A flush rivet is a type of fastener used to join materials together, with the head sitting flush with the surface. Commonly used in aerospace and automotive industries, they provide strength and a seamless finish, improving aerodynamics.

Here we will cover everything you need to know about Flush Rivets, including what they are and the benefits of using them. We will provide a step-by-step guide on installing Flush-Rivets, from selecting the appropriate rivet to inspecting the installation.

You’ll also learn about the tools and materials needed for installation and the different Flush-Rivets available. Say goodbye to unsightly rivets and achieve a professional finish with this comprehensive guide.

Step-By-Step Guide To Installing A Flush Rivets

Using Flush Rivets in your project offers several benefits. Firstly, Flush-Rivets create a smooth and seamless finish, enhancing the overall aesthetics of the project. They also reduce drag and improve aerodynamics, making them suitable for aerospace applications. Additionally, Flush-Rivets prevent snagging or catching on objects, enhancing safety.

Furthermore, these rivets provide a stronger and more secure bond than other types of fasteners, ensuring the durability and longevity of your project. By incorporating Flush-Rivets into your design, you can achieve both visual appeal and functional performance. Here we provide a full guideline to make a full rivet like a pro.

1. Tools And Materials Needed For Installation

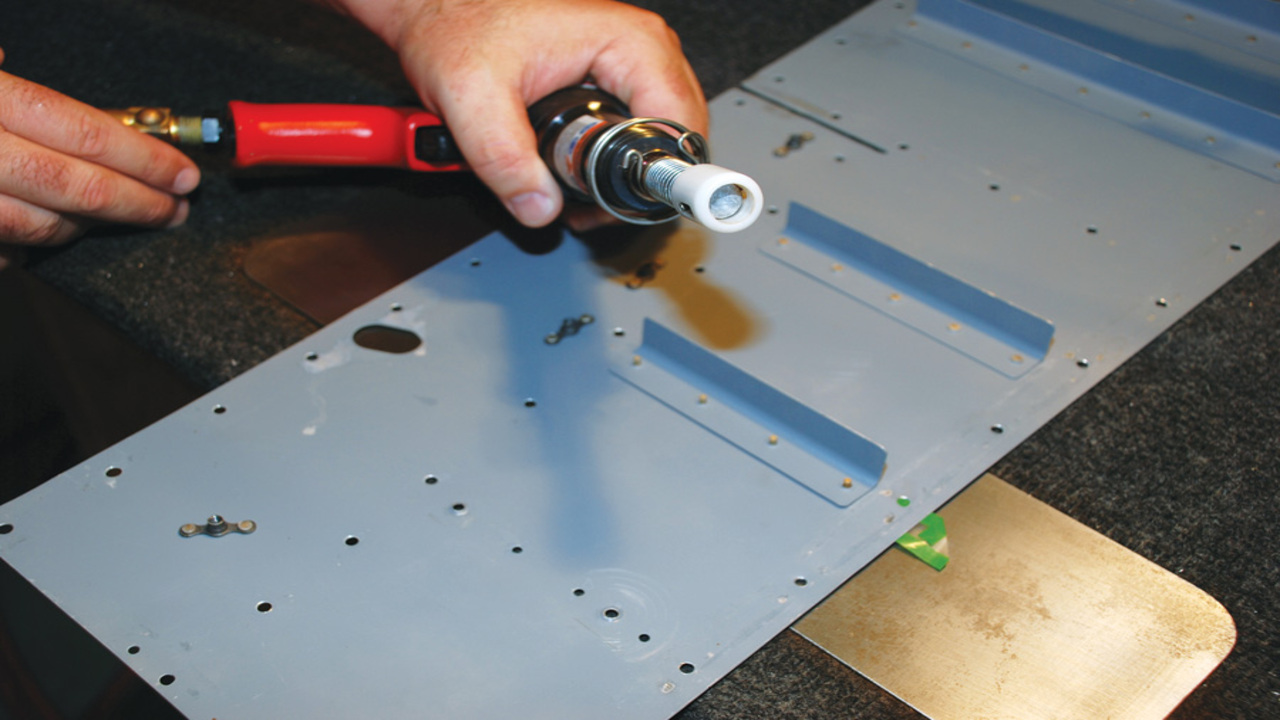

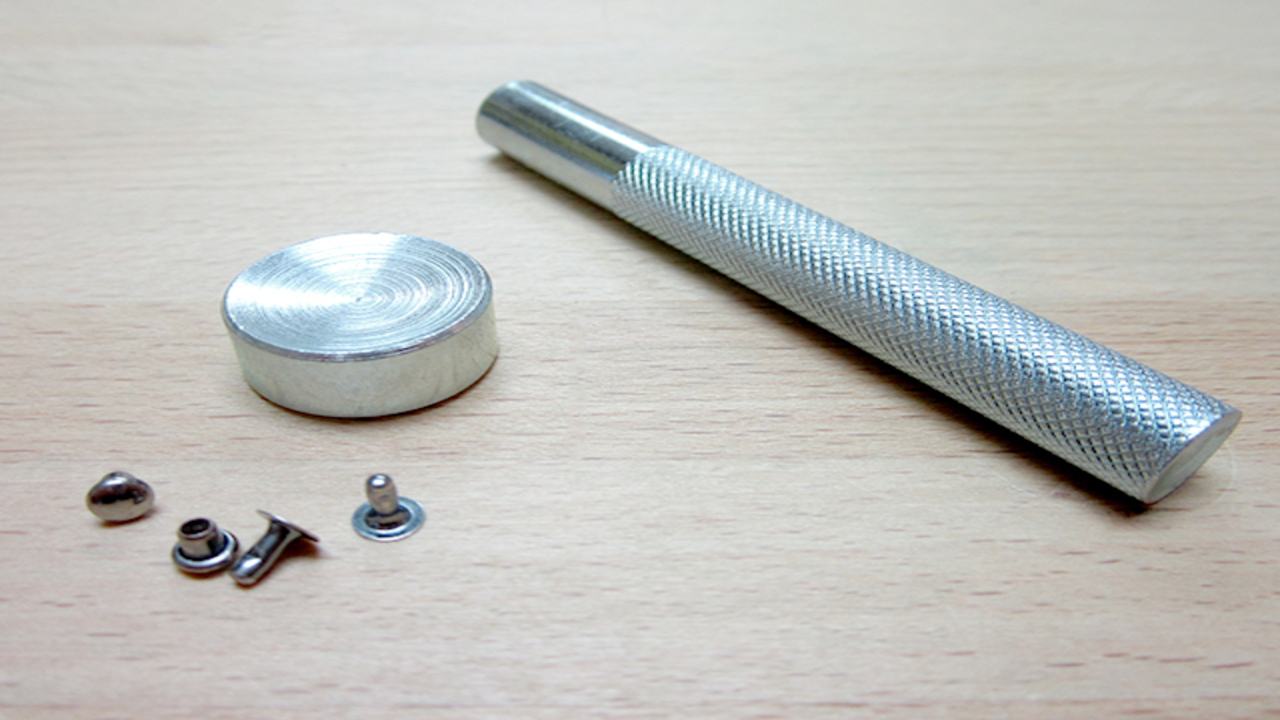

To successfully install Flush-Rivets, you will need several tools and materials. Before you begin, gather the necessary items, such as a rivet gun, Flush-Rivets, drill, metal file, and safety goggles. Measure and mark the desired locations on the materials where you want to install the Flush-Rivets.

Use a drill slightly smaller than the rivet’s diameter to create pilot holes at each marked spot. Insert the flush rivet into one of the pilot holes, ensuring the head is flush against the material’s surface. Place the rivet gun over the exposed end of the rivet and squeeze the handles together to secure it in place. Repeat this process for each marked location, ensuring proper alignment and secure installation.

2. Selecting The Appropriate Rivet

Choosing the appropriate rivet is crucial for a successful installation. Factors to consider include material, size, and grip range. Common rivets include solid rivets, blind rivets, and tubular rivets. Solid rivets are the strongest option, but they require access to both sides of the project.

Blind rivets are suitable when only one side is accessible, and tubular rivets are often used for lightweight materials or decorative purposes. Consider these factors carefully to ensure you select the right rivet for your project.

3. Preparing The Rivet Hole

To prepare the rivet hole, begin by drilling a hole in the materials you are joining. Ensure that it is the correct size for your rivet. Use a deburring tool to remove sharp edges or burrs and clean the surfaces around the hole to remove debris.

Create a recessed area with a countersink tool for the rivet head to sit flush if necessary. Before proceeding with rivet installation, double-check that the hole is clean and free of obstructions.

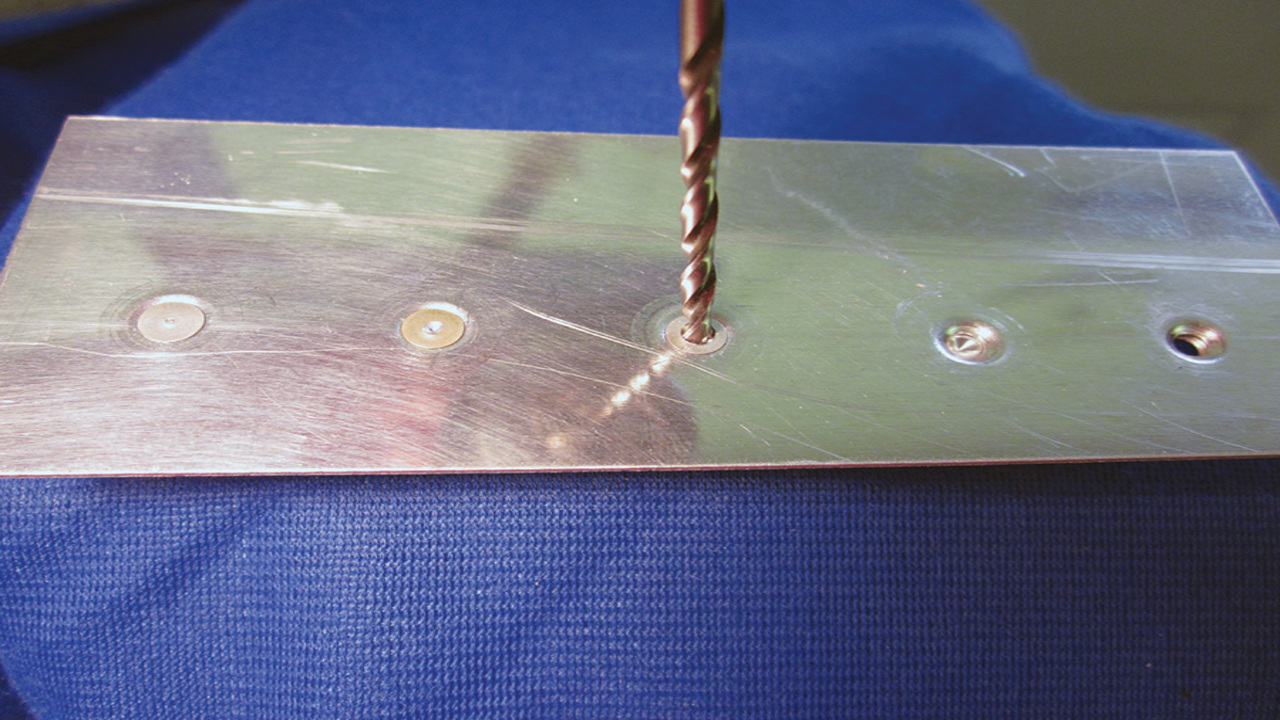

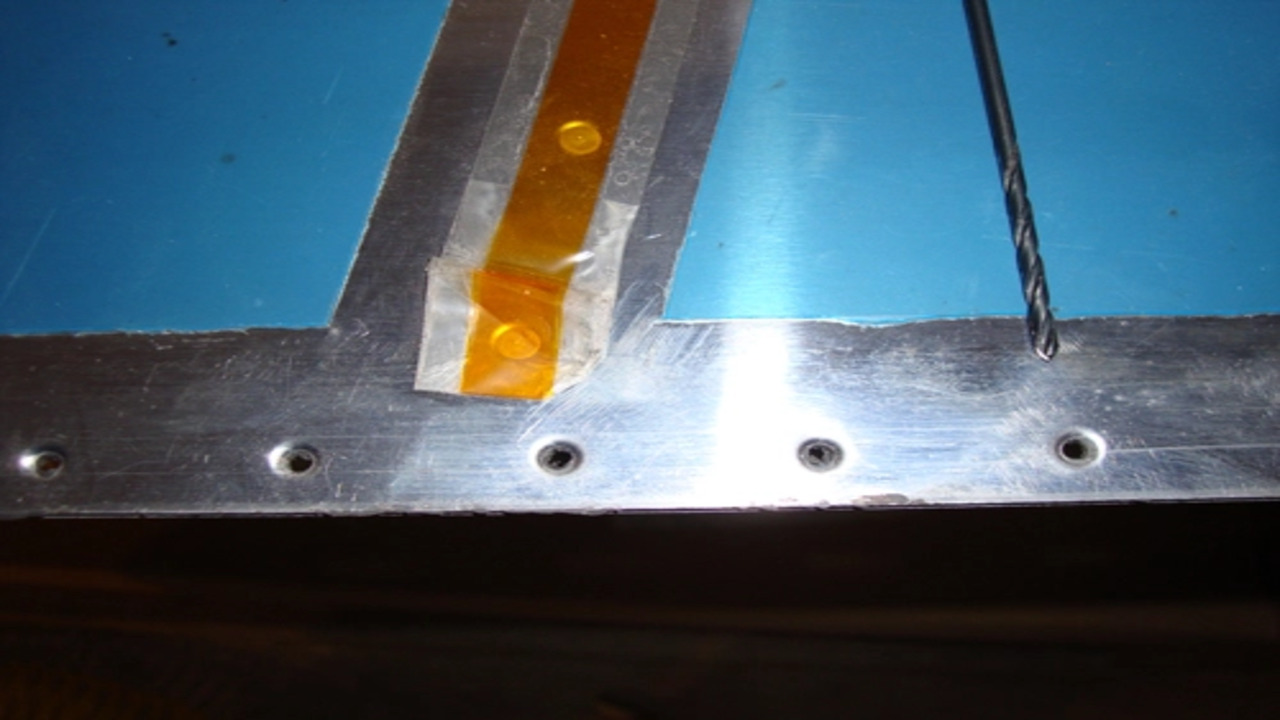

4. Drilling The Rivet Hole

To start drilling the rivet hole, mark the location of the rivet on the materials to be joined. Carefully drill a hole through both materials using a drill bit that matches the size of the rivet. Ensure that the hole is clean and free of debris. Insert the rivet into the hole, with the smooth side facing outwards. Use a rivet gun or hammer to secure the rivet, applying even pressure until it is flush with the surface. Repeat this process for any additional rivets needed.

5. Deburring And Countersinking

Proper deburring and countersinking are crucial steps before installing a flush rivet. Deburring involves removing sharp edges or burrs from the holes in the materials to be joined. This prevents any interference during rivet installation. On the other hand, countersinking creates a conical recess around the hole. It ensures that the rivet sits flush with the surface of the materials without protruding.

6. Installing The Rivet

To install a flush rivet, drill a hole in the desired location. Insert the rivet into the hole, ensuring proper alignment. Use a rivet gun, hammer, and rivet set to secure the rivet, applying even pressure for a tight fit. Trim any excess length from the rivet and smooth out rough edges with a file or sandpaper. This installation ensures you securely fasten the rivet and achieve a clean finish.

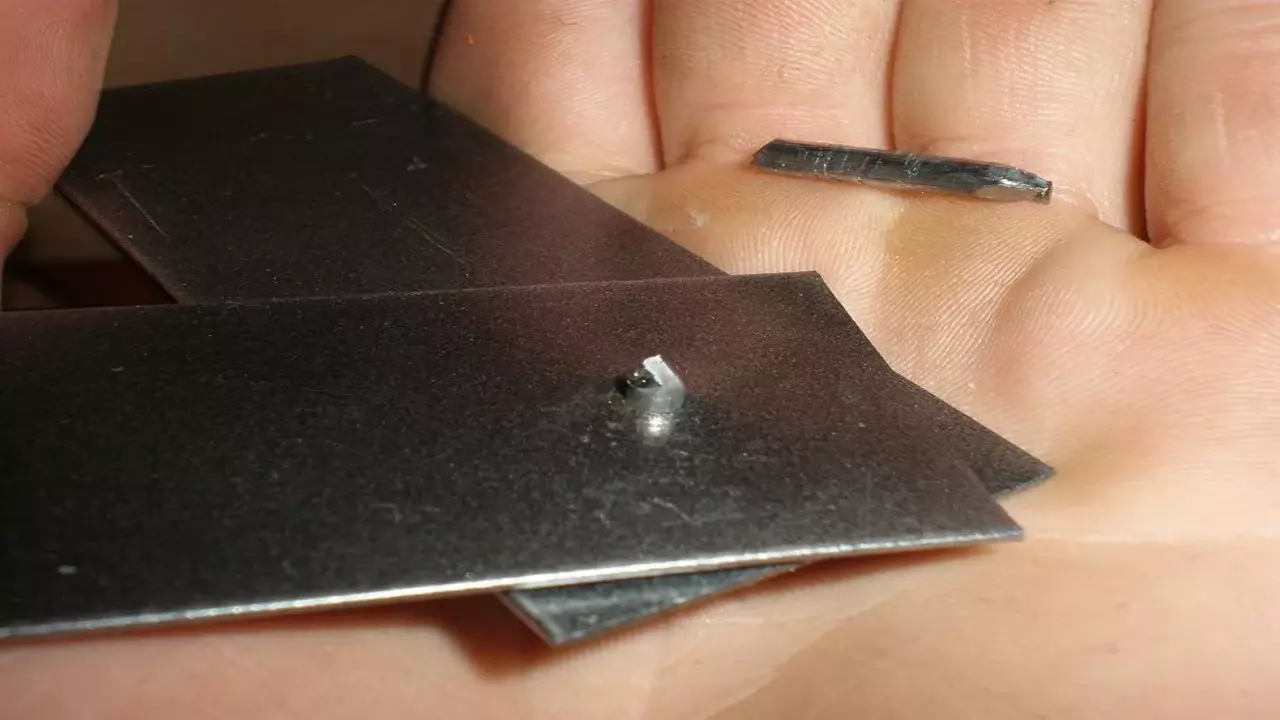

7. Setting The Rivet

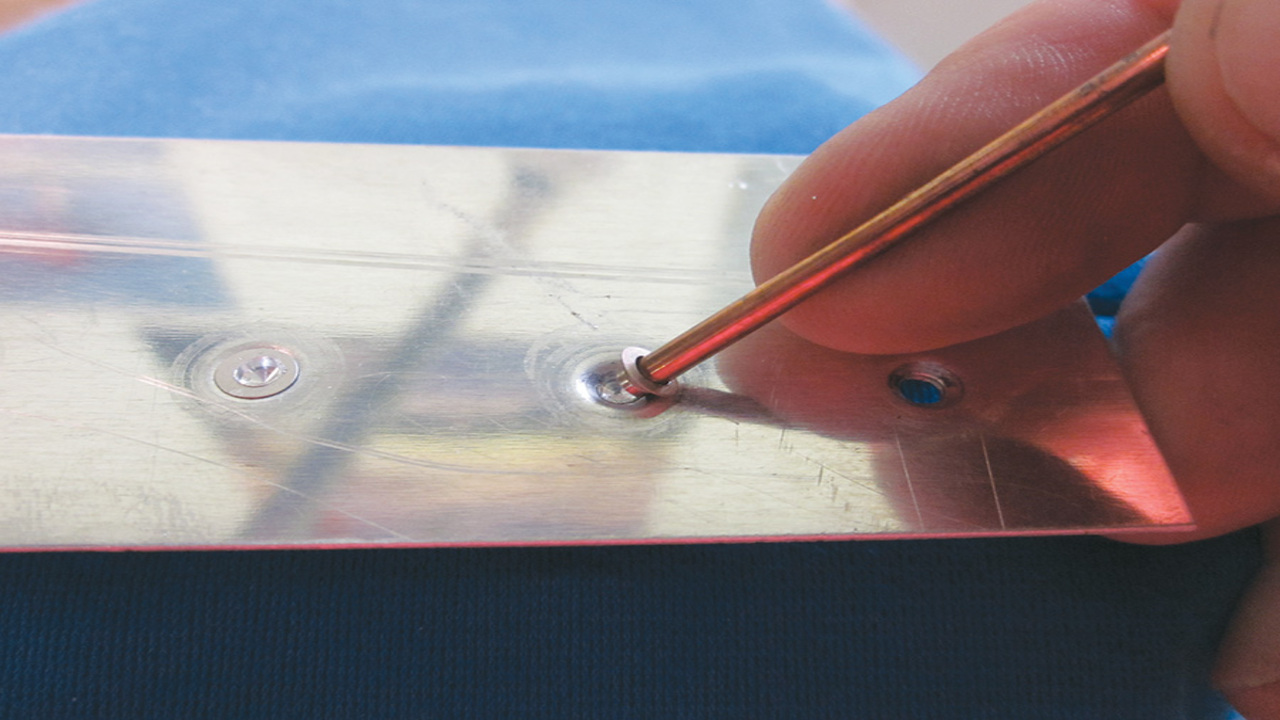

To set the rivet, ensure you have the correct size and type. Position it flush with the surface in the pre-drilled hole. Apply firm pressure with a rivet setter to secure it. Use a rivet gun or hammer to deform the tail and create a tight seal. Inspect its appearance and stability. Repeat for remaining rivets. Follow spacing guidelines as needed.

8. Inspecting The Installation

After the flush rivet installation, it’s crucial to inspect the work to ensure proper execution. Check for any gaps or unevenness between the rivet head and the surface it’s installed on. Use a flashlight to examine the rivet from different angles and ensure it sits flush with the surrounding material.

Run your fingers over the rivet to detect any raised edges or roughness. If any issues are found, use a rivet set tool to tap down raised portions until the rivet is flush carefully. After inspection and necessary adjustments, consider the flush rivet installation complete.

9. Preparing The Door Frame

To prepare the door frame for Flush-Rivets, start by ensuring that the surfaces where the rivets will be installed are clean. Next, measure and mark the locations for the rivets on the door frame, ensuring they are evenly spaced.

Use a drill with a small pilot bit to create holes at each marked location. Insert the rivet into the hole, ensuring it sits flush with the surface of the door frame. Then, use a rivet gun or hammer to secure the rivet in place by applying firm pressure. Repeat this process for each marked location on the door frame.

10. Installing The Flush Rivet

To install a flush rivet, drill a hole in the materials you want to join. Then, insert the rivet through the hole with the smooth head on one side and the rivet tail on the other. Secure the rivet in place using a rivet setter tool.

Place the domed portion of the rivet setter over the rivet head and strike it firmly with a hammer to flatten the tail against the material. Repeat this process for each rivet needed for your project. Finally, ensure all the rivets are flush with the material’s surface.

11. Finishing Touches

Once the flush rivet is installed, use a deburring tool to smooth out any rough edges around the rivet hole. To ensure a seamless finish, sand down any imperfections on the rivet surface using sandpaper or a file.

Apply a primer or paint that matches the surrounding surface to protect the rivet from corrosion. Consider applying a clear coat or sealant over the painted rivet for added durability. Finally, inspect the finished rivet for gaps or inconsistencies and make necessary adjustments.

Types Of Flush-Rivets

Flush-Rivets are essential for creating a seamless surface by countersinking the rivet head. There are three main types of Flush-Rivets to consider. Solid rivets require a rivet gun and can be time-consuming. Blind rivets, or pop rivets, are easier to install with a hand tool. Before installation, properly prepare the surface by drilling and deburring the holes.

Conclusion

When you want to achieve a polished and sophisticated look for your projects, we highly recommend incorporating Flush Rivets. These specialized fasteners offer several advantages, enhancing aesthetics by providing a seamless and smooth appearance.

Flush-Rivets bolster strength and optimize aerodynamics, making them ideal for applications such as aircraft construction or automotive projects.. To ensure a successful installation of Flush-Rivets, following a detailed guide that outlines the necessary tools and materials is important.

By doing so, you can effortlessly create Flush-Rivets with finesse. Whether you’re a professional in the field or an enthusiast engaging in various DIY projects, mastering the art of installing Flush-Rivets is indispensable for achieving secure and seamless fastening.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-2752dd72-b660-4544-8cc7-c4cf836e9c96″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.