The Ryobi Airstrike is a powerful and versatile cordless nail gun favourite among DIY enthusiasts and professionals. Its lightweight design and impressive battery life make it a go-to tool for various construction and home improvement projects.

However, despite its reputation for reliability, some users have reported issues with the Airstrike not firing properly. This can be frustrating and time-consuming, especially when you’re in the middle of a project.

Here, we will delve into reasons Ryobi airstrike not firing and provide solutions to help you get back to completing your tasks efficiently. We will also discuss the steps you can take to prevent this issue from occurring in the future. Whether you’re a seasoned Airstrike user or a beginner, we will provide valuable insights to ensure your tool functions at its best.

Common Reasons Why A Ryobi Airstrike May Not Be Firing

The construction industry widely recognizes and highly regards the Ryobi Airstrike tool. Known for its efficiency and reliability, the Airstrike is a go-to choice for professionals and DIY enthusiasts. However, there may be instances where users encounter issues with the tool, such as the frustrating problem of it not firing. It is important to understand why the Ryobi Airstrike may not be firing to address the issue effectively.

Here are some common reasons why a Ryobi Airstrike may not be firing:

- Empty Or Incorrectly Loaded Magazine: Check if the magazine is empty or the nails/staples are not loaded properly. Make sure to follow the manufacturer’s instructions for loading the magazine correctly.

- Low Battery: If the battery is low or not fully charged, it may not provide enough power for the tool to fire. Try charging the battery or using a fully charged one.

- Jammed Nails/Staples: A jammed nail or staple can prevent the tool from firing. Remove any jammed nails or staples and ensure the tool is clear of any obstructions.

- Safety Mechanism Engaged: The Ryobi Airstrike has a safety mechanism that prevents accidental firing. Check if you have engaged the safety and disengage it if necessary.

- Air Pressure Issue (For Pneumatic Models): If you have a pneumatic Ryobi Airstrike, ensure the air compressor provides enough pressure to operate the tool.

Ryobi Airstrike Not Firing – Troubleshooting Steps

Ryobi Airstrike is a revolutionary tool that has overtaken the construction and DIY industry. With its innovative design and powerful performance, the Ryobi Airstrike has become a must-have for professionals and enthusiasts alike. One of the standout features of the Ryobi Airstrike is its cordless operation.

This eliminates the hassle of dealing with tangled cords or limited mobility. With a long-lasting lithium-ion battery, the Airstrike provides ample power for extended use, allowing users to complete their projects without interruption. The Airstrike delivers consistent and reliable performance, whether driving nails, stapling materials, or even inflating tires. Here are nine steps on Ryobi airstrike not firing:

1.Check The Battery And Ensure It Is Fully Charged

A low battery charge can often cause the tool to malfunction. To do this, remove the battery from the Airstrike and locate the battery charger. Please connect the battery to the charger and allow it to charge until the indicator light shows it is fully charged.

It is important to note that the charging time may vary depending on the battery model. Once the battery is fully charged, reinsert it into the Airstrike and attempt to use the tool again. Further troubleshooting will be necessary to identify and resolve the issue if the Airstrike still does not fire.

2.Inspect The Air Compressor For Any Clogs Or Blockages

Carefully examine the air compressor unit, including the air hose and connections. Look for any signs of debris, dirt, or obstructions preventing the Ryobi Airstrike from firing. Use a flashlight if needed to get a better view of hard-to-reach areas. Pay close attention to the air intake and exhaust vents, as these areas are prone to accumulating dust and dirt over time.

If you notice any clogs or blockages, carefully remove them using a soft cloth or a small brush. Ensure that all passages are clear and free from any obstructions. By thoroughly inspecting and clearing out any clogs or blockages in the air compressor, you can help restore the proper functioning of the Ryobi Airstrike and ensure that it will fire effectively.

3.Clean The Firing Pin And Nail Magazine For Debris

Begin by inspecting the firing pin for any dirt, dust, or other particles that may have accumulated on its surface. Use a soft cloth or brush to wipe away any visible debris gently. Turn your attention to the nail magazine. Check for any nails that may be jammed or misaligned, which can also prevent the Airstrike from firing.

Carefully remove obstructions, ensuring the nails are properly seated and aligned within the magazine. After cleaning the firing pin and nail magazine, reassemble the Airstrike and test it to see if the issue has been resolved. If the problem persists, further assistance or consulting the user manual for troubleshooting guidance may be necessary. Remember always to follow proper safety precautions when working with power tools.

4.Ensure The Depth Adjustment Is Set Correctly

This is a crucial aspect as it can affect the firing mechanism of the tool. First, locate the depth adjustment feature on the tool to do this. It is usually a dial or a switch that allows you to control the depth at which the nail or staple is driven into the material. Once you have located the depth adjustment, carefully inspect it to ensure it is set to the desired depth.

Sometimes, the depth adjustment may have been accidentally changed or set too shallow, causing the tool not to fire properly. Adjust the depth setting by turning the dial or flipping the switch as needed. It is important to note that different projects and materials require different depths for optimal performance.

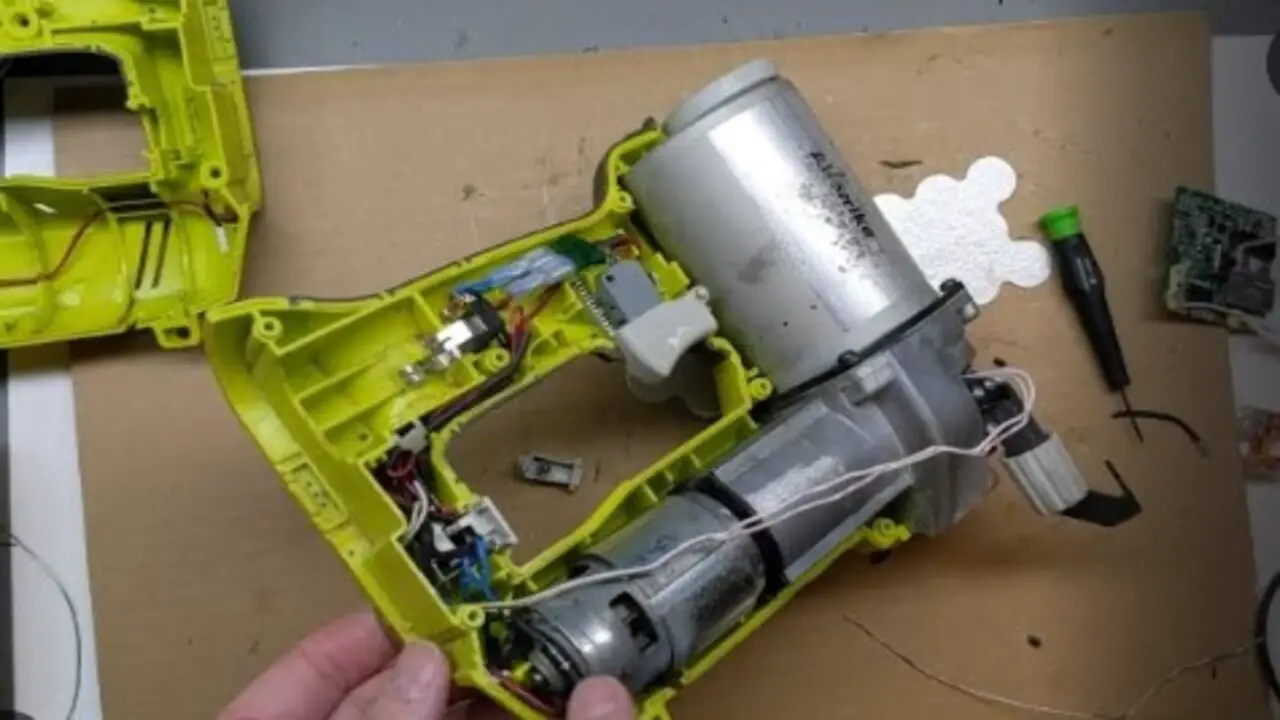

5.Check For Any Faulty Wiring Or Connections

One possible reason the Ryobi Airstrike is not firing could be faulty wiring or connections. Inspecting the tool and its components carefully is important to ensure all wiring is intact and properly connected. Start by turning off the power to the tool and unplugging it from any power sources.

Examine the power cord for visible damage such as cuts, fraying, or exposed wires. If you notice any issues with the power cord, you may need to replace it. Inspect the connections between the power cord and the tool itself. Ensure you securely insert the plug into the tool’s power inlet and check for any loose or damaged connections. If you find any loose connections, tighten them carefully without over-tightening.

6.Checking For Jammed Nails

When your Ryobi Airstrike is not firing, it’s important to check for any jammed gauge nails in the magazine. Take out the battery from the nailer and inspect the magazine for any stuck or misaligned nails. If you find any, use pliers or a nail punch to remove them carefully.

Remove all the jammed gauge nails, reinsert the battery and test the nailer to see if it fires properly. If the issue persists, you may need to clean or lubricate the internal mechanisms of the nailer or seek professional repair. Remember always to ensure your nailer is in good condition and free from obstructions.

7.Addressing Potential Air Leaks

If your Ryobi Airstrike is experiencing issues with firing, one potential cause could be air leaks within the tool. To address this, it’s important to check all the connections and seals to ensure they are tight and free from damage or wear. If you find any damaged or worn seals or O-rings.

We recommend replacing them as they can contribute to air leaks. Applying a small amount of lubricant to the seals and O-rings can also help ensure smooth operation and prevent air leakage. Once you have addressed these potential air leaks, testing the tool to see if the firing issue has been resolved is important. If not, further troubleshooting may be necessary.

8.Cleaning Dust And Dirt Build Up

One potential issue that can cause the Ryobi Airstrike nail gun not to fire properly or consistently is the dust and dirt buildup in the firing mechanism. To troubleshoot this problem, disconnect the nail gun from its power source and remove any nails from the magazine.

Carefully clean out the dust and debris clogging the firing mechanism using compressed air or a small brush. Paying special attention to areas such as the trigger, piston, and firing pin is important. Once you have completed cleaning, reassemble the nail gun and test it to see if it fires properly.

9.Lubricate Moving Parts To Ensure Smooth Operation

To address the issue of the Ryobi not firing, it is important to pay attention to the lubrication of the moving parts. Over time, dust and debris can accumulate, causing friction and hindering the smooth operation of the tool. First, lubricate the moving parts to ensure the tool turn off and disconnected from any power source.

Then, apply a small amount to the areas where the parts move against each other using a suitable lubricant, such as a silicone-based or lithium-based lubricant. Apply the lubricant sparingly, as excess lubrication can attract more debris and cause further issues. A thin, even coating should be sufficient to ensure smooth movement.

Importance Of Using Compatible Nails

Using compatible nails is crucial when using the Ryobi Airstrike nailer. This powerful brad nailer has specific designs to work with specific types and sizes of nails, ensuring optimal functionality and performance. When incompatible nails are handy, it can result in the nailer not firing or functioning properly.

To avoid this issue, always check the manufacturer’s recommendations for compatible nails before using them in the nailer. Using the wrong size or type of nails can not only prevent the nailer from firing but also cause damage to the nailer itself. So, if you’re experiencing trouble with the Ryobi not firing, inspect the nails being handy and ensure they are compatible with the nailer.

Role Of Maintenance In Preventing Firing Issues

Regular maintenance prevents firing issues with the Ryobi Airstrike Brad Nailer. Regularly cleaning and maintaining the nailer can prevent dust and debris from building up, which can cause obstructions and affect its performance.

Additionally, it is important to check the battery and ensure it is fully charged and inserted correctly to ensure optimal power supply. Inspecting the firing mechanism for any obstructions or damage is also essential.

Lastly, lubricating the moving parts of the nailer ensures smooth operation and reduces the chances of jams or misfires. If the issue persists, seeking professional assistance or contacting Ryobi customer support can provide further troubleshooting steps.

How Can Battery Issues Affect The Firing?

Battery issues can significantly impact the firing of a Ryobi Airstrike tool. If the battery is low on charge or not properly connected, it may not provide enough power to engage the firing mechanism. This can result in the tool not firing or firing weakly. Additionally, if the battery is old or damaged, it may not be able to hold a charge effectively, leading to inconsistent performance.

Ensure you fully charge the battery and properly insert it into the tool before using it. If you are experiencing issues with your Ryobi not firing, checking and addressing potential battery issues should be one of your first troubleshooting steps.

Conclusion

If you’re experiencing issues with your Ryobi Airstrike not firing, solutions are available to help fix the problem. Fixing the Ryobi not firing issue is a straightforward process that can be accomplished with a few simple steps. Following the troubleshooting tips. You can quickly identify and fix the problem, ensuring your tool is in proper setting working order.

It’s always important to prioritize safety mechanisms when handling power tools, so follow all safety precautions and manufacturer guidelines. With the right tools and some know-how, you can get your Ryobi Airstrike back up and running in no time.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-d6c7178e-3eaf-4ae1-969b-847cd1cabe20″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.