, making them ideal for use in noise sensitive environments.

They also don’t require any lubricants or oils, making them safe to use in applications where oil contamination is a concern. However, not all oil-less air compressors are the same, and it’s vital to consider the features and specifications of the model before making a decision.

Reduced maintenance expenses – One of the major benefits of using oil-less air compressor tanks is that they reduce maintenance costs. Because these tanks don’t require oil to function, there are no opportunities for it to leak or create other problems. This means less time spent fixing issues and more time focused on running your business or home as efficiently as possible.

Increased efficiency – Another benefit of using oil-less air compressor tanks is their increased efficiency. Compared to systems that use traditional compressed air tank technology, an oil-less system offers several key advantages: fewer operational issues, reduced energy consumption, and longer lifespan.

Easy to use – One of the features that makes oil-less air compressor tanks so desirable is their ease of use. Unlike systems that require a technician to operate them, oil-less air compressors are simple to set up and operate. This means you can save time and energy by using these machines on your own instead of hiring a professional operator.

How To Choose The Right Oil-Less Air Compressor Tank

An oil-free air compressor is a popular choice for air compression due to its low environmental impact, low noise, and low maintenance operation. However, it cannot guarantee 100% oil-free air.

When selecting an oil-free air compressor tank for your application, it is important to consider the size of the tank, the type of material it is made of, and the pressure rating.

Some of the factors affecting the longevity of an oil-less air compressor are the type of oil used for lubrication and debris that may be present in air during compression. Additionally, an air compressor’s lifespan will also depend on how often it is used and how much air it can process at a time.

Tips For Maintaining An Oil-Less Air Compressor Tank

Oil-free air compressors don’t require the use of lubricant, so you should take care of them in a similar way as other oil-filled machines. Utilize Teflon to reduce friction in the compression chamber, as this material reduces wear and tear.

Keep the compression chamber clean by wiping it regularly with a clean cloth and a mild detergent. Also, ensure that no foreign objects or debris collects inside it. Finally, seal the compression chamber properly to prevent contamination from oil.

By following these tips, you can ensure an efficient operation of your oil-free air compressor. Besides, investing in an oil-free compressor can save money on repairs and maintenance costs over time.

The key factor is to provide adequate lubrication of air compressor’s internal parts with clean oilless condensate during normal operation. Also, be sure to collect and dispose of any oil-laden condensate accumulations promptly

Considerations When Purchasing An Oil-Less Air Compressor Tank

Oil-free air compressors are economical, low maintenance, and environmentally friendly. They use solid lubricants such as Teflon to prevent wear and tear on the internal parts of the compressor.

– These types of compressors don’t require oil in the compression chamber, leading to lower maintenance costs and energy savings. It also reduces the amount of waste generated by air compressors.

– Look for air compressors with reinforced tanks to ensure air pressure is maintained and the compressor is reliable. This will ensure that it can function properly under all environmental conditions.

– Consider the total cost of ownership for an oil-less air compressor. Take into account how much electricity it uses and its impact on the environment. Also consider factors such as local environmental regulations when making a purchase decision. An oil-free air compressor is a great investment for any business or individual looking for a clean and cost-efficient compressed air solution.

Expert Advice On Choosing The Right Oil-Less Air Compressor Tank

A large air compressor tank will provide more air as compared to a small one. Teflon is becoming a popular option for high-friction applications such as air compressor cylinders. This material is non-toxic, durable and offers a low environmental impact.

Oil-less air compressors are used in a variety of industries including cleaning operations, power tools and industrial processes. They offer clean, dry oil-free air with no risk of contamination.

Besides, they have low noise, low maintenance operations and low operating costs. Overall, oil-less air compressors provide clean, dry air without the use of harmful chemicals that make them environmentally friendly and cost-effective options for businesses of all sizes.

Oil-less air compressor tanks are used as an environmentally friendly and cost-effective alternative to traditional oil-filled compressor cylinders. They’re used in a variety of industries, from cleaning operations to power tools and industrial processes, for providing clean, dry air with no risk for contamination.

Oil-free air compressors offer low noise and environmental impact, making them popular among homeowners as well. However, choosing the right oil-less air compressor tank is vital for achieving optimal performance and efficiency.

This is because different types of tanks are designed for different applications, with varying features and specifications. It’s important to consider factors like material chosen, size and style of the cylinder, among others, to get the right air compressor tank for your needs.

Conclusion

Oil-free compressors also contain no oil in the entire system, therefore cancelling out any risk of oil contaminating the air. Although oil-free compressors may have higher initial costs, they provide a safer option to ensure no contamination reaches the end product.

It’s true that oil-less air compressor tanks are gaining popularity these days. But before opting for an oil-less air compressor tank, there are a few things you should consider. First of all, oil-less air compressor tanks have their pros and cons as mentioned above. However, what sets them apart from traditional air compressor tanks is the lack of oil.

With no need for oil to be added to the air tanks, maintenance is also saved. Besides, they are portable and can be carried from one job site to another without any hassle. A compressed air tank that saves time and effort at the same time has got to be a godsend.

Frequently Asked Questions

Is It Better To Get Oil-Free Air Compressor?

Yes, it is definitely better to get an oil-free air compressor. They are guaranteed to meet ISO Class Zero certification and provide the highest quality air available. They also operate more cleanly and reliably, eliminating the risk for contamination.

Is Oil-Free Air Compressor Better Than Oiled?

Oil-free compressors are becoming increasingly popular for a variety of reasons. They are guaranteed to meet ISO Class 0 certification, the highest air quality possible. They do not require oil-based or synthetic lubrication and guarantee pure, quality compressed air.

Do Oil-Free Air Compressors Last?

Generally speaking, oil-free air compressors will not last as long as their oil-lubricated counterparts. This is due to the fact that pre-lubrication wears away over time, which can lead to premature failure. However, with proper maintenance and regular inspections, an oil-free compressor can last for years.

What is a good alternative for air compressor oil?

A Good Alternative For Air Compressor Oil Is Vegetable Oil. A Typical Air Compressor Uses Oil To Lubricate The piston and cylinder mechanism. However, oil-less air compressors use naturally lubricating solids like vegetable oil to provide the same function.

How Long Do Oil-Less Compressors Last?

Compressors generally last a shorter amount of time than oil-lubricated models. This is due to the fact that oil-less compressors rely on pre-lubrication, which wears away over time.

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.