Selecting the appropriate type of lumber is essential in construction and renovation projects. Two common options often used in construction projects are dimensional and pressure-treated lumber.

While they may seem similar, these two types of lumber have distinct differences that can greatly impact the success and longevity of your project. It is important for builders and homeowners alike to fully understand these differences to make informed decisions and ensure the safety and stability of their structures.

We will delve into the definitions of dimensional lumber vs pressure-treated lumber and why it is essential to understand their distinctions. So, let’s explore the differences between dimensional lumber and pressure-treated lumber and why it is crucial to know them.

Features Of Dimensional Lumber

Dimensional lumber is commonly handy in outdoor projects due to its durability and strength. However, when using untreated wood, it is important to note that it may be susceptible to rot and decay over time.

Untreated lumber, although cost-effective, requires extra care and maintenance to ensure its longevity when exposed to the elements. Consider treating the wood to enhance its resistance to moisture and pests.

Pros

- A versatile material that can be handy for various construction projects

- Easily accessible and readily available at most hardware stores

- Can be easily cut and shaped to fit specific project requirements

- Provides structural stability and strength to the building

Cons

- Susceptible to warping, twisting, and shrinking over time

Features Of Pressure-Treated Lumber

Pressure-treated lumber is popular for its durability and resistance to insect damage, making it ideal for outdoor applications. Chemicals treat it to protect the wood products from decay and rot caused by exposure to elements.

This treatment extends the life of the wood, providing a wide range of uses from decking to fencing. People often choose pressure-treated lumber for its cost-effectiveness and longevity in various construction projects.

Pros

- Durable and longlasting

- Resistant to rot, decay, and insects

- Can withstand harsh weather conditions

- Easy to paint or stain

Cons

- The initial cost may be higher than untreated lumber

Comparison Between Dimensional Lumber Vs Pressure Treated Lumber

Comparing dimensional lumber and pressure-treated lumber reveals their distinct characteristics and uses. Dimensional lumber is a versatile choice that is commonly handy in construction projects. On the other hand, pressure-treated lumber offers enhanced protection against moisture, rot, and insects.

Understanding the differences between these two types of lumber is crucial for outdoor applications. Considering cost, longevity, and maintenance requirements is important before deciding. By weighing these factors, you can determine which type of lumber best suits your needs. Here is the comparison between dimensional lumber and pressure-treated lumber.

1.Durability And Longevity

When considering durability and longevity, assessing the differences between dimensional and pressure-treated lumber is crucial. Dimensional lumber, while versatile, may not stand the test of time in ground contact due to its untreated nature.

On the other hand, pressure-treated lumber, impregnated with preservatives, offers enhanced resistance against the degradation of wood cells when exposed to ground contact, ensuring longevity and structural integrity.

2.Maintenance Requirements

Maintenance requirements for dimensional and pressure-treated lumber differ significantly, particularly in direct contact with the elements. Dimensional lumber typically necessitates regular inspections and treatments to prevent decay and damage, while pressure-treated lumber boasts enhanced durability and resistance due to its protective chemical treatment.

Furthermore, when handling both types, ensuring proper eye protection is crucial to avoid potential injuries, especially when dealing with chemicals or sawdust. Additionally, identifying and interpreting lumber stamps are key to understanding the wood’s origin and characteristics for proper maintenance and usage.

3.Environmental Impact

When comparing dimensional lumber to pressure-treated lumber in terms of their environmental impact, it is important to consider various factors. Typically, companies source dimensional lumber from sustainably managed forests to minimize deforestation and promote biodiversity.

However, pressure-treated lumber involves using chemicals to enhance its durability, which can negatively affect the environment if not properly handled and disposed of. Additionally, the pressure-treated lumber production process may result in harmful substance emissions. Choosing between the two types of lumber requires carefully assessing their environmental implications.

4.Cost Comparison

Dimensional lumber tends to cost less upfront compared to pressure-treated lumber. However, pressure-treated lumber may be more cost-effective in the long run due to its ability to resist decay and insects, which can lead to lower maintenance costs and longer lifespans. It ultimately depends on the specific project needs and budget constraints.

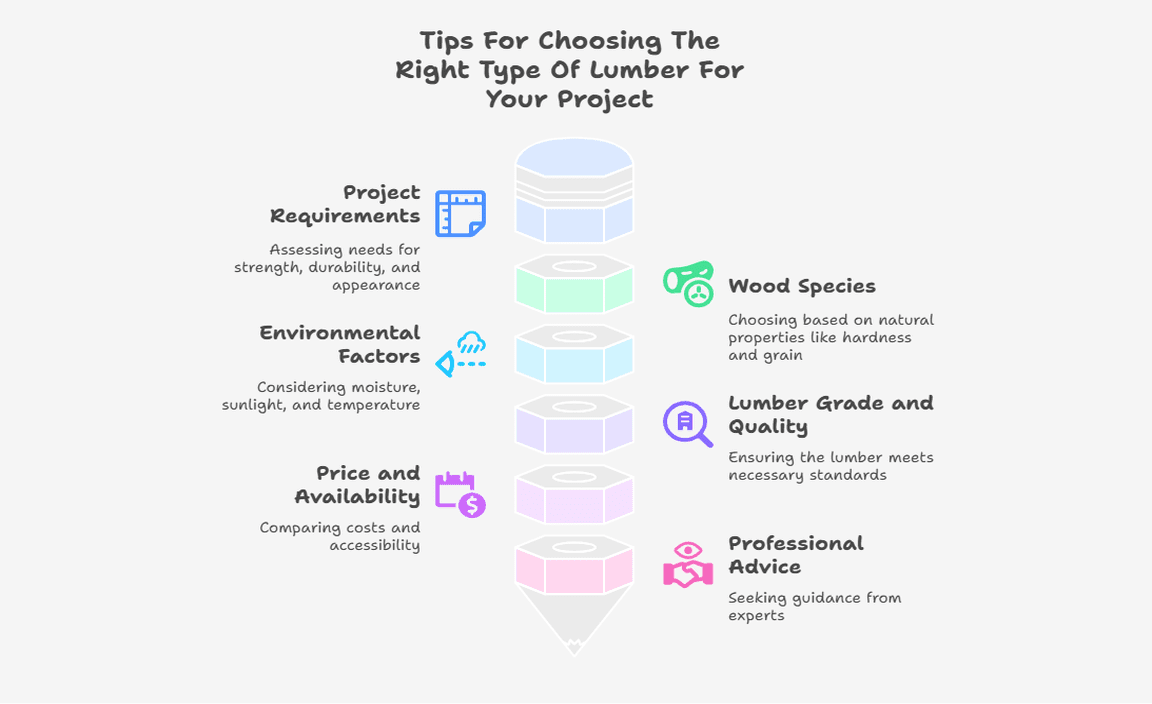

Tips For Choosing The Right Type Of Lumber For Your Project

When selecting the appropriate lumber for your project, it is crucial to consider factors such as the wood species, grade, and cut. Assessing the project requirements carefully is recommended to determine the ideal type of lumber needed.

Additionally, evaluating the lumber’s durability, appearance, and availability will ensure a successful outcome for your project. Here are some tips for choosing the right type of lumber for your project:

- Determine project requirements (strength, durability, appearance)

- Choose suitable wood species based on natural properties (hardness, grain pattern)

- Consider environmental factors (moisture, sunlight, temperature)

- Check lumber grade and quality

- Compare prices and availability

- Seek advice from woodworking professionals or experts

Applications And Best Practices

When considering applications and best practices, comparing dimensional and pressure-treated lumber is important to determine the most appropriate material for the task. From selecting the right material to adhering to installation tips and techniques and implementing necessary safety precautions, it is essential to consider these factors to ensure a successful and durable outcome.

When To Use Pressure Treated Lumber And When To Avoid It

Pressure-treated lumber is a popular choice for outdoor projects such as decks, fences, and landscaping structures due to its resistance to rot, decay, and insect damage. Chemicals infused protect the wood from these issues and extend its lifespan. However, there are instances when using pressure-treated lumber may not be necessary or even recommended.

For interior projects or areas where the wood will not be exposed to moisture or the elements, untreated lumber may be a more cost-effective option. Additionally, suppose you are working on a project that involves direct contact with food or sensitive environments such as vegetable gardens or children’s play areas.

In that case, it is best to avoid pressure-treated lumber altogether and opt for alternative materials. Ultimately, the decision to use pressure-treated lumber should be based on the specific needs of your project and the environment in which it will be used.

Where Can I Use Pressure-Treated Lumber?

Pressure-treated lumber is a versatile building material that can be used in a variety of outdoor applications. Its resistance to rot, decay, and insect infestation makes it an ideal choice for projects such as decking, fencing, and outdoor furniture.

Whether you’re building a new deck for your backyard or constructing a raised garden bed, pressure-treated lumber is designed to withstand the elements and provide longlasting durability.

It is important to note that due to the chemicals used in the pressure-treating process, it is not recommended for use in indoor applications or areas where it may come into direct contact with food or water. However, for all your outdoor construction needs, pressure-treated lumber is a reliable and cost-effective option.

Which Paint Finish Is Right For Your Home’s Interior?

When choosing between framing lumber and pressure-treated lumber, there are a few key factors to consider. Framing lumber is typically handy for structural purposes, such as building walls and floors. It is usually kiln-dried and has a lower moisture content, making it less prone to warping and shrinking. Pressure-treated lumber, on the other hand, is treated with chemicals that help prevent rot and insect damage.

It is commonly handy for outdoor projects like decks and fences, where exposure to moisture is a concern. Ultimately, the choice between framing lumber and pressure-treated lumber will depend on the specific needs of your project and the environmental conditions it will be exposed to. It’s always a good idea to consult with a professional or your local building code requirements to ensure you are using the appropriate type of lumber for your project.

Conclusion

It is important to distinguish between dimensional lumber and pressure-treated lumber for clarity. Choosing between dimensional lumber and pressure-treated lumber ultimately depends on your specific needs. Dimensional lumber is versatile and commonly used for many applications, while pressure-treated lumber offers added protection against moisture and rot.

When deciding, consider factors such as moisture resistance, rot resistance, and strength requirements. Additionally, remember the maintenance and care required for each type of lumber.

Regular inspections and proper maintenance will ensure the longevity and durability of your projects. Whether you choose dimensional or pressure-treated lumber, both options have advantages and can be useful in various construction projects.

Frequently Asked Questions

What Is Better Than Pressure-Treated Wood?

Composite wood is better than pressure-treated wood as it is more durable, resistant to rot and decay, requires less maintenance, and is eco-friendly. Additionally, composite wood is available in various colors and styles, providing a more aesthetically pleasing option than pressure-treated wood.

Why Use Dimensional Lumber?

Dimensional lumber is commonly handy in construction due to its strength, durability, and versatility. Its standardized sizes and straight edges make it easy to work with and ideal for framing, structural support, and other building applications.

What Type Of Wood Is Dimensional Lumber?

Dimensional lumber typically comes from softwood trees such as pine, spruce, or fir. These types of wood are commonly handy for construction and building purposes due to their strength, versatility, and affordability.

Is Dimensional Lumber Solid Wood?

Yes, dimensional lumber is solid wood. It is cut from logs and processed into standard sizes for construction purposes, such as framing and structural support.

How Are Dimensional Lumber Grades?

Graders base dimensional lumber on its appearance, structural integrity, and suitability for specific uses. The grading system typically ranges from high to low quality, with higher grades indicating fewer defects and better performance characteristics.

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.