Hey there, DIY enthusiasts! Troy D Harn here, ready to help you tackle those projects that need a little extra oomph. Ever find yourself wrestling with a tool that just doesn’t have the get-up-and-go you need? Air compressors can feel a bit technical, but choosing the right one doesn’t have to be a headache. We’re talking about finding that sweet spot for power, portability, and just plain getting the job done right. Stick with me, and we’ll find the perfect 20-gallon, two-stage air compressor that’ll make your DIY dreams a whole lot easier to achieve.

Why a 20-Gallon Two-Stage Compressor is a Smart Move

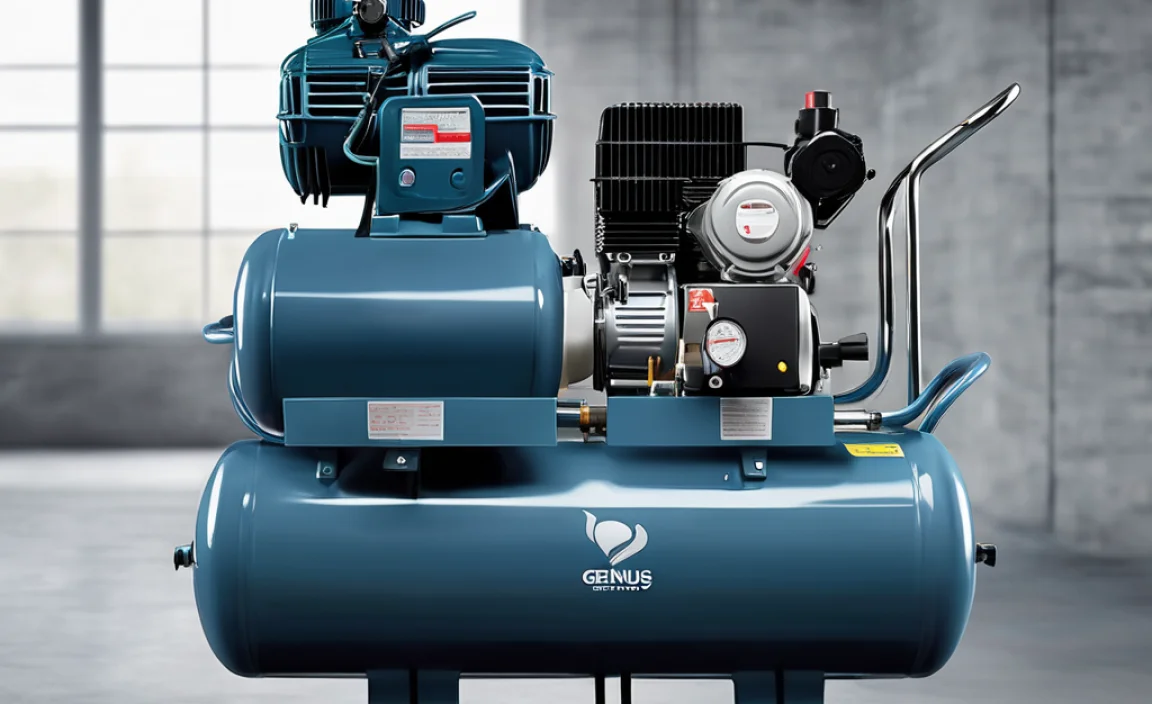

So, you’re looking to power up your DIY game. Maybe you’re dreaming of painting your fence with a spray gun, using an impact wrench for car repairs, or even running a nail gun for that weekend woodworking project. Whatever your goal, you need a reliable source of compressed air. But where do you start? It can feel like a jungle out there with all the different types and sizes. That’s where our hero comes in: the 20-gallon, two-stage air compressor. Let’s break down why this particular choice is often a “genius choice” for many homeowners and hobbyists.

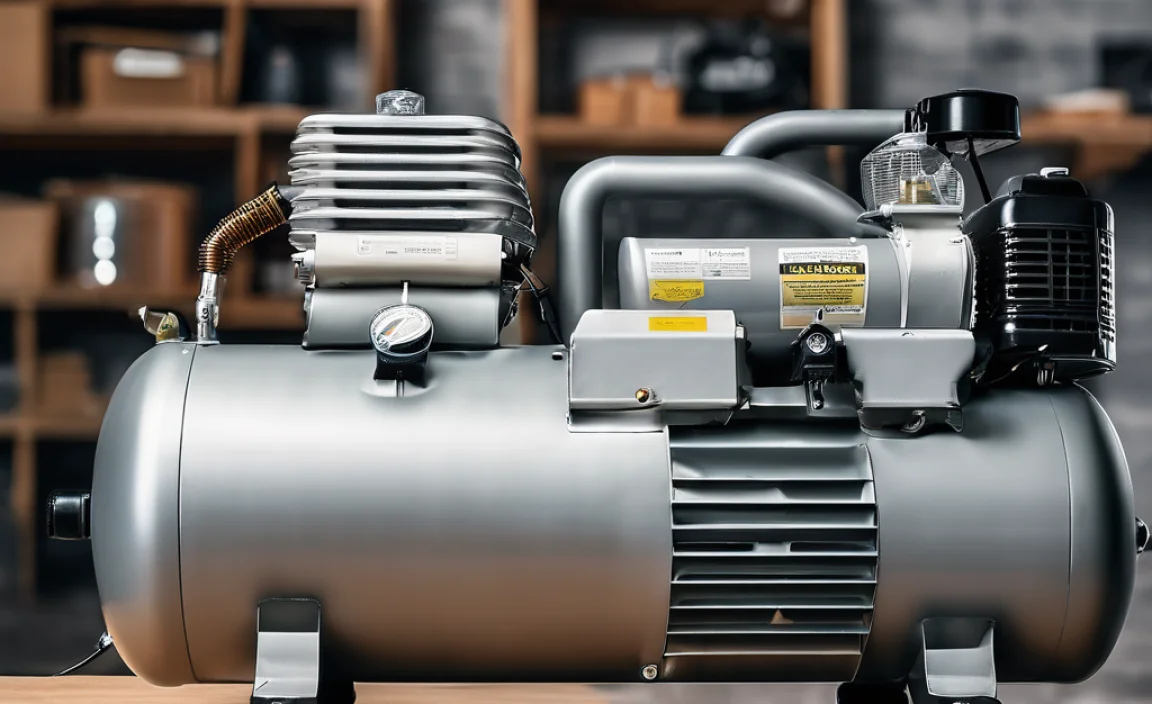

Think of an air compressor as the heart of your pneumatic tool system. It builds up a reserve of air pressure, and then releases it on demand to power your tools. For many DIY tasks, a single-stage compressor might seem “good enough.” It compresses air in one go. However, when you need more sustained power, especially for tools that really suck up a lot of air (we call this a high duty cycle), a two-stage compressor really shines.

What Does “Two-Stage” Actually Mean?

This is where we get a little bit into the technical side, but don’t worry, I’ll keep it simple! A single-stage compressor takes air and compresses it from its initial pressure all the way up to the tank’s maximum pressure in one go. A two-stage compressor does it in two steps. First, it compresses the air to an intermediate pressure. Then, it takes that already compressed air and compresses it further to the final, higher pressure. This process is more efficient, generates less heat, and allows the compressor to run cooler. This means it can often keep up with high-demand tools for longer periods without overheating.

The result? More consistent air flow, less waiting for the tank to refill, and the ability to use more demanding tools without issues. For the average DIYer who wants a bit more power and longevity from their compressor, this is a huge upgrade.

Why 20 Gallons? The Sweet Spot Size

Now, let’s talk capacity – the “20-gallon” part. This refers to the size of the air tank. Why is 20 gallons often the sweet spot? Well, it’s all about balance.

- Enough Air Storage: A 20-gallon tank gives you a good reserve of compressed air. This means you can run tools that require a steady supply of air for longer periods before the compressor motor has to kick back on to rebuild pressure. For tasks like painting, using an impact wrench, or running multiple nail guns, this reserve is crucial.

- Manageable Footprint: Compared to much larger workshop compressors (think 60, 80, or even 120 gallons), a 20-gallon unit is generally more compact. This makes it a viable option for garages, workshops, or even larger sheds where space might be a concern. It’s not so small that it’s constantly running, and not so big that it’s impossible to move around your workspace.

- Portability (Relatively): While not as lightweight as a small pancake or hot-dog style compressor, many 20-gallon models are designed with wheels and sturdy handles. This allows you to move them from one area of your property to another when needed, making them versatile for various projects.

- Power-to-Size Ratio: A 20-gallon tank paired with a two-stage pump usually means a more powerful motor and a higher cubic feet per minute (CFM) rating. This combination is excellent for a broad range of DIY and even some light professional tasks.

Too small a tank, and you’ll be waiting around for it to fill up more often than you’re working. Too big, and you might be paying for capacity you don’t need and struggling to find a place to store it. The 20-gallon two-stage compressor hits that sweet spot for a lot of us!

What to Look for in the Best Two-Stage 20 Gallon Air Compressor

Alright, you’re sold on the idea. Now, how do you pick the “best” one for your needs? It’s not a one-size-fits-all situation, but there are key factors to consider that will help you make a smart decision.

We’re looking for that perfect blend of power, durability, and user-friendliness. Let’s dive into the specs and features that truly matter.

1. Horsepower (HP) and Motor Type

Horsepower (HP) is like the “muscle” of the compressor. For a 20-gallon, two-stage unit, you’ll typically see motors ranging from 2 HP to 5 HP or even more. A higher HP generally means more power to drive the pump and deliver air faster. However, don’t just get fixated on the highest number. A good balance between HP and the pump’s efficiency is what really counts.

You’ll also want to consider the motor type. Most good quality compressors will have induction motors. These are generally quieter, more durable, and more efficient than universal motors you might find in cheaper models. They’re built to last!

2. Cubic Feet Per Minute (CFM) – The Real Measure of Air Delivery

This is arguably the MOST important spec to consider when matching a compressor to your tools. CFM tells you how much air the compressor can deliver at a specific pressure. Air tools are rated in CFM, and you need a compressor that can meet or exceed that rating to run the tool effectively at its intended pressure. If your compressor can’t supply enough CFM, your tool will perform poorly, or not at all.

Manufacturers usually list CFM at different PSI (pounds per square inch) levels. For a 20-gallon, two-stage compressor, you’ll generally want to look for:

- At least 5 CFM at 90 PSI: This is a good baseline for many common DIY tools like impact wrenches, orbital sanders, and die grinders.

- Higher CFM for demanding tools: If you plan on running tools like paint sprayers (especially HVLP guns), sandblasters, or multiple nail guns simultaneously, you’ll want to aim for CFM ratings of 7, 8, or even higher at 90 PSI.

Always find out the CFM requirements for the tools you plan to use. Resource like the U.S. Department of Energy provide general guidelines for tool energy efficiency, which often includes air consumption: Energy.gov Compressed Air Systems.

3. Maximum PSI (Pressure)

PSI tells you how much air pressure the tank can hold and deliver. Most common DIY tools operate in the 70-100 PSI range. Two-stage compressors are excellent at reaching higher pressures, often 150 PSI or even 175 PSI. This higher maximum PSI means that even when the compressor is working hard to maintain lower pressure for your tools, it has plenty of reserve capacity.

A higher maximum PSI also means the compressor can run longer between fills compared to a lower-PSI unit because it’s operating at a lower percentage of its maximum capacity.

4. Tank Size (Revisited) and Duty Cycle

We’ve talked about why 20 gallons is a great size. However, understand what duty cycle means. Duty cycle is the percentage of time a compressor motor can run within a given hour without overheating. For a two-stage compressor, you’ll typically want one with a 75% to 100% duty cycle. This means it’s designed for continuous or near-continuous operation, which is exactly what you need for demanding tasks.

A 20-gallon tank on a 100% duty cycle compressor is a fantastic combination for sustained work.

5. Pump Type and Material

There are two main types of air compressor pumps: cast iron and aluminum.

- Cast Iron: This is the gold standard for durability and longevity, especially in two-stage compressors. Cast iron pumps are heavy-duty, run cooler, and are generally quieter. They’re built to last, making them a smart investment for serious DIYers.

- Aluminum: Often found in smaller, single-stage compressors, aluminum pumps can be lighter but may not offer the same level of long-term durability as cast iron for heavy-duty applications.

For a 20-gallon two-stage compressor, you really want to prioritize a cast iron pump. Look for features like oil-lubricated pumps; they tend to be more robust than oil-free designs for more powerful units.

6. Noise Level (Decibels – dB)

Compressors can be loud! Seriously loud sometimes. If you’re working in a residential area, close to neighbors, or even just in your garage where you spend a lot of time, noise level can be a big factor. Manufacturers often list the decibel (dB) rating. A quieter unit might be around 70-80 dB, while louder ones can be 90 dB or more. For context, 85 dB is roughly the level of a garbage disposal, and prolonged exposure at that level can be harmful to your hearing without protection.

If noise is a concern, look for models that explicitly mention “quiet operation” or have lower dB ratings. Sometimes, this might come with a slightly higher price tag, but it can be well worth it for your comfort and peace with the neighbors!

7. Portability and Build Quality

As mentioned, a 20-gallon compressor isn’t exactly a feather. Check for:

- Sturdy Wheels: Large, durable wheels (often pneumatic or semi-pneumatic) make it much easier to roll the compressor around your garage or yard.

- Well-Placed Handles: Comfortable and robust handles are essential for lifting and maneuvering.

- Overall Construction: Does it feel solid? Are the welds clean? Is the metal gauge substantial? A well-built compressor will have a heft and a robustness that speaks to its durability. Regulators, gauges, and drain valves should feel solid and easy to operate.

8. Power Source (Electric vs. Gas)

For a 20-gallon compressor, you’ll almost exclusively find electric models. This is generally preferred for noise, emissions, and ease of use in a garage or workshop setting. If you absolutely need to work in a remote area far from power outlets, a gas-powered compressor might be an option, but they are typically much larger, louder, and require more maintenance. For the “best 20-gallon two-stage air compressor,” we’re focusing on electric.

Top Features That Make a 20-Gallon Two-Stage Compressor “Genius”

Beyond the basic specs, some clever features can elevate a good compressor to a truly genius choice. These are the little things that make a big difference in your day-to-day use.

1. Oil-Lubricated Pump

As we touched on with materials, an oil-lubricated pump is a sign of a more robust, heavy-duty compressor. While oil-free compressors are lighter and require a bit less maintenance (no oil changes!), oiled compressors are generally quieter, run cooler, and last significantly longer, especially under demanding use. Think of it like engine oil – it makes things run smoother and last longer.

2. Thermal Overload Protection

This is a crucial safety feature. A thermal overload protector is built into the motor. If the motor gets too hot (due to extended runtime or other issues), this protector will automatically shut it down before any permanent damage occurs. Once it cools down, you can usually reset it and get back to work. It’s a lifesaver for the compressor and prevents frustrating breakdowns.

3. Durable Air Filter

A good quality air filter protects the pump from dust and debris, which is essential for longevity. Look for metal filter housings rather than plastic, as they’re generally more robust. Some models might have multi-stage filtration for even cleaner air.

4. Easy-Drain System

Condensation is the enemy of compressed air systems. Water builds up in the tank and can cause rust and damage your tools. All good compressors have a drain valve at the bottom of the tank to let this water out. An “easy-drain” system, like a ball valve or a faucet-style drain rather than a tiny plug, makes this essential maintenance task quick and painless.

5. Pre-installed Regulators and Gauges

You’ll want a regulator to dial in the exact pressure needed for your specific tool, and gauges to monitor both tank pressure and regulated output pressure. Most quality units come with these factory-installed, but check that they are clearly marked and easy to read.

6. Quieter Operation Technology

Manufacturers are increasingly focusing on reducing compressor noise. Features like enclosed pump designs, specialized motor mounts, and better muffler systems can significantly cut down on the decibel level. If noise is a major concern for you, actively seek out models that advertise quiet technology.

Comparing Popular 20-Gallon Two-Stage Air Compressors (Example Scenarios)

To help you visualize, let’s look at how different needs might steer you towards specific models or features within the 20-gallon, two-stage category. Keep in mind that specific models and their exact specs change, so always verify current details.

| Scenario/User Type | Key Needs | Ideal Compressor Focus | Example Features to Look For |

|---|---|---|---|

| The Weekend Warrior (Auto Repair) | Running impact wrenches, air ratchets, tire inflators reliably. Needs good torque and consistent airflow for short bursts. | Moderate to High CFM (6-8 CFM @ 90 PSI), ~150 PSI max, durable pump. | Cast iron pump, sturdy wheels for garage mobility, clear gauges, easy drain. |

| The DIY Painter (Furniture/Fence) | Consistent, clean airflow for spray guns (HVLP or traditional). Needs to avoid pulsating air. | High CFM (7+ CFM @ 90 PSI), smoother airflow, good tank capacity to minimize cycling. | Large tank (20 gal is good), potentially a quieter model to avoid disturbing others, effective moisture trap/filter. |

| The Woodworker (Nail Guns/Staplers) | Running multiple nail guns or heavy-duty staplers for framing or trim work. Needs steady supply. | Good CFM range (5-7 CFM @ 90 PSI), good pressure for nailer triggers, robust construction for frequent use. | Cast iron pump, 100% duty cycle, easy-to-read regulator and gauges. |

| The All-Around Homeowner | Versatility for occasional auto work, inflating tires, light DIY projects, maybe occasional dusting/cleaning. | Balanced CFM (5-6 CFM @ 90 PSI), durable, relatively portable, good value. | Reliable brand, cast iron pump, good warranty, reasonable noise level. |

This table is a guide. Your personal projects might fall between these categories, or have unique demands. The key is to match the compressor’s capabilities to your most demanding tools and tasks.

Tips for Maintaining Your 20-Gallon Two-Stage Air Compressor

Buying a great compressor is only half the battle. Proper maintenance is key to ensuring it lasts for years and performs at its best. Thankfully, with a 20-gallon two-stage unit, maintenance is usually straightforward and incredibly important.

Here’s a simple maintenance checklist:

- Drain the Tank Regularly: This is the MOST important step. As air is compressed, moisture is removed from the air and condenses in the tank. Drain the tank completely after each use, or at least daily if you use it frequently. Use the drain valve at the bottom. For more thorough draining, you can slightly open the valve and let it hiss out.

- Check the Oil Level (for Oil-Lubricated Pumps): If you have an oil-lubricated pump, check the oil level regularly (e.g., weekly or monthly). Most pumps have a sight glass or a dipstick. Top it off with the recommended type of compressor oil if it’s low. Never run an oil-lubricated pump dry!

- Change the Oil Periodically: Follow the manufacturer’s recommendation for oil changes. This is usually every few hundred hours of use or annually

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.