ABS plastic is a versatile and commonly used material in various industries, including automotive, electronics, and household products. Its lightweight and durable properties have become a preferred choice for manufacturers and DIY enthusiasts alike.

However, cutting ABS plastic can be a daunting task, especially for those who are unfamiliar with the material. Incorrect methods or tools can lead to uneven edges, cracks, and even damage to the plastic itself. To ensure a precise and clean cut, it is essential to understand the characteristics of ABS plastic and the proper techniques for cutting it.

Here, we will guide you through the step-by-step process of how to cut ABS plastic. By following these guidelines, you can master the art of cutting ABS plastic easily and confidently, making your projects more efficient and successful.

Tools And Materials To Cut Abs Plastic

In any industry or abs project, it is crucial to have a comprehensive understanding of the specialized tools and materials required to complete tasks efficiently. When it comes to cutting ABS plastic boxes, this knowledge becomes even more essential. Due to its durability and versatility, ABS plastic is widely handy in various applications. Here are the materials you need.

- ABS plastic sheet

- Utility knife or hobby knife

- Razor saw or fine-toothed saw

- Bench vice or clamps

- Measuring tape or ruler

- Sandpaper or file for smoothing edges

- Safety goggles or glasses

- Dust mask or respirator (for protection against plastic dust)

How To Cut Abs Plastic – Full Process

Knowing how to cut ABS plastic is of utmost importance for various reasons. ABS, or Acrylonitrile Butadiene Styrene, is a widely handy thermoplastic polymer popular for its durability, impact resistance, and versatility. It is commonly handy in various industries, such as automotive, electronics, and consumer goods.

Therefore, effectively and accurately cutting Sections of ABS pipe is essential for professionals working in these fields. Many projects require ABS plastic to be cut into specific shapes and sizes. Below, we provide you with step-by-step guidelines for cutting ABS Plastic recycling.

Step 1: Place The Sheet

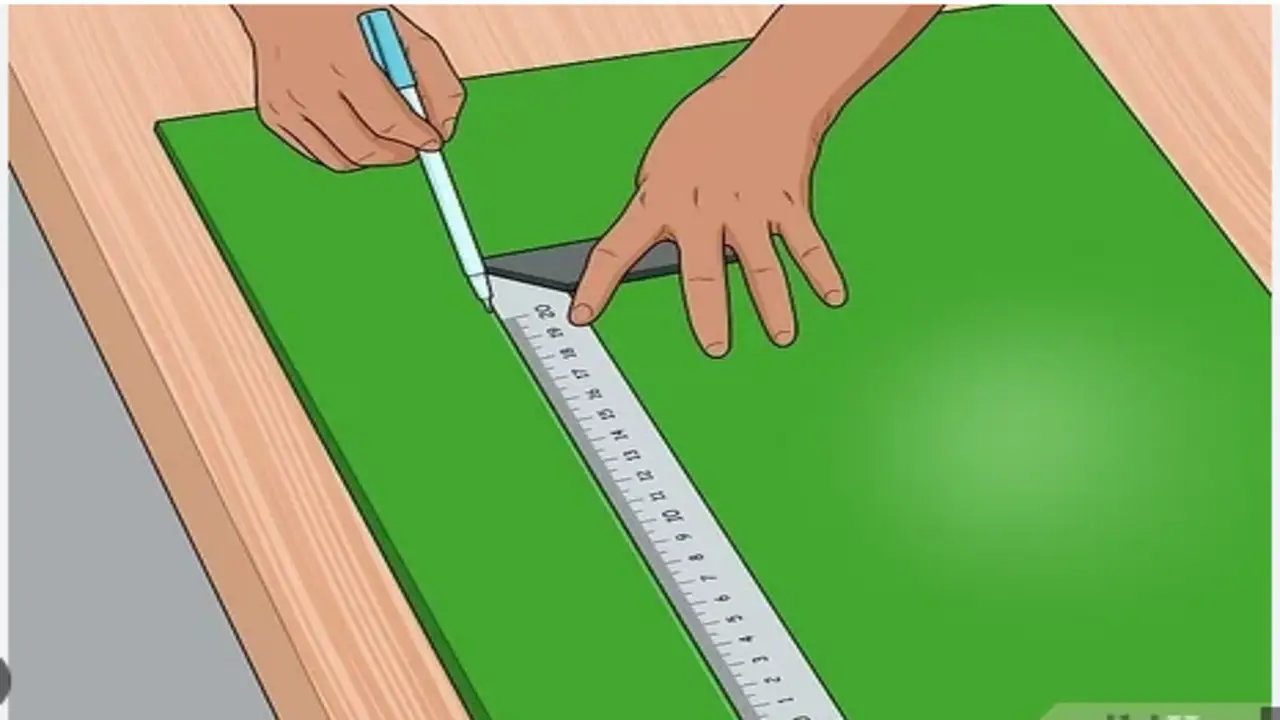

Ensure that the sheet stays in place while you work and that you can make accurate cuts. Next, measure the area you need to cut and mark it with a pencil or marker. You can use a ruler or a straight edge to ensure your vent lines are straight and even.

Once you have marked the cutting lines, it’s time to get your cutting tools. A sharp utility knife or a pair of scissors can be handy for thin sheets of ABS plastic, but a rotary cutter is the best option for precise cuts.

Step 2: Determine The Spot

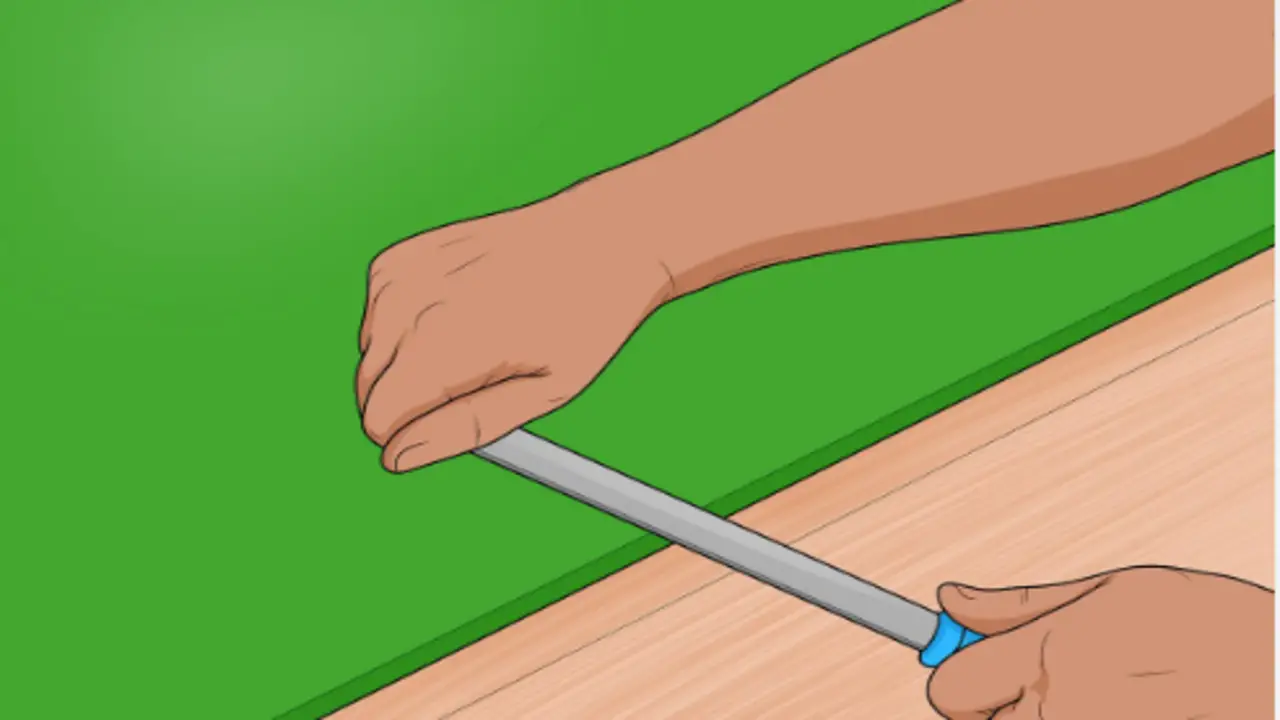

One important step in cutting thin ABS plastic sheets is to determine the spot where you want to make the cut. It is essential to use a straight edge and clean for the smoothest edges to mark the spot accurately, ensuring that the cut is straight and precise. Once you have marked the spot, the next step is to prepare the cutting tool.

A sharp cutting wheel or a sharp utility knife is recommended for cutting thin ABS sheets. It is essential to ensure that the cutting tool is sharp to ensure a clean and smooth cut. Before cutting, it is advisable to clamp down the plastic sheet securely to prevent it from slipping or moving during the cutting process.

Step 3: Cut The Sheet

As you begin the cutting process, remember to apply even pressure throughout the cut. Uneven pressure can result in jagged edges or a crooked cut, which can negatively impact the overall quality and appearance of the sheet. By maintaining consistent pressure, you can achieve a smooth and professional finish.

Additionally, consider using appropriate tools for the task at hand. You may require different cutting tools depending on the sheet’s material. Ensuring that you have the right tool for the job will greatly enhance your cutting experience and yield better results.

Step 4: Unlock The Clamp

Cutting thin ABS plastic sheets can be daunting if you are not equipped with the right tools and techniques. However, you can achieve a clean and precise cut with the correct steps. First, unlock the clamp. The clamp holds the plastic sheet in place, ensuring it doesn’t move during cutting.

By unlocking the clamp, you can easily adjust the sheet’s position and move it to the desired location. It is important to note that before unlocking the clamp, you must ensure that the sheet is properly secured so it doesn’t move around or slip out of place.

Steps Of Cutting The Thick Abs Plastic Sheets

Understanding the steps of cutting thick ABS plastic sheets is crucial for anyone working with this safe material in various industries. Plastic fragments, known for their durability and strength, are widely handy in applications ranging from automotive parts to household appliances.

Knowing how to cut it properly ensures precise and efficient manufacturing processes, ultimately leading to high-quality end products. Below are the steps for cutting the thick ABS plastic sheets.

Step 1: Mark With A Highlighter Pen

It is important to follow a precise and careful process when cutting thick ABS plastic sheets. One useful tool for this task is a highlighter pen. The first step is to mark the sheet with the highlighter pen, indicating where the cut will come from. This ensures accuracy and eliminates any chances of making mistakes during the cutting process.

Carefully place the ABS plastic sheet on a flat and stable surface. Take the highlighter pen and begin by directly outlining the desired cut line onto the sheet’s surface. Ensuring that you draw the line with consistent pressure and in a smooth motion is important, as this will help create a clear and visible guide.

Step 2: Lock The Sheet

Following a systematic approach to achieve optimal results is crucial for cutting thick ABS plastic sheets. The first step is to lock the sheet in place securely. This is of utmost importance as any movement or vibration during the cutting process can result in imprecise cuts or even pose a risk of injury.

We recommend using clamps or a sturdy workbench with clamping capabilities to ensure the sheet remains steadfast. This will firmly hold the plastic sheet in position, minimizing the chances of it shifting or wobbling. Additionally, it is advisable to lay a non-slip mat or rubber padding underneath the sheet to enhance stability and prevent any inadvertent movement.

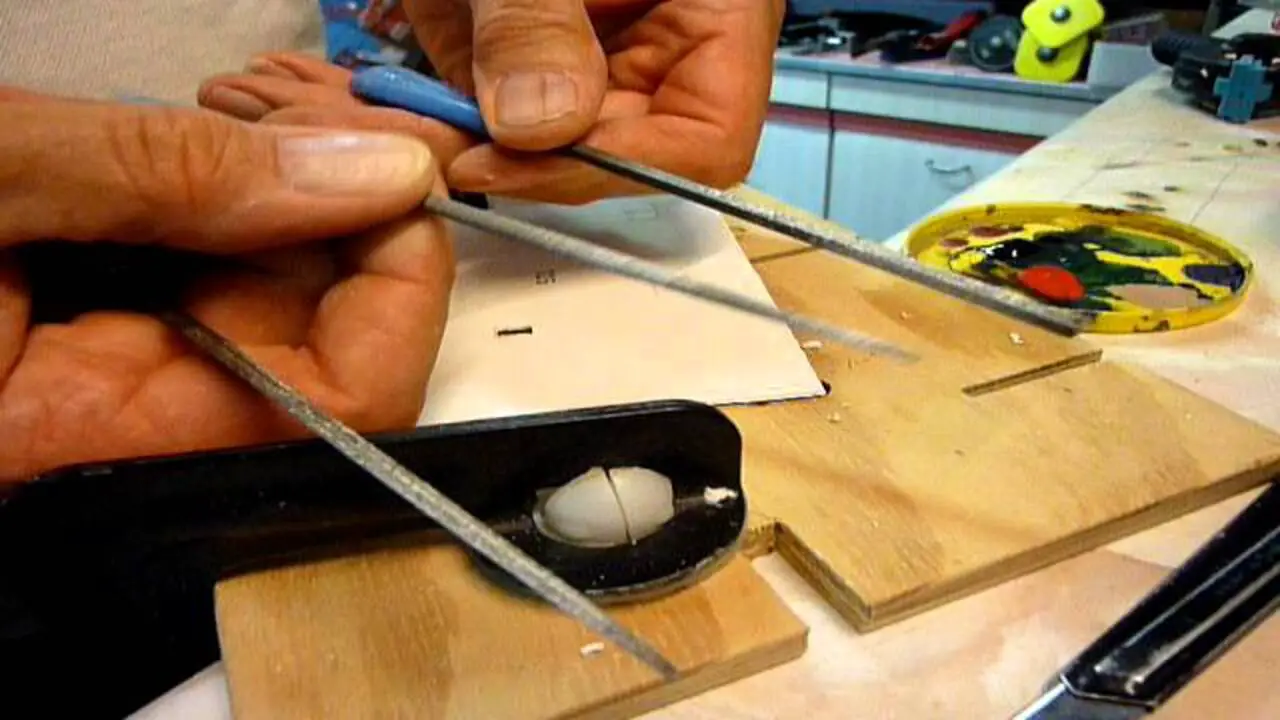

Step 3: Picking The Right Blade

One of the most important steps in cutting ABS plastic sheets is picking the right blade. Using the wrong aggressive blade can result in a messy and uneven cut or, worse, cause damage to the plastic sheet. When choosing a fresh blade for cutting ABS plastic sheets, selecting one specifically designed for cutting plastics is important.

A finish blade with a high tooth count and a fine tooth blade pitch is ideal for cutting thick ABS plastic sheets. This blade type will minimize chipping and cracking and produce clean and accurate cuts.

Step 4: Start The Cutting Process

Handling the saw with utmost care is crucial, ensuring that the blade remains straight and steady throughout the cutting process. Maintaining a steady grip and applying gentle pressure can avoid unnecessary damage or irregularities in the plastic sheet. Once the initial incision has been made, it is imperative to continue cutting along the predetermined marked line.

This requires patience and a meticulous approach to ensure that the black plastic sheet is accurately and cleanly severed. To proceed slowly and deliberately, taking small, controlled movements with the saw. Doing so minimizes the risk of veering off the intended pathway or causing unintended cracks or fractures in the plastic sheet.

4 Different Method To Cut Abs Plastic

Understanding different methods to cut ABS plastic is crucial for various industries and applications. Manufacturers widely use ABS plastic, known for its durability and versatility, in producing consumer products, automotive parts, and even in the construction sector.

However, cutting ABS plastic requires precision and the right techniques to ensure clean edges and avoid any damage to the material. Below, we discuss the 4 different methods to cut ABS plastic.

Using A Plastic Cutter

Using a plastic cutter is one efficient and reliable method for cutting ABS plastic. A plastic cutter is a versatile tool handy to make clean and precise cuts in various plastics, including ABS. This tool utilizes a sharp blade, often made of hardened steel, to slice through the plastic material effortlessly. The process of cutting ABS plastic with a plastic cutter is straightforward and requires minimal effort.

First, securely hold the plastic cutter in your hand to provide full control and stability. Position the cutter at the desired starting point of the cut, ensuring that the type of blade is in contact with the ABS plastic. Apply gentle pressure and smoothly glide the cutter along the cutting path, maintaining a steady pace throughout the process.

Using A Circular Saw/Blade Wood Cutting Blade

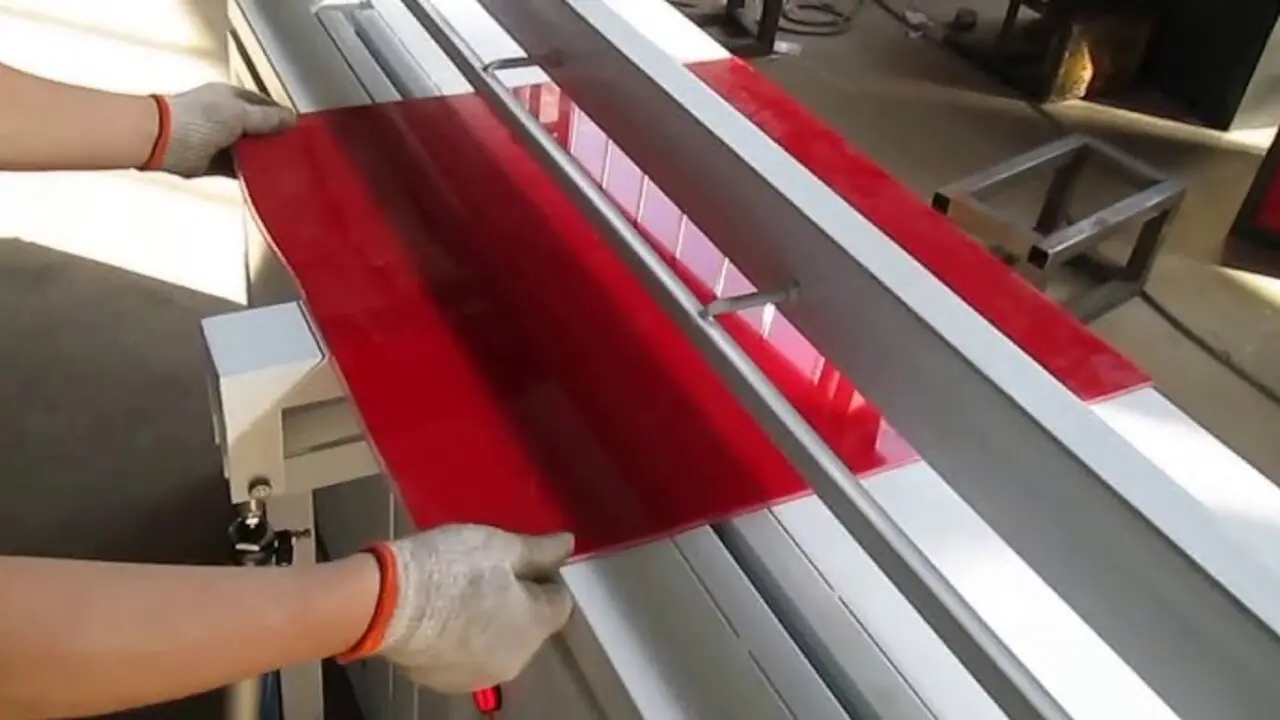

Using a circular saw to cut ABS plastic requires careful preparation and attention to safety. Before cutting, ensure you have the appropriate safety equipment, such as safety goggles and gloves, to protect yourself from potential hazards. It is also crucial to firmly secure the ABS plastic to minimize vibrations and prevent movement during the cutting process. This can be achieved by using clamps or a sturdy workbench.

Using A Jigsaw

You can equip the jigsaw, a versatile power tool with different types of blades to suit various cutting needs. Its ability to make intricate and precise cuts has become a popular choice among professionals and DIY enthusiasts. Selecting the right blade for cutting ABS fittings plastic is crucial to begin the cutting process.

A fine-toothed blade with a high tooth count minimizes chipping and ensures clean edges. Once you insert the appropriate blade into the jigsaw, you must firmly secure the ABS plastic material using clamps or a vise to prevent movement during cutting.

Using A Band Saw

A band saw is a highly efficient and precise method used for cutting ABS plastic. The band saw, equipped with a continuous loop of teethed blades, ensures accurate and clean cuts on ABS plastic.

Its robust design and adjustable settings allow precise control over the cutting process, enabling craftsmen and manufacturers to achieve the desired shape and dimensions easily. The sharp teeth on the band saw blade efficiently slice through the ABS plastic, minimizing the risk of chipping or cracking during the cutting process.

Caution When Cutting ABS Plastic

As professionals in various industries, it is crucial for us to have a comprehensive understanding of the precautions involved when working with different materials. ABS plastic, a commonly used thermoplastic polymer, is no exception. Knowing the cautionary measures associated with cutting ABS plastic is paramount to ensure our own safety, the integrity of the material, and the quality of the end product.

- Wear protective eyewear and gloves to protect yourself from any flying debris or sharp edges.

- Use a sharp utility knife or a fine-toothed saw specifically designed for cutting plastics.

- Score the ABS plastic lightly before applying more pressure to ensure clean and precise cuts.

- Always cut in a well-ventilated area to avoid inhaling any ABS fumes that may be generated during the cutting process.

- Take breaks if necessary to avoid fatigue, which may affect your accuracy and increase the risk of accidents.

- Secure the ABS plastic firmly in place before cutting to prevent it from slipping or moving during the process.

- Dispose of any waste pipes material properly and safely, as ABS plastic can harm the environment if not disposed of correctly.

Tips When Cutting ABS Plastic

understanding the tips when cutting ABS plastic ensures safety. Working with any type of material requires caution, and ABS plastic is no exception. Following the correct cutting techniques can help prevent accidents, such as injury from mishandling sharp tools or inhaling harmful fumes. By knowing the appropriate tips, professionals can reduce the risk of injuries and create a safer working environment.

- Ensure that you have the appropriate safety equipment, such as safety goggles and gloves, to protect yourself while cutting ABS plastic.

- Use a sharp blade or saw designed for cutting plastics to ensure clean and precise cuts.

- Take your time and use steady, even pressure when cutting ABS plastic to avoid cracking or splintering.

- Consider using a cutting guide or template to ensure straight and accurate cuts.

- If using a power tool, such as a jigsaw or rotary tool, make sure to secure the ABS machines plastic firmly in place to prevent it from moving during the cutting process.

- To reduce the risk of melting or overheating the plastic, use a slow cutting speed and periodically pause to allow the material to cool down.

- Consider using a scroll or coping saw when cutting curved or intricate shapes for better manoeuvrability and control.

- After cutting, remove any rough edges or burrs using sandpaper or a file to achieve a smooth finished edge.

Conclusion

Cutting ABS plastic may seem daunting, but it can be done easily and efficiently with the right tools and techniques. Always prioritize safety by wearing protective gear and caution when handling sharp tools.

By following the steps on how to cut ABS plastic, you can achieve precise and clean cuts for all your ABS plastic projects. As always, practice and patience are key to mastering any skill, so don’t be discouraged if it takes a few tries to get it right. With practice, you can cut ABS plastic with professional results confidently.

FAQs

[rank_math_rich_snippet id=”s-7c256b0f-4793-433c-9d71-e96ea20901f7″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.