As an important tool in many industries, air compressors need regular maintenance to ensure they continue to function properly. One essential component of an air compressor is the unloader valve, which releases pressure from the compressor head after it has shut off.

A malfunctioning unloader valve can cause damage to the compressor and compromise its efficiency. Therefore, it is important to be familiar with adjusting the unloader valve. This simple guide will walk you through the steps required to perform this air compressor unloader valve adjustment is functioning at its best.

Initially, adjusting the unloader valve on an air compressor may seem daunting, but you can complete the straightforward process in just a few steps. We will provide you with a comprehensive guide on adjusting the unloader valve on your air compressor.

Effective Air Compressor Unloader Valve Adjustment Tips

An effective air compressor is essential for many industrial applications, but it needs to be properly maintained to ensure optimal performance. One important component of an air compressor is the air compressor unloader valve adjustment, which releases pressure from the compressor head when it shuts off.

Incorrect unloader valve adjustment can cause leaks, overheating, and reduced efficiency. To avoid these problems, there are several tips for adjusting the unloader valve on an air compressor. First, consult the manufacturer’s manual for specific instructions on adjusting the valve. It’s also important to wear appropriate safety gear, such as gloves and eye protection when working with the compressor.

When adjusting the valve, start by loosening the locknut and turning the adjustment screw clockwise to increase and counterclockwise to decrease pressure. Make small adjustments and test the compressor after each to ensure proper function. Once the valve is properly adjusted, tighten the locknut and retest the compressor.

Functionality Of An Unloader Valve

An unloader valve is essential in many hydraulic systems, especially those that use positive displacement pumps. Its primary function is to regulate the pressure within the system by diverting excess fluid back to the tank. When the pump reaches its maximum pressure, the unloader valve opens, and the fluid flows through it, relieving the pressure on the pump and preventing damage.

The unloader valve also helps to maintain the correct pressure level in the system, ensuring that the components receive the required fluid flow and pressure. The unloader valve can also act as a safety mechanism by preventing overpressure that could lead to severe damage or injury.

The functionality of the unloader valve is critical in ensuring the proper operation and longevity of hydraulic systems. It is important to select the right type of unloader valve for the specific application to achieve optimal performance. One must consider pressure ranges, flow rates, and compatibility with other system components.

The Working Mechanism Of An Unloader Valve

An unloader valve is an essential component of a pressure washer that helps regulate the pressure and flow of water. The working mechanism of an unloader valve is relatively simple yet crucial. When the pressure washer gun trigger is released, the unloader valve opens, allowing water to bypass the pump and flow back into the inlet. This action relieves the pressure built up in the pump and prevents damage to the machine’s components.

The unloader valve operates on two critical components, the spring and the piston. The spring applies a force on the piston, keeping it closed, which maintains the pressure in the pump. When the trigger is released, the force on the piston reduces, and the spring pushes it back, opening the valve and diverting water back to the inlet. The unloader valve’s design and working mechanism can vary, depending on the pressure washer’s make and model.

Exploring Different Types Of Unloader Valves

Unloader valves play a crucial role in the functioning of air compressors. Different unloader valves are available, including constant speed and load/unload valves. Properly adjusting the unloader valve is essential for optimal compressor performance.

To adjust the valve, follow a step-by-step guide that ensures it is set correctly. It is also important to know common issues related to unloader valves and troubleshooting tips to resolve them effectively.

Continuous Run Valve Vs Pilot Unloader Valve

Continuous run valves and pilot unloader valves are handy in air compressors. The continuous run valve keeps the compressor running continuously, even when handy, making it suitable for applications with consistent air demand.

On the other hand, the pilot unloader valve automatically stops and starts the compressor based on air demand, making it ideal for applications with fluctuating air demand. The choice between these valves depends on the specific needs of the compressor system.

How To Install An Unloader Valve?

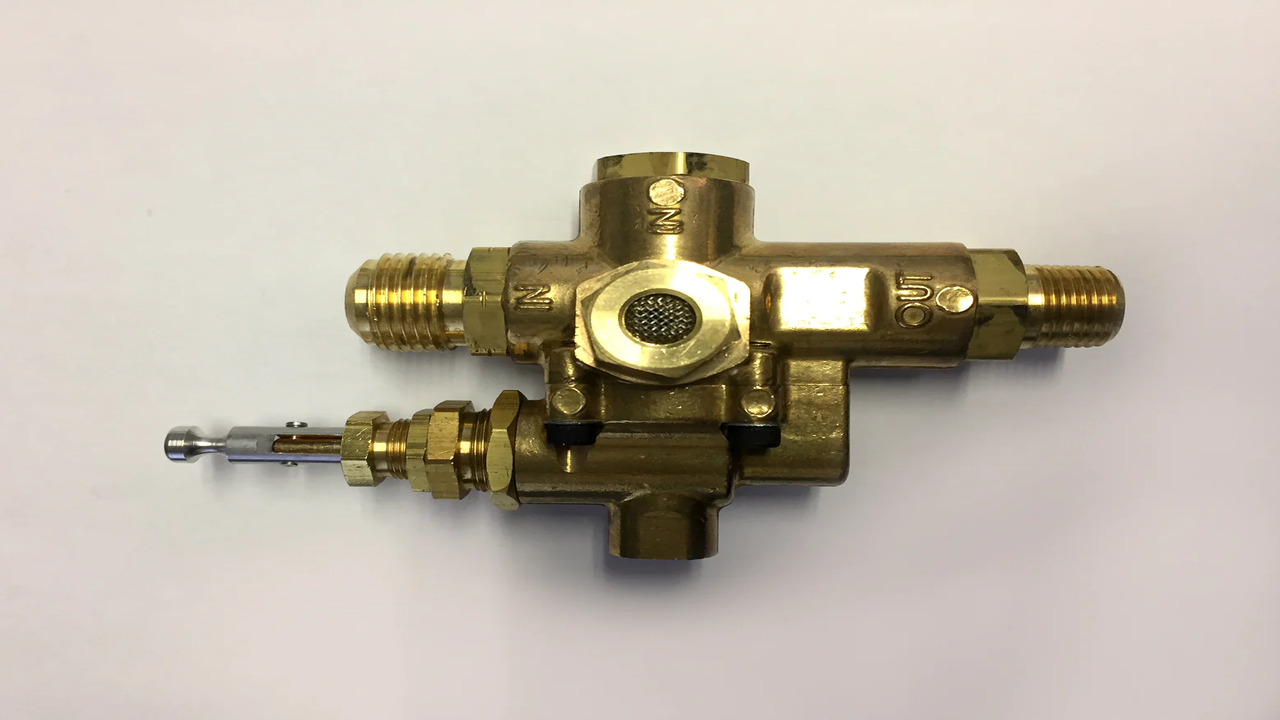

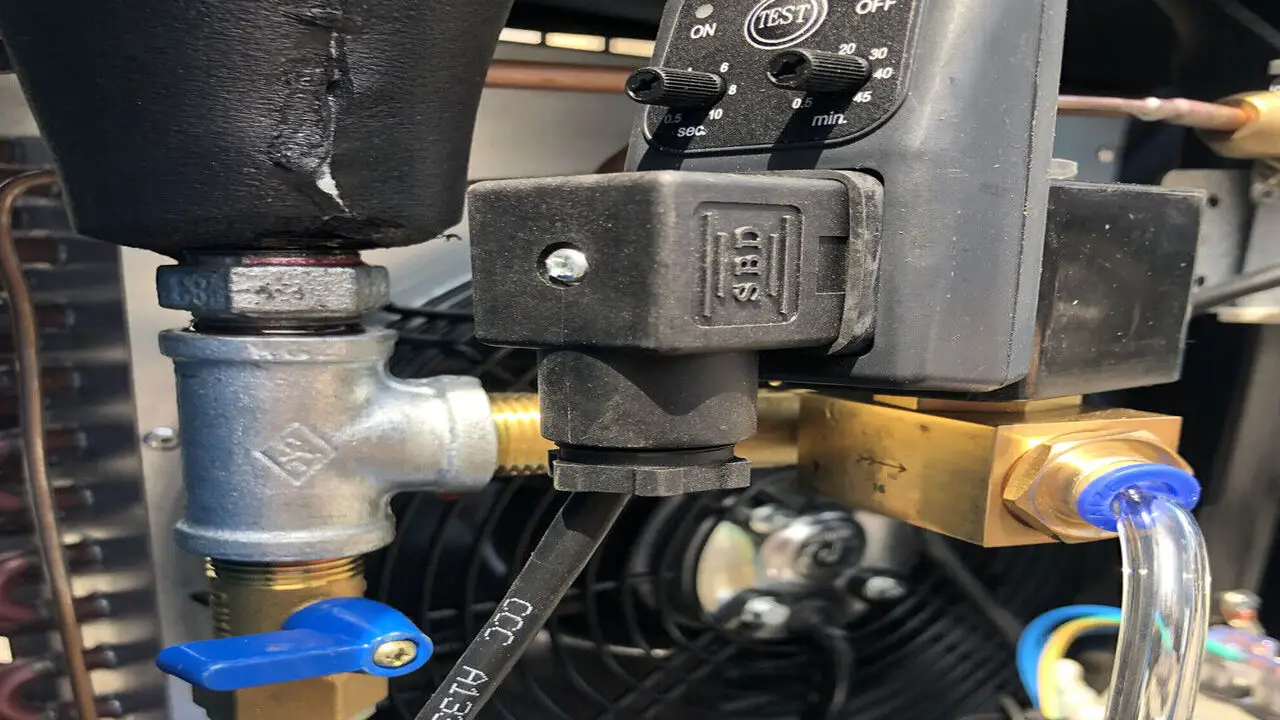

The process is quite simple if you are wondering how to install an unloader valve. First, you will need to locate the unloader valve on your compressor. This valve is typically located near the pressure switch and can be identified by its small size and red or black colour.

Once you have located the valve, remove the old unloader valve from the compressor. This can be done by unscrewing the compressor’s valve or using a wrench to loosen the valve from its mounting bracket. After removing the old valve, you can install the new unloader valve by simply reversing the steps you completed to remove the old valve.

Be sure to tighten the valve securely to prevent any air leaks. Once the valve is installed, you can test it by running your compressor and checking for proper operation. You may need to adjust or replace the valve if you notice any issues, such as air leaks or improper pressure regulation.

Precautions While Adjusting The Unloader Valve

When adjusting the unloader valve of your air compressor, it’s essential to prioritize safety. Make sure you wear protective gear, including safety glasses and gloves. Before attempting any adjustments, ensure the air compressor is turned off and unplugged.

It’s crucial to familiarize yourself with the specific instructions for your particular air compressor model to avoid any potential mistakes. Additionally, take caution not to overtighten or force the adjustment of the unloader valve, as this could cause damage to the valve or other components. If unsure about the procedure, consult the manufacturer’s manual or seek professional assistance.

Troubleshooting Common Problems With Unloader Valve

Regarding pressure washer maintenance, one of the most common problems users encounter is problems with the unloader valve. The unloader valve is responsible for controlling the amount of pressure released from the pump; if it fails, it can cause several problems.

One of the most common problems is low-pressure output, making it difficult to clean surfaces effectively. Other problems include water, strange noises from the pump, and erratic pressure output. Fortunately, these problems are relatively easy to fix. In many cases, the problem can be solved by cleaning or replacing the valve itself.

It is also important to check for clogs or debris in the valve or surrounding components. If the valve continues to malfunction after cleaning or replacement, it may be necessary to seek the help of a professional pressure washer repair service. On top of routine maintenance and when unloader valve issues arise, pressure washer users can ensure that their equipment continues to perform its job.

How Does The Unloader Valve Impact Air Compressor Performance?

The unloader valve is an essential component of an air compressor that plays a critical role in its performance. The valve regulates the compressor’s air pressure, ensuring it remains within a safe and efficient range. When the compressor is in use, the unloader valve remains closed, allowing the pressure to build up in the tank.

However, when the compressor reaches its maximum pressure setting, the valve opens, releasing the excess pressure into the atmosphere. This prevents the compressor from overworking, leading to premature wear and tear and reduced performance.

The impact of the unloader valve on air compressor performance is significant. Without the valve, the compressor would be prone to overheating, which can cause damage to its internal components. Additionally, the valve helps to extend the compressor’s lifespan by preventing excessive wear and tear. In terms of energy efficiency, the unloader valve is also critical.

Conclusion

Understanding the functionality and importance of an air compressor. Air compressor unloader valve adjustmentis crucial for maintaining optimal performance. Whether you are adjusting the valve for the first time or troubleshooting common problems, following the correct steps and taking necessary precautions is essential.

Different types of unloader valves offer unique advantages, so choose one that suits your specific needs. Remember to inspect and adjust the valve to ensure efficient operation regularly. Properly maintaining your air compressor and adjusting the unloader valve when needed can prolong its lifespan and enhance overall performance. Take the time to learn about your specific air compressor model and seek professional assistance if necessary.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-9ea911e8-4e61-438b-906e-3265b0dfcee0″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.