Passive heat sinks are simple devices that cool components without needing extra power. They’re known for being reliable, quiet, and needing almost no upkeep. Key features include using natural convection, having a design with fins to boost surface area, and being made from materials that conduct heat well, like aluminum or copper.

Ever feel like your computer is running too hot? Or maybe you’re working with electronics and need to keep things cool? Overheating can cause serious problems, but don’t worry! Keeping your devices cool doesn’t have to be complicated. Passive heat sinks are a simple, reliable way to manage heat without any extra fuss.

In this guide, we’ll walk you through everything you need to know about passive heat sinks. We’ll cover what they are, how they work, and why they’re so useful. By the end, you’ll know exactly how to use them to keep your electronics running smoothly. Let’s dive in!

Understanding Passive Heat Sinks

Passive heat sinks are devices that cool electronic components without using any additional power. They rely on natural convection, radiation, and conduction to dissipate heat. Unlike active heat sinks that use fans, passive heat sinks are quiet, reliable, and require minimal maintenance. Let’s break down the key characteristics.

Key Characteristics of Passive Heat Sinks

Passive heat sinks have several defining features that make them effective for thermal management. Here’s a closer look at each characteristic:

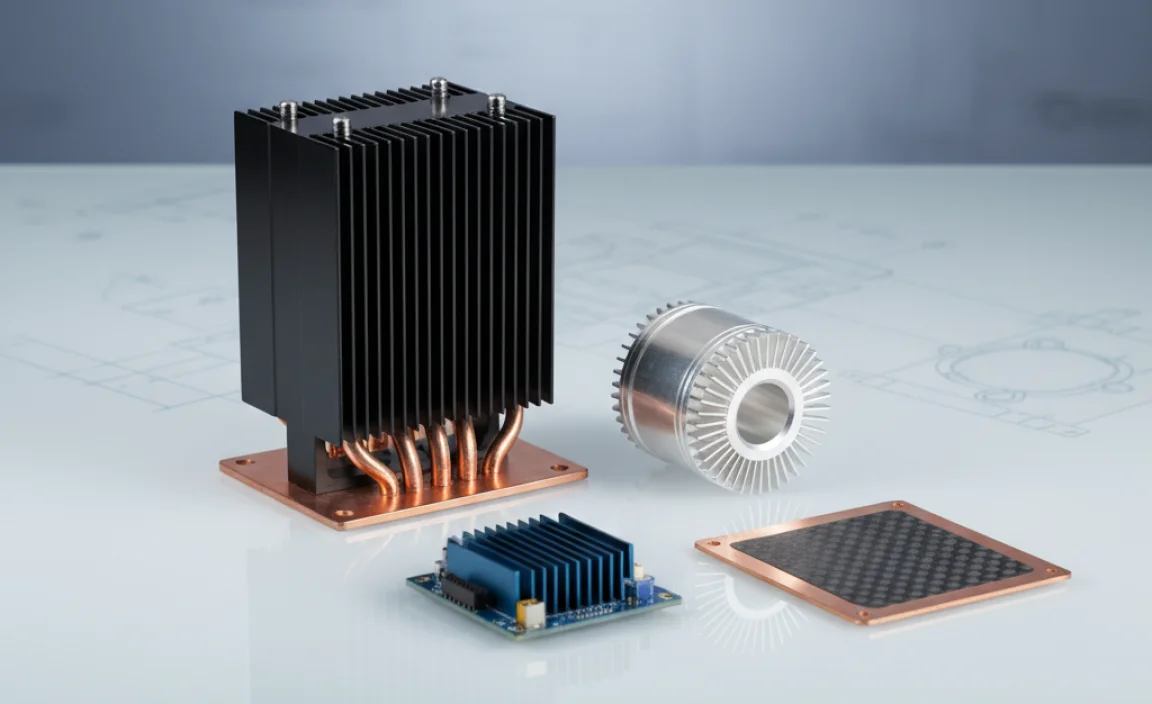

- Material Composition: Typically made from thermally conductive materials like aluminum or copper.

- Fin Design: Features fins that increase the surface area for better heat dissipation.

- Natural Convection: Relies on natural air flow to remove heat.

- No Moving Parts: Operates without fans or pumps, ensuring quiet and reliable performance.

- Simple Installation: Easy to attach to electronic components with thermal paste or adhesive.

Material and Construction

The choice of material is crucial for a passive heat sink’s performance. Aluminum and copper are the most common materials due to their excellent thermal conductivity. Here’s why:

- Aluminum: Lightweight, cost-effective, and has good thermal conductivity.

- Copper: Offers superior thermal conductivity compared to aluminum, but is heavier and more expensive.

The construction of a passive heat sink usually involves extruding or machining the metal into a specific shape. This shape often includes fins to maximize the surface area.

Fin Design

The fins on a passive heat sink are designed to increase the surface area that comes into contact with the air. This increased surface area allows for more efficient heat transfer. Here are some common fin designs:

- Straight Fins: Simple and cost-effective, suitable for many applications.

- Pin Fins: Offer good performance in all directions, ideal for complex airflow environments.

- Flared Fins: Designed to optimize airflow and reduce thermal resistance.

The optimal fin design depends on the specific application and the available space.

Natural Convection

Passive heat sinks rely on natural convection to dissipate heat. Natural convection is the process where warm air rises and is replaced by cooler air. This creates a natural airflow that removes heat from the heat sink.

To maximize natural convection, it’s important to ensure that the heat sink is oriented vertically. This allows the warm air to rise freely and be replaced by cooler air. Proper ventilation around the heat sink is also essential.

Advantages of Passive Heat Sinks

Passive heat sinks offer several advantages over active cooling solutions. These include:

- Reliability: With no moving parts, passive heat sinks are less likely to fail.

- Quiet Operation: They operate silently, making them ideal for noise-sensitive environments.

- Low Maintenance: Require minimal maintenance, reducing the need for frequent inspections and repairs.

- Energy Efficiency: Do not consume any power, reducing overall energy consumption.

- Cost-Effective: Generally less expensive than active cooling solutions.

Disadvantages of Passive Heat Sinks

While passive heat sinks have many advantages, they also have some limitations:

- Lower Cooling Capacity: Less effective than active cooling solutions in high-heat applications.

- Size Constraints: Can be bulky, requiring more space than active coolers.

- Orientation Sensitivity: Performance can be affected by orientation and airflow.

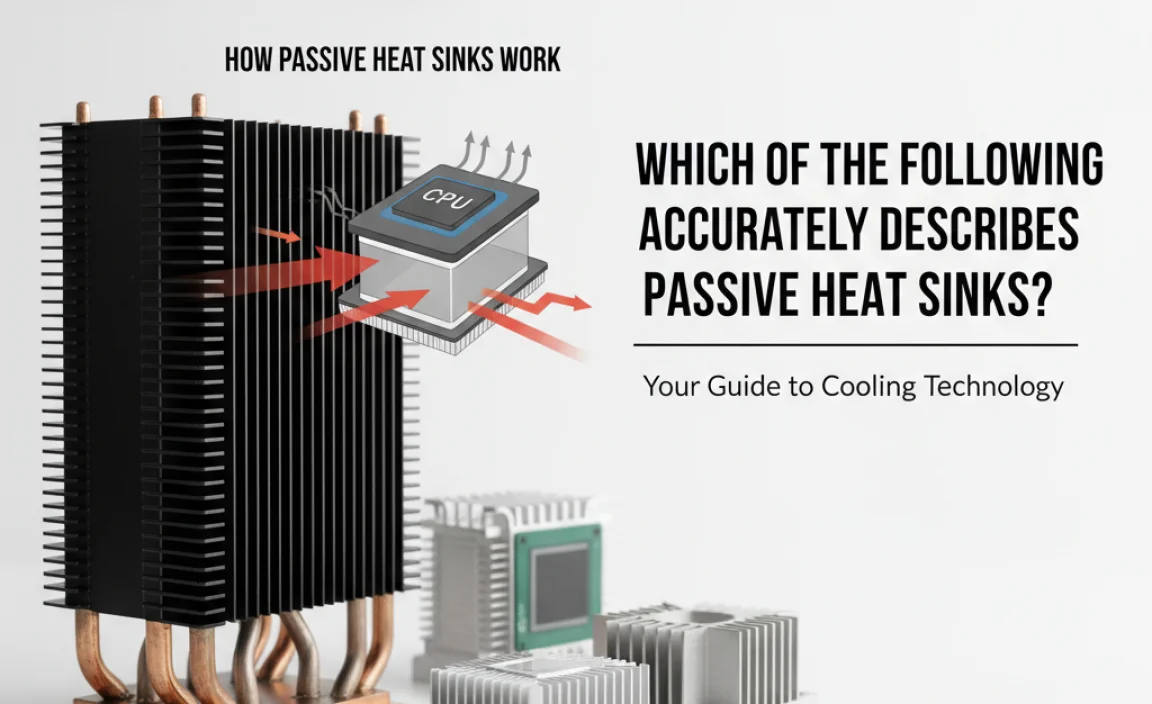

How Passive Heat Sinks Work

Passive heat sinks operate on three primary principles: conduction, convection, and radiation. Understanding these principles will help you appreciate how they effectively manage heat.

Conduction

Conduction is the transfer of heat through a solid material. In a passive heat sink, heat is conducted from the electronic component to the heat sink itself. The heat sink material, typically aluminum or copper, facilitates this transfer due to its high thermal conductivity.

To ensure efficient conduction, it’s important to use thermal paste between the electronic component and the heat sink. Thermal paste fills in any microscopic gaps and improves the thermal contact between the two surfaces. You can find quality thermal paste at stores like Newegg.

Convection

Convection is the transfer of heat through the movement of fluids, in this case, air. As the heat sink absorbs heat from the electronic component, the air around the heat sink becomes warmer. This warm air rises, creating a natural airflow that carries the heat away from the heat sink.

The fin design of the heat sink plays a crucial role in convection. The fins increase the surface area that comes into contact with the air, allowing for more efficient heat transfer. The more surface area, the more heat can be dissipated through convection.

Radiation

Radiation is the transfer of heat through electromagnetic waves. All objects emit thermal radiation, and the amount of radiation depends on the object’s temperature and surface properties. A heat sink radiates heat into the surrounding environment, contributing to the overall cooling process.

The surface finish of the heat sink can affect its radiative properties. Darker surfaces tend to radiate heat more effectively than lighter surfaces. However, the effect of radiation is generally less significant than conduction and convection in most passive heat sink applications.

Selecting the Right Passive Heat Sink

Choosing the right passive heat sink for your application involves considering several factors. These include the thermal load, available space, and environmental conditions. Here’s a step-by-step guide to help you select the best heat sink.

Step 1: Determine the Thermal Load

The first step is to determine the amount of heat that the electronic component will generate. This is typically specified in watts (W) and can be found in the component’s datasheet. Knowing the thermal load is crucial for selecting a heat sink with sufficient cooling capacity.

If the datasheet doesn’t provide the thermal load, you can estimate it based on the component’s power consumption and efficiency. For example, if a component consumes 10W and is 80% efficient, it will generate 2W of heat.

Step 2: Evaluate Available Space

Next, consider the amount of space available for the heat sink. Passive heat sinks can be bulky, so it’s important to ensure that there is enough room in the enclosure. Measure the available space and choose a heat sink that fits within those dimensions.

Keep in mind that the heat sink needs adequate airflow to function effectively. Avoid placing it in a confined space where air circulation is restricted.

Step 3: Choose the Right Material

Select the appropriate material for the heat sink based on the thermal load and budget. Aluminum is a good choice for most applications, but copper may be necessary for high-heat components. Consider the pros and cons of each material:

| Material | Pros | Cons |

|---|---|---|

| Aluminum | Lightweight, cost-effective, good thermal conductivity | Lower thermal conductivity than copper |

| Copper | Superior thermal conductivity | Heavier, more expensive |

Step 4: Select the Fin Design

Choose a fin design that is appropriate for the application. Straight fins are suitable for most applications, while pin fins are better for complex airflow environments. Flared fins can optimize airflow and reduce thermal resistance.

Consider the orientation of the heat sink when selecting the fin design. Vertical fins are best for natural convection, while horizontal fins may require forced air cooling.

Step 5: Consider Environmental Conditions

Finally, consider the environmental conditions in which the heat sink will operate. High ambient temperatures can reduce the effectiveness of the heat sink, while dusty environments can clog the fins and reduce airflow.

If the heat sink will be exposed to harsh conditions, choose a model that is designed to withstand those conditions. Some heat sinks are coated with a protective finish to prevent corrosion and other types of damage.

Installing a Passive Heat Sink

Installing a passive heat sink is a straightforward process that can be completed in a few simple steps. Here’s a step-by-step guide to help you install a passive heat sink correctly.

Step 1: Gather Your Materials

Before you begin, gather the necessary materials. You will need:

- Passive heat sink

- Thermal paste

- Isopropyl alcohol

- Lint-free cloth

- Screwdriver (if necessary)

Step 2: Clean the Component

Use isopropyl alcohol and a lint-free cloth to clean the surface of the electronic component. This will remove any dirt, oil, or old thermal paste that could interfere with the heat transfer. Allow the alcohol to evaporate completely before proceeding.

Step 3: Apply Thermal Paste

Apply a small amount of thermal paste to the center of the component. A pea-sized amount is usually sufficient. Avoid using too much thermal paste, as it can actually reduce the effectiveness of the heat transfer.

You can spread the thermal paste evenly using a plastic spreader or a clean finger covered with a plastic bag. Ensure that the entire surface of the component is covered with a thin layer of thermal paste.

Step 4: Attach the Heat Sink

Carefully place the heat sink on top of the component, aligning it with the mounting holes. Press down firmly to ensure that the heat sink makes good contact with the component. If necessary, use screws to secure the heat sink in place.

Make sure that the heat sink is properly aligned and that there is no excessive pressure on the component. Over-tightening the screws can damage the component or the heat sink.

Step 5: Test the Installation

After installing the heat sink, test the installation by running the electronic component and monitoring its temperature. Use a temperature monitoring tool to ensure that the component is operating within its safe temperature range.

If the temperature is too high, check the installation to ensure that the heat sink is properly attached and that there is adequate airflow. You may need to reapply the thermal paste or adjust the orientation of the heat sink.

Maintaining Your Passive Heat Sink

Maintaining a passive heat sink is simple, but regular maintenance can ensure optimal performance and extend its lifespan. Here are some tips for maintaining your passive heat sink.

Regular Cleaning

Dust and debris can accumulate on the fins of the heat sink, reducing its ability to dissipate heat. Clean the heat sink regularly using a soft brush or compressed air. Avoid using water or other liquids, as they can damage the electronic components.

If the heat sink is heavily soiled, you can remove it from the component and clean it with isopropyl alcohol. Make sure to reapply thermal paste before reinstalling the heat sink.

Check for Corrosion

Inspect the heat sink regularly for signs of corrosion. Corrosion can reduce the thermal conductivity of the heat sink and shorten its lifespan. If you notice any corrosion, clean the affected area with a wire brush and apply a protective coating.

To prevent corrosion, avoid exposing the heat sink to moisture or harsh chemicals. Store it in a dry, well-ventilated area when not in use.

Ensure Proper Airflow

Make sure that the heat sink has adequate airflow to function effectively. Avoid placing it in a confined space where air circulation is restricted. Keep the area around the heat sink clear of obstructions and ensure that there is adequate ventilation.

If necessary, you can use a fan to improve airflow around the heat sink. However, this will turn the passive heat sink into an active cooling solution.

Replace Thermal Paste

Thermal paste can dry out over time, reducing its effectiveness. Replace the thermal paste every few years to ensure optimal heat transfer. Remove the old thermal paste with isopropyl alcohol and a lint-free cloth, and apply a fresh layer of thermal paste before reinstalling the heat sink.

Common Applications of Passive Heat Sinks

Passive heat sinks are used in a wide range of applications, from consumer electronics to industrial equipment. Here are some common applications of passive heat sinks.

Consumer Electronics

Passive heat sinks are commonly used in consumer electronics such as computers, laptops, and smartphones. They help to cool the CPU, GPU, and other critical components, preventing overheating and ensuring stable performance.

In laptops and smartphones, space is limited, so passive heat sinks are often designed to be compact and efficient. They may also be integrated with other components, such as the chassis, to improve heat dissipation.

LED Lighting

LED lighting generates a significant amount of heat, which can reduce its lifespan and efficiency. Passive heat sinks are used to dissipate this heat, ensuring that the LEDs operate within their safe temperature range.

LED heat sinks are often made from aluminum and designed with a large surface area to maximize heat transfer. They may also be integrated with the LED fixture to improve heat dissipation.

Power Electronics

Power electronics, such as power supplies and inverters, generate a significant amount of heat. Passive heat sinks are used to cool the power transistors, diodes, and other components, preventing overheating and ensuring reliable operation.

Power electronic heat sinks are often made from copper and designed with a high thermal conductivity. They may also be equipped with fins or other features to improve heat dissipation.

Industrial Equipment

Passive heat sinks are used in a variety of industrial equipment, such as motors, generators, and transformers. They help to cool the critical components, preventing overheating and ensuring reliable operation.

Industrial heat sinks are often designed to be robust and durable, capable of withstanding harsh environmental conditions. They may also be equipped with features such as corrosion resistance and vibration damping.

Conclusion

Passive heat sinks are a simple, reliable, and cost-effective solution for cooling electronic components. Understanding their characteristics, how they work, and how to select and install them will help you keep your electronics running smoothly and prevent overheating. By following the tips and guidelines in this guide, you can ensure that your passive heat sinks provide optimal performance and extend the lifespan of your electronic devices. So go ahead, give it a try, and keep those components cool!

FAQ About Passive Heat Sinks

Here are some frequently asked questions about passive heat sinks to help you better understand their use and benefits.

What is a passive heat sink?

A passive heat sink is a device that cools electronic components without using any additional power. It relies on natural convection, radiation, and conduction to dissipate heat.

How does a passive heat sink work?

A passive heat sink works by conducting heat away from the electronic component, then dissipating that heat into the surrounding air through convection and radiation.

What materials are passive heat sinks made of?

Passive heat sinks are typically made from thermally conductive materials like aluminum or copper. Aluminum is lightweight and cost-effective, while copper offers superior thermal conductivity.

What are the advantages of using a passive heat sink?

The advantages include reliability (no moving parts), quiet operation, low maintenance, energy efficiency, and cost-effectiveness.

What are the disadvantages of using a passive heat sink?

The disadvantages include lower cooling capacity compared to active solutions, potential size constraints, and sensitivity to orientation and airflow.

How do I choose the right passive heat sink for my application?

Consider the thermal load, available space, material, fin design, and environmental conditions. Ensure the heat sink can handle the component’s heat output and fits within the available space.

How do I install a passive heat sink?

Clean the component, apply a small amount of thermal paste, and attach the heat sink firmly. Ensure proper alignment and secure it with screws if necessary. Test the installation by monitoring the component’s temperature.