An air compressor is a device that converts power into compressed air, which can power various tools. They come in different types and sizes, such as portable or stationary, and choosing the right one for your needs is crucial.

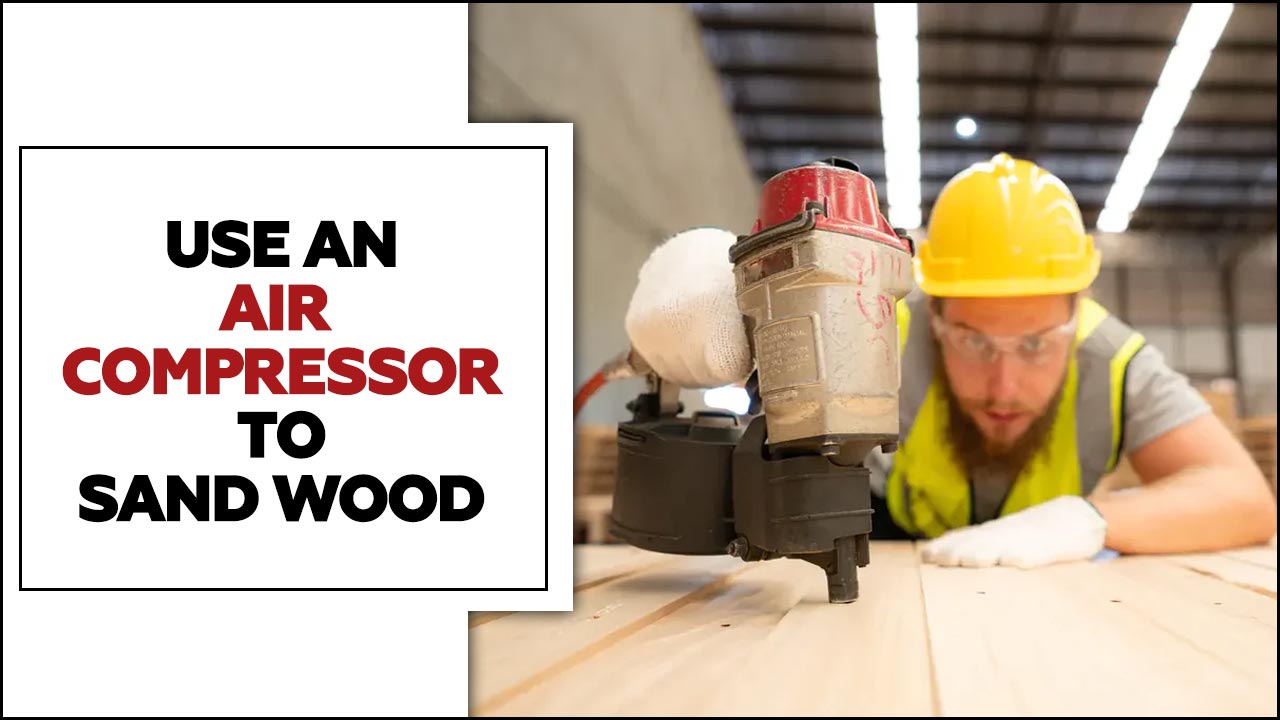

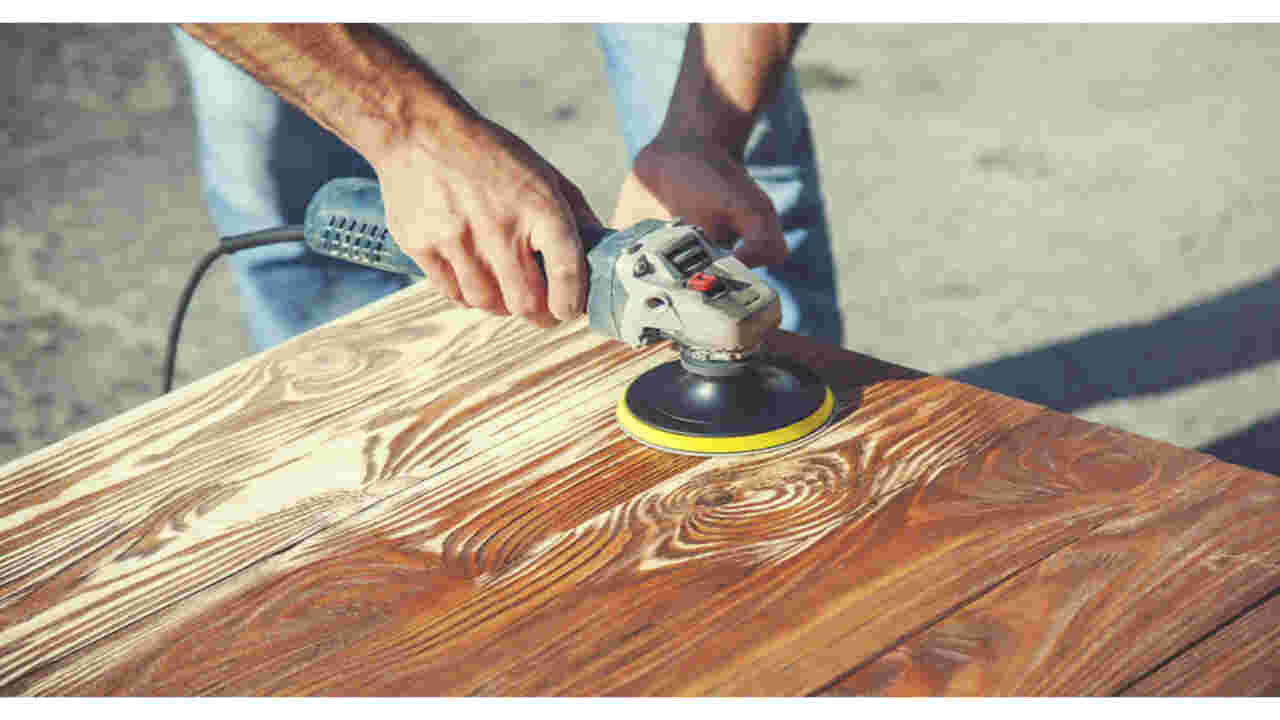

If you’re looking for an efficient way to sand wood, an air compressor might be just what you need. An air compressor can quickly and easily smooth out rough surfaces, making it a go-to tool for woodworkers. Here we will go over the basics of how to use an air compressor to sand wood.

We’ll cover everything from setting up your workspace to choosing the right air compressor and preparing the wood surface. So if you want to take your woodworking skills to the next level, keep reading to learn about using an air compressor for sanding wood.

Types Of Sandblasters

Several types of sandblasters can be used when using an air compressor to sand wood. One option is a pump sandblaster, which uses a high-pressure pump to propel abrasive material onto the wood surface. This type of sandblaster is often used for heavy-duty sanding tasks and can remove tough stains or paint. There are several types of sandblasting:

- Gravity-Fed Sandblasters

- Pressure Blasters

- Siphon Sandblaster

How To Use An Air Compressor To Sand Wood

Using an air compressor for sanding wood requires some important considerations. To start, you need a sanding attachment compatible with your compressor, which can come in various sizes and types, such as portable or stationary, oil-lubricated or oil-free.

Next, adjust the air pressure (measured in psi) according to your needs and choose between electric or pneumatic (air-powered) sanders. Always use protective gear like safety goggles and masks while operating at an optimal rpm range, depending on your abrasive material (usually between 8-12k). And below, see how to use an air compressor to sand wood.

1.Preparing The Workspace

To achieve a smooth and efficient workflow when sanding wood with an air compressor, start by preparing the workspace. Choose a well-ventilated area and wear the appropriate safety gear, like goggles and a dust mask.

Clear away any debris that could hinder your work. Check that your air compressor is in good working order before use. Set up your sanding tools within reach for easier access.

2.Setting Up The Compressor

To ensure the effective use of an air compressor in sanding wood surfaces, it is crucial to choose the right type of abrasive material and securely attach it to your sander or sandblaster. Always prioritize safety by wearing appropriate protective gear like goggles and a dust mask.

Be sure to adjust the air pressure based on the type of wood being sanded, and keep your sanding tool moving continuously to prevent uneven spots on the surface of the wood.

3.Using The Air Compressor To Sand Wood

To use an air compressor to sand wood successfully, you must first prepare your workspace correctly. This involves choosing a well-ventilated area and wearing appropriate safety gear like goggles and a dust mask. Removing loose debris or objects that could impede your work is also important.

Additionally, before using an air compressor to sand wood, ensure it’s clean and in good working condition. Lastly, organize your sanding tools and materials within easy reach for a smooth workflow.

4.Choosing The Right Air Compressor

To choose an ideal air compressor for sanding wood effectively, consider various factors like the size of your project, tools needed, and portability. A bigger gallon tank would mean more consistent airflow with higher cubic feet per minute (cfm), so it is essential to ensure that your compressor can produce enough psi and cfm to run your sander correctly.

Sanders requires different rpm or horsepower (HP), so check what your sander needs before buying a big compressor. Oil-free compressors by brands like Festool or Bosch come highly recommended as they do not release oil into the air, which could damage the surface of the wood.

5.Preparing The Wood Surface

To prepare the surface of the wood for sanding using an air compressor, begin by removing loose debris and filling in any holes or cracks with wood filler. Once dry, use coarse-grit sandpaper to eliminate rough spots and imperfections before finishing with fine-grit sandpaper for a polished result.

Choosing the appropriate grit size is essential based on your project’s requirements and following manufacturer instructions regarding air pressure, CFM, nozzle type, etc. Consider purchasing oil-free compressors that are more suitable for woodworking projects since they do not release oil into the air that could damage the wood.

6.Sanding With An Air Compressor

To use an air compressor for wood sanding, attach an appropriate sanding disc or belt, and wear safety gear like eye protection and dust masks. Adjust air pressure for desired RPMs around your sander or hose PSI.

Keep your sander moving continuously over your work area, and don’t blast too much air on a wood surface at once, as this can create harmful marks. Regularly tools with cleaning, cubic feet per minute (CFM) requirements per portability preference, or gallon tank capacity if you need a lot of air in one shot.

7.Cleaning Up After Sanding With An Air Compressor

Efficiently cleaning up after sanding with an air compressor requires proper technique and safety precautions. Choose appropriate nozzle attachments like a blowgun or vacuum attachment, and always wear protective gear such as goggles and a dust mask.

Use controlled bursts of air pressure to avoid damaging the wood surface. Regular maintenance of your air compressor and its nozzle attachments will ensure optimal performance in future projects.

Choosing the Right Size Air Compressor for Sandblasting

Choosing the right size compressor is crucial for achieving the best results. The size of the compressor will depend on several factors, including the tools you plan to use, such as grinders, electric sanders, or a blast cabinet. It’s important to consider each tool’s required volume of air to operate efficiently.

For example, larger tools like grinders may require a higher air volume than smaller tools like electric sanders. Additionally, if you plan on using multiple tools simultaneously or for extended periods of time, you may need a larger compressor with a higher capacity.

Understanding the specific needs of your woodworking projects and selecting the appropriate size compressor will ensure you have enough power and airflow to complete your sanding tasks effectively.

How To Prevent Sanding Marks On Wood With An Air Compressor

To prevent unwanted marks on your wooden surface while using an air compressor for sanding. It is crucial that you follow some essential steps. Always select the appropriate sandpaper grit according to the wood type and project requirements.

Circular motion and use a dust extraction system and an air compressor for better cleaning. Lastly, ensure that the pressure setting of the compressor is not too high. Remember these tips to achieve satisfactory outcomes while sanding with an air compressor.

How Does An Air Compressor Work?

An air compressor is a machine that converts power into potential energy stored in compressed air. It works by drawing air from the atmosphere and compressing it to a higher pressure. The compressed air can then be used for various applications, such as powering pneumatic tools or filling tires.

The most common type of air compressor is the reciprocating compressor, which uses pistons to compress the air. As the piston moves up and down, it draws in air through an intake valve and compresses it into a smaller space until it reaches a predetermined pressure.

Regardless of the type of compressor, all work on the principle of using mechanical energy to increase the pressure of air molecules. Which can then be harnessed for various industrial and commercial purposes.

How to Size an Air Compressor For Sandblasting

Having the right size air compressor is crucial. The size of the air compressor tank will determine how long you can blast before needing to stop and allow the tank to refill with compressed air. For most small to medium-sized projects, a shop compressor with a tank capacity of 20-30 gallons should be sufficient.

However, if you are working on larger or more frequent sandblasting projects, you may want to consider investing in a larger tank size. Additionally, it is important to ensure that your air compressor has enough power (measured in horsepower) to operate your palm sander or other electric tools effectively. Lastly, use coarse sandpaper specifically designed for wood sanding to help you achieve the best results.

What Kind Of Air Compressor For Sandblasting?

When sandblasting with an air compressor, choosing the right air compressor for the job is important. One popular option is the Mirka Ceros, known for its power and reliability. It is also important to consider the volume of air that your compressor can produce, as this will determine how effective your sandblasting will be.

Additionally, using an air hammer attachment can help achieve a smooth wood finish. Before starting the sandblasting process, it is recommended to test it out on a scrap piece of wood to ensure that you are achieving the desired results. With the right equipment and techniques, using an air compressor, you can achieve a professional-looking finish on your woodworking projects.

CFM Requirements For Sandblasting

Considering the CFM (cubic feet per minute) requirements for sandblasting is important. A 6-8 CFM compressor should suffice for smaller jobs, but larger tasks may require a 10-12 CFM compressor. Always refer to the manufacturer’s recommendations before use. Sandblasting requires a high airflow volume to effectively remove paint or rust from surfaces.

The CFM rating of your air compressor will determine if it is suitable for sandblasting. Additionally, having a large enough air tank is crucial as it ensures a continuous supply of compressed air without interruptions. Another factor to consider is the quality of your tools and attachments.

Using a bristle attachment can help achieve a smoother finish and prevent damage to the wood surface. By considering these factors, you can ensure that you have the right equipment and accessories for sanding wood with an air compressor.

Conclusion

An air compressor is a versatile and efficient tool that can be used for many tasks, including sanding wood. Following the right steps, you can use an air compressor to sand wood easily and precisely.

It is important to choose the right type of air compressor for your needs and prepare your workspace beforehand. Also, choose the right nozzle size and pressure settings for optimal results. To prevent sanding marks on wood, it’s crucial to maintain consistent movement and pressure while sanding.

Remember to follow safety protocols when using an air compressor, such as wearing protective gear and ensuring proper ventilation. Incorporating this technique into your woodworking routine can take your projects to the next level.

Frequently Asked Questions:

[rank_math_rich_snippet id=”s-3732c296-d19a-4b8e-a6a8-c9340a01f9bd”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.