An air compressor is a device that converts power into potential energy stored in pressurized air. Widely used in construction and automotive repair industries, they draw air into a storage tank and pressurize it for various applications, such as powering tools and equipment.

If you’re a professional or DIY enthusiast who works with air compressors, you know how important it is to have the right tools for the job. Here we’ll provide an overview of the Pro 4000 air compressor and explain why knowing how to use it properly is important.

We’ll also walk you through a step-by-step guide on setting up, operating, and maintaining the Pro 4000. Plus, we’ll share some troubleshooting tips for common issues that may arise. So whether you’re new to air compressors or want to brush up on your skills, this expert advice will ensure you get the most out of your Pro 4000-Air Compressor.

Understanding Pro 4000-Air Compressor: An Overview

The Pro 4000 Compressor is a versatile and powerful tool in various industries. Familiarize yourself with its components, features, operating procedures, and safety precautions for optimal use. Maintenance and troubleshooting tips can help you maintain its performance.

For expert advice on maximizing efficiency and longevity, consult professionals with extensive experience using this equipment. They can provide valuable insights to avoid common pitfalls and achieve desired results in your projects.

Step-By-Step Guide For Using Pro 4000 Air Compressor

To ensure safety and prevent damage, it’s crucial to understand how to use the Pro 4000 Air compressor correctly. Following operating procedures and troubleshooting common issues can protect yourself, extend the compressor’s lifespan, and save time and money.

Proper maintenance is vital for optimizing the compressor’s performance and efficiency. Regularly inspecting, cleaning, checking parts, replacing as needed, and lubricating moving components will improve productivity and benefit industries relying on the Pro 4000-air compressor.

Seeking expert advice on using the Pro 4000-air compressor can provide invaluable insights and tips for maximizing its potential. From optimal pressure settings to best practices for specific applications, expert guidance can help you maximise your equipment. Here are step by

1.Setting Up The Pro 4000-Air Compressor

Choose a stable and well-ventilated location to set up the Pro 4000 air compressor. Place the compressor on a stable surface. Connect it to a power source, ensuring it is turned off before plugging it in. Check and maintain the oil level following the manufacturer’s instructions.

Attach an air hose securely to the outlet valve, preventing air leakage. Adjust the pressure regulator according to your task’s requirements. Turn on the air compressor and wait for it to reach maximum pressure before using it for your applications.

2.Operating The Pro 4000 Air-Compressor

To operate the Pro 4000 Air-Compressor, familiarise yourself with its components. These include the pressure gauge, on/off switch, and air hose connections. Before powering up the compressor, ensure that it is placed on a stable surface and that all connections are secure.

Don’t forget to check the oil level and add more if needed, following the manufacturer’s instructions for the specific type of oil required. Once everything is set up, plug in the compressor and turn on the power switch.

The motor should start running. Adjust the pressure regulator knob to set your desired PSI, which will determine the amount of pressure the compressor generates. Simply attach the air hose to the compressor to connect tools or accessories.

3.Maintenance And Care Tips

Regular maintenance is crucial for the proper functioning of your Pro 4000-Air Compressor. Check the oil level and add more to ensure optimal performance. Additionally, it is important to clean or replace the air filter regularly to maintain optimal airflow. Take the time to inspect and tighten any loose bolts or fittings to prevent potential issues.

Another important maintenance aspect is draining any accumulated moisture from the tank to prevent corrosion. Lastly, lubricate the moving parts, such as pistons and valves, to reduce friction and extend their lifespan. By following these maintenance and care tips, you can ensure that your Pro 4000-Air Compressor operates smoothly for years.

4.Troubleshooting Common Issues

Before using the Pro 4000-Air Compressor, ensure it is properly assembled and all connections secure. Check the oil level in the compressor and add oil if needed. Turn on the power switch and allow the compressor to build up pressure until it reaches the desired level.

Attach the air hose to the compressor and connect the other end to your desired tool or equipment. Adjust the pressure regulator to the appropriate level for your task. Start using the tool or equipment connected to the air compressor, following safety guidelines and precautions.

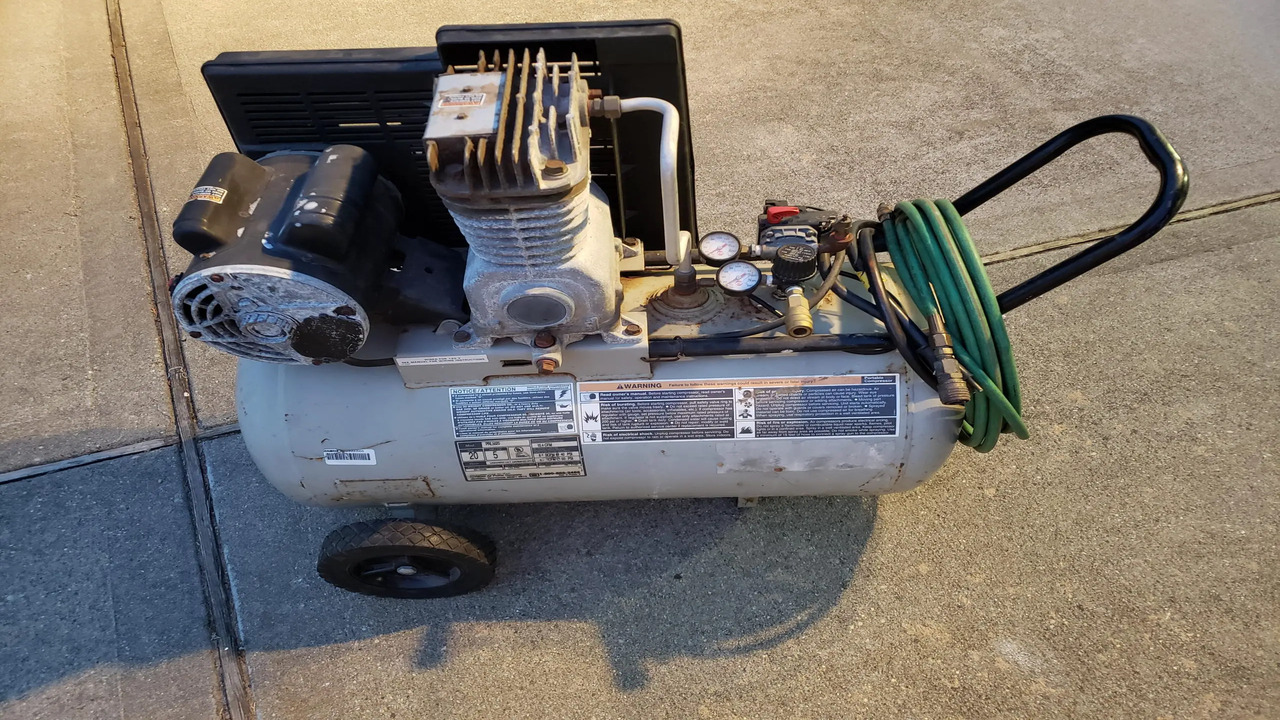

5.Types Of Air Compressors

Various air compressors are available in the market, each designed for specific purposes. One common type is the reciprocating air compressor, which uses a piston and cylinder to compress air. Another type is the rotary screw air compressor, which utilizes two rotating screws to compress the air. Centrifugal air compressors, on the other hand, employ a rotating impeller to create high-speed airflow, which is then compressed.

For those who require portability, there are portable air compressors that are compact and lightweight, making them easy to transport and use on the go. On the contrary, stationary air compressors are larger and fixed units, ideal for heavy-duty industrial applications. Lastly, there are oil-lubricated and oil-free air compressors. While oil-lubricated compressors require regular oil changes, they may not be suitable for applications that demand clean, oil-free air.

How To Troubleshoot Common Air Compressor Issues

When using the Pro 4000-Air Compressor, be aware of common issues that may arise. Troubleshoot by checking for leaks, maintaining proper oil levels and cleaning air filters. Inspect and clean the pressure switch and relief valve.

Address motor or compressor overheating promptly to avoid damage. Low air pressure or slow performance may indicate valve, fitting, or compressor problems. Regular maintenance and servicing prevent future issues. Follow these steps for smooth operation and a longer lifespan of your Pro 4000-Air Compressor.

Guidelines For Selecting The Right Air Compressor

To choose the right air compressor, determine your specific needs. Consider factors like power source, portability, capacity, and pressure output. Look for features such as noise reduction and safety measures.

Research and compare brands and models, consult experts and consider warranties, shipping options, and payment methods. Follow these guidelines to confidently select a compressor that meets your needs while prioritizing safety. Understand proper operation and maintenance for reliable performance and durability.

Safe Use Of Accessories And Tools With An Air Compressor

When using an air compressor, prioritize safety by following the manufacturer’s instructions and guidelines. Choose appropriate accessories and tools for your specific model. Regularly inspect and maintain them. Use proper safety equipment like goggles and gloves. Avoid overloading the compressor. Store and secure accessories properly when not in use. You can safely use the Devilbiss Pro 4000-Air Compressor by following these measures.

How Does The Simplifying Pro 4000-Air Compressor Work?

The Simplifying Pro 4000-Air Compressor utilizes a piston-cylinder mechanism. When the motor is activated, it drives the piston back and forth within the cylinder, creating a vacuum on one side. This draws in air from the atmosphere, which is then compressed and stored in a tank for future use.

Conclusion

The Pro 4000 air compressor is an incredibly powerful tool that can streamline work and enhance productivity. To maximize its potential, it is important to familiarize yourself with its features and follow the step-by-step usage guide for safe and efficient operation.

Regular maintenance and proper care are crucial for extending the lifespan of your air compressor and addressing any common issues that may arise. It is essential to choose the right air compressor for your specific requirements and always prioritize safety when using accessories and tools. For further insights on effectively utilising the Simplifying Pro 4000-Air Compressor and optimising its functionality.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-2e5c7268-7ad1-4859-a623-c632ebb9bcfc”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.