Compressor oil is a vital component in ensuring the longevity and efficiency of your compressor. However, over time, it may accumulate and cause issues such as reduced performance and overheating.

This is where vacuuming out compressor oil comes into play. Does vacuum remove compressor oil? We will delve into the details of what compressor oil is, how vacuuming affects it, the benefits and risks associated with vacuuming out compressor oil, tips for doing it safely, and the maintenance required after vacuuming. We will also outline some things to avoid while performing this task to ensure that you don’t cause any damage to your compressor or yourself.

What Is Compressor Oil?

Compressor oil, also known as lubricant or oil, is a vital component in the operation of a compressor. It is specifically designed to provide lubrication and cooling to the compressor’s moving parts, such as the pistons or rotors. Compressor oil is formulated to withstand high temperatures and pressures, ensuring efficient and smooth performance of the compressor.

Additionally, it helps prevent wear and damage to the internal components, prolonging the compressor’s lifespan. Overall, compressor oil plays a critical role in maintaining a compressor system’s overall functionality and longevity.

Does Vacuum Remove Compressor Oil? Explained

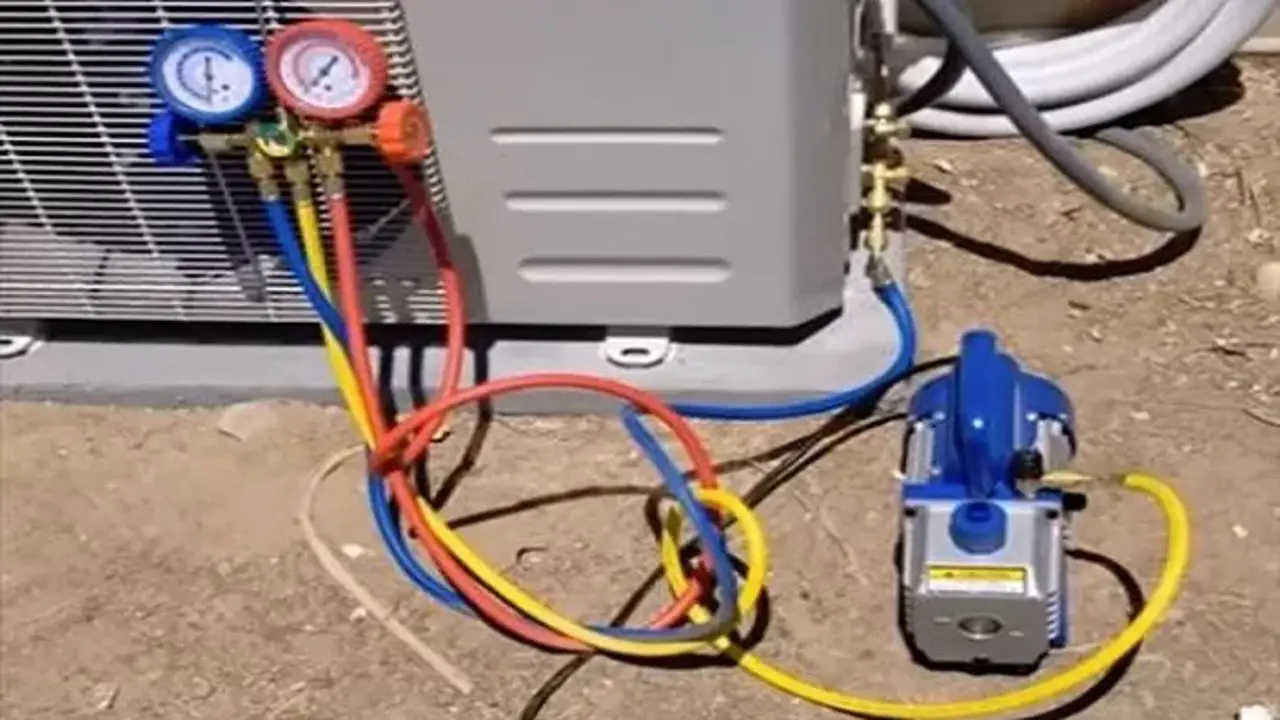

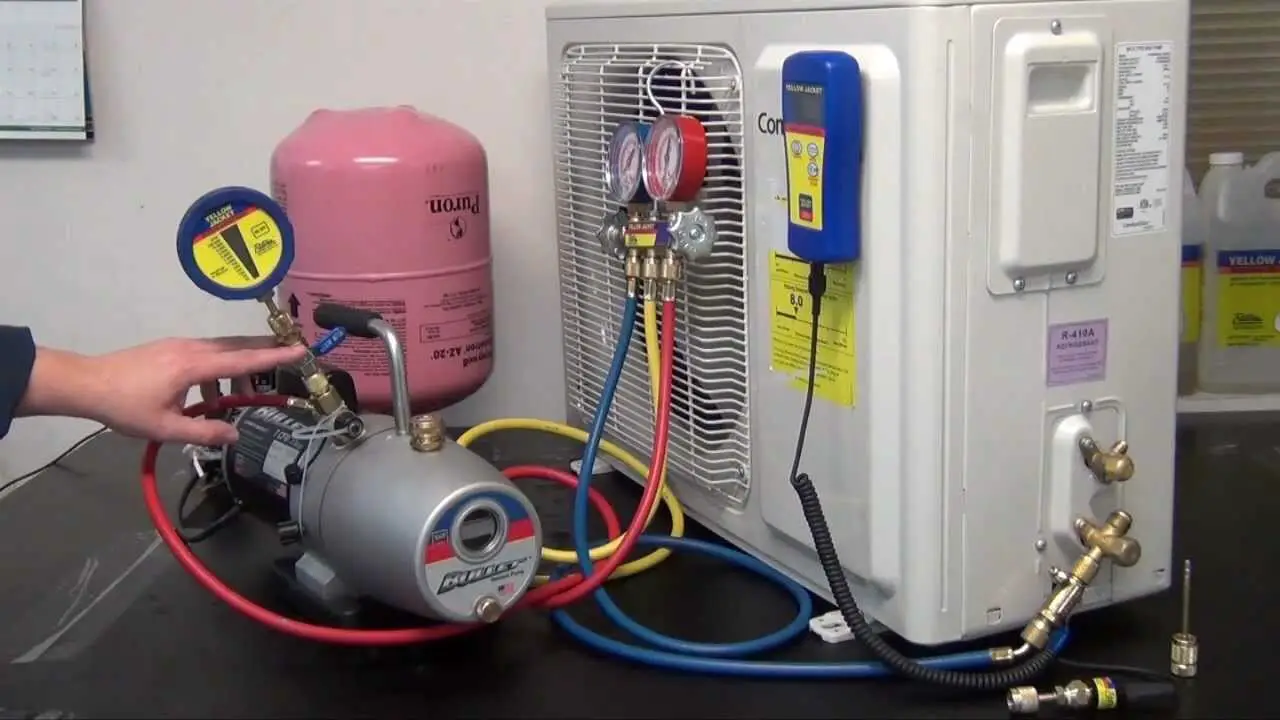

When removing compressor oil, using a vacuum can be an effective method. The vacuum creates negative pressure, which helps to suck out the oil from the compressor system. However, it is important to note that not all vacuums can remove compressor oil. You will need a vacuum specifically designed for this purpose, such as a refrigeration vacuum pump.

These pumps have the power and filtration systems to effectively remove oil from the compressor system. Additionally, following proper procedures and safety precautions when using a vacuum to remove compressor oil is crucial, as mishandling can lead to accidents or damage to the equipment. It is best to consult with a professional or refer to the manufacturer’s guidelines for specific instructions on safely and effectively removing compressor oil using a vacuum. Below we discuss in details on does vacuum remove compressor oil?

The Limitations Of Vacuuming In Removing Compressor Oil

While vacuuming can be an effective method for removing debris and contaminants from a system, it has limitations when it comes to removing compressor oil. Here are some key points to consider. It is important to consult the manufacturer’s guidelines and recommendations for proper cleaning and maintenance procedures for your specific compressor system.

– Vacuuming can remove some oil, but it may not be able to remove all of it. Compressor oil is designed to adhere to surfaces and provide lubrication, so it can be difficult to completely remove with just a vacuum.

– The viscosity of the oil can also impact its removal. Thicker oils may be more challenging to extract using a vacuum.

– Vacuuming may not be able to reach all areas where oil may accumulate, such as in tight corners or crevices.

– In some cases, additional methods such as flushing or using specialized cleaning agents may be necessary to fully remove compressor oil.

Other Methods For Removing Compressor Oil

There are a few different methods you can try to remove compressor oil. Here are some alternative options. Remember, proper maintenance and regular checks of your compressor system are key to ensuring optimal performance and longevity.

- Flushing the system: This involves using a flushing agent to clean out the system and remove the oil. The flushing agent is typically circulated through the system and then drained out.

- Using a compressor oil separator: This device is designed specifically to remove oil from compressed air systems. It uses filters or centrifugal force to separate the oil from the air.

- Draining and refilling: If you don’t have access to vacuum equipment, you can try draining the system of oil and then refilling it with fresh lubricant. This may not remove all traces of the old oil, but it can help minimize contamination.

- Seeking professional help: If you’re unsure about how to properly remove compressor oil or if you’re dealing with a complex system, it may be best to consult with a professional who specializes in HVAC or refrigeration systems. They will have the knowledge and tools necessary to effectively remove the oil without causing damage.

Tips For Vacuuming Out Compressor Oil

Vacuuming out compressor oil can be challenging, but with the right tips and techniques, it can be done effectively. Following these tips, you can vacuum out compressor oil and keep your equipment running smoothly. Here are some tips to help you get the job done:

Use a high-quality vacuum pump: When vacuuming out compressor oil, it is important to use a vacuum pump specifically designed for this purpose. A low-quality or ineffective vacuum pump may not effectively remove all the oil from the system.

Follow manufacturer guidelines: Each compressor and vacuum pump may have specific instructions for properly vacuuming out compressor oil. It is important to carefully read and follow the manufacturer’s guidelines to use the correct techniques and equipment.

Use proper safety precautions: Vacuuming out compressor oil can be a potentially hazardous, as it involves working with machinery and potentially harmful substances. It is important to wear appropriate protective gear, such as gloves, goggles, and a respirator, to minimize the risk of injury or exposure to harmful fumes.

Empty and clean the vacuum pump regularly: Over time, compressor oil residue can build up in the vacuum pump, reducing its effectiveness. It is important to regularly empty and clean the vacuum pump to maintain its efficiency and prevent any contamination of future projects.

Dispose of compressor oil properly: Compressor oil is considered hazardous waste and should be disposed of according to local regulations. Contact your local environmental agency or waste disposal company for guidance on properly disposing of used compressor oil.

Benefits Of Vacuuming Out Compressor Oil

There are several benefits to vacuuming out compressor oil. Overall, vacuuming out compressor oil is a proactive maintenance practice that offers numerous benefits for both short-term performance and long-term durability of your equipment. Here are some of the key advantages:

– Prevents contamination: Vacuuming out compressor oil can help prevent contamination of the system. Over time, compressor oil can become contaminated with debris, moisture, and other impurities, which can negatively impact the performance and efficiency of the compressor. By regularly vacuuming out the oil, you can remove these contaminants and ensure that the system is running smoothly.

– Extends the life of the compressor: Regularly removing old and contaminated compressor oil through vacuuming can help extend the life of the compressor. Contaminated oil can cause increased friction and wear on internal components, leading to premature failure. By keeping the oil clean and free from impurities, you can help prolong the lifespan of your compressor.

– Improves efficiency: Clean compressor oil allows for better lubrication and reduces friction within the system. This, in turn, can improve the overall efficiency of the compressor, leading to lower energy consumption and cost savings.

– Enhances performance: Removing old and contaminated compressor oil through vacuuming can help restore optimal performance to the system. Clean oil ensures that all moving parts are properly lubricated, reducing wear and tear and promoting smooth operation.

– Minimizes maintenance needs: Regularly vacuuming out compressor oil helps to minimize maintenance needs. By preventing contaminants from building up in the system, you reduce the likelihood of clogs or other issues that may require costly repairs or downtime.

How Does Vacuum Affect Compressor Oil?

Many people wonder how it affects compressor oil when it comes to vacuuming. The truth is vacuuming can impact the oil in a compressor. When a vacuum is applied to a compressor, it can cause the oil to vaporize and be removed from the system.

This can lead to a loss of lubrication for the compressor’s moving parts, resulting in increased friction and potential damage to the compressor. Therefore, taking precautions when vacuuming around compressors is important to minimize the risk of oil loss. This may involve using specialized equipment or techniques to protect the compressor and ensure its longevity.

Risks Of Vacuuming Out Compressor Oil

Vacuuming out compressor oil can be a risky endeavour. While it may seem like a quick and easy solution to remove excess oil from your compressor, several potential risks are involved. First and foremost, vacuuming out the oil can lead to damage to the compressor itself. The vacuuming process can create a significant amount of suction, which can cause internal components to become dislodged or damaged.

Additionally, vacuuming out the oil can disrupt the balance of lubrication within the compressor, potentially leading to decreased performance and increased wear and tear on the system. It is always best to consult with a professional before removing compressor oil, as they will have the knowledge and experience necessary to safely and effectively address any issues you may be experiencing.

What Else Can You Do To Remove Compressor Oil?

While vacuuming can help to remove some compressor oil, it may not be enough to eliminate all traces of the oil. If you are dealing with a particularly stubborn or heavy oil spill, there are some additional steps you can take to ensure thorough removal.

One option is to use an absorbent material, such as kitty litter or sawdust, to soak up as much oil as possible before vacuuming. You can also use a degreaser or solvent to remove oil stains. Be sure to follow the instructions provided by the manufacturer and take proper safety precautions when using these products.

Additionally, if the oil spill has seeped into porous surfaces, such as concrete or asphalt, you may need to consult a professional for specialized cleaning techniques.

Maintenance After Vacuuming Out Compressor Oil

After vacuuming out compressor oil, it is important to perform proper maintenance to ensure your compressor’s continued efficiency and longevity. Here are some steps you can take:

- Replace the oil filter: After removing the old compressor oil, it is crucial to replace it. This will help remove any remaining contaminants and prevent them from circulating through the system.

- Refill with fresh compressor oil: Once the oil filter is replaced, refill the compressor with fresh, high-quality compressor oil. Be sure to use the recommended type and grade of oil specified by the manufacturer.

- Check for leaks: After refilling with oil, carefully inspect the compressor for any signs of leaks. Leaks can lead to a loss of oil and compromise the performance of your compressor. If any leaks are detected, repair or replace the affected parts as necessary.

- Monitor oil levels: Regularly check and maintain proper oil levels in your compressor. Low oil levels can cause overheating and damage to internal components.

- Schedule regular maintenance: Schedule regular maintenance for your compressor to ensure optimal performance and prevent costly repairs. This may include routine inspections, lubrication, and filter replacements.

By following these maintenance steps after vacuuming out compressor oil, you can help prolong the life of your compressor and keep it running smoothly for years to come.

What To Avoid When Vacuuming Out Compressor Oil

When vacuuming out compressor oil, there are a few things to avoid to ensure a smooth and efficient process. Here are some key points to keep in mind. By avoiding these common mistakes, you can ensure a successful and safe process when vacuuming out compressor oil from your system.

- Avoid using a regular household vacuum cleaner. Compressor oil is thick and sticky, which can clog and damage the motor of a conventional vacuum cleaner. Instead, opt for a vacuum specifically designed for industrial or automotive use.

- Do not vacuum out hot compressor oil. Allow the oil to cool down before attempting to remove it with a vacuum. Hot oil can cause burns or damage the vacuum equipment.

- Avoid excessive suction power. While you want enough suction power to effectively remove the oil, too much pressure can cause damage to the compressor system or create leaks in the hoses and connections.

- Do not forget proper disposal methods for the extracted oil. Compressor oil may contain contaminants that require special handling and disposal procedures. Follow local regulations and guidelines for disposing of used compressor oil safely and responsibly.

Conclusion

vacuuming out compressor oil can be an effective removal method, but it is important to understand the risks and take necessary precautions. While vacuuming can help remove oil residue and contaminants, it may not fully eliminate all traces of oil. It is crucial to follow proper maintenance procedures after vacuuming to ensure the longevity and efficiency of your compressor.

Additionally, be mindful of potential risks such as damaging the compressor or inhaling harmful fumes. Always consult the manufacturer’s guidelines and consider professional assistance when necessary. By being informed and cautious, you can make the best decisions regarding the maintenance of your compressor. We hope you now understand does vacuum remove compressor oil? or not.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-a13b6766-da72-4660-9c94-1dfeaad64132″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.