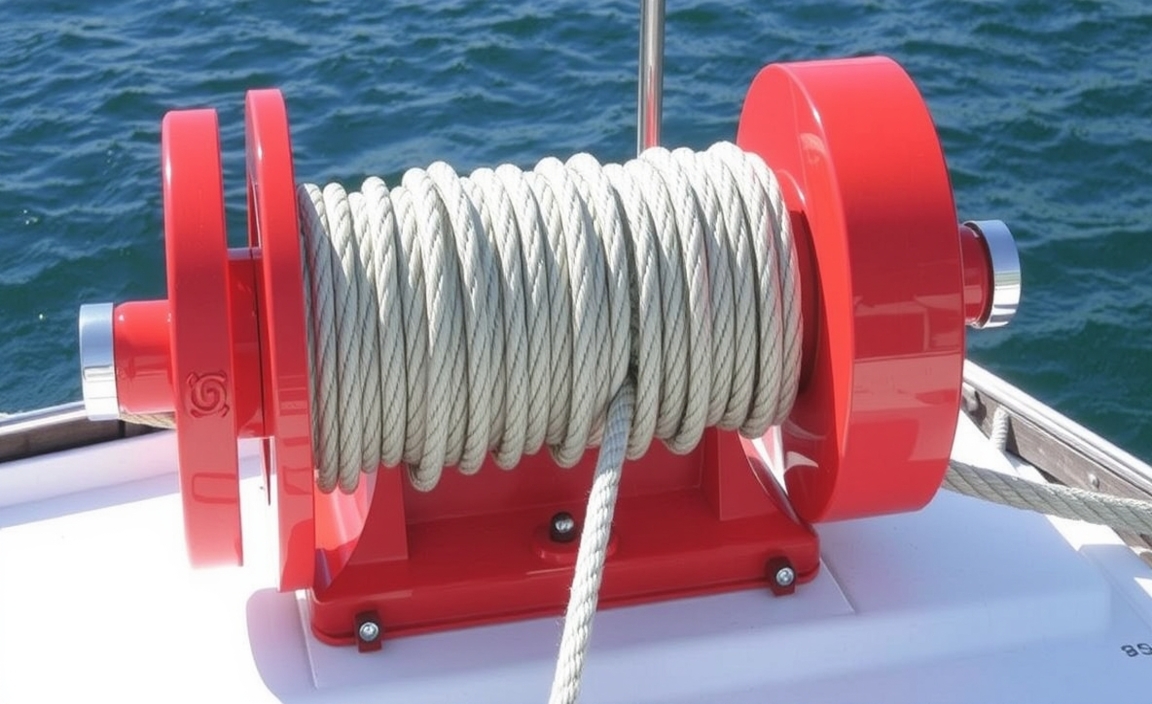

Capstan rope winches are essential for various industries, from maritime and construction to forestry and rescue operations. These powerful machines are handy for lifting and pulling heavy loads easily, making them crucial in many operations. Capstan rope winches offer pulling power and versatility in a compact design.

They use friction to pull loads with a rope, making them ideal for applications requiring long distances or steep slopes. These winches are lightweight and portable for easy transportation. With a virtually unlimited length of rope, capstan winches deliver dependable performance. Their design incorporates features like Simpson capstan rope winch, line speed, and dependability. Here, we will dive into the details of a capstan rope winch and explain its working mechanism step-by-step.

What is a capstan rope winch?

A capstan rope winch is a mechanical device to wind or unwind ropes. It consists of a cylindrical drum and a capstan, which rotates when force is applied. The ropes are wrapped around the capstan, and as it turns, they are either wound onto the drum or released from it.

Capstan rope winches are commonly handy in various industries such as maritime, construction, and transportation. They are especially useful for tasks that require heavy lifting or pulling, as they provide a reliable and efficient method for handling ropes and cables.

How Capstan Rope Winches Work And How to Operate

Capstan rope winches are mechanical devices that lift or move heavy loads using a rotating drum and a rope. Capstan rope winches are mechanical devices commonly handy in various industries for lifting and pulling heavy loads. They wrap a rope or cable around a drum and then rotate it with a motor or manual effort. Capstan rope winches are versatile tools commonly handy in various industries such as construction, maritime, and forestry. They offer a reliable and efficient method for handling heavy loads safely and effectively. Below is a detailed explanation of how to capstan rope operates.

1: Attaching the rope to the drum or capstan head

To ensure proper operation, it is crucial to fasten the rope securely to the drum or capstan head of the capstan rope winch. Follow the manufacturer’s instructions for proper attachment and check for any knots or obstructions that may affect the winch operation. It is important to distribute the rope evenly on the drum or capstan head and double-check the connection to ensure a strong and reliable grip. This will prevent slippage and ensure the winch works effectively.

2: Engaging the power source (manual or electric)

Different methods depend on whether a manual or electric winch is used to engage the power source for a capstan rope winch. A winch handle is handy for turning the drum or capstan head for manual winches. On the other hand, electric winches require the activation of the power source according to the manufacturer’s instructions. It is important to ensure that the power source is securely connected and functioning properly while also paying attention to any safety precautions provided. Monitoring the winch operation for any irregularities is crucial throughout the power engagement process.

3: Applying tension to the rope and starting the winching process

To ensure a smooth winching process, it is important to gradually increase tension on the rope, avoiding any sudden jerks or slippage. Keeping a firm grip on the rope allows for better control. Monitoring the tension applied is crucial to prevent overloading the winch. Ensuring proper rope alignment on the drum or capstan head is also essential. To start the winching process, turn the drum or capstan head in the desired direction.

4: Monitoring the speed and direction of the winch

To ensure smooth operation of the capstan rope winch, it is important to monitor the speed and direction of the winch. Please pay close attention to the speed you pull in or let out the rope and adjust it to maintain control and prevent rope entanglement. Regularly check the direction of the winching operation to ensure it aligns with the intended movement, and be aware of any potential obstacles or hazards in the winching path. Continuously monitor the winch operation for any signs of malfunction or abnormality.

5: Safely stopping and disengaging the winch

To safely stop and disengage the winch, gradually release tension on the rope to bring the winching process to a controlled stop. Ensure you fully release the rope from the drum or capstan head before disengaging the power source. Follow proper safety protocols when handling and storing the winch. Inspect the winch for any damage or wear that may require maintenance or repair. Store the winch in a secure location to prevent unauthorized use or damage.

Tips for maintaining and troubleshooting capstan rope winches

Maintaining and troubleshooting capstan rope winches is essential to ensure their optimal performance and longevity. By following these maintenance tips and addressing any troubleshooting needs promptly, you can prolong the lifespan of your capstan rope winch and keep it functioning smoothly for years to come. Here are some tips to help you keep your capstan rope winch in top shape:

- Regularly inspect the winch for wear or damage, such as frayed ropes or loose bolts. Address any issues immediately to prevent further damage.

- Clean the winch regularly to remove dirt, debris, and salt buildup, especially in marine environments. Use a mild detergent and water to clean the winch gently.

- Lubricate the moving parts of the winch with a high-quality lubricant to reduce friction and ensure smooth operation. Follow the manufacturer’s recommendations for the type of lubricant to use.

- Check the rope’s tension regularly to ensure it is properly aligned and not too tight or loose. Adjust as needed.

- If you encounter any issues with your capstan rope winch, refer to the manufacturer’s troubleshooting guide or contact customer support for assistance. They may be able to provide specific instructions or recommend a professional technician for repairs if necessary.

Checking for any signs of wear or damage on the rope

When using capstan rope cable winches, it is important to regularly check for any signs of wear or damage on the rope. The rope is a crucial component of the winch system, and any weaknesses or fraying can compromise its strength and effectiveness. By inspecting the rope before each use, you can identify any potential issues and take the necessary steps to address them, such as replacing the rope if needed. This simple maintenance task can help ensure that your capstan rope winch operates safely and efficiently, giving you peace of mind during lifting and pulling operations.

Common problems and solutions with capstan rope winches

Regarding capstan rope winches, users may encounter a few common problems. One issue is the rope slipping or jamming on the capstan drum. This can be caused by improper rope tensioning or debris caught in the mechanism. To solve this problem, it is important to ensure the rope is properly tensioned and free from obstructions.

Another common issue is the motor overheating due to excessive use or inadequate ventilation. In this case, give the motor time to cool down and ensure the winch is used within its specified cable capacity.

Lastly, some users may experience issues with the control system, such as buttons not responding or inconsistent speed control. These problems can often be resolved by checking the connections and properly calibrating the control system. By addressing these common problems and implementing appropriate solutions, users can maximize the efficiency and longevity of their capstan rope winches.

Frequently Asked Questions

What is the difference between a winch and a capstan?

A winch and a capstan serve different purposes. While a standard Norse Winch is handy for pulling or lifting heavy loads, a capstan is primarily handy for hauling and controlling ropes. They also differ in power source, axis of rotation, and common applications.

What is the difference between a capstan and a windlass?

A capstan is a rotating machine used to apply force to ropes or cables, typically by turning a horizontal drum, while a windlass is a device used for hoisting or hauling that uses a vertical drum. The key difference lies in the orientation of the drum – horizontal for the capstan and vertical for the windlass.

What is a Capstan Winch and How Does It Work?

A capstan winch is a type of winch that utilizes a rotating drum to wind and unwind rope or cable. Powered by an engine or motor, the drum’s rotation draws in or releases the rope/cable as needed. This mechanism creates friction and grip, allowing for controlled movement.

What is a Portable Capstan Winch?

A portable capstan winch is a compact and transportable device that utilizes a drum and rope mechanism to provide a mechanical advantage for pulling heavy loads. It is commonly handy in forestry, hunting, and outdoor activities. Popular brands include Portable Winch Co., Warn Maritime Industries, and Ramsey Winch.

What is a galvanized capstan winch?

A galvanized capstan winch is a rope winch with a protective zinc coating to prevent rusting. These winches utilize a rotating drum to pull in or pay out rope or cable. They are commonly handy on boats and ships for anchoring, mooring, and towing.

Conclusion

Capstan rope winches are reliable and efficient tools for various industries. Regular maintenance and troubleshooting are essential to keep the winch in optimal condition. By inspecting and lubricating the components and checking for any signs of wear or damage on the rope, you can extend the lifespan of your winch and prevent potential issues. In case of common problems, such as rope slippage or motor failure, referring to the user manual or seeking professional assistance can help resolve the issues promptly. With proper care and usage, a capstan rope winch can provide reliable pulling power for various applications.

Resource:

Rope safety inspection: https://www.osha.gov/sites/default/files/publications/osha3120.pdf

Basic mechanical friction principles: https://www.engineeringtoolbox.com/friction-coefficients-d_778.html

Safe lifting techniques: https://www.ccohs.ca/oshanswers/safety_haz/liftin.html

Electric motor overheating tips: https://www.nidec.com/en/technology/motor/basic/003/

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.