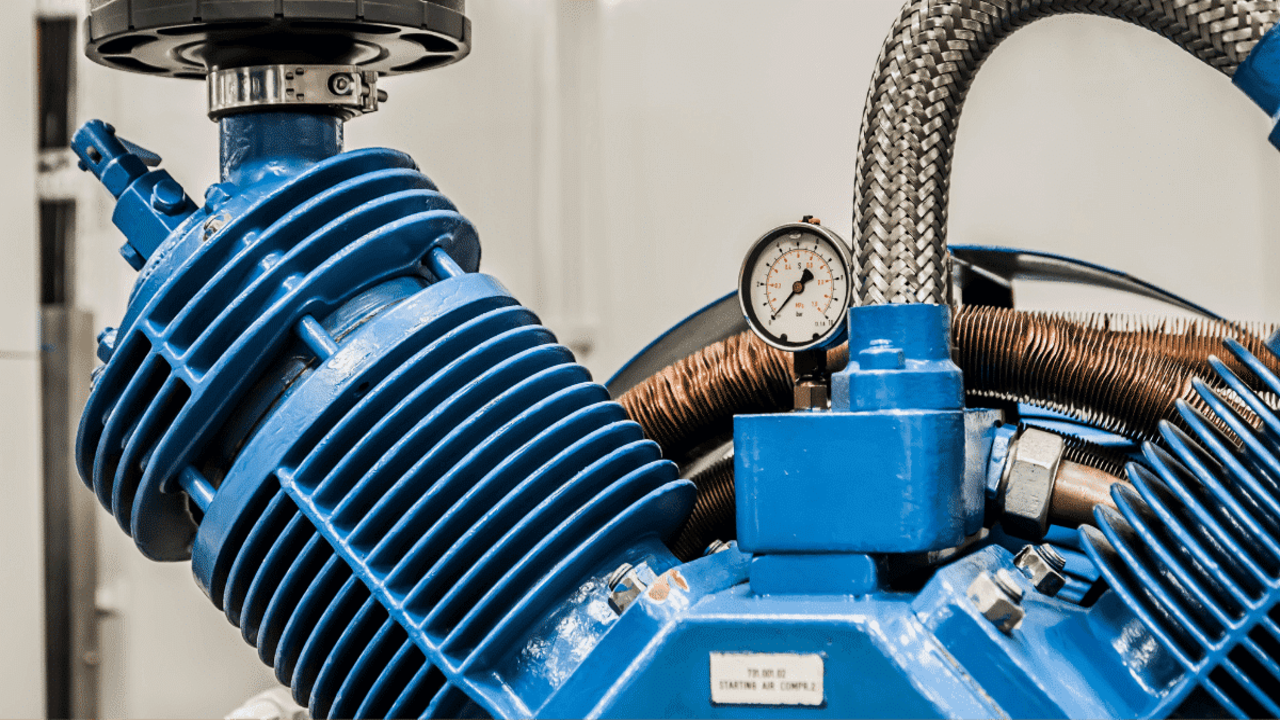

A US general air compressor is a versatile tool that uses compressed air to power various applications. Available in different types and sizes, it is commonly used in industries, construction sites, and even for personal projects.

When purchasing one, consider important features such as horsepower, gallon capacity, and PSI rating. Proper maintenance and troubleshooting techniques can help keep your US Air Compressor running smoothly.

Here we will dive deep into the world of air compressors and uncover all the secrets using these powerful machines. Whether you are a DIY enthusiast or a professional, understanding how to use a US Air Compressor step by step is crucial for getting the most out of your equipment. So, get ready to unlock the secrets of the US Air Compressor and take your projects to new heights.

How To Use US General Air Compressor – Compatible User Guide

Understanding the capabilities and applications of US air compressors, selecting the right one for your needs, and maintaining it properly is key. Troubleshooting common issues helps keep it running smoothly. Exploring additional features and accessories can enhance performance. Consider these tips to make the most of your US general air compressor. Here are a step-by-step guide to using a US air compressor.

Step 1: Safety Precautions

When operating the US air compressor, it is essential to prioritize safety. Before beginning, wear appropriate safety gear, such as goggles and gloves, to protect yourself from hazards. Additionally, ensure that the compressor is placed on a stable surface and that all connections are secure to prevent accidents or damage.

Inspecting the hoses for any leaks or signs of damage before use is crucial. Lastly, always follow the manufacturer’s instructions and guidelines for proper usage and maintenance of the air compressor. By adhering to these safety precautions, you can ensure the safe and efficient operation of the US air compressor.

Step 2: Power Source

To utilize the US air compressor effectively, it is essential to have a proper power source. This type of air compressor typically requires a 120-volt electrical outlet. Before plugging it in, carefully inspect the power cord for any signs of damage or fraying.

Additionally, ensure the power source can handle the required amperage to prevent overloading other connected devices. Taking these precautions will help maintain the safety and functionality of the air compressor during operation.

Step 3: Inspect And Prepare The Compressor

Before using the US air compressor, it is essential to conduct a thorough inspection to ensure its safety and optimal performance. Check for any signs of damage or leaks, as these can compromise the compressor’s functionality and pose risks.

Verify that proper grounding is in place to prevent electrical hazards. Additionally, inspect and clean the intake filters to maintain efficient airflow. Finally, double-check and adjust the pressure settings to meet your specific requirements. Following these steps will help ensure the US air compressor’s smooth and trouble-free operation.

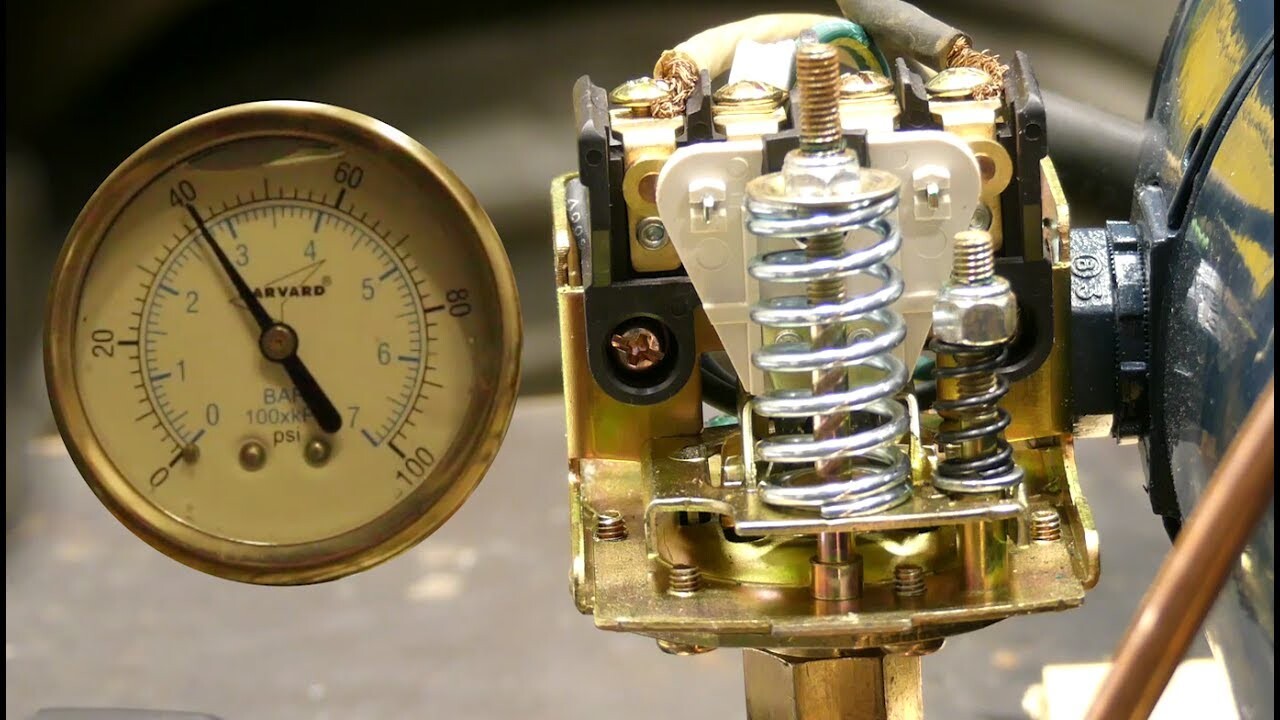

Step 4: Adjust Pressure Settings

After connecting the air compressor to a power source and ensuring it is properly lubricated, the next step is to locate the pressure regulator knob or dial. This control allows you to adjust the pressure output of the compressor. To increase the pressure, turn the knob clockwise, and to decrease it, turn it counterclockwise.

It is important to consult your user manual or recommended guidelines for your specific model to determine the appropriate pressure settings for your intended use. Once you have set the desired pressure, lock the regulator knob to maintain consistent airflow.

Step 5: Start The Compressor

To start the US air compressor, follow these steps for a safe and efficient operation. Firstly, ensure the power switch or button is in the “off” position before connecting it to a power source that meets the voltage requirements. If there are any safety switches or valves, ensure they are turned on.

Once everything is set, press or flip the power switch/button to the “on” position. You will notice that the motor starts running, and the pressure gauge will rise as air compresses. It is important to regularly check the pressure levels and perform routine maintenance to ensure optimal air compressor performance.

Step 6: Connect Tools Or Equipment

You must first identify the correct connector to connect your tools or equipment to the US air compressor. The compressor and the tool must be turned off before connecting them. Begin by attaching one end of an air hose to the outlet port of the compressor and the other end to the inlet port of your tool. Once everything is securely connected, you can turn on the compressor and allow it to build up pressure. This will ensure a steady compressed air flow to power your tools effectively.

Step 7: Operate The Compressor

Operating a compressor requires a few essential steps to ensure its proper functioning. First, ensure you have a correct power connection and the valves are in the right position. Then, simply flip the switch or press the start button to turn on the compressor.

Pay attention to the pressure gauge as it runs, indicating when the desired pressure is reached. If necessary, adjust the regulator to control the output pressure. Finally, attach your air tools using fittings compatible with your compressor. Always follow safety guidelines and instructions provided by the manufacturer when using any tools or equipment connected to the compressor.

Step 8: Shutting Down And Maintenance

Following a few simple steps is essential to ensure the proper shutdown of your US air compressor after use. Begin by turning off the power switch or unplugging the compressor to disconnect it from the electrical supply. Next, release any remaining pressure in the tank by opening the drain valve. Once the pressure has been released, close the drain valve securely.

It is crucial to check that all valves and fittings are tightly closed to prevent leaks. Take a moment to inspect the compressor for any signs of wear or damage and address any issues accordingly. Finally, clean the exterior of the compressor using a soft cloth or brush to remove dirt and debris, ensuring that it remains in optimal condition for future use. Following these steps, you can maintain your air compressor’s performance and prolong its lifespan.

Benefits Of Using A US Air Compressor

Using a US air compressor offers many benefits for both professional and personal use. The first major advantage is its versatility. The US air compressor can handle everything if you need to power pneumatic tools, inflate tires, or operate machinery. Its high-powered motor ensures efficient and reliable performance, allowing you to complete tasks quickly and effectively.

Additionally, the durable construction of the compressor ensures longevity, making it a worthwhile investment. Moreover, the compact design and portability of the US air compressor make it easy to transport and store. With its user-friendly features and powerful capabilities, this air compressor is a valuable tool for any workshop or job site.

Maintenance And Care Tips For Keeping Your US Air Compressor In Top Condition

Proper maintenance and care are essential for keeping your US air compressor in top condition. Regularly inspect the compressor for any signs of wear or damage, such as leaks or loose fittings, and address these issues promptly. It is also important to clean the compressor regularly to remove any dirt or debris that may have accumulated.

Additionally, follow the manufacturer’s guidelines for oil changes and filter replacements. This will help ensure that your compressor operates efficiently and extends its lifespan. Finally, store your air compressor in a clean and dry environment when not in use to prevent rust and other damage. These maintenance tips can keep your US air compressor running smoothly for years.

Conclusion

To maximize the benefits of your US General Air Compressor, it is essential to understand how to use it properly. Following the step-by-step guide we have provided will ensure your compressor’s safe and efficient operation. Remember always to prioritize safety precautions and inspect your equipment before each use.

By familiarizing yourself with the power source, adjusting pressure settings, and connecting tools correctly, you can unlock the full potential of your air compressor. Lastly, don’t forget proper shutting-down procedures and regular maintenance to keep your US Air Compressor in top shape for years. Want to learn more about using air compressors? Try out o air compressors practically and share your experience with fellow enthusiasts.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-e59177df-b027-44f5-a26a-bf4006e78c66″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.