M12 batteries have become integral to various electronic devices, from power tools to smartphones. These compact and efficient batteries provide a reliable power source, making them popular among consumers.

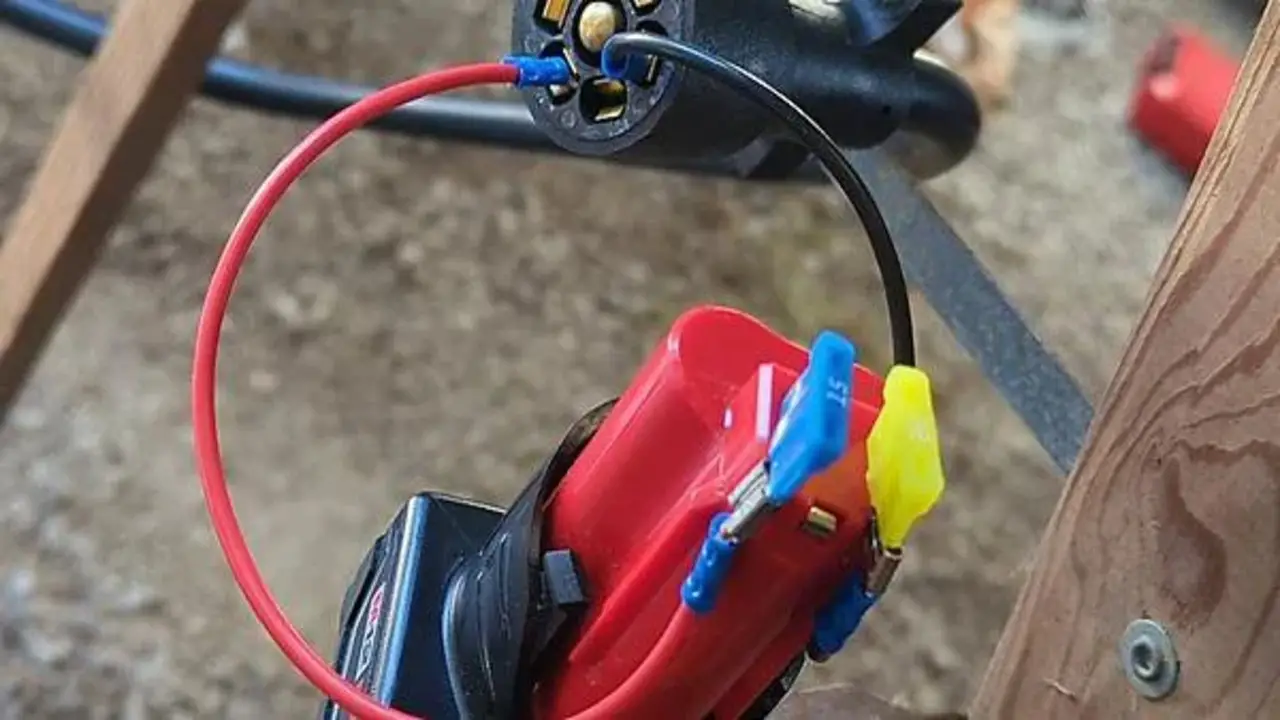

However, understanding the basics of M12 batteries, specifically the positive battery terminal and negative aspects, is crucial for their optimal functioning and longevity. The positive terminal of an M12 battery is marked with a plus sign (+) and is used to connect the battery to other devices.

On the other hand, the negative terminal is marked with a minus sign (-) and accepts electrons from the electronic device when it needs energy. We will investigate the details of M12 battery positive and negative battery terminals, their functionalities, and the importance of proper maintenance. So, let us explore the intricate workings of M12 batteries and unlock their full potential for your devices.

The Limitations Of M12 Battery Positive And Negative – Different Problem And Solutions

In any battery-powered device or system, understanding the correct polarity of the battery is of utmost importance. This holds particularly true for the Milwaukee M12 battery, a widely used power source in various industries.

Knowing the positive and negative terminals of the M12 battery is crucial for safety and functionality reasons. Reversing the polarity can result in ineffective operation and pose significant risks. Incorrectly connecting the battery can damage the device or even cause it to malfunction.

Moreover, it can result in short circuits, overheating, and potential fires or explosions. By being aware of the correct polarity, users can confidently and securely link the battery to their equipment, minimizing the chances of accidents or damage. Below, we discuss more in detail on M12 battery positive and negative.

M12 Battery Positive Site

Individuals must comprehensively understand the M12 battery-positive site and its significance. The M12 battery positive site serves as a connection point for the battery’s positive terminal, ensuring the proper flow of electrical current within a device or system. By knowing the correct location and function of the M12 battery-positive site, individuals can effectively and safely utilize their devices that rely on this specific battery type.

- The M12 Battery Positive site is a specific location or area designed for the replacement, installation, or connection of the positive terminal of an M12 battery.

- It is typically marked with a plus sign (+) to indicate the positive terminal.

- The M12 battery positive site is usually located on devices or equipment that utilize M12 batteries, such as power tools or electronic devices.

- Properly connecting the positive terminal to the M12 battery positive site is essential for the device or equipment to function correctly.

- To prevent any power loss or malfunction, ensuring a secure and stable connection between the positive terminal and the M12 battery positive site is important.

M12 Battery Negative Site

Understanding the importance of the M12 battery negative site is crucial for anyone working with equipment or devices that utilize this specific battery type. The M12 battery negative site refers to the terminal or connection point on the battery where the negative charge is directed. This may seem like a small detail, but it plays a significant role in maintaining the functionality and safety of the equipment.

- The M12 Battery Negative site refers to the negative terminal or contact point on the M12 battery.

- It is on the battery pack and is usually marked with a minus sign (-) or a symbol indicating the negative terminal.

- The M12 Battery Negative site is where you connect the negative wire or terminal of a device or equipment to complete an electrical circuit.

- It is important to ensure a secure and proper connection to the M12 Battery Negative site to avoid any electrical issues or malfunctions.

- When connecting a device or equipment to the M12 Battery Negative site, follow the manufacturer’s instructions and guidelines for proper installation and connection.

How Do M12 Battery Connections Work?

They understand that M12 battery connections are essential for anyone working with power tools or equipment that utilizes this type of battery. M12 batteries are commonly used in various industries, including construction, automotive, and manufacturing. These batteries provide a reliable and efficient power source, and knowing how the connections work can ensure the smooth and safe operation of the tools.

- The M12 battery connections work using a proprietary system developed by the manufacturer.

- The M12 batteries feature a unique design with a specific shape and size that are compatible only with devices and tools designed for M12 batteries.

- To connect an M12 battery to a device or tool, align the battery with the corresponding battery slot on the device.

- Once aligned, slide the battery into the slot until it clicks into place. Ensure that the battery is securely connected before using the device.

- The M12 battery connections are designed to provide a reliable and stable connection, ensuring proper power transfer between the battery and the device.

- When removing an M12 battery, press the release button or lever on the device or tool to disengage the battery from the connection.

- It is important to use genuine M12 batteries and compatible devices to ensure proper functionality and avoid potential damage to the battery or the device.

The Potential Issues With Reversed Battery Polarity

Understanding the potential issues with reversed M12 battery polarity is paramount to ensure the safe and efficient operation of electrical devices. The polarity of a battery refers to the positive and negative terminals and their respective connections.

When the polarity of an M12 Battery Platform is reversed, it can lead to many problems that can compromise the performance and longevity of the device and pose serious safety hazards.

- Reversed M12 battery polarity can cause damage to the electrical components of devices or equipment.

- It may lead to a short circuit, which can result in overheating, melting, or even explosion of the battery.

- The reversed polarity can damage the charger or charging circuit, causing it to malfunction or fail.

- Reversed battery polarity can also damage the battery, reducing lifespan and performance.

- It can lead to incorrect readings or malfunctions in devices that rely on battery power, such as power tools or electronic devices.

- The reversed polarity can cause damage to the internal circuitry of the device, rendering it inoperable or requiring costly repairs.

- In some cases, the reversed polarity can cause a safety hazard, especially if the battery is not properly secured or insulated.

- It is important always to double-check the battery polarity before installation to prevent these potential issues.

Common Causes Of Reversed Battery Polarity

Understanding the common causes of reversed M12 battery polarity is crucial for ensuring electrical systems’ safe and efficient operation. Reversing the polarity of a battery can have serious consequences, including damage to equipment, decreased battery life, and even the risk of electrical fires. Therefore, knowing why this occurs is essential in preventing these issues.

- Incorrect Installation: One common cause of reversed M12 battery polarity is simply installing the battery in the wrong orientation. This can happen if you are not paying attention or if you are not familiar with the proper battery installation procedure.

- Lack Of Proper Marking: Sometimes, battery voltage may not have clear markings indicating the correct polarity. This can lead to confusion and increase the chances of accidentally reversing the polarity.

- Faulty Connectors: Another cause of reversed M12 battery polarity can be faulty connectors. If the connectors are loose, damaged, or poorly designed, they may not provide a secure connection, leading to accidental reversal of the bad battery polarity.

- Inadequate Training Or Knowledge: Many individuals may not have proper training or knowledge on handling batteries correctly. This lack of understanding can result in accidental reversal of the battery polarity.

- Rushing Or Not Paying Attention: Finally, rushing or not paying attention during the battery installation process can easily lead to reversed M12 battery polarity. Taking your time and being mindful when handling batteries is important to prevent this dangerous mistake.

The Dangers And Risks Associated With Reversed Battery Polarity

Understanding the dangers and risks associated with reversed battery adapter converter polarity is of utmost importance in ensuring electronic devices’ safe and effective operation. Reversed battery polarity occurs when a battery’s positive and negative terminals are connected in the wrong orientation. This simple mistake can have severe consequences, leading to device malfunctions, electrical damage, and even personal injury.

- Reversed m12 battery polarity can lead to short circuits and electrical malfunctions.

- It can cause the battery to overheat, leading to the risk of fire or explosion.

- Reversed polarity can damage the electronic devices or equipment connected to the battery.

- It may result in the release of toxic gases or chemicals from the battery.

- Reversed polarity can cause irreversible damage to the battery itself, rendering it unusable.

- It can risk the safety of individuals working with or handling the battery.

- Reversed m12 battery polarity can void warranties or insurance coverage for the battery or any affected devices.

- To avoid these dangers and risks, it is important to double-check the polarity before connecting or installing the battery.

How To Prevent And Fix Reversed Battery Polarity Issues

Knowing how to prevent and fix reversed M12 battery polarity issues is of utmost importance to ensure the safety and functionality of electrical devices. Reversing the polarity of a battery can lead to serious consequences, such as damaging the device or causing electrical malfunctions. Therefore, it is crucial to understand the reasons behind this issue and how to avoid and rectify it effectively.

- Always double-check the battery polarity before inserting it into the device. Ensure that the positive and negative terminals match the corresponding markings on the device.

- Use batteries specifically designed for the device to minimize the risk of reversed polarity issues.

- If you accidentally insert the battery with reversed polarity, immediately remove it from the device to prevent any damage.

- Inspect the battery and device terminals for any signs of damage or corrosion. Clean them if necessary before reinserting the battery.

- If the device shows signs of malfunction or doesn’t work after inserting the battery with reversed polarity, do not force it to operate.

- Consult the device’s manual or contact the manufacturer for guidance on fixing reversed polarity issues.

- In some cases, devices may have been built with reverse polarity protection. Check if your device has this feature and follow the recommended steps for fixing reversed polarity issues.

- Consider using a Battery Convert Adapter that provides reverse polarity protection if you frequently use M12 batteries.

- Educate yourself and your team members on the importance of battery polarity and the risks associated with reversed polarity.

Tips For Safely Handling And Installing M12 Batteries

In the world of power tools and equipment, M12 batteries have become increasingly popular due to their compact size and reliable performance. However, knowing the proper tips for safely handling and installing these batteries is essential. M12 batteries are designed to deliver high levels of power, and mishandling them can result in accidents or damage to the battery itself.

- Always read and follow the manufacturer’s instructions before handling or installing M12 batteries.

- When handling batteries, wear appropriate personal protective equipment, such as gloves and safety glasses.

- Ensure that the battery is compatible with your device or tool.

- Inspect the battery for any signs of damage or defects before installing it.

- Ensure the device or tool is turned off before installing or removing the battery.

- Align the battery properly with the device’s compartment and ensure it is securely inserted.

- Avoid exposing the battery to extreme light, temperatures or moisture, as this can affect its performance and safety.

- Store 12Volt Battery in a cool, dry place when not in use.

- Do not attempt to disassemble or modify the battery, as this can lead to safety hazards.

If you encounter any issues or difficulties with the battery, contact the manufacturer or a qualified professional for assistance.

Conclusion

It is a matter of concern to knowm12 battery positive and negative terminals. Understanding the positive and negative terminals of an M12 battery is crucial for proper usage and maintenance. Whether using the battery for power tools or other electronic devices.

Ensuring that the correct terminals are connected is essential for optimal performance. With the proper knowledge, you can ensure the longevity and effectiveness of your M12 battery, whether it be for your power tools or other devices. Always handle the battery cautiously and follow safety guidelines to prevent accidents.

Remember the polarity and ensure proper connections to avoid any damage or malfunction. With the right care and attention, your M12 battery will continue to power your devices efficiently.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-ec75f511-6712-42d1-b30a-725549bb77bb”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.