The US General 60 Gallon Air Compressor is a powerful and reliable machine that has specific designs to meet the needs of both professional and DIY enthusiasts.

With a sturdy construction and a high-quality motor, this air compressor is built to last and provide consistent performance for all your pneumatic tools. Its 60-gallon capacity tank ensures a steady supply of compressed air, making it suitable for various applications, from automotive repair and construction work to woodworking and painting projects.

Whether you are a professional contractor looking for a reliable source of compressed air on the job site or a hobbyist needing a powerful tool for your home workshop, this air compressor is the perfect choice. We will take a closer look at the features, performance, and benefits of the US General 60-gallon Air Compressor and why it has become a favorite among users in the market.

An Overview Of Us General 60 Gallon Air Compressor

The us general 60 gallon air compressor is a highly powerful and durable machine, making it an ideal choice for various applications. Its large tank capacity and robust motor enable efficient operation, delivering excellent performance.

This compressor has advanced features such as pressure control, oil lubrication, and noise reduction technology, ensuring optimal functionality. Positive customer reviews attest to its reliability, and the included warranty provides added peace of mind for buyers. The US General 60-gallon Air Compressor is a top-notch option for those needing a high-quality and dependable air compressor.

Features

- 60-gallon tank capacity

- Powerful motor for efficient performance

- Maximum pressure of XX PSI

- Oil-lubricated pump for enhanced durability

- Two-stage design for improved air delivery

- Heavy-duty cast-iron construction for stability and long-lasting use

- Equipped with a pressure gauge and on/off switch for easy operation

- Comes with built-in thermal overload protection for safety

- Includes a high-flow regulator and quick-connect fittings for versatile use

- Ideal for various applications such as powering air tools, inflating tires, and operating pneumatic machinery.

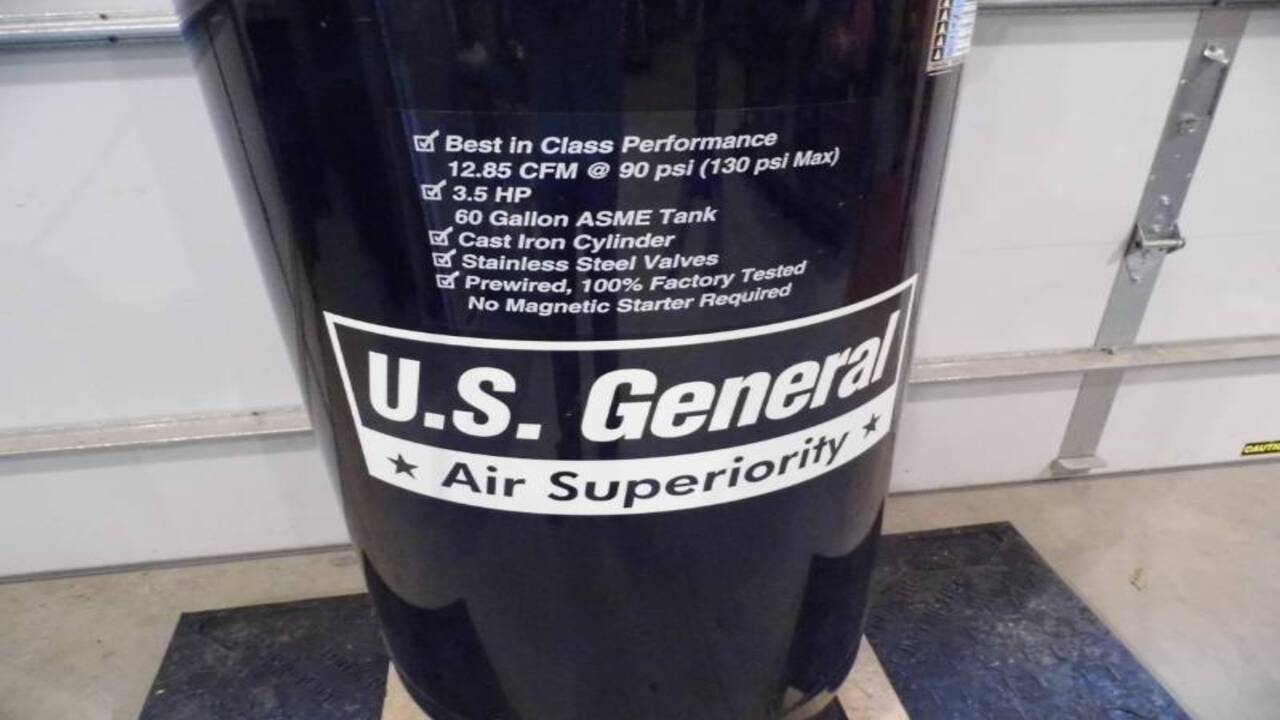

Specifications

- Model: Us General 60-Gallon Air Compressor

- Tank Capacity: 60 gallons

- Maximum Pressure: 135 PSI

- Horsepower: 3.5 HP

- Voltage: 120V/240V

- Amps: 15/7.5

- Air Delivery: 13.4 CFM at 40 PSI, 11.5 CFM at 90 PSI

- Pump Type: Oil-lubricated

- Pump Speed: 950 RPM

- Outlet: 1/4″ NPT

- Weight: Approximately 240 lbs

- Dimensions: 31.5″ L x 29″ W x 72″ H

- Warranty: Limited 1-year warranty.

Different Applications And Uses For The Air Compressor

The US General 60 Gallon Air Compressor is a versatile tool in various applications. Whether you are a DIY enthusiast, a professional contractor, or an automotive technician, this air compressor has the power and capacity to meet your needs. Some common uses for the US General 60-gallon Air Compressor include powering pneumatic tools such as nail guns, impact wrenches, and paint sprayers.

It can also inflate tires, clean surface dust and debris, and operate air-powered machinery. With its large tank capacity and high air flow rate, this air compressor has specific designs to provide reliable and consistent performance in any application. So whether you are working on a construction site, in a workshop, or in your garage, the US General 60-gallon Air Compressor is a valuable asset.

How To Use US General 60-Gallon Air Compressor

Using the US General 60-Gallon Air Compressor is a fairly straightforward process. Always follow manufacturer guidelines and safety precautions when operating machinery or equipment, including air compressors. Here are some steps to help you get started:

1.Familiarize yourself with the compressor: Before using the air compressor, take the time to read the user manual and understand its features and controls.

2.Prepare the compressor: Ensure that the compressor is placed on a stable surface and securely connected to a power source. Also, ensure the pressure regulator is set to zero before starting.

3.Connect your tools: Attach the appropriate air hose or tool to the outlet valve of the compressor. Make sure that all connections are secure.

4.Start the compressor: Turn on the power switch and allow the compressor to build up pressure until it reaches its cut-off point. This may take several minutes.

5.Adjust pressure settings: Adjust the pressure regulator knob to match your requirements once the desired pressure has been reached.

6.Use your tools: With the air compressor running, you can use your pneumatic tools or equipment as needed. Be mindful of safety precautions, such as wearing appropriate protective gear and ensuring proper ventilation in enclosed spaces.

7.Shutting down: When you have finished using the air compressor, turn off the power switch and release any remaining pressure from the tank by opening the drain valve.

Benefits Of Using A US General 60-Gallon Air Compressor

- Increased air capacity: The 60-gallon tank of the US General air compressor allows for a larger volume of compressed air to be stored, providing longer run times and improved efficiency.

- Versatility: With its high air capacity, the US General 60-gallon air compressor can power many pneumatic tools and equipment, including impact wrenches, paint sprayers, sanders, and more.

- Powerful performance: This air compressor has specific designs to deliver high CFM (cubic feet per minute) ratings, ensuring sufficient air pressure for demanding tasks and heavy-duty applications.

- Durability and reliability: Built with quality materials and robust construction, the US General 60-gallon air compressor has specific designs to withstand continuous use and provide long-lasting performance.

- Quieter operation: Equipped with advanced noise reduction technology, this air compressor operates at lower decibel levels than other models, minimizing noise disruptions in the working environment.

Customer Reviews And Ratings Of The Air Compressor

Regarding the US General 60 Gallon Air Compressor, customer reviews and ratings can provide valuable insights into the product’s performance and reliability. By reading these reviews, potential buyers can better understand the air compressor’s strengths and weaknesses and its overall quality. Customers often share their experiences with the product, highlighting its durability, efficiency, and noise level.

Additionally, ratings can help determine the overall satisfaction of customers who have purchased the air compressor. By considering both customer reviews and ratings, buyers can decide whether the US General 60-gallon Air Compressor is the right choice for their needs.

Common Troubleshooting Tips

When troubleshooting an air compressor that is not turning on, first check to ensure it is properly plugged in and the power switch is on. If the compressor is running but not generating enough pressure, inspect for leaks in the air hose or fittings, as this can cause a decrease in pressure.

Excessive noise or vibrations can often be resolved by placing the compressor on a stable surface to minimize movement. It is also important to regularly clean or replace air filters to prevent clogging and maintain optimal performance. Additionally, referencing the manual for specific maintenance instructions and recommended oil changes will help prolong the lifespan of your air compressor and ensure it operates efficiently.

If you’re experiencing any issues with your US General 60 Gallon Air Compressor, there are several common troubleshooting tips that you can try before calling for professional assistance. Here are a few things to check:

- Ensure that the power source is properly connected and supplying enough voltage to the compressor.

- Check the pressure gauge to ensure it is set appropriately for your intended use.

- Inspect the air filter for any debris or clogs hindering airflow.

- Examine the hoses and connections to ensure they are tight and leak-free.

- If the compressor is running but not building pressure, there may be an issue with the piston rings or valves, requiring further inspection and repair by a professional.

Always refer to your owner’s manual for specific troubleshooting instructions and safety guidelines.

How To Maintain A US General 60-Gallon Air Compressor

Regular maintenance is essential for ensuring the optimal performance of an air compressor and preventing debris from entering the compressor. One crucial maintenance task is regularly checking and replacing the air filter to keep it clean and free from dust and dirt.

It is also important to drain the tank regularly to remove any moisture buildup, as this can lead to corrosion over time. Lubricating moving parts according to the manufacturer’s recommendations helps prevent wear and keeps the compressor running smoothly.

Additionally, inspecting hoses and connections for leaks or damage is important to avoid potential issues. Following the manufacturer’s maintenance schedule is highly recommended, as it may include tasks such as changing the oil or inspecting belts, which are crucial for maintaining the longevity of the air compressor.

Tips For Improving Performance

To improve the performance of your US General 60 Gallon Air Compressor, there are a few tips you can follow. First, make sure that the compressor is properly maintained and regularly serviced. This includes checking and replacing oil, filters, and belts as needed. Additionally, ensure the compressor operates in a well-ventilated area to prevent overheating.

It’s also important to monitor the pressure levels and adjust them accordingly for optimal performance. Finally, consider using high-quality tools and accessories compatible with your air compressor to maximize its efficiency. Following these tips ensures that your US General 60 60-gallon air Compressor performs at its best and meets all your air compression needs.

What To Look For When Buying A Us General 60-Gallon Air Compressor

When buying a US General 60-gallon Air Compressor, it is important to consider the horsepower and CFM rating. These factors determine the power and efficiency of the compressor. Additionally, durability is crucial, so look for a model with a heavy-duty cast iron pump and a sturdy steel tank.

Another aspect to consider is whether the compressor is oil-lubricated or oil-free. Oil-lubricated models require regular maintenance but are more durable, while oil-free models are easier to maintain but may not last as long. Noise level is also important, especially if you plan to use the compressor in a residential or noise-sensitive environment.

Lastly, checking customer reviews before making a purchase is always beneficial. With this, you can gain insights into the reliability and performance of the specific model you’re interested in. Additionally, features like a pressure regulator can provide added convenience and control over the air output.

Tips For Proper Maintenance And Care Of The Air Compressor

Proper maintenance and care of your US General 60-gallon Air Compressor ensures its longevity and optimal performance. Here are some tips to help you keep your air compressor in top shape:

1.Regularly check the oil levels: The oil in your air compressor helps to lubricate the moving parts and prevent friction. Make sure to check the oil levels regularly and top up as needed.

2.Change the oil: Over time, the oil in your air compressor can become dirty and lose its effectiveness. Changing the oil at least once a year or after every 500 hours of use is recommended.

3.Clean or replace the air filter: The air filter helps to keep dust and debris out of the compressor system. Regularly clean or replace the air filter to ensure proper airflow and prevent damage to the compressor.

4.Drain the moisture from the tank: Moisture can build up in your air compressor tank, leading to corrosion and reduced performance. Regularly drain any accumulated moisture from the tank using the drain valve.

5.Inspect for leaks: Check all connections and fittings for any signs of leaks. A leak can cause a drop in pressure and affect the overall efficiency of your air compressor. Tighten any loose fittings or replace any damaged components.

6.Keep it clean: Dust and debris can accumulate on the exterior of your air compressor, hindering its performance. Regularly clean the unit using a soft cloth or brush, paying attention to vents and cooling fins.

By following these maintenance tips, you can prolong the lifespan of your US General 60-gallon Air Compressor and ensure that it continues to operate at its best.

Where To Buy The Air Compressor And Pricing Options

The US General 60 Gallon Air Compressor is popular among DIYers and professionals. If you’re in the market for one, you’ll be pleased to know that several options are available for purchasing this air compressor.

One of the most convenient ways to buy is through online retailers like Amazon or Home Depot’s website. These platforms offer a wide selection of air compressors, including the US General 60 Gallon model, and often provide customer reviews and ratings to help you make an informed decision.

Another option is to visit your local Harbor Freight store to see the compressor in person and speak with knowledgeable staff members who can assist you with any questions or concerns. As for pricing, the cost of the US General 60 Gallon Air Compressor can vary depending on where you purchase it and if there are any ongoing promotions or discounts available. It’s always a good idea to compare prices across different retailers to ensure you get the best deal possible.

Conclusion

The US General 60 Gallon Air Compressor is a versatile and dependable tool that greatly enhances your productivity and efficiency. This air compressor boasts various features to simplify your work, including a powerful motor, a high-capacity tank, and a quick recovery time.

Whether you’re a professional contractor or a DIY enthusiast, investing in the right equipment is crucial for achieving optimal results. In addition to its impressive performance capabilities, the US General 60-gallon Air Compressor has several benefits.

Moreover, this air compressor offers quiet operation, reducing noise pollution and creating a more comfortable working environment. Regularly inspecting and cleaning the compressor, checking for leaks, and lubricating moving parts are essential to maximise lifespan and functionality. Additionally, troubleshooting tips can help you quickly identify and resolve any issues that may arise during operation.

Frequently Asked Questions

Is 60-Gallon Air Compressor Good?

Various applications consider a 60-gallon air compressor a good size. It offers a higher capacity and longer run time compared to smaller compressors. This makes it suitable for operating pneumatic tools, painting, and inflating tires. Factors such as CFM rating and horsepower should be considered to ensure the compressor meets specific needs.

What Is The CFM Of A 60-Gallon Air Compressor?

The CFM (cubic feet per minute) of a 60-gallon air compressor can vary depending on the model. Typically, it falls within the range of 10 to 15 CFM. When choosing a 60-gallon air compressor, consider your intended use and the required CFM for your applications. Higher CFM ratings are better for powering larger or multiple tools at once.

How Heavy Is A Ingersoll Rand 60-Gallon Air Compressor?

The weight of an Ingersoll Rand 60-gallon air compressor can vary, typically weighing between 350 to 500 pounds. It’s important to consider the weight for transportation and installation purposes. Always check the product specifications or contact the manufacturer for the exact weight of your specific model.

Which Air Compressors Last The Longest?

Air compressors that last the longest are typically from reputable brands like Ingersoll Rand, Quincy, and Campbell Hausfeld. Look for models with cast iron cylinders and strong motor horsepower for increased durability. Regular maintenance, including oil changes and filter cleaning, will also help extend the lifespan. Consider the warranty offered as an indicator of longevity.

Who Makes Central Pneumatic Air Compressors?

Harbor Freight Tools manufactures Central Pneumatic air compressors. A well-known retailer specializing in affordable tools and equipment. As one of their brands, Central Pneumatic offers a range of air compressors and pneumatic tools.

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.