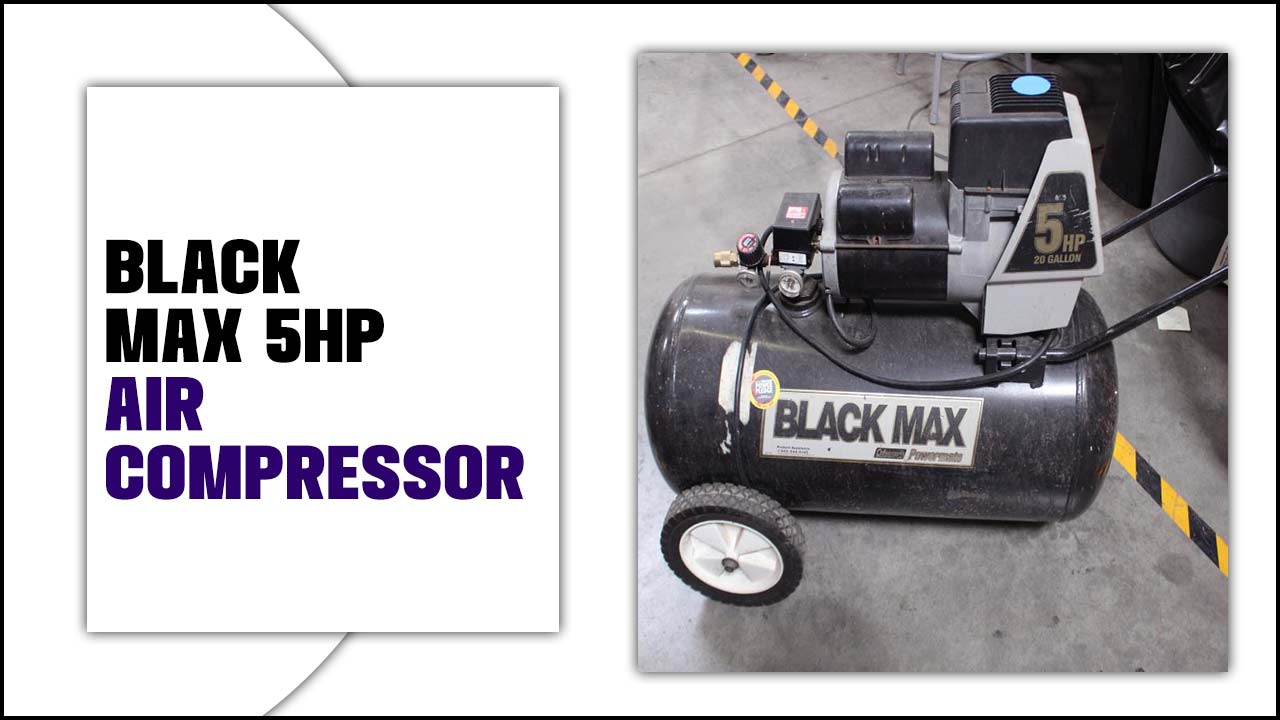

The Black Max 5HP Air Compressor is a powerful and efficient tool used in various industries for its ability to provide high-pressure air to power various tools and equipment.

As its name suggests, this compressor has a 5-horsepower motor that delivers maximum performance and reliability, making it a popular choice for professional and DIY enthusiasts. Its compact and portable design allows easy transportation, a significant advantage for those who need to move the compressor to different job sites.

This Air Compressor is also known for its durability and longevity, ensuring that it will last for years with proper maintenance. Whether you use it for sanding, painting, or powering pneumatic tools, this air compressor is a valuable addition to any workshop or job site.

With its impressive features and functionality, it’s no wonder why this Air Compressor is a top choice for those who require reliable air compression power. Here we will discuss the full step-by-step processes of installing a black max -5hp air compressor.

Gather The Necessary Tools And Materials For Installation

Before starting the installation, thoroughly read the user manual provided by Black Max for specific instructions and safety guidelines. Ensure you have all the tools and materials ready to make the installation smooth and efficient. Consider consulting a professional if you’re unsure about any aspect of the installation process. To install this air compressor, you will need the following tools and materials:

Tools:

- Adjustable wrench

- Screwdriver set (Phillips and flathead)

- Socket wrench set

- Pliers

- Teflon tape or pipe thread sealant

- Pipe cutter or hacksaw (if needed for modifying airlines)

- Level

- Tape measure

- Drill (if required for mounting)

- Anchors and screws (if mounting the compressor)

Materials:

- Air compressor oil (if it is an oil-lubricated model)

- Air filter element (if applicable, for maintenance)

- Pressure regulator (if not included with the compressor)

- Pressure relief valve (if not built into the compressor)

- Air hoses and fittings (as required for your setup)

- Compressor mounting pad or base (if necessary)

- Piping and connectors for air distribution (if not included)

How To Install Black Max 5hp Air Compressor

This air compressor is essential for anyone who needs to power air tools or inflate tires. This powerful compressor can deliver up to 175 PSI of pressure, making it suitable for a wide range of applications.

One of the most significant advantages of this air compressor is its high output capacity. It can deliver a lot of compressed air, making it ideal for heavy-duty tasks requiring much power. This means it can easily handle tools such as sanders, grinders, and impact wrenches.

Additionally, it can provide a steady stream of air to inflate tires and other inflatable objects in seconds. This air compressor is a powerful, durable, and versatile tool that can help you tackle various tasks. Whether you’re a professional mechanic or a DIY enthusiast, this compressor is an essential piece of equipment you won’t regret investing in. Here are explained how to install black max 5hp air compressor.

Locate A Suitable Location For The Air Compressor

When installing this air compressor, the first step is to find an appropriate location. Choose a spot that offers adequate ventilation and sufficient space around the compressor for easy access during maintenance. Additionally, consider placing it away from direct sunlight and excessive heat sources. A level surface is essential to ensure stable operation. Properly locating the air compressor will contribute to its longevity and overall efficiency, making it easier to perform tasks without hindrance.

Unpack The Air Compressor And Remove The Packing Materials

Once you have your air compressor in the desired location, the next step is to unpack it carefully. Remove all the packing materials, such as tape, foam, and plastic wraps, to avoid interfering with the compressor’s moving parts.

Inspect the components as you unpack them to ensure there is no visible damage or missing parts. Properly discarding the packaging materials will not only ensure a smooth installation but also prevent any potential hazards that could arise from leaving them lying around.

Inspect The Air Compressor For Any Damage

Before installing your air compressor, perform a thorough inspection to check for any damage. Look for signs of dents, scratches, or other external issues that might have occurred during shipping. Additionally, examine internal components, such as the pressure gauge and motor, to ensure they are intact and in good condition. Addressing any damage at this stage will prevent potential problems during operation and help maintain the compressor’s longevity.

Attach The Air Hose To The Air Compressor

With the inspection completed and the compressor free of damage, it’s time to attach the air hose securely. Locate the compressor’s outlet and connect one end of the air hose, ensuring a tight and stable fit. The other end of the hose should be reserved for connecting pneumatic tools or other devices. A proper attachment will prevent air leaks and optimize the compressor’s performance during operation.

Connect The Air Compressor To A Power Source

Connecting an air compressor to a power source is a relatively simple process, but taking the necessary safety precautions to avoid accidents is important. Make sure the air compressor is turned off and unplugged before beginning the process of connecting it to a power source. Locate an electrical outlet compatible with your air compressor’s voltage and amperage requirements.

You can find this information in the user manual or the compressor itself. Connect the power cord to the air compressor. Ensure that the cord is securely attached and that there are no exposed wires or damage to the cord. Plug the power cord into the electrical outlet. Make sure that the outlet is grounded and that it is not overloaded with other appliances. Turn on the air compressor and check the pressure gauge to ensure that the compressor is functioning properly.

Set The Pressure Regulator To The Desired Pressure

Locate and set the pressure regulator to adjust the air compressor’s output pressure according to your specific needs. Follow the manufacturer’s instructions to set it to the recommended pressure level for the pneumatic tools or applications you plan to use. Proper pressure adjustment is vital for achieving optimal performance and preventing damage to tools or equipment.

Turn On The Air Compressor And Let It Pressure

With the pressure regulator properly set, switch on this air compressor. Allow it to run and build pressure until it reaches the preset level. The compressor’s built-in pressure switch will automatically stop the motor once the desired pressure is attained. This step ensures the compressor functions correctly and can reach the required pressure for your tasks.

Test The Air Compressor By Using It With A Pneumatic Tool

The final step is to put this air compressor to the test. Connect a pneumatic tool to the air hose and activate it to verify the compressor’s functionality. Ensure that the air tool operates smoothly and that the compressor can maintain the required pressure during prolonged use. This step confirms that the installation was successful and the air compressor is ready for your various pneumatic applications.

How Much Does An Air Compressor Cost

As of my last update in September 2021, the cost of an air compressor can vary depending on factors such as the seller, location, and additional features included. On average, you can expect to pay between $500 to $800 for this type of air compressor. However, please note that prices may have changed since then, and I recommend checking with various retailers or online stores for the most up-to-date pricing information.

Conclusion

The black max 5hp air compressor is an excellent investment for anyone needing a reliable and efficient air compressor. Its specificity and attention to detail make it stand out among other models on the market, and its success in delivering high-performance results is second to none.

Whether you are a professional mechanic or a DIY enthusiast, this air compressor will meet all your needs and exceed your expectations. Its importance in any workshop or garage cannot be overstated, and its versatility allows it to be used for a wide range of applications. Overall, This air compressor is a product that delivers on its promises, and its success has made it a top choice for many people in need of a high-quality air compressor.

FAQ’s

[rank_math_rich_snippet id=”s-7c310280-0624-45dc-a3ae-b9bac052f49e”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.