In today’s world, innovation and creativity are highly valued skills. One area where these skills can be put to use is in the creation of homemade gadgets and devices.

One such device that has gained popularity among DIY enthusiasts is the compressed air cannon. This simple yet powerful tool uses compressed air to launch objects at high speeds, making it an ideal choice for various activities such as target shooting and even potato launching.

While it may seem like a complex project, building a compressed air cannon is actually quite simple and can be completed with just a few basic tools and materials. We will guide you through the step-by-step process of how to make a compressed air cannon. By the end, you will have a functioning and impressive piece of technology that will surely impress your friends and family.

What Is A Compressed Air Cannon?

A compressed air cannon is a device handy to shoot objects or projectiles through the air using powerful air pressure. This type of cannon uses an electric motor to power a high-pressure air pump, which forces the air through a nozzle and creates the projectile.

This can be a great option for people looking for a way to launch objects without using a launcher or gun. Since compressed air cannons are powered by electricity, they can be handy for a variety of tasks, such as shooting pellets, confetti, or balls.

How Does A Compressed Air Cannon Work?

A compressed air cannon works by harnessing the power of compressed air to propel objects at high speeds. The basic principle behind a compressed air cannon is simple: a large volume of air is rapidly released, creating a force that propels an object forward.

The cannon consists of a chamber or reservoir where the air is stored under pressure and a valve or trigger mechanism that releases the air when activated. When the valve is opened, the pressurized air rushes out of the chamber, pushing the projectile out with great force.

Gather Materials & Tools

In the realm of engineering and construction, it is crucial to possess a comprehensive understanding of the significance of knowing how to gather the appropriate materials and tools for the creation of a compressed air cannon.

Understanding the materials required ensures the cannon’s structural integrity and operational efficiency. By selecting suitable materials that possess the necessary strength, durability, and resistance to high pressures, one can ensure the cannon’s ability to withstand the forces exerted during operation.

- PVC pipe (various sizes)

- PVC fittings (elbows, tees, end caps)

- PVC primer and cement

- PVC cutter or hacksaw

- Drill

- Drill bits (various sizes)

- Air compressor

- Air hose

- Pressure gauge

- Ball valve or solenoid valve

- Teflon tape

- Safety glasses

- Gloves

- Measuring tape

- Marker or pencil

- Sandpaper or file (for smoothing edges)

- Pipe wrench or pliers (for tightening fittings)

- Air chamber (such as a PVC pipe or pressure vessel)

- Projectile (foam balls, tennis balls, etc.)

- Lubricant (such as silicone spray or oil)

7 Steps How To Make A Compressed Air Cannon

Knowing how to make a compressed air cannon is of great importance in various fields and industries. The ability to construct and operate such a device is not only fascinating but also holds immense practical significance.

Compressed air cannons are utilized in a wide range of applications, including, but not limited to, science experiments, engineering projects, and even recreational activities. By understanding the principles behind its design and operation, individuals can grasp fundamental concepts of physics, such as pressure, force, and projectile motion.

This knowledge can be particularly beneficial for students studying science and engineering, as it allows them to apply theoretical concepts to practical, hands-on projects. Below, we provide detailed guidelines for making a compressed air cannon.

1.Making The Air Tank

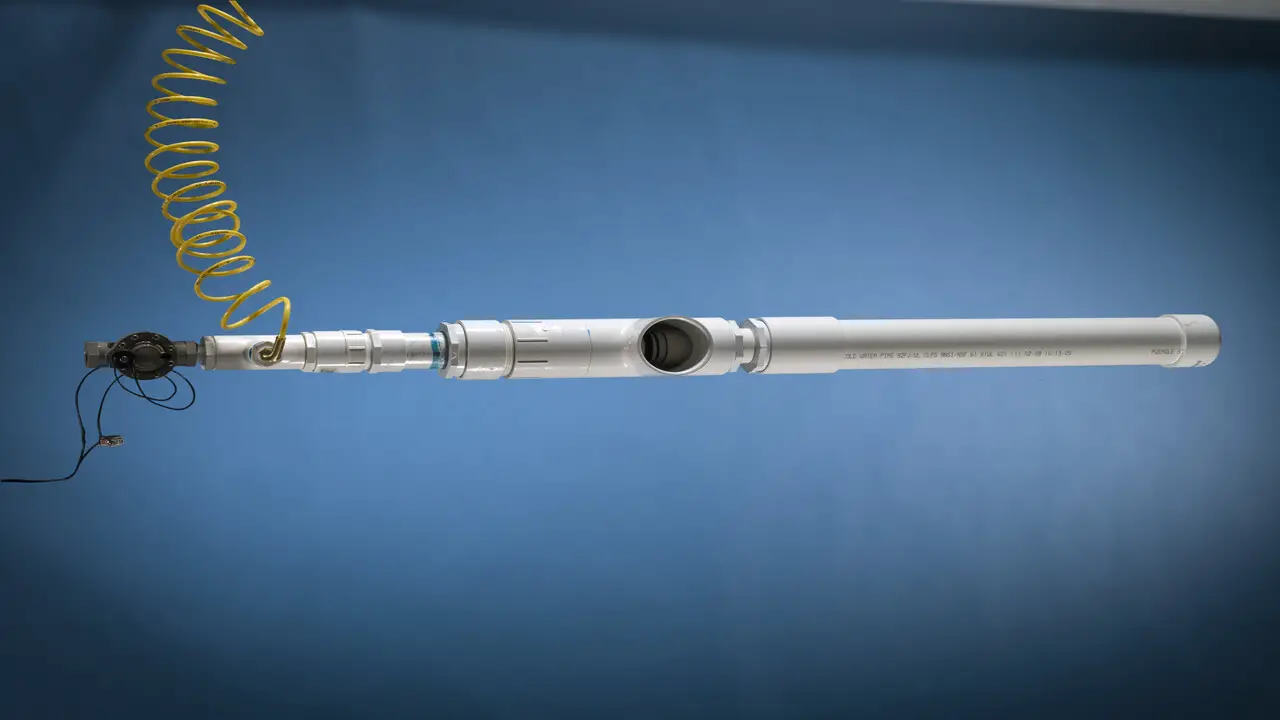

To build a compressed air cannon, one of the crucial components you will need is the air tank. The air tank serves as the main reservoir for storing the compressed air and gas mixture, which is essential for propelling projectiles. Constructing a reliable and efficient air tank is paramount to ensure optimal performance and safety of the cannon.

When designing the air tank, it is imperative to select a suitable material that can withstand the high pressure generated during firing. Common choices include durable metals such as steel or aluminium, known for their strength and ability to withstand extreme conditions.

The tank should also be carefully engineered with appropriate thickness and reinforcement to prevent any potential leaks or ruptures. Additionally, integrating safety features like pressure relief valves and pressure gauges can help monitor and control the internal pressure, reducing the risk of accidents or damage to the cannon.

2.Making The Barrel

The barrel of the compressed air cannon is one of the most important parts, and it needs to be made from a strong and durable material. Some popular materials that can be handy for this include metal, plastic, and fibreglass.

When considering materials for the construction of a compressed air cannon barrel, several factors come into play. First and foremost, the material must possess high tensile strength to withstand the pressure exerted by the compressed air. Additionally, it should have excellent resistance to deformation and corrosion to ensure longevity and reliability.

Common materials used for this purpose include high-grade metals such as stainless steel or aluminium alloys, which offer a favourable combination of strength and durability. These materials exhibit exceptional mechanical properties, enabling the barrel to withstand the intense internal pressure and repetitive loading cycles without compromising structural integrity.

3.Installing The Fill Valve

When installing a fill valve for a compressed air cannon, it is important to choose a high-quality valve that is compatible with the cannon’s specifications. The valve should be capable of withstanding the pressure levels generated by the compressed air system and should also have a reliable sealing mechanism to prevent any leakage.

It is advisable to consult the manufacturer’s instructions or seek professional advice to select the most suitable fill valve for your specific cannon model. Once the appropriate fill valve is obtained, the installation process involves securely attaching the valve to the air reservoir of the cannon.

This typically requires connecting the valve using appropriate fittings and ensuring a tight seal to prevent any air leakage. It is crucial to follow the manufacturer’s guidelines for proper installation to ensure the valve functions optimally and guarantees the safety of both the operator and the device.

4.Capping The Tank

Capping the Tank is crucial to ensure that the air cannon does not explode during use. After each use, it is important to cap the Tank to prevent the air from escaping and causing damage to the cannon. There are a variety of caps available that will fit different air cannons.

One popular option is the blow-off cap, a valve cap with a built-in release valve that allows air to escape after pressurization but prevents excess pressure from building up in the Tank. Capping the Tank will also prevent dirt, dust, and other particles from entering the Tank and clogging it up. By ensuring that the air cannon can safely store and use air, you can reduce harmful environmental impact and save money on cost per shot.

5.Attaching The Ball Valve

To create a compressed air cannon, you will need a ball valve. Ball valves are available in a variety of sizes and can attach to the air cannon using a hose. When attaching the ball valve, it is important to ensure that it fits securely and does not leak air. Once you attach the ball valve, it’s time to fill the air cannon with compressed air.

To release the pressurized air, simply depress the ball valve. This will reduce the pressure in the cannon and allow it to release. You must regularly check ball valves for leaks or other issues because they are not maintenance-free. So be sure to check your ball valve regularly and replace it if necessary.

6.Attaching The Barrel

Regarding attaching the barrel, it is important to consider the specific requirements of your air cannon. The barrel serves as the conduit through which the compressed air is propelled, and its design can greatly impact the effectiveness and performance of the device. There are various types of barrels available, each with its unique characteristics.

One popular choice for constructing the barrel is using PVC pipe. PVC pipes are readily available, affordable, and easy to work with. They come in different diameters and lengths, allowing for customization based on the desired power and range. Additionally, you can easily connect PVC barrels to the air source and other components of the air cannon.

7.Firing The Cannon

To fire the compressed air cannon, you must fill the air tank with pressurized air and attach the nozzle. Once the cannon is level and ready to fire, press the trigger to release the air. The cannon will launch a projectile about 50 feet away.

It’s best to shoot in a direction with no obstacles or people around it, as the projectile can easily hit someone or something nearby. Aim at a target several feet away from the cannon for best results rather than directly in front of it. This will give you more distance to work with and minimize any risk of accidents.

Troubleshooting Tips When Making A Compressed Air Cannon

Knowing troubleshooting tips when making a compressed air cannon is of utmost importance for several reasons. First and foremost, understanding the potential issues that may arise during the air cannon installations and operation of a compressed air cannon ensures that it can be built and utilized safely.

By being aware of the common problems and their solutions, individuals can prevent accidents or malfunctions that could result in serious injuries or property damage.

- Ensure that you tightly secure all connections and fittings to prevent any air leaks.

- Check the pressure gauge to ensure that the air pressure is within the recommended range for the cannon.

- Inspect the air tank for any signs of damage or leaks.

- Verify that the air bulk materials are functioning properly and are not stuck or blocked.

- If the cannon is not firing or has a weak projectile launch, check the barrel for any obstructions or debris that may be affecting the airflow.

- Make sure the projectile is the correct size and weight for the cannon, as using improper ammunition can cause performance issues.

- If the cannon is not pressurizing or maintaining pressure, inspect the compressor or air source for any issues, such as low air pressure or a faulty regulator.

- If the cannon is consistently misfiring or experiencing inconsistent performance, consider adjusting the air pressure or experimenting with different projectile designs.

- Safety should always be a top priority when troubleshooting and operating a compressed air cannon. Follow all recommended safety guidelines and never aim the cannon at people or animals.

Air Compressor Types For Making A Compressed Air Cannon

Being knowledgeable about air compressor types enables you to make a well-informed assessment of the compressor’s capabilities and limitations. Different compressors have varying pressure and flow rates, which directly impact the power and velocity of the projectiles launched by the air cannon. By understanding these specifications, you can select a compressor that provides the necessary force to achieve your desired outcomes.

- Reciprocating air compressors

- Rotary screw air compressors

- Centrifugal air compressors

- Portable air compressors

- Oil-lubricated air compressors

- Oil-free air compressors

- Single-stage vs. two-stage compressors

- Electric vs. gasoline-powered compressors

Maintenance And Care Tips For Keeping Your Compressed Air Cannon In Good Condition

Knowing maintenance and care tips for keeping your compressed air cannon in good condition is crucial for several reasons. First and foremost, regular maintenance ensures the optimal performance and longevity of your equipment. By following the recommended maintenance procedures, you can prevent potential malfunctions and breakdowns, ultimately saving you time and money.

- Regularly inspect the compressed air cannon for any signs of damage or wear.

- Clean the barrel and other components of the cannon after each use to remove any debris or residue.

Lubricate moving parts, such as the trigger mechanism, to ensure smooth operation. - Check and tighten all bolts and connections to ensure they are secure.

- Store the compressed air cannon in a cool, dry place to prevent moisture buildup and rust.

- Regularly check and replace any worn or damaged seals or O-rings to maintain proper air pressure.

- Avoid exposing the cannon to extreme temperatures or direct sunlight, as this can affect its performance and lifespan.

- Use only compatible and recommended projectiles, and avoid using excessive force or overloading the cannon.

- Follow the manufacturer’s instructions for proper maintenance and care, including any specific cleaning or storage guidelines.

- Periodically test the cannon’s performance and function to ensure it is operating safely and efficiently.

Components Of A Compressed Air Cannon

A compressed air cannon is a popular and effective project for any budding engineer or Maker. It is also a fun and engaging way to explore engineering and science principles. A compressed air cannon is made up of many components, but the essential component is the air tank.

This component holds the compressed air and provides pressure to the cannon. The tennis balls valve provides control over the airflow into the cannon and is used to release the ball when it has reached its target.

The cylinder fires the ball using compressed air and is connected to the trigger, which acts as a switch to fire the ball from the cylinder. The important part of this project is understanding how all these components work together to create a functional and safe device.

Use Of Compressed Air Cannons

In today’s industrial and manufacturing sectors, the use of compressed air cannons has become increasingly prevalent. These powerful devices utilize compressed air to generate force and propulsion, making them essential tools for a wide range of applications.

Understanding how to effectively and safely operate compressed air cannons is of utmost importance, as it ensures optimal performance, minimizes risks and maximizes productivity.

- Ensure that the compressed air cannon is properly assembled and in good working condition.

- Connect the compressed air source to the cannon using the appropriate fittings and hoses.

- Make sure that the cannon is pointed in a safe direction and that there are no people or objects in the immediate vicinity.

- Load the cannon with the desired projectile, such as a foam ball or confetti, following the manufacturer’s instructions.

- Adjust the air pressure to an appropriate level, considering the type of projectile and the distance you want to achieve.

- Stand at a safe distance from the cannon and use the trigger mechanism to release the compressed air and launch the projectile.

- Always follow safety guidelines, such as wearing protective eyewear and ensuring that bystanders are aware of the upcoming launch.

- Regularly inspect and maintain the compressed air cannon to prevent any malfunctions or accidents.

- Familiarize yourself with any local regulations or restrictions regarding the use of compressed air cannons, especially in public spaces or events.

- Enjoy the fun and excitement of using compressed air cannons responsibly and safely.

Conclusion

Creating a compressed air cannon can be a fun and exciting project for those interested in DIY and physics. By following the steps on how to make a compressed air cannon,you can build your own compressed air cannon and experience the thrill of launching objects through the air with force. However, it is important to exercise caution and prioritize safety when working with compressed air.

Always wear protective gear and operate the cannon responsibly. Whether you’re using it for recreational purposes or educational experiments, a compressed air cannon is sure to provide hours of entertainment. So gather your materials, put on your thinking cap, and get ready to launch projectiles into the sky.

Frequently Asked Questions

How Much PSI Is In An Air Cannon?

The amount of PSI (pounds per square inch) in an air cannon can vary depending on its design and purpose. However, most air cannons typically operate within a range of 80 to 120 PSI.

What Is A Compressed Air Cannon?

A compressed air cannon is a device that uses compressed air to launch projectiles. It typically consists of a cylindrical barrel, a compressed air source, and a valve or trigger mechanism.

What Are The Components Of An Air Cannon?

The components of an air cannon typically include a chamber, a valve, and a barrel. The chamber is where the compressed air is stored, usually achieved by using a pump or an air compressor.

What Is The Physics Behind Air Cannon?

An air cannon works based on the physics principle of compressed air. By rapidly releasing a large volume of pressurized air, the cannon creates a force that propels objects forward.

How Much Air Is 100 PSI?

100 PSI (pounds per square inch) refers to the amount of pressure chamber exerted by air. It does not directly indicate the volume or amount of air present.

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.