ABS plastic is a versatile and popular material used in various industries, from automotive to medical devices. Its durability, lightweight nature, and ability to be molded into various shapes make it a preferred choice for many applications.

One of the key advantages of ABS plastic is its ease of molding and shaping, allowing for intricate designs and structures. However, traditional tools such as saws can be cumbersome when cutting ABS plastic and may not produce the desired results.

Due to these properties, ABS plastic finds common use in automotive parts, home appliances, and consumer electronics. Its versatility and durability make it a popular choice across industries. Here, we will walk you through the step-by-step process of cutting ABS plastic using simple tools you might already have at home.

4 Easy Steps to cut ABS plastic without a saw

You can cut ABS plastic without a saw with the right tools and technique, even though it may seem daunting. Always wear protective gloves and eyewear when working with tools and materials, and exercise caution to avoid injury. You can successfully cut ABS plastic without a saw for your DIY projects or repairs with patience and practice. Here is a step-by-step guide to cut ABS plastic without a saw.

1. Measure and mark your cut

Measuring and marking your cut is an important first step when cutting ABS plastic without a saw. Carefully measure the length or shape you want to cut using a ruler or measuring tape. Then, use a permanent marker or pencil to mark the cut line on the surface of the ABS plastic. This will guide your cutting tool and help ensure you make an accurate and clean cut. Taking the time to measure and mark your cut properly can make all the difference in achieving the desired result when cutting ABS plastic without a saw.

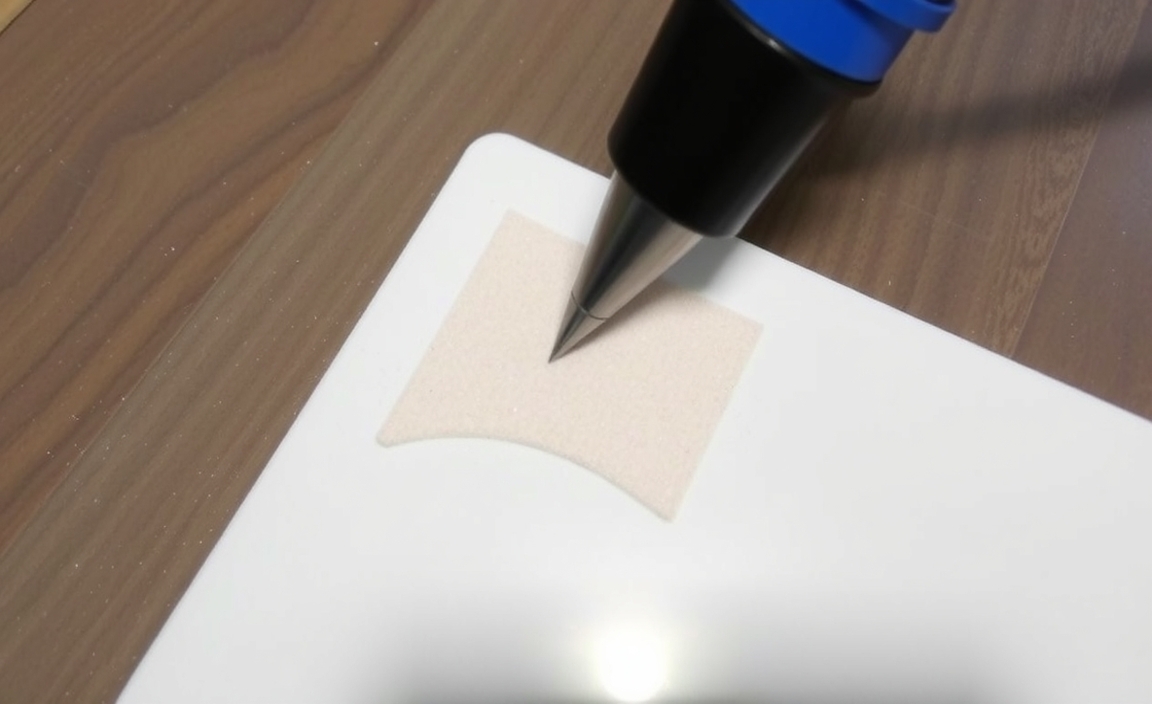

2. Score the plastic

Scoring the plastic can be helpful when cutting ABS plastic without a saw. You will need a sharp knife, utility knife, or a box cutter to score the plastic. Start by marking the line where you want to cut with a pencil or marker. Then, firmly hold the plastic and use the knife to make a shallow cut along the marked line. Repeat this process multiple times, gradually increasing the depth of each cut until you can break off the desired piece of plastic surface. Scoring the plastic helps weaken it along the cut line, making it easier to break off cleanly without a saw. Remember to take your time and be cautious while scoring to avoid accidents or injuries.

3. Bend the plastic

You can use it when cutting ABS plastic without a saw bending the plastic. ABS plastic is populr for its flexibility to create clean and precise cuts with a little heat and pressure. Start by marking the desired cutting line on the plastic. Then, use a heat source such as a heat gun or boiling water to soften the plastic along the marked line. Once the plastic is pliable, carefully bend it back and forth until it snaps along the marked line. This method may require some practice to achieve perfect cuts, but you can effectively cut ABS plastic without a saw with patience and precision.

4. Finish the cut

After successfully making the initial cut in your ABS plastic without a saw, it is important to finish it properly for a clean and smooth edge. One method is using a file or sandpaper to carefully smooth and shape the cut edge. Start with a coarse grit file or sandpaper to remove rough edges or excess material, then gradually work to finer grits for a smoother finish. Another option is using a deburring tool or utility knife to remove any burrs or rough spots along the cut edge. Remember to take your time and work slowly and cautiously to ensure a precise and professional-looking finish.

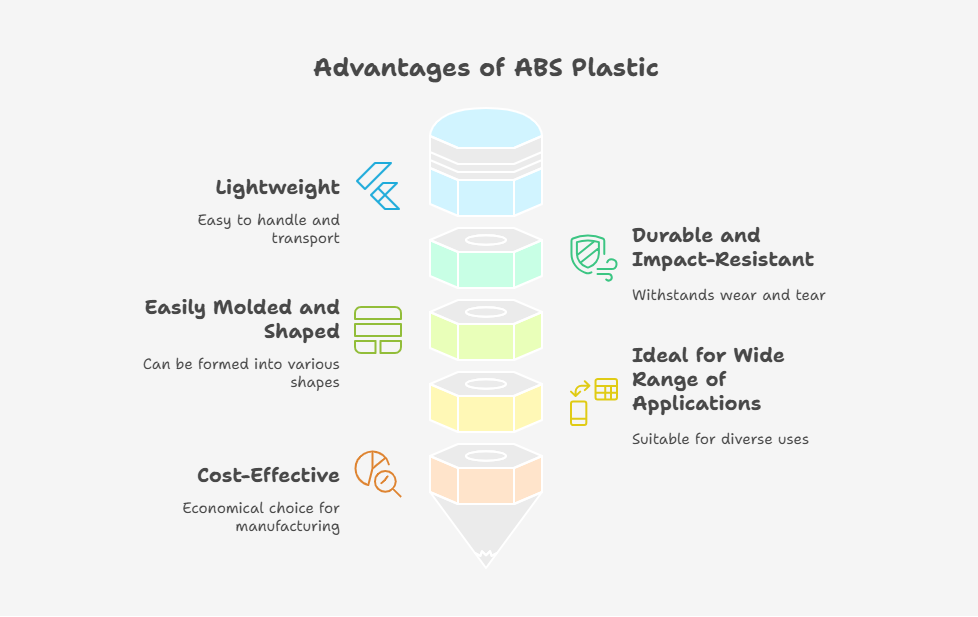

Why Use ABS Plastic?

Due to its exceptional mechanical properties, ABS (Acrylonitrile Butadiene Styrene) plastic is a popular choice in manufacturing. Its ability to maintain dimensional stability and its low moisture absorption make it an ideal material for several applications. Moreover, it has good electrical insulation properties, making it suitable for electrical equipment and appliances. Here’s why to use ABS plastic:

– Lightweight material

– Durable and impact-resistant

– Can be easily molded and shaped

– Ideal for a wide range of applications

– Cost-effective option

Tips for a Smooth ABS Cutting Experience

Cutting ABS plastic without a saw may seem daunting, but it can be done smoothly with the right tools and techniques. Always wear safety goggles and work in a well-ventilated area with ABS plastic. With these tips, you can achieve clean and smooth cuts in ABS plastic without using a saw. Here are some tips to help you achieve a smooth ABS cutting experience:

Use a sharp utility knife or scoring tool: A sharp utility knife or scoring tool can make clean cuts in ABS plastic. Score multiple times to create a groove along the cutting line, then apply pressure to snap the plastic along the score.

Heat the plastic: Heating the ABS plastic can make it more pliable and easier to cut. You can use a heat gun or a hairdryer to warm the plastic before cutting.

Use a jigsaw or rotary tool with a fine-toothed blade: If you have access to power tools, using a jigsaw or rotary tool with a fine-toothed sharp blade can give you precise cuts in ABS plastic. Secure the plastic firmly before cutting, and use slow, steady movements.

Sand the edges: After cutting, you may notice rough edges. Use sandpaper or a file to smooth out these edges for a polished finish.

Finishing and smoothing the edges of the cut ABS plastic

To achieve a polished finish on the cut ABS plastic, use sandpaper or a file to smooth out any rough or jagged edges left after cutting. Apply gentle pressure and move the sandpaper or file back and forth to create a smooth surface. It’s important to wipe away any debris or dust from the ABS plastic after finishing the edges to ensure a clean appearance. Additionally, you may consider using a heat gun to melt and smooth the edges for a slightly seamless look. However, exercise caution when using heat to avoid overheating or deforming the ABS plastic. Remember, these techniques will help you achieve a professional and finished result without needing a saw.

Other alternative methods for cutting ABS plastic without a saw

You can try several alternative methods to cut ABS plastic without a saw. One option is to use a rotary tool with a cutting wheel attachment. This allows for precise and intricate cuts on ABS plastic. Another method is to use a hot knife or soldering iron to melt through the plastic, creating clean cuts. If you have access to a laser cutter, this can provide precise and accurate cuts on ABS plastic. Additionally, you can look into waterjet cutting services that can professionally cut the plastic to your desired specifications. Lastly, outsourcing the cutting process to a professional fabrication service may be viable if you have more complex projects. Utilizing these alternative methods allows you to achieve the desired cuts on ABS plastic without needing a saw.

Frequently Asked Questions

How do you cut ABS plastic by hand?

To cut ABS plastic by hand, first, score the plastic boxes using a utility knife or fine-toothed saw to create a shallow line. Then, carefully bend the plastic along the scored line to break it apart. Sand down any rough edges to smoothen the cut.

What tool is used to cut ABS plastic?

A rotary tool with a cutting or grinding attachment is commonly used to cut ABS plastic breakage due to its precision and ability to create clean cuts.

How do you cut plastic without a saw?

Plastic can be cut without a saw using various alternative methods such as a utility hobby knife, scissors, hot knife, wire cutter, or even a Dremel tool. Each method is effective for different types of plastic and thicknesses.

Can ABS material be cut?

Yes, ABS material can be cut using a saw, knife, or laser cutter. To prevent accidents, it is important to ensure proper safety measures when cutting ABS material.

Can you cut ABS with scissors?

ABS is a thermoplastic material and can be cut with scissors, although it may require some effort due to its toughness. It is recommended to use sharp, heavy-duty scissors designed for cutting plastic materials to achieve clean and precise cuts.

Conclusion

The right tools and techniques can cut ABS plastic without a saw. By following the steps here and using alternative methods like scoring and snapping or using a utility knife, you can achieve clean and precise cuts without the need for a saw. Remember to take safety precautions and wear protective gear when working with any material. Additionally, smoothing and finishing the edges of the cut ABS plastic will ensure a professional and polished look. Whether working on DIY projects or professional applications, these tips will help you achieve accurate cuts without needing a saw.

Resource:

Plastic properties and types: https://www.britannica.com/science/plastic

Safe cutting techniques for DIY projects: https://www.familyhandyman.com/project/how-to-cut-plastic/

What is a utility knife and how to use it: https://www.popularmechanics.com/home/tools/a39636984/how-to-use-a-utility-knife/

Heat gun safety and usage guide: https://www.thespruce.com/how-to-use-heat-gun-1824765

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.