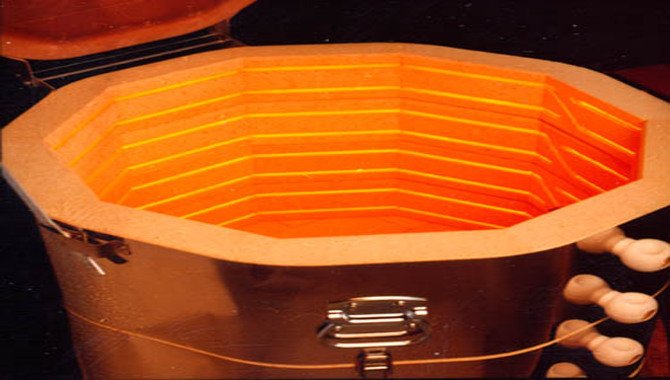

Kiln firing is the process of heating kiln-dried clay to temperatures high enough to fuse the clay together, making it sturdy and durable. Most pottery kilns are kiln firing units.

Kiln firing is a popular way to produce kiln-fired ceramics, pottery, glass, leather items, bricks, tiles, and more. The ideal temperature for firing pottery or ceramists’ wares is around 2,000 degrees Celsius (3,362 degrees Fahrenheit). A kiln is a type of temperature chamber used for the purpose of heating materials to high temperatures.

The purpose of a kiln is to provide a controlled environment for heating materials quickly and efficiently. The types of kilns available in the market vary from small tabletop models to gigantic industrial sized kilns. Different types of kilns use for different purposes such as ceramic, pottery, fiberglass, and metal. However, the most common type of kiln is the electric kiln.

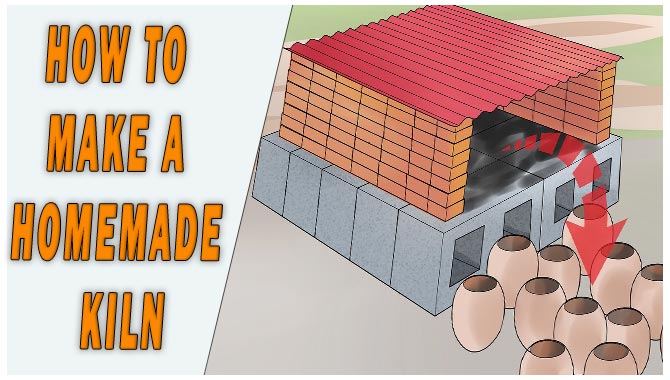

A homemade kiln can make using a basic understanding of how a kiln works and some resourceful ideas. We’ll explore how to build a home kiln that can use for firing kiln-dry clay. We’ll also discuss the benefits of using a kiln and the different types of kilns that exist in the market today. Read on.

Types Of Kilns

There are four types of kilns. These are hot kilns, cold kilns, pie and dough ovens, and masonry ovens. Hot kilns are used for high-temperature cooking, such as baking, roasting, and other high-temperature cooking.

They are generally made of metal or other material with high heating capacity and can reach temperatures up to 1,000°C. Cold kilns are used for low-temperature cooking, such as boiling water or making preserves. They are generally made of ceramic material and can reach temperatures up to 500°C.

Pie and dough ovens are made for baking pies and bread in the oven. They are also popular as bakehouses or brick ovens, and they can be large or small, depending on the device’s purpose. Masonry ovens are made of fired clay bricks and use for baking bread, pizzas, pastries, and other items in the oven. Ceramic kilns make of fired clay material and used to make pottery and other ceramic items.

6 Steps To Make A Homemade Kiln

If you’re interested in creating your own pottery or ceramics, then a kiln is a great way to do it. A kiln is essentially a oven that helps to dry the pottery out so that it can fire in the oven. A kiln can help you achieve the desired firing temperature quickly and reliably, which means that your pottery will be of high quality. To make a simple kiln out of clay and straw, follow these 6 steps:

1.Cutting The Channels

If you’re interested in making your own kiln, then you’ll need to first cut the channels. This is a vital step because it will allow you to properly vent the kiln and generate heat. Without channels, the heat will not be able to escape and your wood objects may end up getting burnt. There are a few different ways to cut the channels, but the most common method is using a jigsaw.

You’ll need to make sure that the blade sharpens properly so that it can easily cut through metal and plastic. You can also use a saw if you have access to one, but this will take longer and may lead to more inaccuracies.

2.Putting In The Element

After you’ve cut the channels, it’s time to put in the element. The element is basically the heating component of the kiln and it will help to generate heat. There are a few different elements available, but the most common is an electric burner. You’ll need to unscrew the burner from its cover and then attach it to either side of the kiln using metal rods or screws. Make sure that both ends of each rod or screw fit properly so that there is enough space for air circulation.

3.Making The Frame

If you’re thinking of starting a kiln, then you’ll need to make a frame first. This will help hold everything together while it’s burning and protect your walls from the heat. There are a few different options for making a frame, but the most basic one is to use wooden boards that nail or screwed together.

You can also use metal frames, but they tend to be more expensive and require more maintenance. To make the frame, you will need a piece of lumber at least 2-by-4 inches in size and a strapping tool. Using the strapping tool, strap the lumber together along the long edge so that it forms a rectangular box. Next, use the same strapping tool to strap the remaining two long edges of the timber together.

4.Making The Door

To make the door for your homemade kiln, you will need a piece of plywood, a drill, and screws. To make the door for your homemade kiln, you will need a piece of plywood and a drill to create the hole in the center of the plywood board. Once you have drilled the hole in the center of the plywood board, you can screw the plywood door onto it. Before screwing the door in place, ensure that it properly align.

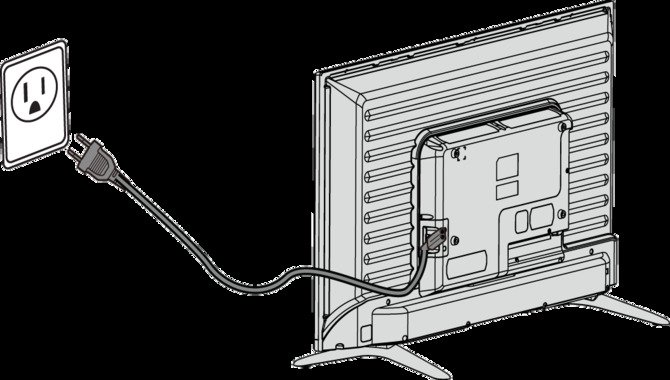

5.Connecting The Power

The electric burner included with the kiln will need to connect to an outlet. Once the burner has been plugged in, you can begin heating the kiln by turning on the switch. The temperature gauge will indicate how hot the kiln is getting and when it reaches a certain temperature, it will start burning wood.

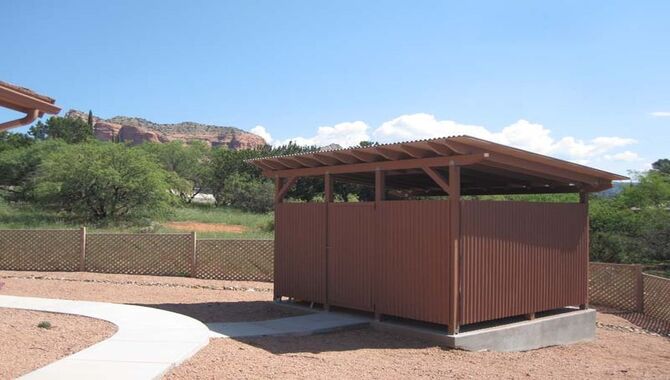

6.Finished Kiln!

Your homemade kiln is now ready to use. If you’re looking for a unique way to heat your home, a kiln is a great choice. A kiln can use to quickly and effectively heat ceramic products, such as pottery and tiles. You can quickly fire ceramics in the range of 1,200°F to 1,800°F.

This makes it ideal for firing large batches of items with consistent temperatures and temperatures fast enough to avoid burning the product. Once you have your kiln installed and ready to use, you’ll be able to fire all of your favorite materials quickly and easily.

Tips For Using A Kiln

If you’re looking to start a business in the arts, then a kiln is an essential tool. A kiln can help you create durable pieces of art that are sure to impress your customers. Here are some tips for using a kiln:

- Choose the right type of kiln for your project. There are various types of kilns, so make sure to choose the one that will best suit your needs.

- Plan your project carefully. Make sure to account for everything from the size and shape of your pieces to the amount of heat you need to use.

- Use proper safety precautions when operating a kiln. Always wear protective gear and keep an eye on the temperature gauges to make sure everything is going according to plan.

What Are The Benefits Of Using A Kiln?

A kiln is a high- temperature device that uses to dry, cure, and harden various items. It can use to dry fruits, vegetables, flowers, and other plant matter. A kiln can also use to cure meat and leather. It can use to make ceramic items such as pottery items, ceramics bricks and tiles.

A kiln can also use to make ceramic items like bowls, plates, and other eating utensils. A kiln is a convenient way to make different shapes and sizes of ceramics. With the help of a kiln, you can easily create ceramic items of your choice without much fuss.

A kiln is an indispensable part of every household now days. There are many benefits to using a kiln, and it can be a great way to produce high-quality ceramics, glassware, and other objects. Here are just a few of the most common benefits:

- Kilns produce consistent results every time, which is critical for accurate artwork.

- Kilns are easy to use and navigate, so you don’t have to be a professional craftsman to use them.

- Kilns can heat up quickly and reach very high temperatures, which makes them ideal for producing delicate pieces of art.

- Kilns provide a realistic finish that’s hard to achieve with other methods.

Conclusion

A kiln is a device that uses to heat objects up to a high temperature in order to convert their material into a new form. It works by using an oven-like chamber filled with ash and fuel, which slowly burns away the object’s mass. As the mass burns away, it releases energy that heats the chamber further. This cycle continues until the object is completely melted down and changed into a new form.

A kiln is a great way to help you craft and fire your pottery pieces simultaneously. They are easy to set up, use and maintain. Besides, they can give you the control of firing your pottery at the right temperature and minimize the risk of pottery degradation. So, go ahead and try it out. If you want to learn more about home pottery firing, here’s an eBook on the topic that can help you understand better.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-48d8e3e7-7f69-4ecf-861f-e2168a65891f”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.