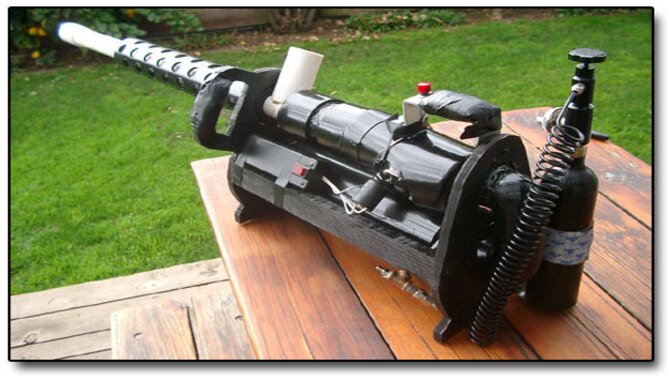

A compressed air cannon is a powerful tool to shoot objects or projectiles long distances. These devices are easy to use and can operate by anyone with some knowledge and basic equipment.

Building compressed air cannons (CACs) is all the craze these days. They’re used by hobbyists and professionals for various purposes, from making soda bottles out of paper to softening clay for sculpting, among others.

They’re also extensively used in film production, electro-pop scene, and art shows, as they allow the artist to create a large range of effects without carrying heavy equipment. But before you can use a CAC creatively or practically, you first need to make one. We will tell you how to build a compressed air cannon and see the wonders it can perform. Let’s begin.

What Is A Compressed Air Cannon?

A compressed air cannon is a versatile device that can be used for various purposes, such as shooting targets, launching projectiles, or creating bubbles. Some common uses for compressed air cannons include shooting water balloons, building materials, and even small animals.

A compressed air cannon comes in various sizes and configurations, allowing you to find the perfect one for your needs. They are great for both professional and amateur users as they provide high-intensity bursts of air without the need for batteries or other power sources. With a compressed air cannon, you can create fun and exciting experiences without the hassle of using traditional projectile devices.

How To Build A Compressed Air Cannon: Performing Steps

Compressed air cannons are a popular tool for removing debris, insects, and other objects from cars and vehicles. They use compressed air to shoot objects high into the air and safely dispose of them. Building a compressed air cannon is surprisingly simple but requires some special tools and ingredients. Building a compressed air cannon may seem daunting, but it is quite simple if you have the right tools and follow the proper instructions.

The difficulty level of building a compressed air cannon can vary depending on the type of cannon you want to build. There are different designs, each with its own set of instructions and required materials. The most important factor in building a compressed air cannon is safety. You must ensure that you use the right materials and follow the instructions carefully to avoid accidents. Here are the steps you need to take to build your own:

1. Materials & Tools

Building a compressed air cannon can be a fun and rewarding DIY project, but having the right materials and tools is important before getting started. By gathering these materials and tools ahead of time, you’ll be well-prepared to build your very own compressed air cannon. To build a compressed air cannon, you will need the following materials:

- A compressor (or another power source)

- A canister of compressed air

- An air-release valve

- Screws and bolts to attach the compressor to the canister

- An air hose or pipe

2. Making The Air Tank

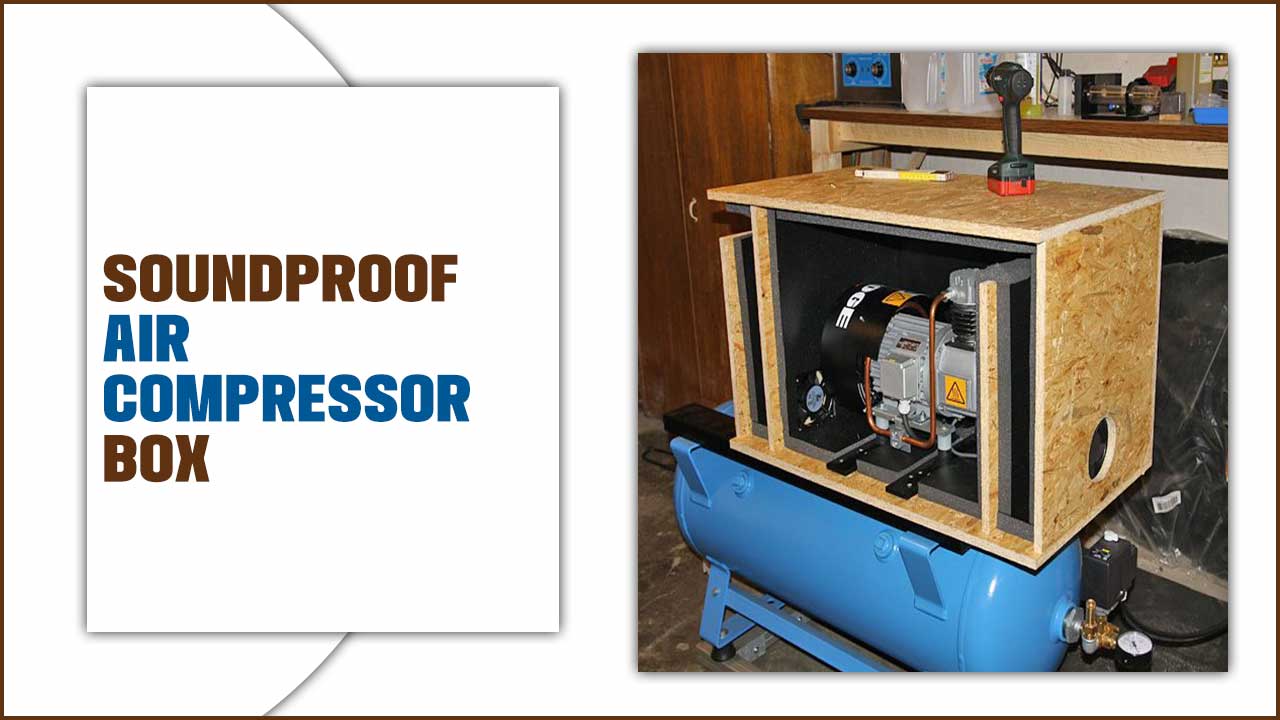

The air tank is the most important part of a compressed air cannon. It must be tough enough to withstand high pressures and heavy loads and pliable enough to avoid breaking. In addition, the air tank must be able to store a large amount of air for long periods.

You will need brass nickel plating, PVC pipe, and fittings to make the air tank. Once you have assembled the air tank, it’s time to build the compressor. To make the air tank, you will need PVC pipe, end caps, and a valve.

Cut the length of the PVC pipe to your desired size for the air tank and attach end caps to both ends with PVC cement. Next, drill a hole in one of the end caps and insert the valve. Make sure the valve fits tightly so that no compressed air can escape.

3. Making The Barrel

You must make a barrel to make the most of your compressed air cannon. The barrel is the core component of your cannon and is essential for compressing the air and firing the projectile. You can make a barrel from various materials depending on your preferences and needs.

Some common materials used to make barrels include steel, aluminum, plastic, and wood. The barrel can make in a variety of ways, but one of the most common methods is by using a molding process. This involves forming a specific diameter and length barrel using a series of molds.

Other methods may be more time-consuming or require special tools, such as 3D printers, so they are usually reserved for high-production applications. Once you have made the barrel, it’s time to start assembling your cannon.

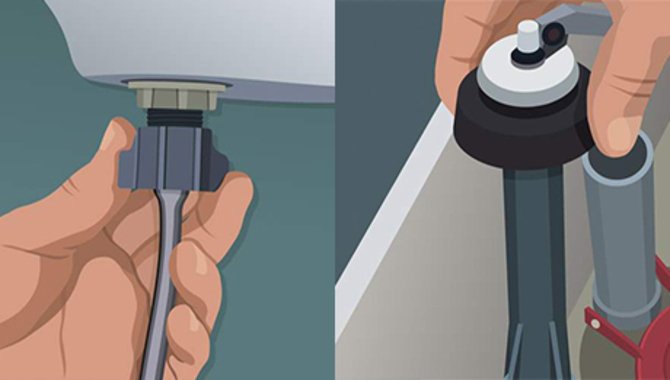

4. Installing The Fill Valve

After you have constructed the cannon, it is time to install the fill valve. This valve allows you to control the flow of air into the cannon and allows for precise aiming. The fill valve should install in a location that is inaccessible to children.

In addition, the final step in installing a compressed air cannon is to connect the air hose to the fill valve. This hose can attach to a compressor or air source. Once connected, air will flow into the cannon and out of the other end of the hose, creating a powerful force that can destroy targets with great accuracy.

5. Capping The Tank

Capping the tank of a compressed air cannon is an important step to prevent air from escaping and causing damage. It is also necessary to protect the gun from dust and other debris. To cap the tank, use a ball valve or a Union cap. If you are using a ball valve, place it over the end of the hose and tighten the fitting.

If you use a union cap, wrap it around the end of the hose and tighten the fitting. After capping the tank, test to ensure that air cannot escape through gaps in the cap. When finished with a project, always safely store your cannon and ensure it is in good working order before disposal.

6. Attaching The Ball Valve

You will need to attach the ball valve to the air hose. This valve allows you to control the airflow into the cannon and help prevent excess pressure from building up. Ensure that the ball valve is securely attached to the air hose and that it is not leaking before you continue with your project.

7. Attaching The Barrel

Attaching the barrel is the final step in building your compressed air cannon. In this step, you must attach the barrel to the base of the gun. The barrel should be strong enough to support the weight of the air compressor and the gunpowder.

Once you have attached the barrel, you must ensure that it is evenly balanced so that it doesn’t affect the firing accuracy of the cannon. Next, you must connect the air hose to the air compressor and test your cannon for accuracy.

8. Firing The Cannon

To fire the compressed air cannon, you must fill it with air. You can either place a ball valve in the cannon or use a compressor to fill it. Once the air is in the cannon, you can press a button to release the air and shoot objects or birds high into the sky. This amazing device is perfect for recreational and entertainment purposes, and it is easy to build and customize to your needs and preferences.

How Does A Compressed Air Cannon Work?

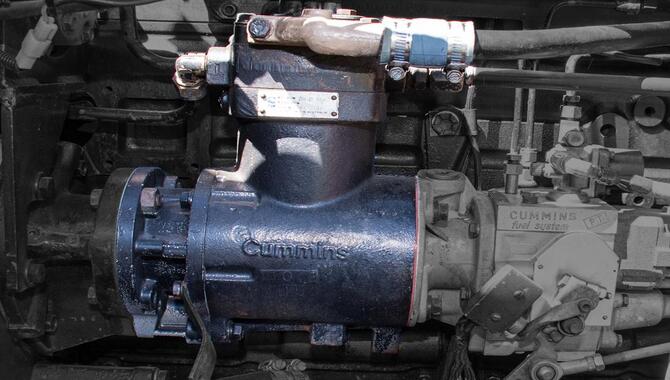

A Compressed air cannon is a device that uses air pressure to launch objects or projectiles. It comprises an air tank, compressor, valves, pipe fittings, and connections. To operate the cannon, you must fill the air tank with compressed air, connect the compressor to the air tank, and open the valves to release the pressure. This will cause the object or projectile to be shot from the cannon.

To shoot objects or projectiles with a compressed air cannon, you must aim the cannon and depress the trigger to release the air pressure. This will cause the object or projectile to fire out of the cannon. A Compressed air cannon is a great way of engaging in outdoor activities like hunting or recreation without investing in expensive devices.

Construction Tips For A Compressed Air Cannon

If you want to build a compressed air cannon, choosing the right material for the job is vital. Different materials and constructions offer varying levels of durability and performance. This ensures that there is no damage or malfunction during use.

You must understand how atmospheric pressure works to aim for an air cannon. Also, you must consider the wind speed, trajectory, and target height when aiming for an air cannon. Here are some popular options:

- Wooden air cannons are durable and easy to assemble but may not be as efficient as others.

- Paper air cannons are easy to make and can be made with a variety of materials such as paper, cardboard, and even cloth. However, they may not be able to reach high altitudes.

- Air cannon made of PVC pipe is popular because of their versatility and durability. It can shoot projectiles up to 20 feet away and can often use outdoors. But they may not be as efficient as others.

Assembling an air cannon involves following the instructions provided by the manufacturer. This will help ensure that the air cannon is functional and durable. Before launching a projectile or shooting an air cannon, it is vital to test it thoroughly.

Testing And Using Your Compressed Air Cannon

Before using your compressed air cannon, ensure it is properly assembled and ready to shoot. When choosing the right ammunition for your cannon, consider the size of the object you want to shoot, the power of the air cannon, and the distance you plan to air the cannon. In particular, BBs are a popular choice for air cannons due to their size and consistent flight path.

Before testing a compressed air cannon by shooting small objects such as BBs or pellets, it’s vital that you check the air pressure and volume output. You should also test the cannon by shooting large objects, such as targets or balls, to ensure everything works properly. Finally, store your air cannon in a safe and secure place after each use to prevent it from getting damaged.

How to maintain and clean your compressed air cannon

Maintaining and cleaning your compressed air cannon is essential to ensure its longevity and reliable performance. By following these simple maintenance steps, you can ensure that your compressed air cannon remains in good shape for years to come. Here are some tips to help you keep your compressed air cannon in top condition:

1. Regularly clean the barrel and breech with a soft cloth or brush to remove any debris or residue.

2. Inspect the O-rings and replace them if they appear worn or damaged.

3. Lubricate the O-rings and other moving parts with a silicone-based lubricant to prevent friction and wear.

4. Store your compressed air cannon in a dry, cool place to prevent rust or corrosion.

5. Check the pressure gauge regularly and refill the tank as needed.

Conclusion

Air cannons are also relatively easy to operate, making them ideal for those not experienced in technical fields. Plus, they’re relatively affordable, making them a great option for anyone looking for an easy way to get creative with their photography or video interests.

Compressed air cannons are a fun and inexpensive way to propel objects across the yard, into the air, or just for fun play. They use the same pressure and force to launch the object as an air cannon, but they can produce longer-range and more powerful shots.

While you can make your air cannon at home with a few tools, there are also plenty of designs and plans available online that you can use to make one. Use the tips and plans mentioned above on how to build a compressed air cannon.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-b4c7c07c-34b1-43e6-b7d9-69c861e52d81″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.