PEX, or cross-linked polyethylene tubing, has become increasingly popular in recent years as a piping material due to its flexibility, durability, and cost-effectiveness.

However, it doesn’t just limit to plumbing applications. PEX can also be utilized in air compressor systems, providing a reliable and efficient solution for transporting compressed air. We’ll explore everything you need to know about PEX for air compressors – from its benefits and drawbacks to installation tips and best practices.

As a professional in the compressed air industry, it’s essential to understand the different piping options available and their respective advantages and limitations. PEX is an excellent choice for air compressor systems, but it’s important to use the right type and size of tubing to ensure optimal performance and safety.

What Is PEX?

PEX, which stands for cross-linked polyethene, is a flexible plastic tubing commonly used in plumbing and heating applications. PEX tubing is an ideal choice for various applications due to its durability, resistance to corrosion and chemicals, and flexibility. People often use PEX tubing in air compressor systems to distribute compressed air throughout a building or facility.

It can handle high-pressure and temperature conditions without leaking or degrading, making it a reliable option for air compressor installations. Additionally, PEX is easy to install and requires fewer fittings than traditional metal piping systems, reducing installation time and costs.

Types Of PEX Pipe

There are several types of PEX pipe available for use with air compressors. The most common types include PEX-A, PEX-B, and PEX-C. There are a few different types to consider. Each type has advantages and considerations, so choosing the right one for your specific needs is important.

PEX A

PEX A, or cross-linked polyethylene type A, is a highly flexible and durable pipe commonly used in various applications, including air compressor systems. Its ability to withstand high temperatures and pressures makes it an ideal choice for such systems. One of the key advantages of PEX A pipes is their ease of installation.

Without elbows or fittings, one can easily bend them, reducing the risk of leaks. Additionally, PEX A pipes offer excellent resistance to chemicals, corrosion, and scaling, ensuring long-lasting performance. Another benefit is their low thermal conductivity, which helps to minimize energy loss and improve system efficiency. With its flexibility, durability, and other advantages, PEX A is a reliable option for air compressor systems.

PEX B

PEX B is a highly popular type of PEX pipe used in air compressor systems. It is made from high-density polyethylene (HDPE) and is well-known for its flexibility and durability. One of the key advantages of PEX B pipes is their resistance to cracking and bursting, making them an excellent choice for high-pressure applications.

They also offer corrosion and chemical resistance, ensuring long-lasting performance. PEX B pipes can handle the demands of air compressor systems, providing reliable and efficient airlines. Their flexibility makes installation easier, and their durability ensures minimal leaks or damage.

PEX C

PEX C is a cross-linked polyethylene pipe commonly handy in air compressor systems. It offers higher temperature and pressure resistance than other PEX pipe types. PEX C pipes are flexible and easy to install, making them popular for DIY projects. They also boast excellent corrosion and chemical resistance, ensuring the longevity of your air compressor system.

With different sizes available, PEX C pipes can accommodate various air compressor setups. When selecting the right piping material for your air compressor, PEX C provides durability, flexibility, and ease of installation, making it a reliable choice for your compressed air needs.

PEX-AL-PEX

PEX-AL-PEX is a type of PEX pipe that incorporates multiple layers, including an aluminum layer, to enhance its strength and durability. This particular type of PEX pipe is widely utilized in air compressor systems due to its ability to withstand high pressure and temperature.

One of the key advantages of PEX-AL-PEX pipes is their exceptional corrosion resistance, making them ideal for hot and cold air applications. Additionally, the aluminum layer within the pipe helps maintain its form, preventing any unwanted kinks or bends. When considering PEX for your air compressor system, it is crucial to consider factors such as the required pressure rating and compatibility with other components.

How To Use Pex For Air Compressor

To use PEX for air compressor systems, it’s important to understand its benefits. PEX tubing is flexible, durable, and resistant to corrosion and chemical damage. When installing PEX tubing in an air compressor setup, follow proper techniques to ensure a secure and reliable connection.

various fittings and connectors can be used with PEX tubing, such as compression fittings, copper crimping, expansion connections, push-fit connections, and stainless steel clamps. It’s also crucial to consider maintenance and potential issues associated with using air compressors, such as leaks and moisture.To maximize efficiency and performance, properly lay out the PEX tubing and take advantage of tips and tricks for optimal use.

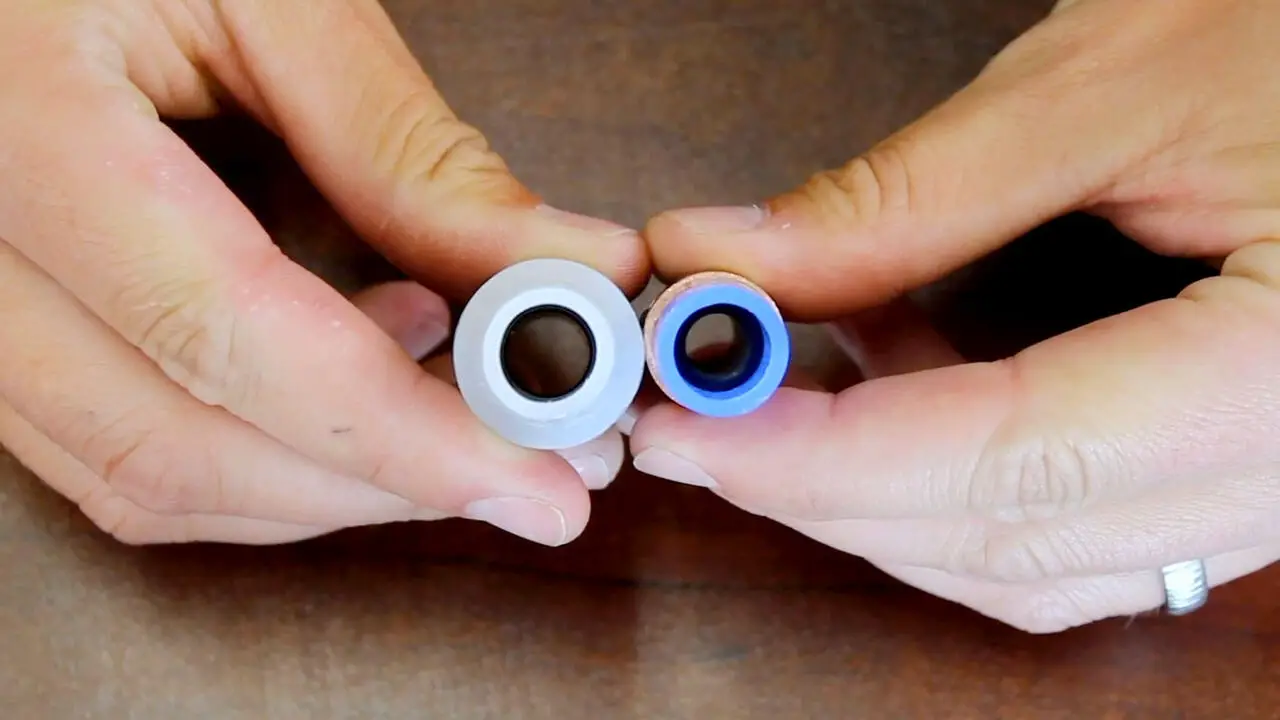

Compression Fittings

Compression fittings are a common choice for connecting PEX tubing to various components in an air compressor system. PEX tubing, known for its flexibility and durability, is ideal for air compressor systems.

Compression fittings create a tight seal by compressing the tubing against a fitting using a nut and ferrule. Selecting compression fittings compatible with PEX tubing and specifically designed for air compressor systems is crucial.

Proper installation techniques, such as ensuring clean and smooth cuts on the tubing, are significant in achieving a secure and leak-free connection. You can ensure a reliable and efficient air compressor system without compromising performance by choosing the appropriate compression fittings and following proper installation practices.

Copper Crimping

Copper crimping is a popular method for connecting PEX (cross-linked polyethene) tubing in air compressor systems. This method uses copper crimp rings to securely attach the PEX tubing to fittings, creating a tight and reliable connection. A specialized tool compresses the copper ring onto the PEX tubing and fitting to complete the crimping process.

It is essential to ensure proper installation to achieve a leak-free connection and optimize the performance of the air compressor system. Copper crimping is preferred for its durability and flexibility, making it an excellent choice for air compressor applications. Following the correct installation techniques ensures your air compressor system operates efficiently and effectively.

Expansion Connections

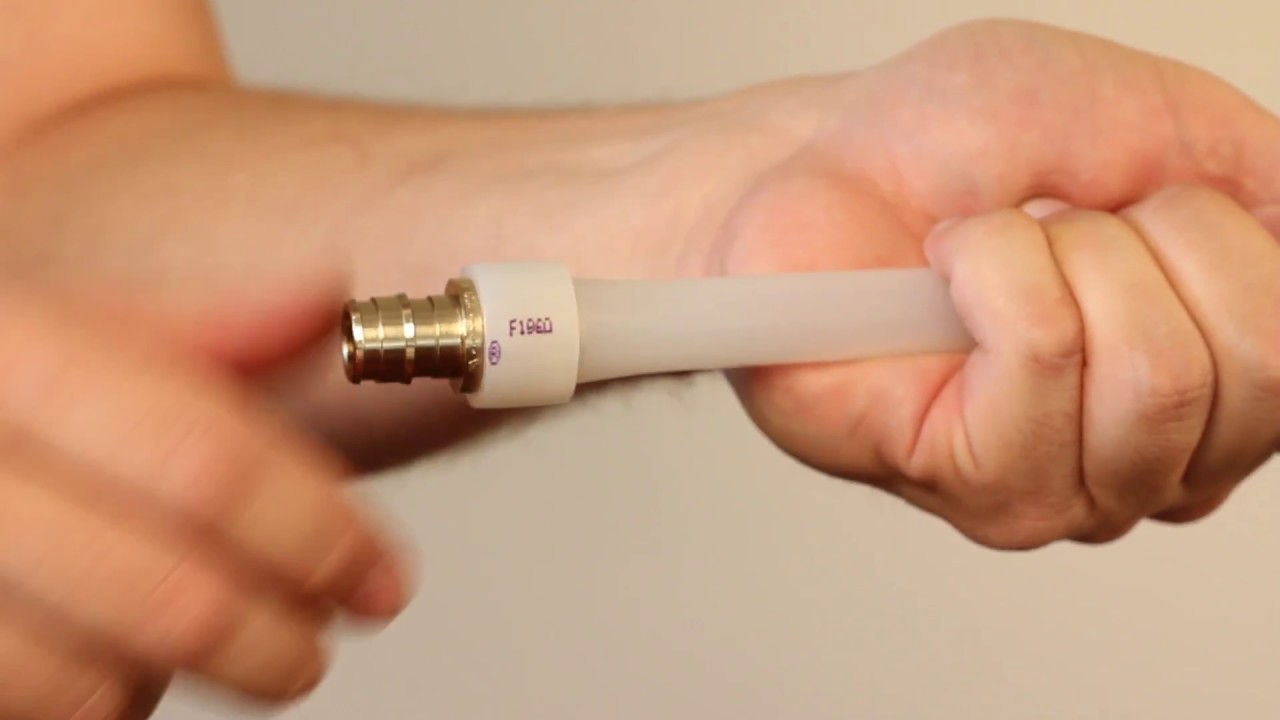

Expansion connections are essential when using PEX tubing for air compressor systems. PEX (cross-linked polyethene) is a flexible and durable material that can withstand changes in temperature and pressure. The PEX tubing can expand and contract without causing any damage or leaks by utilizing expansion couplings or expansion rings.

Following manufacturer guidelines and local building codes is crucial to ensure proper installation. These expansion fittings allow for the flexibility necessary in an air compressor system. Remember to choose fittings compatible with PEX tubing and designed for air compressor use. You can ensure a reliable and long-lasting system by incorporating expansion connections into your PEX air compressor setup.

Push-Fit Connections

Push-fit connections are popular for connecting PEX tubing in air compressor systems. PEX tubing, known for its durability and flexibility, is commonly used due to its leak-free and secure connection provided by push-fit connectors.

These connectors eliminate the need for special tools or soldering, making the installation process quick and hassle-free. To use push-fit connections with PEX tubing, measure and cut the tubing to the desired length. Then, insert one end of the tubing into a push-fit connector, ensuring it clicks into place. Repeat the process for the other end, ensuring both connections are secure.

Finally, connect the other end of the push-fit connector to the appropriate fitting on the air compressor or air tool. With push-fit connections, you can confidently rely on a strong and efficient air compressor system.

Stainless Steel Clamps

PEX tubing, also known as cross-linked polyethene, is a durable and flexible material commonly used in air compressor systems. To ensure a secure and leak-free connection, it is recommended to use stainless steel clamps when securing PEX tubing to fittings.

These clamps provide a strong and reliable connection that can withstand high pressures. When installing PEX tubing for an air compressor system, ensuring proper sizing and compatibility with the compressor’s requirements is crucial.

Regular inspections and maintenance should be conducted to check for any signs of wear or damage to the PEX tubing and the stainless steel clamps. By utilizing stainless steel clamps, you can ensure the longevity and efficiency of your air compressor system.

Advantages Of Using PEX Tubing For Air Compressors

PEX tubing offers several advantages when it comes to air compressor applications. Its flexibility and ease of installation make it an ideal choice for air compressor setups. The tubing can be easily bent and maneuvered, allowing easy routing and installation in tight spaces. Additionally, PEX tubing is corrosion-resistant, ensuring long-lasting performance even in high-pressure environments.

This makes it a reliable option for air compressor systems that require durability. Moreover, PEX tubing is cost-effective compared to traditional metal piping systems. Its affordability makes it a practical choice for small-scale and large-scale air compressor installations.

Another advantage of PEX tubing is its excellent thermal properties. It allows for efficient heat transfer, reducing energy loss and improving system performance. Lastly, PEX tubing is versatile and can be used in various air compressor setups, including underground installations. Its adaptability makes it suitable for various environments and applications.

Disadvantages Of Using PEX Tubing For Air Compressors

While PEX tubing is a popular choice for various plumbing applications, it has disadvantages when used for air compressors. Firstly, PEX tubing is unsuitable for high-pressure applications, as it may not handle the increased stress.

Additionally, PEX tubing can degrade when exposed to certain chemicals or UV rays, potentially compromising its structural integrity. Moreover, PEX tubing has a lower temperature resistance than other materials, making it less suitable for extreme-estimating applications.

Another drawback is that larger PEX tubing sizes may have limited availability, posing challenges when designing air compressor systems. Lastly, PEX tubing may require additional fittings and connectors, increasing installation complexity and cost.

Conclusion

Pex for air compressor systems is an excellent alternative to traditional metal piping. It offers a range of benefits, including affordability, durability, and flexibility, making it a popular choice in the industry. When installing a PEX system, following the manufacturer’s guidelines and using the appropriate fittings to ensure a secure and safe connection is essential.

A PEX air compressor system can provide years of reliable service with proper installation and maintenance. As professionals, staying up-to-date with the latest materials and technologies is important, and PEX tubing is worth considering for your next air compressor project.

Frequently Asked Questions

1.Is PEX Suitable For Compressed Air?

Ans: PEX is not recommended for compressed air systems as it can become brittle and crack under high-pressure conditions. It is best to use materials specifically designed for compressed air, such as metal or reinforced PVC. Using PEX for compressed air can be dangerous and may lead to system failures.

2.How Much Air Pressure Can PEX Hold?

Ans: PEX can typically withstand air pressure of up to 160 psi. However, the specific pressure rating may vary depending on the type and brand of PEX. It is important to follow manufacturer guidelines and local building codes for proper installation and usage of an air compressor. Consulting a professional or conducting thorough research will help determine the appropriate pressure limits for your specific application.

3.What PSI Rating Is PEX For Air?

Ans: PEX for air typically has a PSI rating of 100-150. It’s crucial to check the manufacturer’s specifications for the specific PEX product you’re using. The PSI rating determines the maximum pressure the PEX can handle without bursting, so ensure it matches or exceeds your air compressor’s operating pressure.

4.What Is The Best Line To Use For An Air Compressor?

Ans: PEX (cross-linked polyethene) is a popular choice for air compressor lines. It offers durability, flexibility, and resistance to corrosion. However, other options like copper and PVC are also available. The best line for an air compressor depends on factors like the specific application and budget.

5.What Are The Benefits Of Using PEX For Air Compressor Systems?

Ans: PEX for air compressor systems offers several advantages. It is highly resistant to corrosion, ensuring durability. The flexibility of PEX makes it easy to install and enables seamless routing of airlines. Additionally, PEX has excellent thermal insulation properties, reducing energy loss. Moreover, it is a cost-effective alternative to traditional metal piping systems.

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.