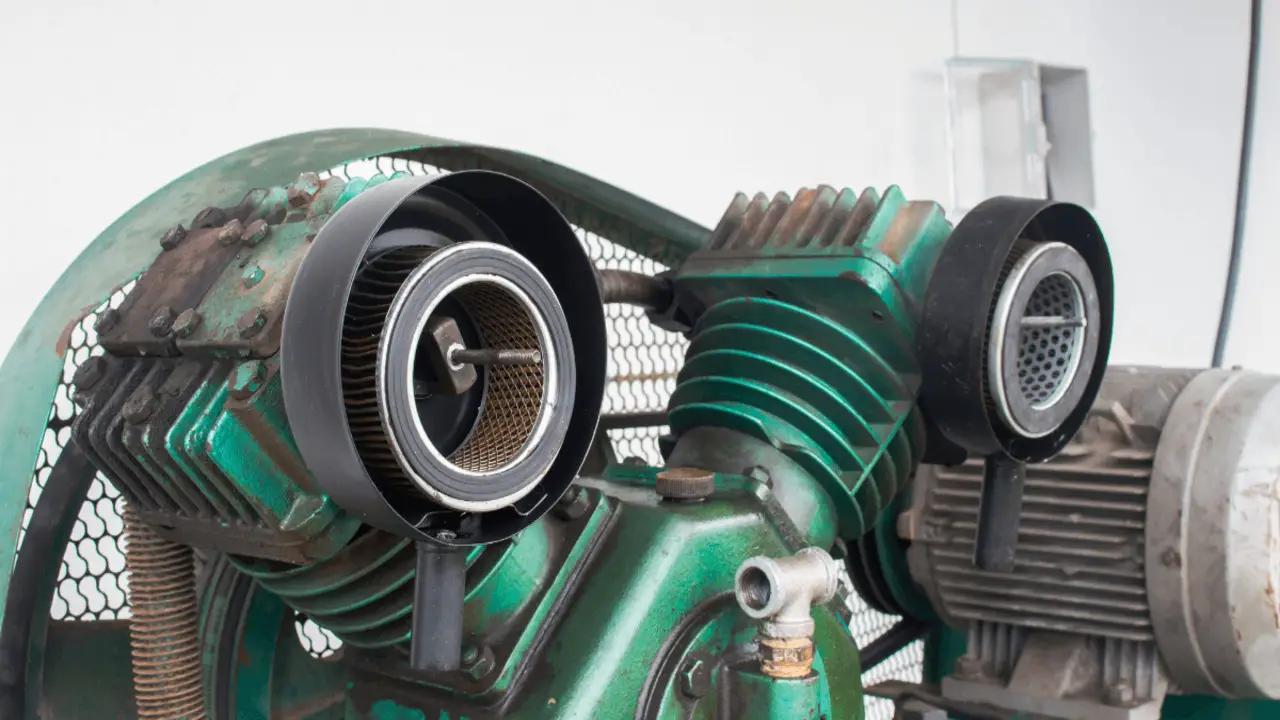

A craftsman 12 gallon air compressor is used to apply air pressure to tools and to inflate tires. This type of air compressor is designed to generate compressed air from an electric motor or gasoline engine.

The air compressor can produce air at pressures of up to 150 pounds per square inch (psi). Here we will dive deep into the world of the Craftsman 12-gallon Air Compressor, your ultimate resource for all your pneumatic needs.

From understanding the safety features and precautions before operating the compressor to setting it up and properly maintaining it, we’ve got you covered. We will also explore the benefits of owning this powerful machine and provide troubleshooting tips for common issues that may arise.

How To Use Craftsman 12 Gallon Air Compressor Safely?

A Craftsman 12 Gallon Air Compressor can be a great addition to your workshop or garage. However, it is important to know how to use it safely. The first step is to read the user manual and familiarize yourself with the compressor’s features and specifications.

Wear appropriate safety gear, such as eye and ear protection, and avoid wearing loose clothing or jewelry that could get caught in the machine. When handling the air hose, inspect it for any damages and replace it if necessary.

Never exceed the recommended pressure limit for the compressor, as this could cause serious injury or damage to the equipment. It is also important to properly maintain the compressor by regularly checking the oil level and cleaning the air filter. When using the compressor, never leave it unattended, and always turn it off when not in use. Finally, make sure to store the compressor in a dry, well-ventilated area away from any sources of heat or flames.

The Safety Features Of The Air Compressor

Air compressors have become an essential tool in many industries. They are widely handy in construction, manufacturing, and automotive repair. However, it is important to understand the safety features of an air compressor before using it.

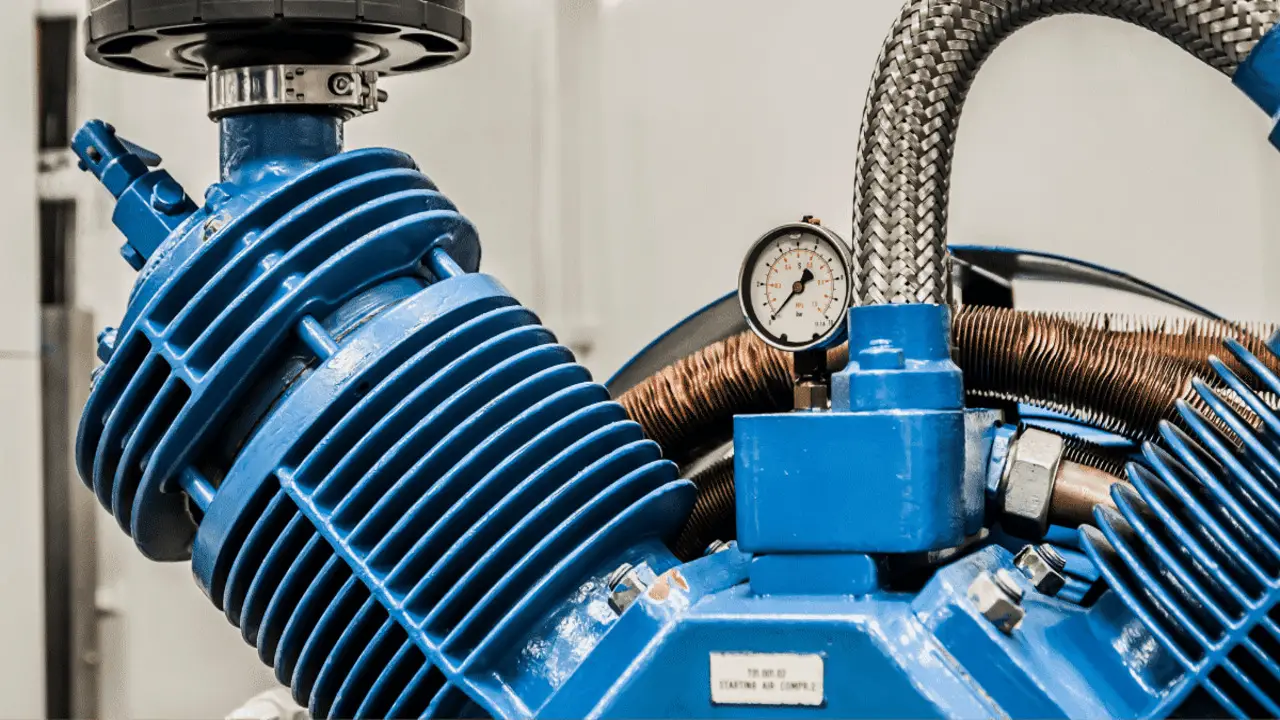

One of the most critical safety features is the pressure relief valve. This valve is designed to release the pressure inside the tank when it exceeds the maximum level. It can prevent explosions or other accidents that may result from overpressure. Another important safety feature is the automatic shut-off switch.

This switch turns off the compressor when the pressure reaches a certain level, preventing the compressor from running continuously and overheating. Thermal overload protection is a safety feature that protects the motor from overheating. It shuts off the compressor when the motor exceeds a safe temperature. One should note that safety features apply not only to the compressor itself but also to its accessories and tools.

Safety Precautions Before Operating The Air Compressor

Before operating an air compressor, it is important to take all necessary safety precautions to prevent accidents and injuries. First and foremost, place the compressor on a stable and level surface to avoid tipping over or falling.

It is also important to check the oil levels and ensure no leaks in the system. Wearing appropriate personal protective equipment, such as safety glasses and earplugs, is crucial to prevent eye and ear damage from the loud noise the compressor creates.

Before starting the compressor, it is essential to inspect all the hoses and connections to ensure that they are securely fastened and free of any damage or cracks. Additionally, following the manufacturer’s instructions and guidelines for the specific compressor model is essential.

Never exceed the pressure rating and always operate within the recommended pressure range to avoid accidents. Finally, always turn off the compressor and unplug it when not in use to prevent any unexpected start-up or accidents.

Setting Up And Installing The Air Compressor

Setting up and installing an air compressor can seem daunting, but ensuring the machine’s smooth operation is necessary. A crucial first step is selecting an appropriate location for the compressor. Place it on a level surface, away from heat sources, and in a well-ventilated area. Once you’ve found the right spot, it’s time to begin the installation.

Start by ensuring the power source matches the voltage and amperage requirements of the compressor and that all electrical connections are secure. The next step is to attach the air intake filter and connect the air hoses.

Use the correct fittings and hoses for the specific compressor model. After attaching the hoses, turn on the compressor and check for leaks. Adjust the pressure switch to the desired level, and the compressor is ready. Remember to check and replace the air filter periodically and regularly drain the moisture from the tank to ensure longevity and efficient operation.

Setting Up And Operating The Air Compressor

Setting up and operating an air compressor can seem daunting for beginners, but it can become a simple task with the right guidance. First, ensuring that the air compressor is placed on a stable, flat surface and connected to a reliable power source is important.

Once done, the user can set the pressure regulator to the recommended level for the specific task. The next step involves attaching the air hose to the compressor and checking for leaks.

It is essential to use the appropriate fittings for the hose and to secure them tightly to avoid any safety hazards. Once the user sets up the air compressor correctly, they can operate it.

This often involves turning on the power switch and allowing the compressor to build up air pressure in the tank. Monitoring the pressure gauge and switching the compressor off once the desired pressure level is reached is essential.

Proper Use And Maintenance Of The Air Compressor

An air compressor’s proper use and maintenance are critical to ensure safe and efficient operation. To begin with, it is essential to read and follow the manufacturer’s instructions carefully. This includes understanding the compressor’s maximum pressure and flow rate to avoid overloading it.

Additionally, ensure you install the compressor on a flat, stable surface. Keep the air intake clean of debris, such as dust and dirt, to prevent clogging of the filters. You should conduct regular checks to verify that the compressor’s hoses and connections are secure and leak-free.

Furthermore, keeping the compressor’s lubrication system in good condition is important by following the manufacturer’s recommendations on using lubricants. You should carry out regular oil changes and filter replacements to keep the compressor running smoothly. During use, monitoring the compressor’s performance and shutting it down immediately if any unusual noises or vibrations are observed is important.

Safety Tips For Operating The Air Compressor

Before using the Craftsman 12 -Gallon Air Compressor, follow the manufacturer’s instructions and safety guidelines carefully. Always place the compressor on a stable surface and wear appropriate safety gear such as goggles and ear protection. Regularly inspect the pressure gauge and safety valve for proper functionality. Keep the area around the compressor clean, and never leave it unattended.

Benefits Of Owning A Craftsman 12-Gallon Air Compressor

Experience the versatility of the Craftsman 12-gallon Air Compressor for a wide range of tasks. Save time and money by using this compact, powerful tool for inflating tires, powering pneumatic tools, and cleaning. Its large tank capacity and ample air supply make it perfect for longer use without frequent refilling. Follow safety guidelines to use it properly.

Troubleshooting Common Issues With The Air Compressor

Air compressors are essential tools for many industries, but they can also be frustrating when they fail to work properly. Troubleshooting common issues with the air compressor can help you identify and fix problems quickly, saving time and money.

One of the most common issues is a lack of pressure or airflow, which a clogged air filter can cause, a leak in the system, or a faulty regulator. To fix this issue, check the air filter and clean or replace it if necessary.

Next, inspect the system for visible leaks and repair them as needed. If the problem persists, it may be a regulator issue, and you may need to replace it. Overheating can cause another common issue, and it can be due to a dirty or clogged cooling system, a low oil level, or a faulty motor. To prevent this, clean the cooling system regularly and check the oil level before each use.

Conclusion

The Craftsman 12 Gallon Air Compressor is a powerful and versatile tool that can be handy for many tasks. However, it’s important to prioritize safety when using this equipment. Familiarize yourself with the safety features and precautions before operating the air compressor. Follow the proper setup, installation procedures, and guidelines for operating and maintaining the equipment.

Additionally, we’ve discussed the benefits of owning a Craftsman 12-Gallon Air Compressor and provided troubleshooting tips for common issues. Invest in this reliable and efficient air compressor if you’re ready to take your DIY projects to the next level. Get yours today and experience the difference it makes in your workshop.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-b77cf6fb-5b47-469c-8994-4b4583c97964″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.