Air compressors are powerful and essential tools used in various industries and settings, such as construction, auto repair, and manufacturing. However, these machines are also notorious for being loud and creating a lot of vibration.

This is why many people build air compressor sheds to protect their equipment and reduce noise pollution. A well-designed air compressor shed can make a significant difference in the safety and efficiency of your workplace. With the right design and materials, you can protect your compressor from the elements while reducing noise pollution and vibrations that can cause damage to your equipment.

We will explore everything you need to know about building the perfect air compressor shed. From choosing the right location and materials to designing the layout and ventilation system, we will walk you through every process step.

What Is An Air Compressor Shed?

An air compressor shed is a structure designed to house and protect an air compressor. It provides a designated space for the air compressor, keeping it safe from the elements and reducing noise levels. The shed is typically constructed with durable materials, such as metal or wood, and may have insulation or soundproofing features to reduce noise further.

An air compressor shed can help prolong the lifespan of the equipment by providing a secure environment and protecting it from potential damage. It can also help maintain a clean and organized workspace by keeping the air compressor in its dedicated area.

How To Build The Perfect Air Compressor Shed

Building the perfect air compressor shed involves several important factors. First, you need to determine your shed’s ideal size and location. Consider the space you have available and ensure it’s easily accessible.

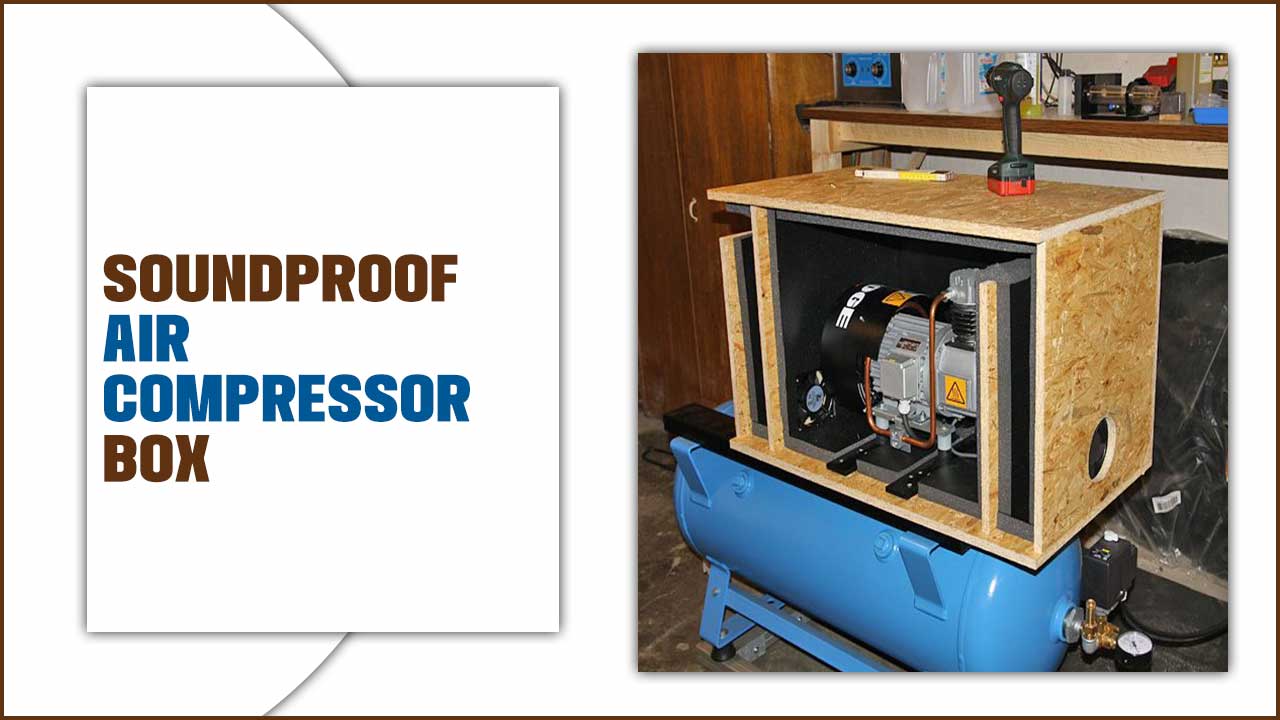

Next, choose durable and weather-resistant materials for construction. This will protect your air compressor from external elements. Proper ventilation and insulation are crucial to prevent extreme temperature fluctuations.

Additionally, ensure proper electrical connections and safety measures are in place. Organize the interior space for easy access and maintenance of your air compressor. You can also consider additional features like soundproofing or enhanced security measures.

Choosing The Right Location For The Shed

When choosing the location for your air compressor shed, it’s important to consider several factors. First and foremost, the shed should be easily accessible and close to where the air compressor will be used. This ensures convenience and efficiency in operation.

Additionally, the shed should be placed on a level surface to maintain stability and prevent potential damage to the air compressor. Another crucial consideration is the noise level of the air compressor – it’s best to choose a location that is not too close to living areas or neighbours to minimize any disturbances.

Adequate ventilation is essential to prevent overheating, so ensure the location allows for proper airflow. Be aware of any local building codes or regulations that may affect the placement of the shed. Consider the air compressor’s size and dimensions when finalizing the location.

Designing The Shed Layout

When designing the layout for your air compressor shed, it’s important to consider several factors to ensure optimal functionality and efficiency. Start by determining the size of the shed based on the dimensions of your air compressor and any additional equipment or tools that may be stored inside.

Next, plan the placement of doors and windows for easy access and natural light. Consider the ventilation needs of the compressor and include sufficient airflow vents to prevent overheating. Additionally, allocate space for storage shelves or cabinets to keep accessories organized and easily accessible.

Lastly, think about the overall aesthetics of the shed to ensure it blends seamlessly with your outdoor space. By carefully designing the layout, you can create a functional and visually appealing air compressor shed that meets all your needs.

Setting The Foundation

Building a solid and even foundation is crucial for the stability and longevity of your compressor shed. You have multiple options, including concrete slabs, gravel pads, or pressure-treated wood frames. Consider the size and weight of your air compressor when determining the dimensions and thickness of the foundation.

Proper drainage should be ensured to prevent water damage to the compressor and the shed. And depending on local regulations, consulting with professionals or obtaining permits may be necessary before construction.

Framing The Structure

The first step is to frame the structure to build an air compressor shed. Determine the size and dimensions of the shed based on your air compressor’s size. Use pressure-treated lumber for durability and resistance to rot. Begin by constructing the level and secure base. Build the walls and roof using proper framing techniques like studs and trusses. Add siding or other exterior materials for protection from the elements.

Installing Roofing And Siding

When constructing an air compressor shed, selecting resilient roofing and siding materials that can withstand different weather conditions is crucial. Many people opt for metal roofing for its durability and ability to endure harsh elements.

Another popular choice for siding is vinyl, as it requires minimal maintenance and provides insulation and protection for the shed. Proper installation of the roofing and siding is essential to prevent leaks and ensure a watertight seal. It may be beneficial to consult professionals for expert advice on installation techniques.

Adding Windows And Ventilation

Windows and proper ventilation are crucial aspects of an air compressor shed. Not only do windows allow natural light into the shed, making it easier to work and find tools or equipment, but ventilation helps remove excess heat and fumes, ensuring a safe working environment.

Strategic placement of windows and vents maximizes airflow while maintaining security and insulation. Consider incorporating adjustable louvres or exhaust fans to control air circulation within the shed.

Electrical Wiring And Lighting

When constructing an air compressor shed, it is crucial to consider the electrical wiring and lighting requirements. To prevent overloading other circuits in your home, have a dedicated circuit for your air compressor.

Install suitable outlets and switches in the shed to connect and control your compressor safely. Additionally, consider incorporating extra lighting fixtures to enhance visibility and safety while operating the compressor. It is advisable to consult with a licensed electrician to ensure compliance with local building codes and regulations.

Maintaining The Air Compressor In Your Shed

Proper maintenance of your air compressor is crucial for its optimal performance. To ensure this, focus on the following aspects. First, ensure your shed has proper ventilation and insulation to prevent overheating in hot climates and freezing in colder ones. Regular cleaning and maintenance of the air compressor, including checking and changing the air filter, will help keep it in top shape.

Securing your shed with sturdy locks and implementing safety measures like proper grounding and fire prevention will protect your air compressor from theft or damage. Finally, organize your space efficiently for easy access and storage of tools and accessories.

How Much Does An Air Compressor Shed Cost?

Regarding air compressor sheds, the cost can vary depending on the HVAC system you choose. However, as a general estimate, air compressors s range in price from $800 to $3,000.

It’s important to remember that this is just an average price range and that additional factors such as size, features, and brand can all impact the final cost. To get a more accurate estimate for your specific needs, it’s best to consult with a professional who can assess your requirements and provide a personalized quote.

Conclusion

building the perfect air compressor shed requires careful planning and execution. From choosing the right location to designing the layout, setting the foundation, framing the structure, and adding windows and ventilation, every step is crucial to ensure the functionality and durability of your shed.

Also, properly maintaining your air compressor is essential to prolong its lifespan and optimize its performance. While the cost of an air compressor shed may vary depending on factors such as size, materials, and additional features, investing in a well-built shed is worthwhile to protect your equipment and create a safe working environment.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-8f9e2e8a-bd4d-40a2-af13-d8726395bebd”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.