When painting a car, air compressors play a crucial role in achieving a smooth and precise finish. However, selecting the right size air compressor for your painting project can be daunting, especially for those new to the game.

The size of an air compressor is determined by its horsepower, tank size, airflow rate, and pressure rating. The bigger the compressor, the more powerful it is. But it also has a higher price tag and requires more storage space. For those on a budget or with limited space, finding the minimum size air compressor can be the key to getting the job done effectively and efficiently.

Here, we will explore the minimum size air compressor for painting a car – Compact Power Selecting” We will explore the factors to consider when choosing the right air compressor for painting a car. We will discuss the benefits and drawbacks of small compressors and provide tips for selecting the best one for your needs.

Calculating The Minimum Size Air Compressor For Painting A Car

For painting a car, the minimum size air compressor for painting a car you’ll need depends on the type of paint gun you’re using and the size of the car. Generally, a compressor with a minimum of 3-5 horsepower (HP) and 20-30 gallons tank capacity should suffice for most automotive painting projects.

However, it’s essential to consider your paint gun’s air consumption (CFM) rating and match it with the compressor’s output. Higher CFM requirements may necessitate a larger compressor. Always consult the paint gun and compressor specifications to ensure sufficient air supply for a smooth and efficient painting process.

1.Understanding Air Pressure Requirements For Car Painting

When painting a car, understanding the air pressure requirements is crucial. The air pressure atomises the paint and propels it onto the car’s surface. The minimum size of the air compressor required for painting a car will depend on the type of paint gun used and the job’s size. Generally, a minimum of 5 horsepower (HP) is recommended for most paint guns.

However, higher horsepower compressors may be needed for larger jobs or more advanced painting techniques. It is important to note that the air pressure must also be regulated to ensure consistency and within the recommended range for the specific paint being used. Too much or too little pressure can result in an uneven finish or other issues.

2.Factors To Consider When Choosing An Air Compressor For Car Painting

When it comes to car painting, one of the most important factors to consider is the air compressor you will use. A minimum-size air compressor for painting a car is essential to ensure that you get a professional finish. But what exactly should you look for when choosing the right air compressor for your car painting needs?

- Horsepower and CFM (Cubic Feet per Minute) rating

- Tank size and pressure

- Oil or Oilless compressor

- Noise level

- Portability and size

- Power source

- Type of paint gun being used

- Duty cycle and lifespan

- Cost and budget

3.Types Of Air Compressors Suitable For Car Painting

When you’re looking to paint your car, you must know the types of air compressors suitable for the job. The right type of air compressor can make a significant difference in the quality of your work. For instance, using a compressor that doesn’t meet the required standards may lead to inconsistencies in your paint job. This can be frustrating and time-consuming to fix. By using the right type of air compressor, you can ensure that you achieve a smooth and even finish.

- Reciprocating Air Compressors

- Rotary Screw Compressors

- Scroll Compressors

- Centrifugal Compressors

4.Evaluating Air Compressor Performance For Painting

Evaluating air compressor performance for painting is crucial for achieving a flawless finish. When it comes to painting cars, the size of the air compressor plays a vital role. Choosing the minimum size compressor for painting a car is important.

This is because if you use an air compressor that is too small, it will not be able to provide sufficient airflow, resulting in an uneven finish. On the other hand, using an air compressor that is too big can cause overspray, leading to wasted paint and a messy workspace.

When choosing an air compressor for painting, it’s important to consider the capacity of the air compressor. This is usually measured in cubic feet per minute (CFM). The CFM rating of an air compressor determines how much air it can deliver at a given pressure.

5.Calculating CFM Requirements For Painting A Car

When painting a car, calculating the CFM requirements is crucial to ensure that the job goes smoothly and the finish is flawless. CFM, or cubic feet per minute, refers to how much air an air compressor can provide. You need to consider several factors to determine the minimum size of air for painting a car.

These include the paint gun size, the paint type being used, the air pressure required, and the spray nozzle size. Generally, it would be best to have an air compressor with a CFM rating of at least 6 CFM at 90 PSI for painting a car.

However, this can vary based on the specific requirements of the paint gun and paint being used. It is important to research and consult with experts before purchasing to ensure you choose the right air compressor.

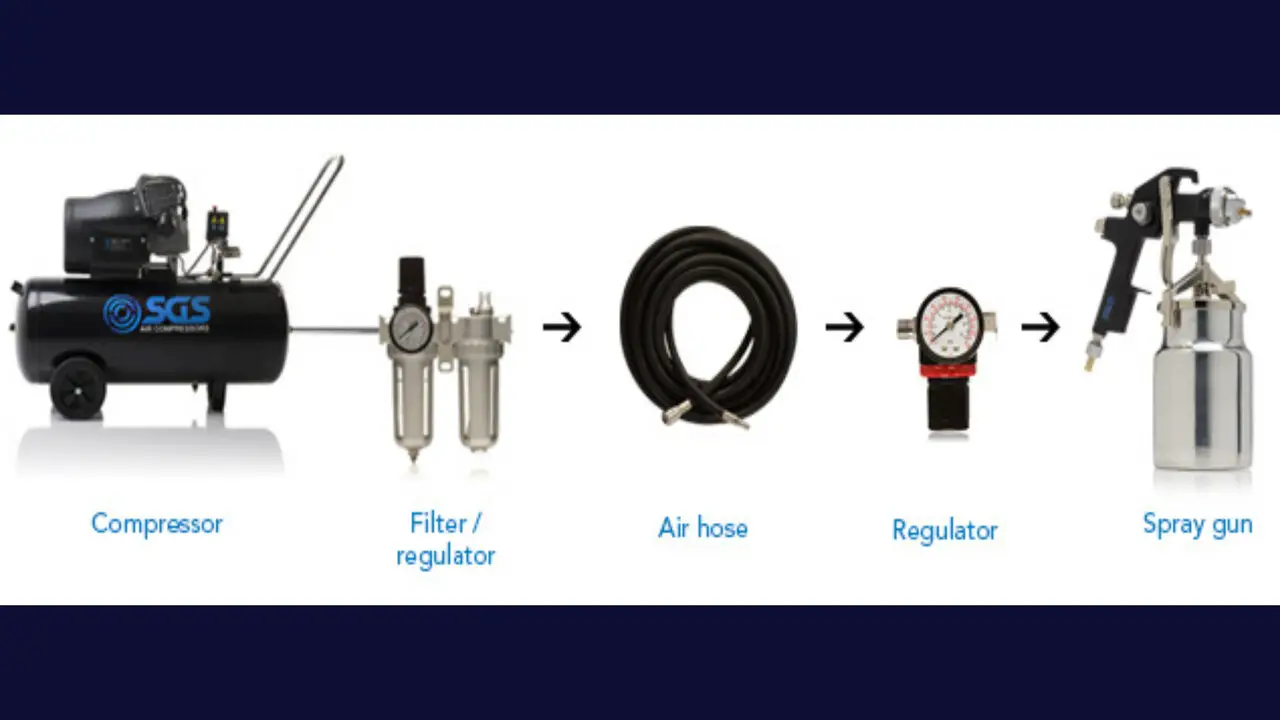

6.Tools And Equipment Necessary For Painting A Car With An Air Compressor

Knowing the tools and equipment necessary for painting a car with an air compressor is essential for achieving professional-looking results. Not only does it save time and money, but it also enhances the overall quality of the finished product. A well-equipped and properly maintained air compressor can provide consistent air pressure, crucial for achieving a smooth and even coat of paint.

- Air compressor with at least 2-3 horsepower and 10-12 CFM

- Spray gun specifically designed for automotive painting

- Air hose with appropriate fittings and connectors

- Paint filters to remove impurities from the paint

- Paint mixing cups and sticks to accurately measure and mix paint

- Sandpaper and sanding blocks of various grits for preparing the car surface

- Masking tape and paper to protect areas not being painted

- Respirator or face mask to protect against paint fumes

- Paint thinner or reducer for cleaning the spray gun and thinning the paint if necessary

- Paint a booth or a well-ventilated area to prevent overspray and ensure proper airflow.

7.Maintaining Your Air Compressor For Optimal Performance

Maintaining your air compressor is crucial for optimal performance and longevity. Neglecting regular maintenance can lead to costly repairs or even the need for replacement. One of the main reasons it is important to know how to maintain your air compressor is to ensure its efficiency.

A well-maintained air compressor will function at its best and use less energy to produce the necessary air pressure, saving you money on energy bills.

- Regularly check the oil level and change the oil as the manufacturer recommends.

- Clean or replace air filters as needed to prevent dust and debris buildup

- Check for leaks in the air compressor system and repair them promptly

- Drain moisture from the air compressor tank regularly to prevent rust and corrosion

- Inspect and maintain belts and hoses for wear and tear

- Lubricate moving parts, such as bearings and pistons, as recommended by the manufacturer

- Keep the air compressor unit clean and free of dust and debris

- Store the air compressor in a dry, cool place when not in use to prevent rust and corrosion.

8.Troubleshooting Common Air Compressor Issues

Knowing how to troubleshoot common air compressor issues is important for several reasons. For one, avoiding unnecessary repairs or replacing the entire unit can save time and money.

Additionally, a malfunctioning air compressor can lead to production delays, impacting a business’s bottom line. Understanding how to diagnose and fix common problems, such as leaks, overheating, or pressure fluctuations, can help keep the compressor operating at peak efficiency, improving productivity and reducing downtime.

- The air compressor won’t start: check the power supply, pressure switch, and motor capacitor.

- Air compressor runs but doesn’t build pressure: check for leaks, clogged air filters, and worn piston rings or valves.

- Air compressor trips the circuit breaker: check for the overloaded circuit, faulty pressure switch, or a malfunctioning motor.

- Air compressor produces low pressure: check for a dirty air filter, leaking hoses, or inadequate pressure regulator setting.

- Air compressor produces excessive noise: check for loose parts, worn bearings, or inadequate lubrication.

- Air compressor pumps oil into the compressed air: check for worn piston rings or damaged cylinder wall, and replace necessary parts.

- Air compressor runs continuously: check for a faulty pressure switch or leaking check valve, and replace if required.

- Air compressor vibrates excessively: check for level and stability of the compressor, worn motor mounts, or damaged pulley or belt.

9.Tips And Tricks For Successful Car Painting With An Air Compressor

Knowing tips and tricks for successful car painting with an air compressor is crucial for those who want professional results. First and foremost, paint jobs can be costly and time-consuming, so having the right knowledge and tools can save time and money. Additionally, a poorly executed paint job can negatively impact the value of your car, so it’s important to do it right the first time.

- Choose the air compressor with enough power and capacity to handle the spray gun and paint requirements.

- Ensure the compressor is clean and well-maintained, with no oil or water contaminants that could ruin the paint job.

- Use a high-quality spray gun with a properly adjusted fan width, fluid flow, and air pressure for the type of paint and surface being painted.

- Practice on a test panel or scrap piece of metal before painting the car to get a feel for the spray gun and the paint flow.

- Apply several thin coats of paint, allowing each coat to dry completely before applying the next one.

- Sand lightly between coats with fine-grit sandpaper or a sanding block to smooth out imperfections or bumps.

- Use a clear coat to protect the paint and give it a glossy finish, applying it like the paint coats.

Conclusion

It’s time to unleash the artist in you and give your car a new paint job. But before you start, ensure you have the right air compressor to complete the job. With the Compact Power Selecting guide, you can easily choose the minimum size air compressor for painting a car. A compact and powerful air compressor is essential to ensure you don’t get a sloppy paint job.

The right air compressor will help you achieve the perfect finish you are looking for. So it’s important to choose the correct size for the job. A minimum-size air compressor powerful enough to paint a car should have a minimum of 5 horsepower and deliver at least 3 to 4 cubic feet of air per minute. Get the right tool for the job and let your creativity run wild.

FAQ

[rank_math_rich_snippet id=”s-32201379-30bf-46f6-b8d8-0ae32360096a”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.