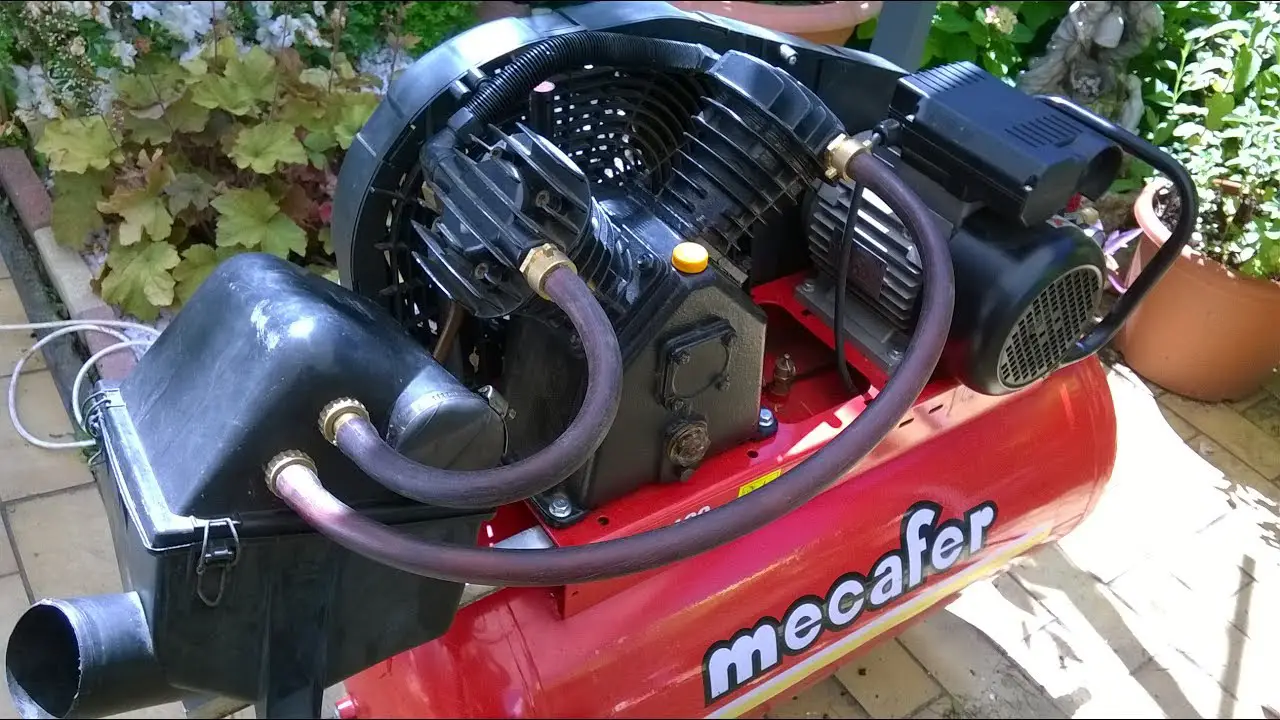

An air compressor is an essential tool for any workshop or garage. It powers pneumatic tools like nail guns, impact wrenches, and spray guns that make tasks a lot easier.

However, the noise generated by an air compressor can be a nuisance for you and your neighbors. That’s where an air compressor muffler comes in handy. It reduces the noise level significantly, making the operation of your air compressor much quieter.

Here we will provide you with a complete guide on how to build an air compressor muffler diy. We will also list all the materials and tools needed for this DIY project, along with step-by-step instructions to guide you through the process. So let’s get started.

Materials And Tools Needed For The DIY Project

Before starting your DIY air compressor muffler project, it’s important to gather all the necessary materials and tools. Here is a list of what you will need. By gathering all the necessary materials and tools beforehand, you can streamline the process of building your own air compressor muffler and achieve the desired noise reduction for your workspace.

- A suitable muffler: Choose a muffler that is compatible with your air compressor and meets your noise reduction requirements.

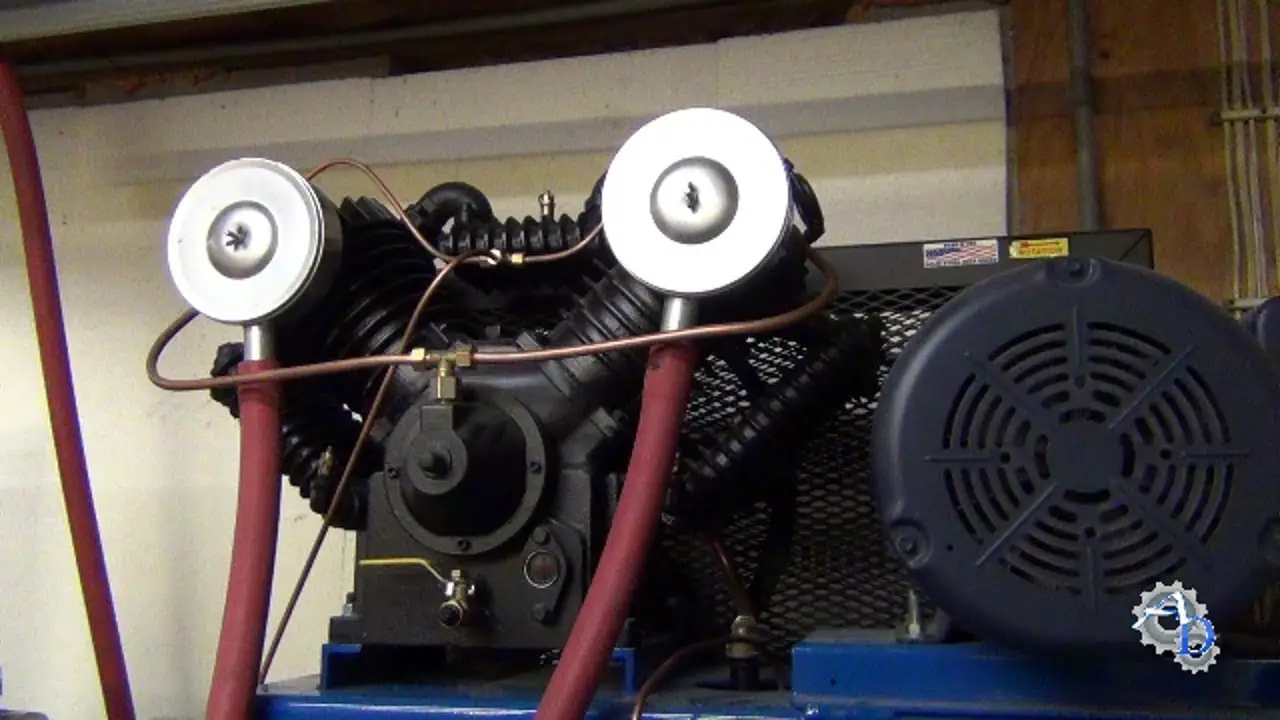

- Piping and fittings: You will need piping and fittings to connect the muffler to your air compressor system. Make sure they are the correct size and type for your setup.

- Clamps or brackets: These will be used to secure the muffler in place.

- Safety equipment: Don’t forget to wear safety goggles, gloves, and ear protection while working on your DIY project.

Step-By-Step Instructions For Building An Air Compressor Muffler Diy

Air compressor muffler diy can help reduce noise levels and create a more pleasant working environment. Here is a step-by-step guide to building your own air compressor muffler. By following these steps, you can create your own DIY air compressor muffler and enjoy a quieter workspace while still benefiting from the functionality of your air compressor:

- Gather the necessary materials: You will need a metal pipe, an end cap, sound-deadening material (such as acoustic foam or fibreglass insulation), and hose clamps.

- Measure and cut the metal pipe: Measure the diameter of your air compressor’s exhaust port and cut the metal pipe to the appropriate length using a saw or pipe cutter.

- Attach the end cap: Securely attach the end cap to one end of the metal pipe using a hose clamp or welding.

- Add sound-deadening material: Fill the inside of the muffler with sound-deadening material, such as acoustic foam or fibreglass insulation. This will help absorb and dampen the noise produced by the air compressor.

- Securely close off the other end: Use another end cap or securely seal off the other end of the metal pipe to ensure that all air flows through the sound-deadening material.

- 6. Install the muffler: Attach the completed muffler to your air compressor’s exhaust port using hose clamps or other appropriate fasteners.

- Test and adjust: Start up your air compressor and listen for any noticeable reduction in noise levels. If needed, you can make adjustments to improve its effectiveness by adding more sound-deadening material or adjusting its position.

Common Mistakes To Avoid When Building A DIY Air Compressor Muffler

Building a DIY air compressor muffler can be a cost-effective way to reduce noise levels and improve the overall performance of your air compressor. However, there are some common mistakes that you should avoid in order to ensure that your muffler functions properly. Here are a few key mistakes to watch out for:

- Using the wrong materials: It’s important to use materials that are designed to withstand high temperatures and pressure. Using low-quality or inappropriate materials can result in a muffler that fails to effectively reduce noise or even poses a safety risk.

- Improper sizing: The size of your muffler should be carefully considered to ensure that it is capable of handling the airflow from your specific air compressor. If the muffler is too small, it may restrict airflow and negatively impact performance. On the other hand, if it’s too large, it may not effectively reduce noise.

- Inadequate insulation: Proper insulation is essential for minimizing noise levels. Failing to adequately insulate your muffler can result in increased noise transmission and reduced effectiveness.

- Poor design or construction: Taking the time to plan and build your DIY muffler correctly is crucial. Make sure to follow proper design principles and construction techniques to ensure optimal performance.

By avoiding these common mistakes, you can increase the chances of building an effective DIY air compressor muffler that helps reduce noise and improves overall functionality.

How To Maintain Your DIY Air Compressor Muffler?

Maintaining your DIY air compressor muffler is essential to ensure its optimal performance and longevity. Here are some tips to help you keep your muffler in great shape. By following these maintenance tips, you can help prolong the life of your DIY air compressor muffler and ensure efficient and quiet operation for all your projects.

- Regular cleaning: Remove any dirt, dust, or debris that may accumulate on the muffler. Use a soft brush or cloth to gently clean the surface and ensure proper airflow.

- Check for leaks: Inspect the muffler for any signs of leaks, such as cracks or holes. If you notice any damage, repair or replace the muffler as soon as possible to prevent further issues.

- Lubricate moving parts: If your muffler has moving parts, such as valves or hinges, apply a small amount of lubricant to ensure smooth operation. Be sure to use a lubricant that is compatible with your specific muffler model.

- Monitor noise levels: Keep an ear out for any unusual noises coming from your air compressor. Excessive noise could indicate a problem with the muffler, so it’s important to address it promptly.

Benefits Of A DIY Air Compressor Muffler

There are several benefits to building your own DIY air compressor muffler. Here are a few advantages that you can enjoy by taking on this project. By taking advantage of these benefits, you can enhance the performance of your air compressor while also saving money and enjoying the satisfaction of completing a DIY project.

- Cost savings: Building your own muffler can be significantly cheaper than purchasing a pre-made one from a store. By using readily available materials and following online tutorials or guides, you can create an effective muffler without breaking the bank.

- Customization: When you make your own muffler, you have the freedom to customize it to meet your specific needs. You can choose the size, shape, and design that will work best for your air compressor setup.

- Noise reduction: One of the main reasons people invest in an air compressor muffler is to reduce noise levels. By constructing your own muffler, you can experiment with different materials and designs to achieve the level of noise reduction that suits your preferences.

- Learning experience: Building a DIY air compressor muffler can be a fun and educational project. It allows you to learn more about how air compressors work and gain hands-on experience in creating a functional component for your equipment.

Other Options For Reducing Noise From An Air Compressor

Reducing noise from an air compressor can be a priority for many individuals, especially if they are using it in a residential or noise-sensitive environment. While purchasing a pre-made muffler is one option, there are also DIY alternatives that can help minimize the noise produced by the air compressor. Some other options to consider include:

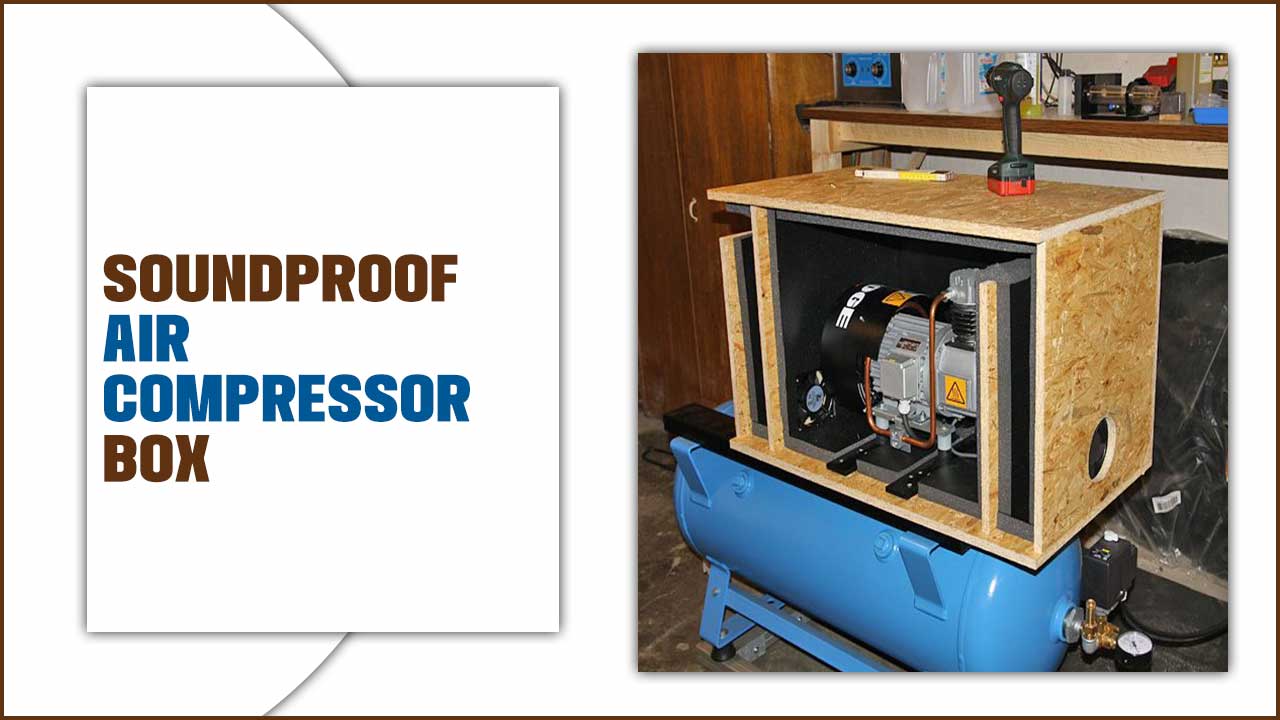

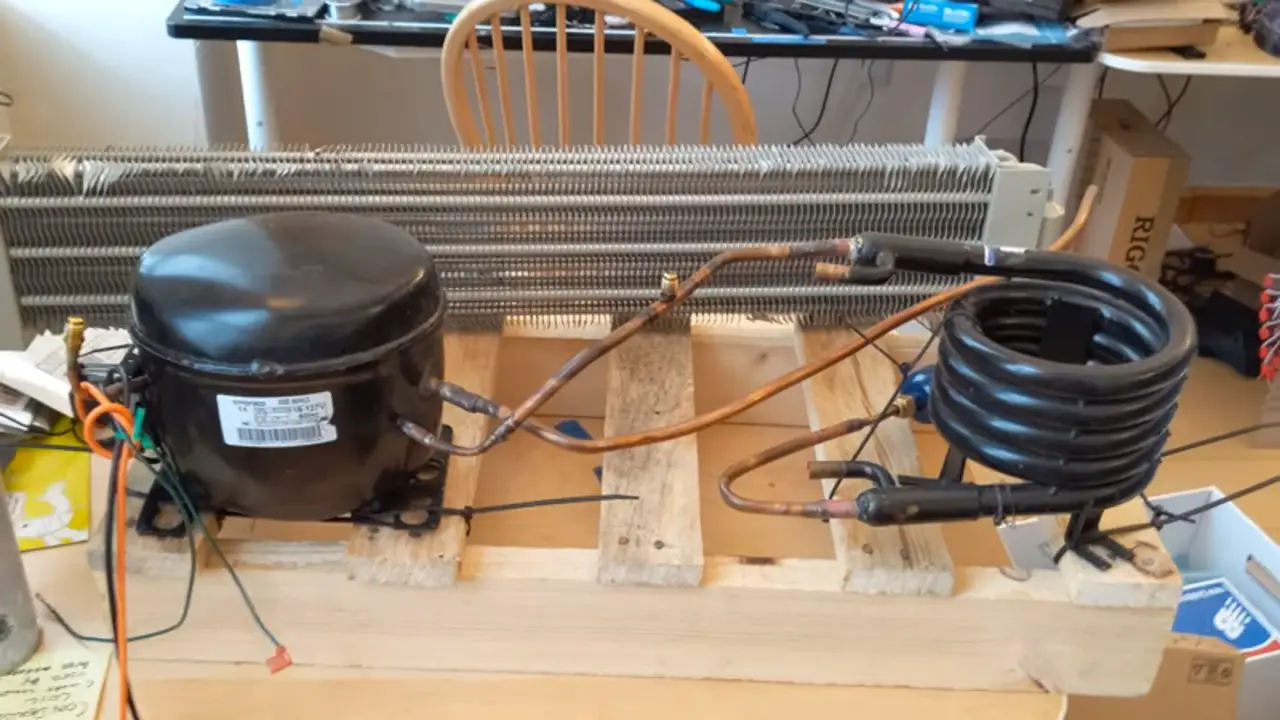

- Building an enclosure: Constructing a soundproof enclosure around the air compressor can effectively reduce noise levels. Using materials such as plywood or acoustic foam can help absorb and block the sound.

- Adding insulation: Insulating the walls of the enclosure with materials like mass-loaded vinyl or foam panels can further dampen noise transmission.

- Installing rubber mounts: Mounting the air compressor on rubber pads or isolators can help absorb vibrations and reduce noise.

- Using flexible hoses: Utilizing flexible hoses instead of rigid piping can help minimize vibrations and noise transmission.

By implementing these DIY solutions, individuals can create a quieter working environment while still enjoying the benefits of their air compressor.

Conclusion

Air compressor muffler diy is a simple and cost-effective way to reduce noise pollution and protect your hearing. By following the step-by-step instructions provided, you can create your own DIY muffler using easily accessible materials and tools.

Not only will this help create a quieter working environment, but it also ensures that you comply with noise regulations and maintain good relations with your neighbors. So, don’t let the loud noise of your air compressor disrupt your peace and tranquility. Take matters into your own hands and build an air compressor muffler to enjoy a quieter and more comfortable workspace. Hope now you know how to make it.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-8373f113-1981-43f2-b300-ee1236003ea1″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.