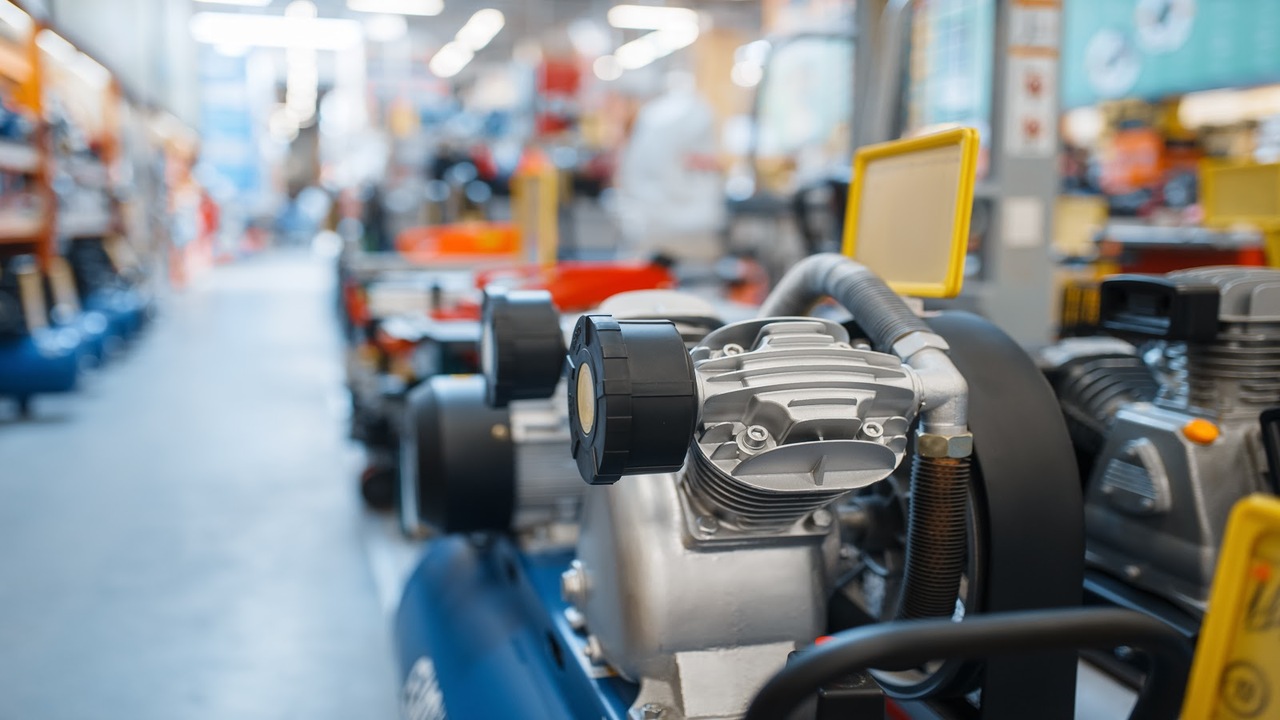

The Wayne air compressor is essential for any DIY enthusiast or professional contractor. Its powerful motor and durable construction make it the perfect machine for powering various pneumatic tools and equipment, from nail guns to air compressors.

With its versatile range of pressure and capacity settings, you can confidently tackle any project. Choosing the right air compressor can make all the difference in your projects, whether you’re a DIY enthusiast or a professional contractor. Here we will walk you through the factors to consider when selecting an air compressor that meets your needs.

From evaluating your usage requirements, determining the right capacity and PSI, understanding power sources, and examining portability and size, we’ve got you covered. We’ll also explore important considerations like noise level, durability, maintenance requirements, and safety features.

Factors To Consider When Choosing A Wayne Air Compressor

When choosing a Wayne air compressor, it’s important to consider your specific needs and application. Consider the required air pressure and volume for your tasks and the available power source options. Don’t forget to assess the compressor’s noise level, portability, durability, and reliability. Additionally, consider any additional features and accessories that may benefit your needs.

Choosing The Right Capacity And PSI For Your Air Compressor

Choosing the right capacity and PSI for your air compressor ensures that your tools and equipment operate efficiently. Capacity refers to the air the compressor can produce, while PSI (pounds per square inch) measures the pressure at which the air is delivered.

Choosing a compressor with the right capacity and PSI depends on the work you will do. If you use the compressor for small DIY projects, a lower capacity and PSI may suffice. However, you will need a higher capacity and PSI if you use it for more heavy-duty tasks, such as running air tools or powering paint sprayers.

When selecting an air compressor, it is important to consider the tools and equipment you will be using it with. Different tools require different PSI levels to operate effectively. For example, nail guns typically require a PSI of 70-120, while sanders and grinders may require 90-100 PSI.

Evaluating Your Air Compressor Needs

When evaluating your air compressor needs, there are several factors to consider. The first step is to determine your specific application requirements. This includes understanding the type of tools or equipment that will be powered by the compressor, as well as the frequency and duration of use. It’s also important to consider the compressed air demands of your operation, including the required pressure and flow rate.

Once you understand your application requirements, you can evaluate different compressor types and models. This may involve researching different brands and manufacturers and comparing features and specifications. Factors to consider when selecting an air compressor include horsepower, tank size, duty cycle, and noise level.

Another important consideration is the overall cost of owning and operating the compressor. This includes the initial purchase price, ongoing maintenance and repair costs, energy efficiency, and the cost of compressed air.

Determining Your Air Compressor Usage

Determining your air compressor usage is important in choosing the right unit for your needs. Knowing how often and for what purposes you will use the compressor is essential. If you plan on using it for light household tasks, such as inflating tires or powering a brad nailer, a smaller unit with a lower CFM (cubic feet per minute) rating may suffice.

However, a larger unit with a higher CFM rating is necessary if you need it for heavy-duty tasks, such as sandblasting or running multiple air tools simultaneously.

Additionally, it is important to consider your tools and equipment’s PSI (pounds per square inch) requirements to ensure that the compressor can provide enough pressure. Another factor to consider is the type of power source available.

If you have access to electricity, an electric compressor may be the best option. If not, a gas-powered compressor may be necessary. Determining your air compressor usage requires careful consideration of your specific needs.

Evaluating The Air Compressor’s Power Source

Evaluating the air compressor’s power source is essential when choosing the right equipment. The power source can significantly impact the compressor’s performance and determine its suitability for specific applications.

Electric, gasoline, and diesel are the most common power sources for air compressors. Electric air compressors are ideal for indoor use and applications that require low noise levels. Gasoline-powered compressors are perfect for outdoor use and applications where mobility is necessary, such as at construction sites.

Diesel air compressors are ideal for heavy-duty applications that require high volumes of compressed air, such as in mining and oil and gas industries. When evaluating the power source of an air compressor, it is crucial to consider factors such as the availability of the power source, fuel efficiency, noise levels, and emissions. It is also essential to ensure that the power source matches the compressor’s requirements and that the equipment’s safety features are adequate.

Understanding The Importance Of Portability And Size

Understanding the importance of portability and size is crucial in today’s fast-paced world, where people are always on-the-go. The need for compact devices that can be easily carried around is increasing daily.

Whether it’s a laptop or a smartphone, people are looking for devices that can fit in their pockets or bags, making it easier to work and communicate while on the move. The portability factor has become a top priority for most consumers, and manufacturers are working to create slim and lightweight devices that are easy to carry around.

The size of a device also plays a critical role in its portability. Smaller devices are easier to carry around and consume less power, making them ideal for people who are always on the move. The size of a device also affects its functionality and usability. A smaller device may have fewer features and a smaller screen, limiting its functionality.

Examining The Noise Level Of Your Air Compressor

When choosing a Wayne compressor, it is crucial to consider the noise level. Wayne offers compressors with different noise levels, allowing you to select one that suits your requirements. Quieter models may come at a higher price due to sound-reducing features.

However, investing in a quieter air compressor can be worth it, especially if you plan to use it in a residential or indoor setting. Noisy compressors can be disruptive and annoying, affecting the overall comfort of your workspace or home.

Durability And Maintenance Requirements Of Your Air Compressor

When evaluating an air compressor, consider its durability and maintenance requirements. Look for high-quality materials that can withstand regular use and potentially harsh conditions. Assess the maintenance needs, such as oil changes and filter replacements. Additionally, think about the intended use, noise level, and any additional features that may be beneficial.

The Importance Of Safety And Warranty

Purchasing a Wayne air compressor, safety and warranty are two important factors. Safety should always be a top priority when using any type of machinery, and an air compressor is no exception.

Wayne compressors have safety features such as pressure relief valves and automatic shut-off switches to prevent accidents and ensure the user’s well-being. Additionally, it is crucial to check the warranty provided by the manufacturer.

A warranty can provide peace of mind knowing that if any issues arise with the air compressor, it will be covered under the terms of the warranty. It is recommended to thoroughly read and understand the warranty terms before purchasing to ensure you are protected in case of malfunctions or defects. Overall, prioritizing safety and considering the warranty when purchasing a Wayne compressor can help you make an informed decision and have a positive experience with your equipment.

Conclusion

Wayne air compressors (also known as WAC compressors) are a type of air compressor designed for light-duty use. They are compact and lightweight, making them ideal for limited-space applications. Choosing the right Wayne- air compressor is crucial to ensure optimal performance and efficiency.

You can make an informed decision by evaluating your air compressor needs, determining your usage requirements, and considering factors such as capacity, power source, portability, noise level, durability, and safety. Selecting an air compressor that aligns with your specific requirements and offers a warranty for added peace of mind is important.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-19aa7061-705b-48ee-947c-956a807ccd97″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.