Stump grinders have become essential for any arborist or landscaper looking to remove tree stumps efficiently. Among the top brands in the market, Crary Bear Cat’s stump grinders are known for their durability and high performance. However, like any other machine, the carbide teeth on these grinders will eventually wear out with heavy use. Replacing these teeth is a crucial maintenance task that ensures the grinder functions optimally. Doing so improves the grinder’s efficiency and extends its lifespan, saving you money on costly repairs or replacements.

Here, we will guide you through the simple steps of replacing the carbide teeth on your Crary Bear Cat stump grinder and provide tips on maintaining them to ensure a smooth and effective grinding experience. So, let’s dive in and learn how to keep your Crary Bear Cat stump grinder in top shape.

Tools and equipment needed for the replacement process

Replacing the carbide teeth on a Crary Bear Cat Stump Grinder requires specific tools and equipment. Gathering these tools and equipment beforehand ensures a smooth and efficient replacement process for your Crary Bear Cat stump grinder’s carbide teeth. Protecting your eyes and hands during the replacement process is important. Here is a list of what you will need for the replacement process:

- Safety goggles and gloves

- Wrenches

- Socket set

- Hammer

- Torque wrench

- Grease gun

Step-by-Step Processes To Replace Carbide Teeth on Crary Bear Cat Stump Grinder

Discover the features and benefits of the Crary Bear Cat stump grinder, which stands out from other models with its ergonomic handlebar, compact design, and best-in-class warranty. Professionals choose this powerful, operator-friendly grinder for its 10-gauge steel body, easy-access belt inspection, and efficient chip removal. Replacing carbide teeth on a Crary Bear Cat stump grinder can be done with a few simple steps. Here is a step-by-step guide on how to replace carbide teeth on a crary bear cat stump grinder.

Prepare the stump grinder.

Before replacing carbide teeth on a stump grinder, it is important to prepare the machine properly. Start by ensuring the stump grinder turns off and disconnects from any power source. Clear away any debris or obstructions around the machine to create a safe and clean work area. Next, gather all the necessary tools and replacement carbide teeth that you will need for the job. A wrench, socket set, and safety gloves can be helpful. Finally, carefully inspect the stump grinder for any signs of damage or wear that must be addressed before replacing the teeth. By preparing the stump grinder, you can ensure a smooth and efficient tooth replacement process.

Remove the old teeth.

The second step is to remove the old teeth when replacing carbide teeth. Start by disconnecting the power source and securing the machine to prevent accidents. Use a wrench or socket set to loosen the bolts that hold the old teeth in place. Once the bolts are loosened, carefully remove the old teeth from their holders. It is important to handle them with care to avoid any injuries or damage to the teeth or machine. Once all the old teeth have been removed, you can install the new ones following the manufacturer’s instructions.

Clean the mounting area.

Before replacing carbide teeth, cleaning the mounting area thoroughly is important. This will ensure a proper fit and prevent debris or dirt from interfering with the replacement process. Removing loose material or dust from the mounting area using a brush or compressed air. Next, use a cleaning solution for carbide teeth to remove grease or residue. Apply the cleaning solution to a cloth and gently wipe down the mounting area, removing any buildup or contaminants. Once the area is clean and dry, you can replace the carbide teeth according to the manufacturer’s instructions.

Install the new teeth.

Installing the new carbide teeth is the final step in replacing them. To begin, carefully align the new teeth with the mounting holes on the cutting tool. Make sure they are positioned correctly and securely in place. Next, tighten the bolts or screws to secure the teeth firmly. Use a torque wrench to ensure they are tightened to the manufacturer’s recommended specifications. Before using the cutting tool, double-check to install and tighten all teeth properly. It is important to follow all safety guidelines and instructions provided by the manufacturer during this process to ensure proper installation and avoid any accidents or damage to the equipment.

Test and adjust

Testing and adjusting is an important step in replacing carbide teeth. Once you have installed the new teeth, testing their performance and making necessary adjustments is crucial. Start by running the machine slowly and observe how the new teeth are cutting. Pay attention to the quality of the cut, the noise level, and any vibrations or wobbling. You may need to adjust if you notice any issues, such as uneven cuts or excessive vibrations. This can include adjusting the position of the teeth, tightening or loosening bolts, or changing the machine settings. By testing and adjusting the new carbide teeth, you can ensure that they are properly installed and performing optimally for your specific needs.

Importance of Carbide Teeth in a Stump Grinder

Carbide teeth play a crucial role in the performance of a stump grinder. These teeth come from a hard and durable material called carbide, which allows them to grind through tough tree stumps effectively. The sharpness and strength of the carbide teeth ensure that the grinder can efficiently remove stumps without dulling or breaking. By maintaining the quality of the carbide teeth, you can ensure that your Crary Bear Cat Stump Grinder continues to deliver high-performance results. Regularly inspecting the condition of the teeth and replacing them when necessary is essential for optimal grinding performance and prolonging the lifespan of your stump grinder.

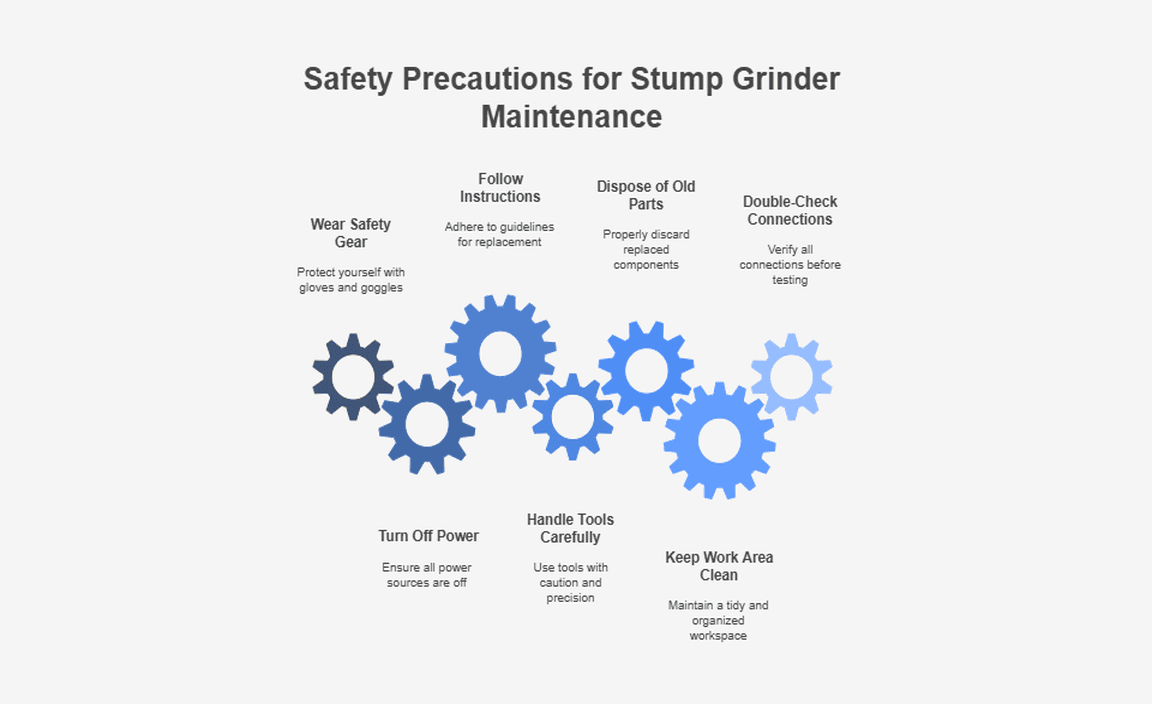

Safety precautions to take during the replacement process

The reliable stump grinder will be ready for action when replacing carbide teeth on the Crary Bear Cat Stump Grinder. With the engine power to tackle tough jobs, power users will appreciate the thickest rotor durability. Whether you’re a weekend warrior or a professional user, the grinder’s performance will not disappoint, making stump grinding tasks efficient and effective. Here are some tips to keep in mind:

- Wear appropriate safety gear (gloves, goggles, etc.)

- Turn off power sources before starting the replacement

- Follow proper instructions and guidelines

- Handle tools and equipment carefully

- Dispose of old parts properly

- Keep the work area clean and organized

- Double-check connections and fittings before testing

Where to purchase replacement carbide teeth for the Crary Bear Cat Stump Grinder

When replacing carbide teeth on your Crary Bear Cat Stump Grinder, knowing where to purchase the replacement teeth is important. Fortunately, there are several options available for buying these essential parts. One option is to contact the manufacturer directly, as they often sell replacement parts for their equipment. Another option is to check with local dealers or distributors specializing in stump grinders and related equipment. Additionally, online retailers and marketplaces can be a convenient source for purchasing replacement carbide teeth. Just compare prices and read customer reviews before purchasing to ensure you get the best quality and value.

How Long Do Cutting Teeth Typically Last?

The lifespan of carbide cutting teeth on a Crary Bear Cat stump grinder can vary depending on several factors, such as the type of wood being ground and the frequency of use. Carbide teeth typically last between 20 to 40 hours of grinding before requiring replacement. However, it is important to regularly inspect the teeth for signs of wear and damage, as worn or damaged teeth can affect the performance and efficiency of the stump grinder. If you notice that the cutting teeth are becoming dull or chipped, replace them promptly to ensure optimal performance and prolong the lifespan of your equipment.

Common mistakes to avoid when replacing carbide teeth

Maintenance of your Crary Bear Cat Stump Grinder: one crucial task is removing stumps and replacing carbide teeth. Ensuring your equipment is in top condition benefits your work’s efficiency and contributes to the overall aesthetic of your yard. With a well-maintained stump grinder, you can enjoy beautiful yards without the hassle of stubborn tree remnants. The knife source for your grinder is essential for precision and effectiveness in grinding operations, guaranteeing a smooth and clean finish. Here are some tips to help you avoid these mistakes:

- Not properly aligning the teeth during replacement

- Using incorrect tools or equipment for the replacement process

- Omitting the step of checking and adjusting the tension of the teeth

- Neglecting to clean and inspect the mounting area before installation

- Failing to follow the manufacturer’s guidelines or instructions

Proper maintenance and care tips for the new carbide teeth

The centrifugal clutch is vital in the grinder’s operation, providing power and control during use. To enhance user experience and prolong the lifespan of your equipment, a reliable filter system powers the grinder, ensuring that it functions optimally and efficiently. By prioritizing these maintenance tasks and components, you can maximize the performance of your Crary Bear Cat Stump Grinder and achieve superior results in your stump removal projects. Here are some tips to help you maintain and care for your new carbide teeth:

- Clean carbide teeth regularly to prevent debris buildup

- Store carbide teeth in a dry and cool place when not in use

- Check for any signs of wear and tear on carbide teeth

- Avoid using damaged carbide teeth to prevent accidents

- Follow the manufacturer’s guidelines for maintenance and care of carbide teeth

Frequently Asked Questions

How do you replace a stump grinder tooth?

To replace a stump grinder tooth, loosen the nut that secures it using a wrench. Slide out the old tooth and slide in the new one, ensuring the cutting edge is facing outward.

Can you sharpen carbide stump grinder teeth?

Carbide stump grinder teeth are extremely hard and brittle and cannot be sharpened. Once they become dull, they need to be replaced with new teeth.

How often should you change stump grinder teeth?

Stump grinder teeth should typically be changed or sharpened every 8-10 hours to maintain optimal performance and efficiency. Regular maintenance of stump grinder teeth is essential to ensure smooth operation and prevent damage to the equipment.

What can I use to sharpen my carbide teeth?

You can use a diamond file or wheel specifically designed for sharpening carbide tools to sharpen carbide teeth. These tools are more effective in sharpening carbide teeth than traditional sharpening stones or files due to the hardness of carbide.

What material sharpens carbide?

Diamond is the material that is commonly used to sharpen carbide due to its hardness and ability to grind and sharpen the tough carbide material effectively.

Conclusion

Replacing the carbide teeth on your Crary Bear Cat Stump Grinder is an essential maintenance task that ensures optimal performance and prolongs the lifespan of your machine. Following the step-by-step guide on carbide teeth on a carry bear cat stump grinder, you can easily replace the carbide teeth and return to grinding stumps effectively. It is important to prioritize safety during the replacement process and adhere to all recommended precautions. Additionally, purchase replacement carbide teeth from a reliable source to ensure their quality and compatibility with your stump grinder. Remember to avoid common mistakes and regularly inspect and clean the teeth to keep them in the best condition possible.

Resource:

tree equipment maintenance tips: https://www.tcia.org/TCIA/Resources/Safety/Electrical-Hazards/Equipment-Maintenance.aspx

tool safety guidelines: https://www.osha.gov/hand-power-tools

choosing the right grinding tools: https://www.finewoodworking.com/2020/04/23/the-right-grinder-for-the-job

properties of tungsten carbide: https://www.sciencedirect.com/topics/materials-science/tungsten-carbide

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.