Air compressors are essential tools with many applications, from powering pneumatic tools to inflating tires. However, one of the most common issues that users encounter with air compressors is rapid pressure loss.

When an air compressor loses pressure quickly, it can be frustrating and even dangerous if used for power tools that require consistent air pressure. Here we will dive into why an air compressor- loses pressure quickly and provide practical solutions to address each issue.

From checking for air leaks in the system to examining the pressure switch and valve, we’ve got you covered. We’ll also discuss troubleshooting tips for specific types of air compressors and when to consult a professional for repairs or maintenance.

Identify The Reasons Why An Air Compressor Loses Pressure Quickly

There are several reasons why an air compressor may lose pressure quickly. First, check for leaks in the air compressor system, including hoses, fittings, and valves. Worn-out parts such as piston rings or valve plates can also lead to a drop in pressure over time.

Inadequate maintenance, such as neglecting to clean, lubricate, and change filters, can affect the air compressor’s performance. Incorrect pressure settings should also be considered, as ensuring proper adjustment is crucial for optimal output. Additionally, overuse or overheating can cause a decrease in pressure, as can using an air compressor that is not properly sized for the intended application.

Common Causes Of Air Compressor Pressure Loss

Leaks in the air compressor system can result in rapid pressure loss, compromising efficiency. Worn-out or damaged seals and gaskets may contribute to the problem. Inadequate maintenance, such as dirty filters or insufficient lubrication, can negatively impact the compressor’s performance and lead to pressure drop.

Faulty pressure regulators or control valves can also cause pressure loss and affect airflow. Additionally, incorrectly sized or worn-out hoses and fittings may result in air leaks and further exacerbate the pressure drop. Proper maintenance and regular checks can help prevent these common causes of air compressor pressure loss.

Check For Air Leaks In The System

If your air compressor is losing pressure quickly, one possible cause could be air leaks. Air leaks can occur at various points in the compressor, such as hoses, fittings, or connections. These leaks can result in a loss of pressure and reduced efficiency. To check for air leaks, you can perform a simple visual inspection of the system, looking for any obvious signs of leakage, such as hissing sounds or visible escaping air.

Additionally, you can use a soapy water solution to spray on potential leak points and look for bubbles forming, indicating the presence of a leak. If you do find any leaks, they should be repaired or replaced promptly to ensure optimal performance and prevent further pressure loss.

Examine The Pressure Switch And Valve.

Examining the pressure switch and valve is important when troubleshooting why an air compressor loses pressure quickly. The pressure switch may be faulty, leading to improper sensing of the tank pressure. Additionally, a leaking valve on the tank can cause air to escape, resulting in reduced pressure.

Dirt or debris blocking the valve can also prevent it from closing fully. Another possible issue could be that the pressure switch is set too low, causing the compressor to shut off prematurely. Regular maintenance and inspection of the pressure switch and valve can help identify and fix any issues.

Inspect The Air Hoses And Fittings For Damage Or Blockages

If your air compressor is losing pressure quickly, there are a few potential causes to consider. Damaged or worn-out air hoses and fittings are one common culprit. Over time, these components can develop cracks, leaks, or other damage that can cause air to escape and pressure loss.

Inspect your air hoses and fittings carefully for any signs of damage, such as visible cracks, loose connections, or leaks. If you notice any issues, it may be necessary to replace the damaged components to restore proper functionality and prevent further pressure loss. Additionally, ensure all connections are tight and secure to minimize potential air leakage. Regular maintenance and inspection of your air compressor’s hoses and fittings can help ensure optimal performance and prevent pressure loss.

Clean Or Replace The Air Filter

If your air compressor is losing pressure quickly, one possible cause could be a dirty or clogged air filter. The air filter plays a crucial role in preventing dust, debris, and other contaminants from entering the compressor and affecting its performance. Over time, the air filter can become clogged with dirt and debris, restricting the airflow and causing the compressor to lose pressure.

To address this issue, cleaning or replacing the air filter regularly is recommended. Cleaning the air filter involves removing it from the compressor and gently tapping it to remove any loose debris. If the filter is heavily clogged or damaged, it may need to be replaced with a new one. Maintaining a clean and functioning air filter can help ensure optimal performance and prevent pressure loss in your air compressor.

Check The Compressor Oil Level And Condition.

Regularly checking the level and condition of compressor oil is crucial for maintaining optimal pressure in your air compressor. Low oil levels or dirty oil can lead to friction and overheating, resulting in pressure loss. Additionally, dirty or contaminated oil can clog the system and affect the compressor’s performance.

Adequate lubrication is essential for smooth operation and preventing leaks that may cause pressure loss. By conducting regular oil changes and practising proper maintenance, you can help prevent pressure loss in your air compressor.

Adjust The Pressure Regulator If Necessary

If your air compressor is losing pressure quickly, there are a few potential causes to consider. One common issue is a problem with the pressure regulator. The pressure regulator controls the amount of pressure released from the compressor tank, and if it is not set correctly, it can cause the compressor to lose pressure rapidly.

To address this issue, you may need to adjust the pressure regulator to ensure it is set at the appropriate level for your desired air pressure. Consult your air compressor’s manual or contact a professional if you are unsure how to adjust the pressure regulator properly.

Consider The Size And Capacity Of The Compressor Compared To Your Needs

When your air compressor loses pressure -quickly, it is important to consider the size and capacity of the compressor. If you are using a small, portable compressor for tasks that require a high volume of air, such as powering pneumatic tools or filling up large tires, it may not have the capacity to maintain pressure for extended periods of time.

You may need to invest in a larger compressor with a higher CFM (cubic feet per minute) rating to meet your specific needs. Additionally, check for any leaks in the airlines or fittings that could be causing the loss of pressure. Regular maintenance and proper air compressor usage can help ensure optimal performance and prevent any issues with pressure loss.

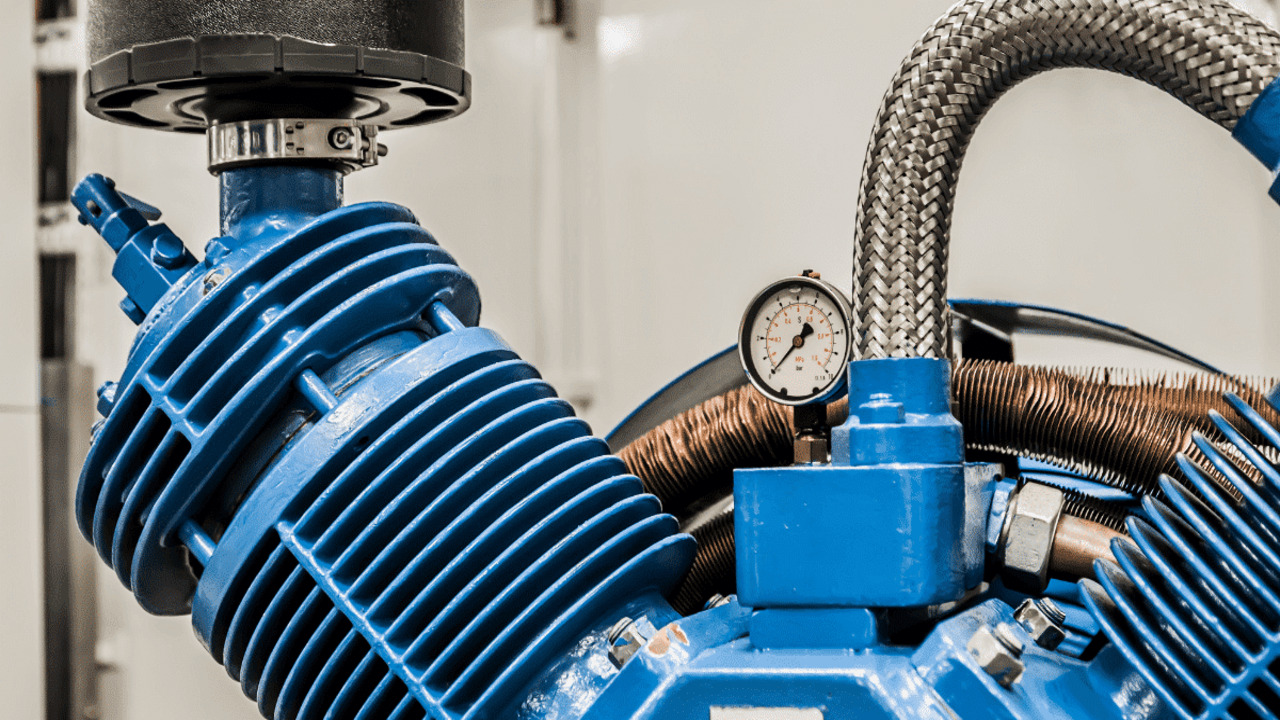

Troubleshooting Tips For Specific Types Of Air Compressors (E.G., Reciprocating, Rotary Screw)

If your air compressor is losing pressure quickly, there could be a few reasons for this issue. First, check for any leaks in the system. Leaks can cause air to escape, leading to a drop in pressure. Inspect all connections and fittings, and tighten or replace any loose or damaged.

- Another potential cause of pressure loss is a faulty pressure switch. The pressure switch regulates the amount of air in the tank, so if it is not functioning properly, it can result in decreased pressure. Consider testing or replacing the pressure switch if necessary.

- Additionally, an undersized compressor may struggle to maintain consistent pressure. If you are using your compressor for demanding tasks that require high airflow, it may be worth considering upgrading to a larger model with a higher CFM rating.

- Regular maintenance is also crucial for maintaining the optimal performance of your air compressor. Clean or replace filters as needed, and correct the oil levels.

By troubleshooting these common issues and taking appropriate measures, you can quickly address the problem of an air compressor losing pressure and restore its functionality.

When To Consult A Professional For Repairs Or Maintenance

If your air compressor is losing pressure quickly, it may be a sign of a larger issue that requires professional attention. While you can take some troubleshooting steps, such as checking for leaks and ensuring proper compressor maintenance, it is important to know when to consult a professional for repairs or maintenance.

If you have tried troubleshooting steps and are still experiencing rapid pressure loss, it may be time to call in a professional. They will have the expertise and knowledge to diagnose and fix any underlying issues with your air compressor, ensuring that it operates efficiently and effectively. By addressing the problem promptly, you can avoid further damage and potential safety hazards.

Conclusion

To maintain optimum pressure and efficiency, it is crucial to identify and address why an air compressor loses pressure quickly. Common causes include air leaks, faulty pressure switches or valves, damaged or blocked air hoses and fittings, dirty air filters, inadequate compressor oil levels, and improper pressure regulator settings.

It’s important to troubleshoot and fix these issues promptly to avoid further damage and ensure the longevity of your air compressor. However, if you are unsure how to proceed or if the problem persists, it is recommended to consult a professional for repairs or maintenance. Remember, regular maintenance and proper care are key to maintaining the performance of your air compressor.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-5cab4770-ed74-40d2-94e6-82d51df98826″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.