A Farmhand Air Compressor is an essential tool for agricultural use. It powers various equipment, like pumps and nail guns, on the farm. These portable compressors are designed to withstand harsh conditions in different sizes to meet different farming needs.

This powerful tool is essential for various tasks, from inflating tires to powering tools and equipment. However, setting up the Farmhand Compressor perfectly is crucial to ensure its smooth operation and longevity. Here we will walk you through the entire process of setting up a Farmhand Compressor.

We’ve covered you with the tools and materials to connect it to the power supply, adjust its settings, and test its functionality. We’ll also provide some valuable tips for using the Farmhand Compressor effectively. So let’s dive in and get your Farmhand Compressor up and running smoothly in no time.

Step-By-Step Guide To Set Up Farmhand Air Compressor

The proper setup ensures optimal performance and efficiency, reducing the risk of accidents or malfunctions. The correct installation allows for easier maintenance and repairs, extending its lifespan and reducing operational costs. Following a step-by-step guide ensures all safety measures are considered during setup. Here are the full processes to set up Farmhand Air Compressor.

1.Tools And Materials Required To Set Up The Compressor

Before beginning the setup process, gather the necessary tools and materials, such as an adjustable wrench, Teflon tape, a pressure regulator, and any additional accessories specific to your Farmhand Compressor model. Securely connect the pressure regulator using Teflon tape, and check for leaks by applying soapy water to the connections.

2.Connecting The Compressor To The Power Supply

To connect the compressor to the power supply, ensure you have a suitable outlet and correct voltage. Before plugging in, make sure the power switch is off. Connect the power cord to a grounded outlet, checking for secure connections and no damaged wires. Turn on the power switch and listen for any abnormalities. If all sounds good, begin using your Farmhand Compressor.

3.Turning On The Compressor

Before switching on the compressor, ensure its stability and connection to a power source. Check the oil level and add if needed. Turn the pressure regulator knob counterclockwise to a minimum. Connect the air hose and plug in the compressor. Use the pressure gauge to build up pressure until the desired level.

4.Adjusting The Compressor’s Settings

To adjust the compressor’s settings, ensure it’s on a stable surface. Connect the power cord securely and check the oil level. Follow the manufacturer’s instructions to add oil if necessary. Adjust the pressure regulator knob as per your specific application. Attach the air hose tightly and turn on the compressor to reach the desired pressure level.

5.Choosing The Right Compressor

Consider your farm’s specific needs and intended applications for the air compressor. Determine the required horsepower and CFM. Decide if a portable or stationary compressor is more suitable. Choose between single-stage and two-stage options based on power and efficiency. Ensure proper placement, noise level, ventilation, and maintenance accessibility. Install necessary accessories as per manufacturer instructions.

6.Mounting And Securing The Compressor

Choose a suitable location away from flammable materials or heat sources. Securely attach the compressor to a stable surface using mounting brackets or bolts. Connect the air intake filter and install the pressure relief valve and gauge according to the manufacturer’s instructions. Connect the compressor to a power source and ensure proper grounding.

7.Connecting The Compressor To Your Air Supply

To connect the compressor to your air supply, ensure a stable surface and proper grounding. Attach the air intake filter to the compressor’s air inlet port. Connect an air hose from the outlet port to the necessary fittings or accessories. Close valves and set pressure relief valves. Plug in and turn on the compressor, allowing pressure buildup.

8.Setting The Compressor’s Operating Parameters

Setting up your Farmhand Compressor is a straightforward process. Select a stable location for the compressor, ensuring it is well-supported and level. Connect the power cord to a suitable power source and ensure it is securely plugged in.

Make sure to attach the air hose to the compressor tightly to prevent any leaks. Before starting the compressor, check the oil level and top up if necessary. Once everything is in place, turn on the compressor and adjust the pressure regulator to your desired output pressure.

9.Adjusting The Pressure And Airflow Of The Farmhand Compressor

To adjust the pressure and airflow of your Farmhand compressor, start by reading the instruction manual provided. Ensure the compressor is turned off and unplugged, then locate the pressure adjustment knob. Turn the knob to increase or decrease the pressure. Adjust according to the requirements of your tools or equipment, then turn on the compressor and allow it to build up to the desired pressure level.

Testing The Compressor And Adjusting Settings As Necessary

Before starting, gather necessary tools like a wrench and pressure gauge. Connect the Farmhand Compressor to a power source in a well-ventilated area. Check and add oil, if needed, following manufacturer instructions. Turn on the compressor and monitor pressure levels. Adjust settings as required for specific tasks. Test the compressor with various air tools to ensure proper functionality.

Things To Keep In Mind While Setting Up A Farmhand Compressor

When setting up a Farmhand Compressor, reading and understanding the manufacturer’s instructions for proper installation is crucial. Ensure you have the necessary tools and equipment, choose a suitable location considering noise level and ventilation, install any required piping or hoses, test the compressor before regular use, and regularly inspect and maintain it for efficient operation.

How Does A Farmhand Compressor Work?

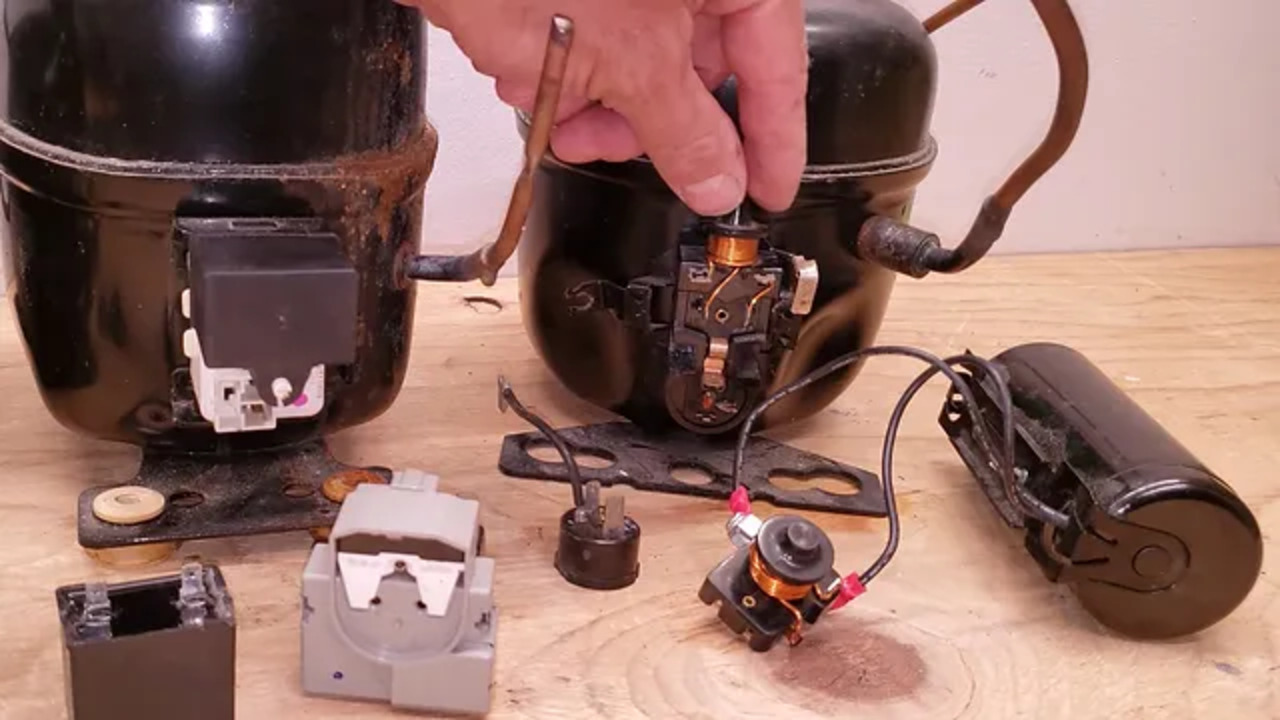

A Farmhand Compressor uses an electric motor or gas engine to power a piston or rotary screw. This component compresses air stored in a tank for later use. Compressed air is released through a hose or pipe for various applications like inflating tires and powering tools when needed.

Tips For Using A Farmhand Compressor Effectively

To make the most of a Farmhand Compressor, it is vital to acquaint yourself with its features and controls. This will enable you to operate it efficiently and effectively. Additionally, you should perform regular maintenance and cleaning to guarantee the compressor’s optimal performance and longevity.

It is also crucial to follow safety precautions, such as wearing appropriate protective gear and working in a well-ventilated area. Proper compressor setup, including positioning it on a stable surface and connecting it to a reliable power source, is essential for safe operation. Lastly, adjusting pressure settings and monitoring airflow are important steps to prevent overworking the compressor and maximize lifespan.

Troubleshooting Common Issues With The Air Compressor

Troubleshooting common issues with the air compressor can be frustrating, but with a little knowledge and patience, most problems can be resolved. One of the most common issues is a lack of air pressure, which various factors, such as leaks in the system, a faulty pressure switch, or a clogged air filter, can cause.

To troubleshoot this issue, check for any visible leaks and repair them if necessary. Next, inspect the pressure switch to ensure it functions properly and adjust it if needed. Finally, clean or replace the air filter to improve airflow and increase pressure. Another common issue is excessive noise or vibration coming from the compressor. This can be due to loose or worn-out components, such as belts or bearings.

Conclusion

Setting up a Farmhand Air Compressor correctly is crucial for optimal performance and safety. Following our step-by-step guide, you can ensure your compressor is set up accurately and ready to use. We cover every aspect of the setup process, from gathering the necessary tools and materials to adjusting the compressor’s settings.

Additionally, we provide tips for using the Farmhand Compressor effectively and highlight important considerations to remember during the setup. Whether a beginner or experienced user, this guide will help you get the most out of your Farmhand Compressor. For more detailed instructions and illustrations, search for online resources.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-361deb35-29b6-4e70-9c6c-853151267791″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.