An air compressor silencer box plays a significant role in reducing the noise produced by an air compressor. By utilizing various materials like foam, plywood, and fiberglass insulation, the silencer box effectively absorbs and dampens sound waves, resulting in a quieter workspace.

In addition to noise reduction, these boxes protect the air compressor, preventing dust, debris, and moisture from entering the system. Different types of air compressor silencer-boxes are available on the market, allowing users to choose the one that best suits their needs.

Proper silencer box selection and installation are crucial for optimal performance. Regular maintenance and troubleshooting are necessary to keep the silencer box functioning efficiently. Here we will walk you through everything you need to know about mastering air compressor silencer-box techniques. Say goodbye to noisy workspaces and hello to a more peaceful and productive environment with an air compressor silencer- box.

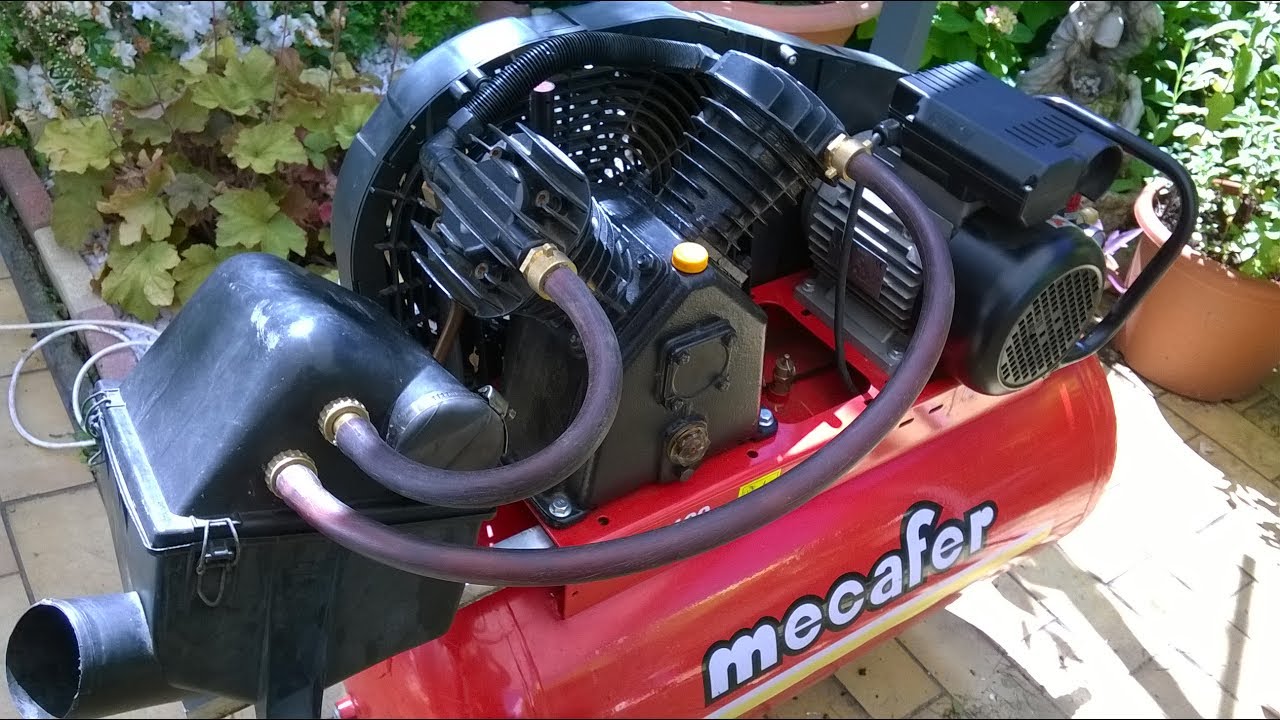

Techniques To Building An Air Compressor Silencer Box

Understand the importance of an air compressor silencer box in reducing noise pollution and protecting your compressor. Gather all the necessary materials and tools, including plywood, foam, screws, and soundproofing materials. Use precise measurements to cut the pieces of wood or sound-absorbing material. Below we provide full step-by-step guidelines to make a silencer box.

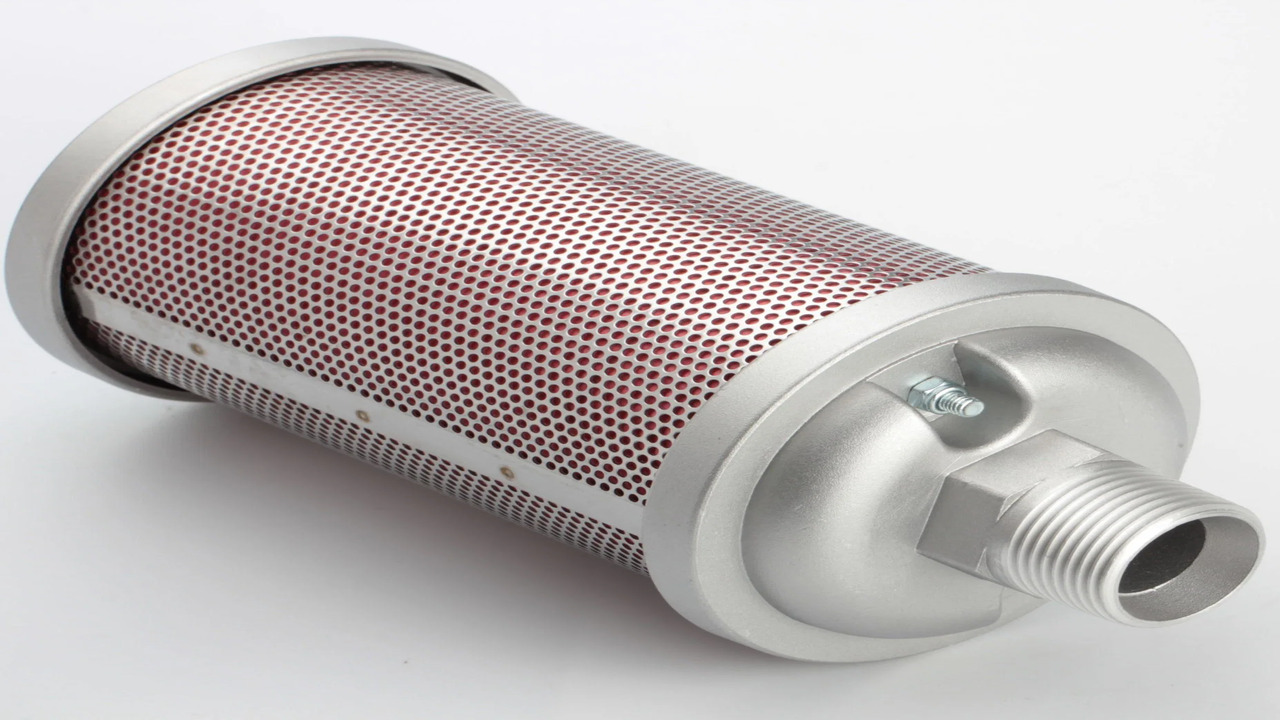

Selecting The Right Materials

When selecting the right materials for your compressor silencer box, remember a few key considerations. First and foremost, you’ll want to choose durable materials that can withstand the air compressor’s noise and vibration. Additionally, it’s important to consider using soundproofing materials such as mass-loaded vinyl or acoustic foam to reduce noise levels.

Opting for materials that are easy to work with and can be cut, shaped, and assembled as needed will make the construction process much smoother. Fire-resistant materials should also be chosen to prevent any potential hazards. Finally, considering the dimensions and weight of the materials is crucial to ensure they are suitable for constructing the silencer box.

Assembling The Box

To assemble an compressor silencer box, you need to bring together the various components of the box. Start by choosing durable materials like plywood or MDF for soundproofing and longevity.

It’s crucial to ensure the box is properly sealed to prevent any air leaks that could compromise its effectiveness. Remember to create an opening for the air compressor intake and an exhaust vent to release hot air. Lastly, follow the step-by-step instructions carefully to guarantee a successful assembly process.

Installing The Compressor In The Box

Installing the air compressor inside a silencer box offers several benefits. By reducing noise pollution, it creates a more peaceful environment. Proper placement and secure compressor mounting ensure optimal performance while preventing vibrations from transferring to the surroundings.

Additionally, it is important to allow enough space around the compressor for proper ventilation and air circulation. This helps maintain airflow and prevent overheating. Regular maintenance and cleaning of the compressor inside the box are essential for long-lasting performance. Ensure the air compressor is installed correctly in the silencer box for maximum effectiveness.

Important Factors To Consider For Effective Air Compressor Silencing

Effective air compressor silencing requires careful consideration of several important factors. First and foremost, the primary purpose of an compressor silencer box is to reduce noise levels. Choosing a silencer box that is the right size and compatible with your specific air compressor model is crucial.

Additionally, be mindful of any potential airflow restrictions caused by the silencer box. Opt for a silencer box made from durable, sound-absorbing materials to reduce noise effectively. Regular silencer box maintenance and cleaning are essential to ensure optimal performance and longevity.

Size Of The Compressor

The size of an air compressor plays a significant role in determining the size and design of the silencer box. Larger compressors generally require larger silencer boxes to reduce noise levels effectively. It is important to ensure that the silencer box is properly sized to accommodate the airflow requirements of the compressor.

By choosing the right size, you can guarantee optimal noise reduction and overall air compressor performance. Consider the available space for installation when determining the appropriate size of the compressor silencer box.

Ventilation Requirements

Proper ventilation is essential for optimal performance in an compressor silencer box. To ensure efficient air circulation and prevent overheating, it’s important to have a well-ventilated silencer box. When considering ventilation requirements, carefully assess the size and location of the openings. This will help maximize airflow while minimizing noise leakage.

Achieving the right balance between ventilation and sound attenuation is crucial for effective noise reduction. It’s recommended to consult the manufacturer’s guidelines to determine specific ventilation requirements based on the air compressor’s specifications.

Suitable Materials For Silencer Box

When choosing suitable materials for a silencer box, the right selection can significantly impact its effectiveness in reducing noise. High-density foam or sound-absorbing panels are excellent options, as they can effectively absorb and dampen sound waves. It’s also crucial to consider fire-resistant and durable materials for long-lasting performance.

The thickness and density of the chosen material will also play a role in noise reduction capabilities. Additionally, selecting materials that are easy to install and maintain will ensure convenience and efficiency. Remember to consider these factors when determining the best materials for your silencer box.

How To Ensure Safety While Using A Silencer Box?

Always follow the manufacturer’s instructions to ensure safety while using a silencer box. Securely attach the box to the air compressor and wear protective equipment like ear protection and goggles. Regularly inspect for damage or leaks and repair as needed.

Overheating And Thermal Overload Switch

Proper ventilation and airflow are crucial in preventing overheating inside the silencer box. Thermal overload switches are installed to enhance safety, automatically shutting off the compressor if it reaches dangerous temperatures. Regular maintenance and inspection of the silencer box can help identify any potential issues related to overheating or thermal overload.

It’s important to follow manufacturer guidelines and recommendations for safe operation. Investing in a high-quality silencer box with built-in temperature monitoring and protection mechanisms adds an extra layer of safety. Remember, prevention is always better than dealing with the consequences.

Regular Maintenance Tips

Regularly inspecting the silencer box is crucial to ensure its optimal performance. It is important to check for any signs of damage or wear, such as cracks or holes, and address them promptly. Additionally, regular cleaning of the silencer box is necessary to remove dirt and debris that may accumulate and affect its functionality.

Check the connections and seals to ensure they are secure and free from any leaks. Lubricating the moving parts of the silencer box will help maintain smooth operation. Lastly, following the manufacturer’s guidelines for maintenance and servicing is essential to keep the silencer box in good condition.

How Does A Silencer Box Impact The Efficiency Of An Air Compressor?

A silencer box plays a crucial role in improving the efficiency of an air compressor. It reduces noise levels, creating a safer and more comfortable work environment. The design allows for efficient airflow while minimizing pressure drop, helping to maintain optimal performance and efficiency.

Noise Reduction

Silencer boxes significantly reduce noise levels generated by air compressors, creating a safer and more comfortable workplace for operators. By complying with occupational health and safety regulations regarding noise, these boxes contribute to a better work environment.

Additionally, the quieter operation of air compressors with silencer boxes allows for improved communication and concentration among workers. Moreover, reducing noise pollution benefits the overall environmental impact of air compressor operations. The integration of silencer boxes decreases noise and enhances the overall efficiency and functionality of air compressors.

Energy Efficiency

Reducing the noise level of an air compressor while maintaining its energy efficiency is made possible with a silencer box. This enclosure ensures minimal air leakage, optimizing the compressor’s energy usage. Investing in a high-quality silencer box allows you to operate the air compressor at lower noise levels without compromising energy efficiency.

Not only does this create a more comfortable working environment, but it also reduces energy waste caused by noise. A silencer box can achieve energy efficiency and noise reduction for a more efficient and productive workspace.

Conclusion

An air compressor silencer box reduces noise levels and ensures a safer working environment. You can build an effective and efficient silencer box by following the step-by-step guide, selecting the right materials, and considering important factors such as size and ventilation requirements.

Additionally, regular maintenance and safety precautions like overheating protection and thermal overload switches are essential for your air compressor’s optimal performance and longevity.

With a properly designed and functioning silencer box, you can experience significant noise reduction and improved energy efficiency, ultimately extending the lifespan of your air compressor. So, invest time and effort in mastering air compressor silencer-box techniques for a quieter and more efficient workspace.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-cb7ade7b-05ee-49ff-afbf-2095cc9461ee”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.