An air compressor is a device that converts power into potential energy stored in pressurized air. It is used to power various pneumatic tools and equipment.

Air compressors come in different sizes and capacities, ranging from small portable units to large industrial-grade compressors. This step-by-step setup guide will walk you through everything you need to do to get your air compressor up and running smoothly.

Then, we’ll dive into the nitty-gritty details of the setup process, covering everything from choosing the right air compressor to connecting the hoses and regulators. By the time you finish reading, you’ll be a pro at setting up your Ingersoll Rand T10 air compressor and ready to tackle any project that comes your way. Let’s get started.

How To Set Up An Ingersoll Rand T10 Air Compressor

Proper setup of an Ingersoll Rand T10 air compressor is essential for performance and efficiency. Incorrect installation can damage the equipment and void the warranty. A well-set-up compressor improves safety, extends equipment lifespan, and reduces maintenance costs.

For a seamless setup, choose the right compressor, prepare and install it correctly, and check oil levels and air pressure. Prioritize safety and follow manufacturer guidelines. Here are step-by-step guides to set up T10 Air Compressor.

1.Choosing The Right Air Compressor

Choosing the right air compressor involves considering your tools’ needs and requirements. This determines the appropriate size and capacity. Make sure the T10 Air Compressor is compatible with your power source, whether electric or gas-powered.

Set up a suitable location for proper ventilation and stability. Install necessary accessories following the manufacturer’s instructions and securely connect air hoses and fittings to prevent leaks. Adjust pressure settings to match tool requirements.

2.Preparing The Equipment

Gather all the necessary equipment and tools before setting up the T10 Air Compressor. Ensure you have a suitable location for the compressor, preferably a well-ventilated area with enough space for operation and maintenance.

Check the compressor’s electrical requirements and ensure you have the appropriate power supply in place. Inspect the compressor for any damage or loose parts before the setup. Connect the air intake filter to the compressor, ensuring a secure fit. Attach any necessary accessories, such as hoses or connectors, to the compressor according to your specific needs.

3.Installing The Air Compressor

To install the air compressor, select a suitable location that provides proper ventilation and enough space for airflow. Ensure the power source is compatible with the compressor’s voltage requirements and connect it to a grounded outlet.

Check the oil level and add oil if needed, following the manufacturer’s instructions. Attach the intake filter securely to the air inlet and connect an appropriate air hose to the outlet using any necessary adapters. If available, set the pressure regulator to your desired level. Now, your T10 Air Compressor is ready for use.

4.Connecting The Equipment

To connect the equipment, ensure the power supply is disconnected air compressor is turned off. Connect the air intake filter to the compressor’s air inlet using a suitable adapter or connector. Next, attach the discharge hose to the compressor’s outlet port, ensuring a secure fastening.

You can then connect any additional accessories or tools, such as air hoses or pneumatic tools, to the appropriate ports on the compressor. Don’t forget to check all connections for leaks and tighten them if needed. Once everything is connected, plug in the power supply and turn on the air compressor.

5.Compressor Accessories

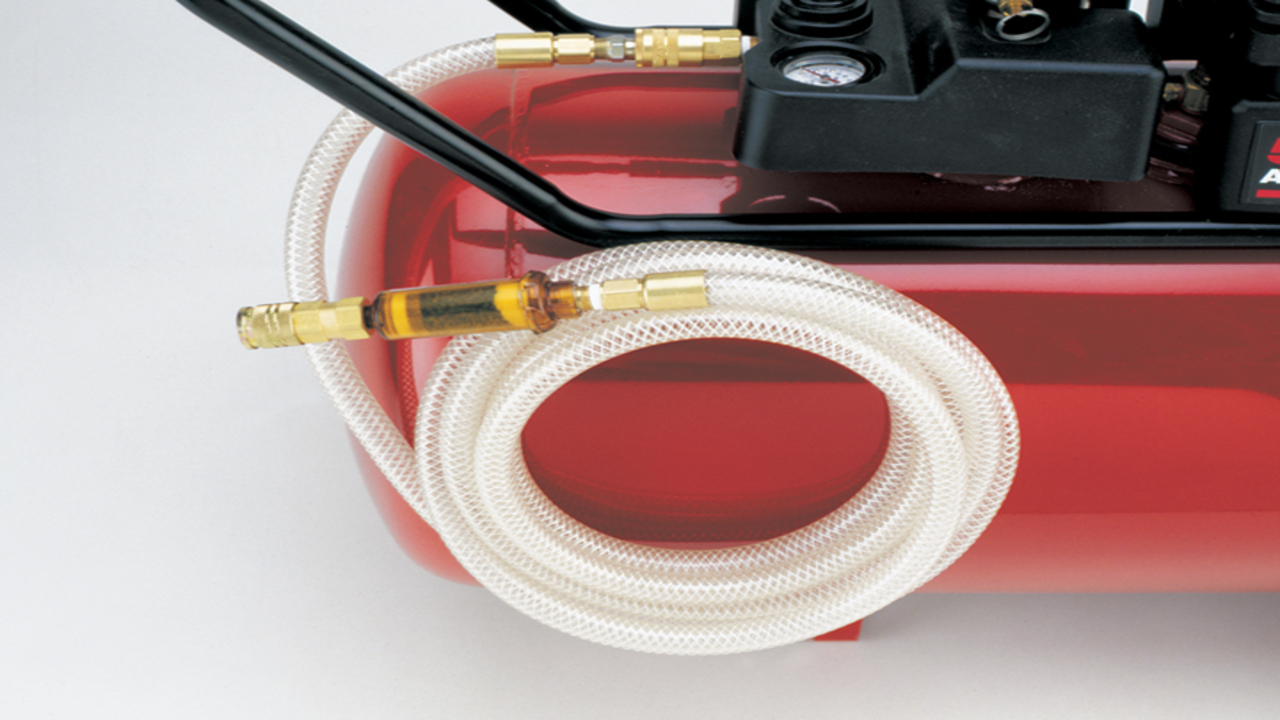

Having the necessary accessories is crucial when setting up a T10 Air Compressor. Common accessories include an air hose, pressure regulator, and air filter. The air hose connects the compressor to your tools or equipment, while the pressure regulator allows you to control the pressure. An air filter removes impurities for cleaner operation. It’s important to properly install and connect these accessories according to the manufacturer’s instructions. Doing so ensures the efficient and effective operation of your T10 Air Compressor.

6.Connecting The Compressor To The Power Source

To connect the T10 Air Compressor to a power source, ensure compatibility with the voltage and amperage requirements of the compressor. If necessary, use a high-quality extension cord rated for the appropriate amperage.

Connect one end of the extension cord to the power outlet or generator and the other to the compressor’s power cord. Check all connections for security and damage. Prior to turning on the compressor, confirm proper switch positions and functioning safety features. Finally, start the compressor by flipping the power switch or pressing the start button.

7.Connecting The Air Hose To The Compressor

To connect the air hose to the compressor, start by ensuring that the air hose is clean and free from any debris or obstructions. Locate the air outlet on the compressor and remove the protective cap. Insert the male end of the air hose into the air outlet, creating a secure connection.

If necessary, you can use a wrench to tighten the connection, but be careful not to overtighten and damage the threads. Afterwards, check for any air leaks by running your hand along the connection and feeling for any escaping air. If you detect leaks, simply adjust or re-tighten the connection as needed.

8.Checking The Oil Level And Adjusting The Compression Setting

To set up the T10 Air Compressor, gather the necessary tools: a wrench, oil, and a pressure gauge. Place the compressor on a stable surface. Check the oil level by removing the fill cap and using the dipstick. Add oil if needed. Adjust the compression setting with a wrench to your desired pressure range. Connect an air hose securely to the tank’s outlet port. Plug the power cord into a grounded electrical outlet compatible with your model.

9.Checking The Air Pressure And Adjusting The Discharge Setting

First, ensure the compressor is turned off and disconnected from any power source. Locate the air pressure gauge on the compressor tank and use a tire pressure gauge to check the air pressure. The recommended operating pressure for the T10 Air Compressor is typically between 100-125 PSI. If the air pressure is too low, adjust the discharge setting using an air compressor regulator. Turn on the compressor and monitor the air pressure gauge as you adjust. Check for leaks or abnormal noises once you reach your desired operating pressure.

10.Unpacking The Compressor

To begin setting up your T10 Air Compressor, unpack the compressor and remove any packaging materials. Inspect the compressor for any shipping damage and check all connections and fittings to ensure they are secure and undamaged.

Find a well-ventilated area for the compressor, away from any flammable materials. Place the compressor on a level surface to prevent tipping or instability. Finally, connect the power cord to a grounded outlet, ensuring it is securely plugged in.

11.Connecting The Hoses And Regulators

To connect the hoses and regulators of your T10 Air Compressor, start by attaching the intake air hose to the compressor’s intake port. Next, connect the pressure regulator to the outlet port of the compressor. Then, attach the desired air hose or tool to the other end of the pressure regulator.

Adjust the pressure regulator to the desired PSI for your specific application. Ensure that all connections are tight and secure. Finally, power the air compressor and allow it to build up pressure.

12.Checking The Oil Level

Before beginning the setup process for your T10 Air Compressor, it is essential to check the oil level. Locate the oil fill cap on the top of the compressor and remove it. To determine the oil level, use a dipstick or sight glass, referencing the markings provided.

Ensure that the oil level matches the recommended range indicated. If the oil level is low, add the appropriate type and amount per the manufacturer’s instructions. Once the oil level is corrected, securely replace the oil fill cap. Regularly monitoring and maintaining the proper oil level will contribute to the optimal performance and longevity of your T10 Air Compressor.

13.Setting The Speed And Pressure

Before setting up the T10 Air Compressor, ensure a suitable location with proper ventilation and enough space. Connect the air intake filter to the compressor’s air inlet to prevent dust and debris entry. Then, plug the compressor into a grounded power source using the right electrical cord.

Check the oil level and add oil if necessary, following the manufacturer’s instructions. Adjust the pressure regulator knob for your desired working pressure, controlling the compressed air amount delivered. Finally, set the speed control knob to determine the compressor’s operating speed.

Conclusion

Properly setting up an Ingersoll Rand T10 air compressor is essential for ensuring its optimal performance and longevity. Each step in the setup process, from selecting the right air compressor to connecting hoses and regulators, contributes to the overall functionality of the tool.

It is crucial not to skip any steps or rush through the process, as this can result in damage or subpar performance. For a comprehensive and detailed guide on how to set up your T10 Air Compressor, we invite you to download our comprehensive setup guide now. This guide will provide step-by-step instructions and helpful tips to ensure a successful setup process.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-104b8f19-6986-4019-bb22-776385884160″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.