If you’re a professional who spends long hours in a workshop or garage, you know the importance of a quiet and peaceful work environment.

Unfortunately, an air compressor is one of the noisiest tools that can disrupt concentration and productivity. An air compressor’s loud and constant noise can significantly distract and even impact your hearing. Soundproofing your air compressor box is necessary to eliminate this problem and create a more comfortable work atmosphere. But where do you start?

Here we will walk you through soundproof air compressor box and provide step-by-step guidance on how to get the job done right. Whether you’re a professional contractor or a do-it-yourself enthusiast, we’ve covered you with all the tips and tricks you need to transform your noisy workshop into a peaceful and productive space.

Materials You’ll Need

- Plywood or MDF boards

- Mass-loaded vinyl (MLV) or soundproofing blankets

- Acoustic foam or fiberglass panels

- Green glue (sound-damping compound)

- Caulk or weatherstripping

- Screws and nails

- Hinges and latches (for the access door)

- Screwdriver and/or drill

- Soundproofing sealant

9 Ideas To Build Soundproof Air Compressor Box Step-By-Step Process

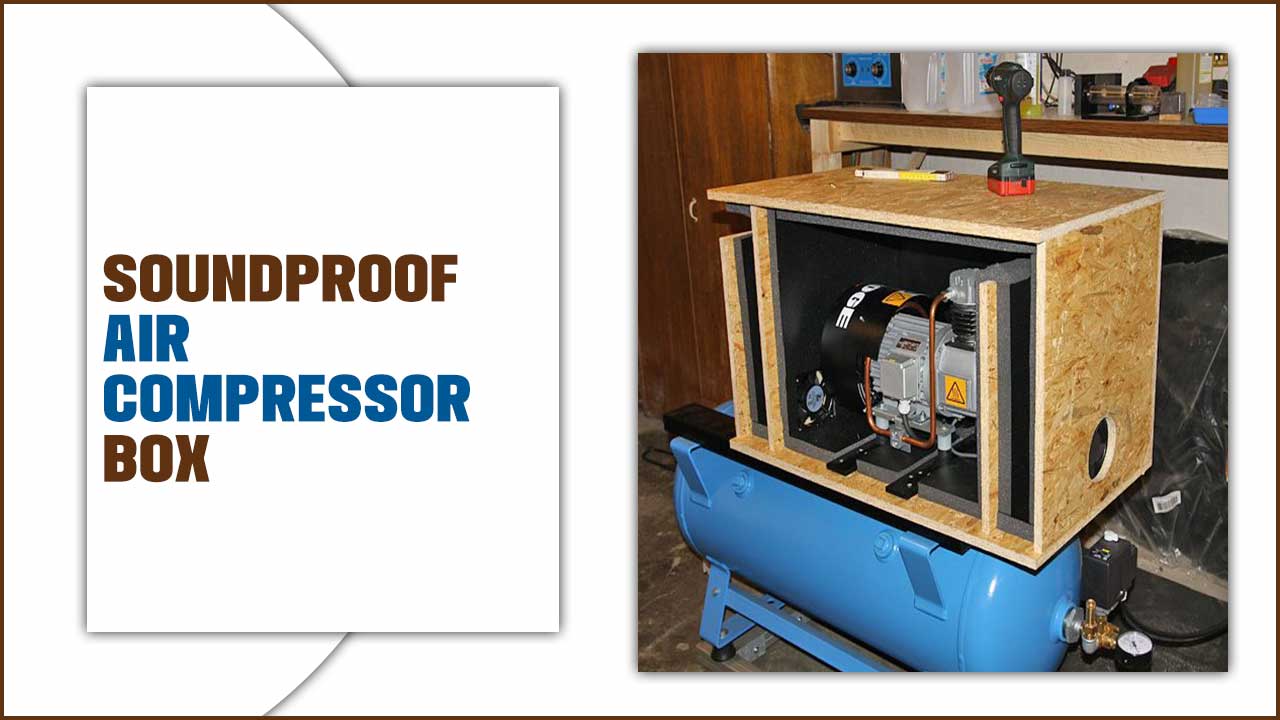

A soundproof air compressor box is an enclosure designed to reduce the noise generated by an air compressor. It typically consists of sound-absorbing materials like foam or insulation that dampen the compressor’s vibrations and absorb sound waves. The box’s construction prevents noise from escaping, making it ideal for noise-sensitive environments or residential areas.

Controlling the noise within the box minimizes disruptions and promotes a quieter workspace. Additionally, these enclosures often feature ventilation to prevent overheating while maintaining efficiency. Using a soundproof compressor box improves overall comfort, safety, and productivity in various settings that require compressed air applications. Read below to know more.

1.Measure And Design The Box

Several key steps are essential to measure and design a soundproof compressor box to ensure effective noise reduction. Firstly, conduct a noise assessment to determine the compressor’s sound levels and frequency components. This data will aid in understanding the extent of noise reduction needed.

Next, choose appropriate soundproofing materials like mass-loaded vinyl, foam insulation, and acoustic panels to absorb and block sound. Ensure these materials have high Sound Transmission Class (STC) and Noise Reduction Coefficient (NRC) ratings.

2.Construct The Box Frame

Constructing a box frame soundproof air compressor involves building a sturdy enclosure to reduce noise levels and provide a quieter working environment. To line the interior, start by selecting thick plywood or MDF for the walls and dense soundproofing material, such as mass-loaded vinyl or foam. Assemble the box frame with precise measurements, ensuring a tight fit to prevent sound leakage.

3.Line The Inside Of The Box

Several methods can be employed to soundproof the inside of an air compressor box. First, use acoustic foam or sound-absorbing materials to line the interior surfaces. These materials dampen sound waves and prevent them from bouncing around the enclosure. Additionally, ensure a tight and well-sealed construction to minimize sound leakage.

Consider installing noise-isolating barriers, such as mass-loaded vinyl or resilient mounts, to further block sound transmission. These barriers will act as a buffer between the compressor and its surroundings.

4.Add Acoustic Foam Or Fiberglass Panels

Adding acoustic foam or fiberglass panels to soundproof an air compressor box can significantly reduce noise levels. These materials effectively absorb and dampen sound waves, preventing them from escaping the enclosure and minimizing noise pollution in the surrounding area.

The acoustic foam absorbs sound energy with its porous structure, while fiberglass panels trap sound through their dense and fibrous composition. Combining both materials can lead to better results.

5.Use Green Glue

Using Green Glue to soundproof an air compressor box can be an effective solution for reducing noise transmission. Green Glue is a viscoelastic compound designed to dampen sound vibrations and dissipate them as heat, making it an excellent soundproofing material.

To use Green Glue for soundproofing, apply it between layers of drywall or other suitable soundproofing materials while constructing the compressor box. The compound’s unique properties help break the soundwave transmission path, preventing noise from escaping the enclosure.

6.Seal Gaps And Joints

Several techniques can be employed to soundproof an air compressor box and effectively seal gaps and joints. First, use high-quality acoustic insulation material to line the interior walls of the box, reducing sound transmission. Next, seal gaps or openings with weatherst ripping or acoustic caulk to prevent sound leakage.

Choose a sturdy box material like heavy-duty plywood or MDF for optimum sound reduction, minimizing vibrations and resonance. Additionally, consider installing anti-vibration pads beneath the compressor to reduce noise further.

7.Construct An Access Door

Constructing an access door for a soundproof compressor box is essential to ensure ease of maintenance while maintaining effective noise reduction. Choose high-quality sound-absorbing materials like acoustic foam or mass-loaded vinyl to line the box’s inner walls. The access door should be made of sturdy, soundproof materials, such as medium-density fiberboard (MDF) or soundproofed plywood.

8.Ventilation Considerations

When designing an air compressor box, ventilation considerations are crucial to maintaining effective cooling and noise reduction. A balance must be struck between adequate airflow to prevent overheating and soundproofing measures to minimize noise emissions.

Firstly, opt for sound-absorbing materials to line the interior walls of the box. This helps dampen the noise produced by the compressor. Additionally, seal any gaps or openings to prevent sound leakage.

Regarding ventilation, incorporate a system that allows sufficient airflow without compromising soundproofing efforts. Use acoustic air vents with baffles or insulated ducting to mitigate sound transmission. Implement a fan or blower with low noise levels strategically positioned to optimize cooling efficiency.

9.Test The Box

Testing the soundproof air compressor-box involves evaluating its effectiveness in reducing noise generated by the compressor. The process includes several steps to ensure its functionality and performance. Firstly, conduct baseline noise measurements of the compressor without the box to establish a reference. Then, place the compressor inside the soundproof box and run it at different load levels.

Maintenance And Cleaning Tips For A Soundproof-Air Compressor Box

Proper maintenance and cleaning of a soundproof compressor box are crucial to ensure its longevity and optimal performance. By following these maintenance and cleaning tips, you can extend the lifespan of your air compressor box and ensure it continues to operate efficiently and effectively. Here are some tips to help you maintain and clean your soundproof compressor box:

- Regularly inspect the box for any signs of damage or wear. Look for cracks, loose fittings, or any other issues that may affect the functionality of the box.

- Clean the exterior of the box regularly to remove dust, dirt, and debris. Use a soft cloth or sponge dampened with mild soap and water to gently wipe the surfaces. Avoid using abrasive cleaners or harsh chemicals that may damage the soundproofing materials.

- Check and clean the air filters regularly to prevent dust and debris from clogging them. Follow the manufacturer’s instructions for removing and cleaning the filters properly.

- Inspect the ventilation system of the box to ensure proper airflow. Clear any obstructions such as leaves or debris that may hinder the airflow.

- Lubricate moving parts, such as hinges or latches, as recommended by the manufacturer to ensure smooth operation.

- Schedule regular professional inspections and maintenance checks to identify any potential issues before they become major problems.

Alternatives To Building A DIY Soundproof Box For Your Air Compressor

Building a DIY soundproof box for your air compressor can be a time-consuming and challenging task. If you’re looking for alternatives. While these alternatives may help in reducing noise levels, they may not provide as effective noise reduction as a dedicated soundproof box. It’s important to choose an option that suits your specific needs and budget. Here are some tips to help reduce the noise generated by your air compressor without constructing a soundproof box:

- Relocate the compressor: Consider moving your air compressor to a more isolated area, such as a basement or garage, to minimize the noise impact on your living or working space.

- Use anti-vibration pads: Placing anti-vibration pads underneath the air compressor can help absorb and dampen the vibrations that contribute to noise.

- Install soundproof curtains: Hang soundproof curtains around the area where your air compressor is located. These curtains are designed to absorb sound waves and reduce noise levels.

- Insulate walls and ceilings: Adding insulation materials like acoustic foam or mass-loaded vinyl to the walls and ceilings surrounding your air compressor can help block and absorb sound waves.

- Use noise-reducing accessories: Consider using accessories like mufflers or silencers specifically designed for air compressors. These devices can help reduce noise by decreasing airflow turbulence.

Conclusion

With these effective soundproofing techniques, you can now enjoy a peaceful working environment without the constant noise disturbance from your air compressor. Whether you build soundproof air compressor box-absorbing materials, there is a solution for everyone.

Investing a little time and effort into soundproofing can make a big difference in your work’s quality and overall well-being. Ensure the area is well-ventilated and away from other noises interfering with your peace and quiet. So, let’s get to it and say goodbye to noisy air compressors once and for all.

FAQ

[rank_math_rich_snippet id=”s-753d8b34-632d-46f9-a4c8-b1d6fbba2a9a”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.