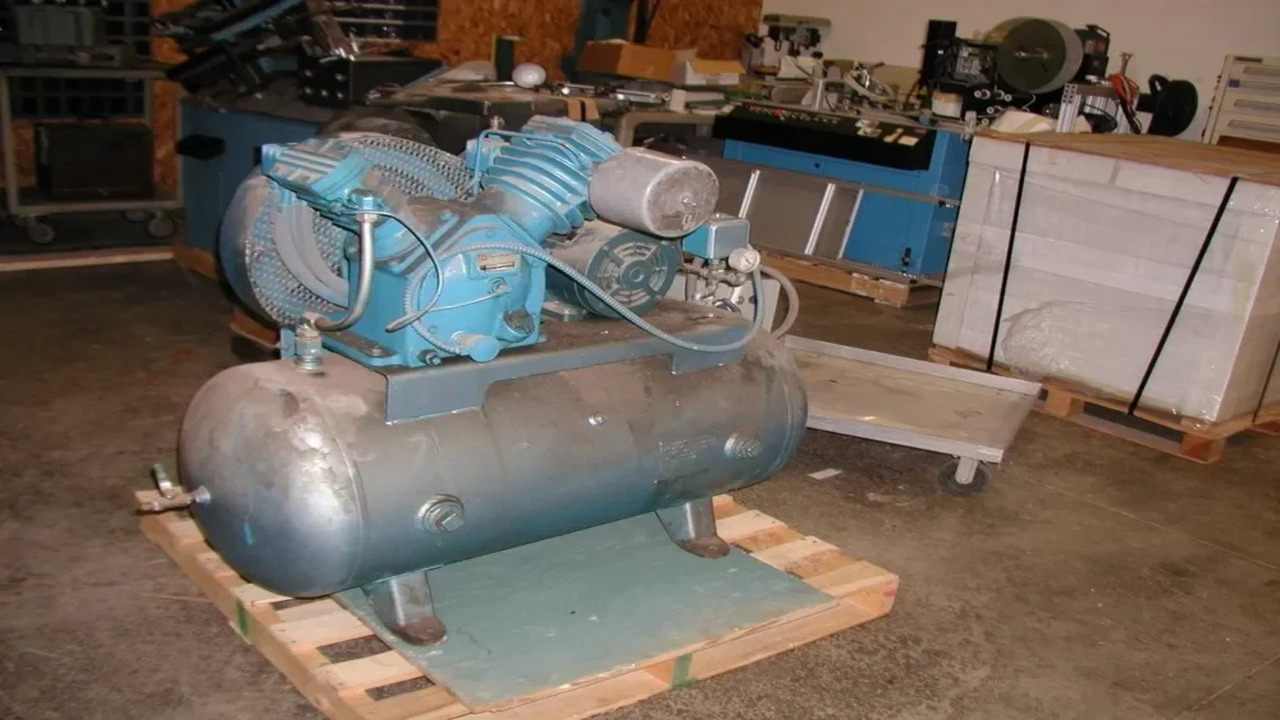

The old champion air compressor had been in use for decades, faithfully powering the machinery in the factory. We’ll show you how to unlock the power of air compressor and make the most out of it.

We’ve got you covered, from starting and operating the compressor to troubleshooting common issues. We’ll also discuss how you can upgrade your old champion-air compressor for even better performance. And don’t worry about maintenance and cleaning – we’ll guide you through that too.

Plus, if you ever need replacement parts, we’ll tell you exactly where to find them. Get ready to breathe new life into your old champion-air compressor and take your projects to the next level.

Mastering The Use Of An Old Champion Air Compressor

To assess the functionality of your old champion air compressor, start by examining its overall condition. Look for any signs of damage or wear and tear that may affect its performance. If you can locate the user manual or any other documentation with the compressor, consult it for specific instructions on using your particular model.

Regular cleaning and maintenance are essential to ensure optimal performance. Remove any dust or debris from the compressor and its components, and check for any loose connections or leaks. Familiarize yourself with the compressor’s controls, gauges, and safety features to operate it safely and efficiently.

Exploring different applications and uses for your air compressor can help you make the most out of it. For example, you can use it to inflate tires, power pneumatic tools, or even operate machinery. Experimenting with pressure settings and airflow adjustments will allow you to fine-tune the compressor’s output to suit your specific needs and achieve desired results.

Starting An Old Champion-Air Compressor

To safely operate a compressor, it is important to follow a few steps. Before starting the compressor, check the oil level and ensure it is at the recommended level. Then, turn on the power switch to activate the compressor. Allow the compressor to build up pressure in the tank before using it.

Once the desired pressure is reached, use the release valve to drain any excess moisture that may have accumulated. Attach them securely to the compressor’s outlet to connect air hoses or tools. Finally, adjust the pressure regulator according to your specific task.

Always follow safety precautions when using air tools or equipment, such as wearing protective gear and being mindful of proper usage techniques. By adhering to these guidelines, you can safely and effectively utilize a compressor for various applications.

Operating An Old Champion-Air Compressor

When operating an older model of a Champion air compressor, it is important to have a good understanding of its specific features and functions. Before using the compressor, thoroughly inspect it for any signs of damage or wear and make necessary repairs. Following the manufacturer’s instructions for proper setup and maintenance is crucial, ensuring the compressor is placed on a stable surface with sufficient ventilation.

Use appropriate hoses, connectors, and fittings to connect the compressor to tools or equipment. Regularly checking and cleaning the air filters is essential to maintain optimal performance. This will help prevent blockages and ensure the compressor continues functioning efficiently. Additionally, regular maintenance, such as oil changes and lubrication, should be carried out per the manufacturer’s recommendations to extend the compressor’s lifespan.

Troubleshooting Common Issues With An Old Champion-Air Compressor

Troubleshooting common issues with an old champion air compressor is essential for optimal performance. Leaks, low pressure, and noisy operation are some of the problems you may encounter. To address leaks, check for loose fittings and damaged hoses, replacing them as necessary.

Low pressure can be resolved by inspecting, cleaning, or replacing components like pressure switches, valves, and air filters. Noisy operation may indicate worn bearings, loose belts, or a malfunctioning motor, which can be addressed through lubrication, tightening, or professional repair.

Regular maintenance and cleaning, including filter maintenance and oil level checks, can help extend the lifespan of your old champion-air compressor.

Upgrading Your Old Champion-Air Compressor

To ensure the optimal functioning of your old champion-air compressor, it is essential to assess its condition and determine if any repairs or maintenance are required. Upgrading motor or pressure switch components can significantly enhance performance and efficiency.

Following the manufacturer’s guidelines to use and maintain your specific model properly. Regularly cleaning and lubricating the compressor will contribute to its longevity and functionality. If you are unsure about using or upgrading your old champion-air compressor, seeking professional assistance is recommended.

Maintenance And Cleaning Of An Old Champion-Air Compressor

Regular maintenance is essential to ensure an air compressor operates at its best. Start by cleaning the air filters and replacing them if necessary. This will ensure proper airflow and prevent clogging. It’s also important to regularly check and change the oil to prevent overheating.

Inspect the hoses and connections for wear or leaks, and replace them as needed. Cleaning the compressor tank by draining any accumulated moisture and checking for rust or damage is crucial. If there are any issues with the compressor, it’s always a good idea to refer to the manufacturer’s manual or seek professional assistance. These maintenance steps can keep your air compressor running smoothly for years.

Where To Find Replacement Parts For An Old Champion-Air Compressor

If you’re in need of replacement parts for your old champion-air compressor, there are several options to consider. You can contact the manufacturer directly to inquire about available parts or recommended retailers. Online marketplaces like eBay or Amazon may also have a selection of replacement parts for old champion-air compressors.

Additionally, local hardware stores or specialized machinery stores might carry compatible parts or be able to order them for you. Knowing where to find these replacement parts ensures that your old champion-air compressor functions properly and serves you well.

Conclusion

An old champion air compressor still has much potential if you know how to unlock its power. By mastering your old champion-air compressor, starting it correctly, operating it efficiently, troubleshooting common issues, and upgrading it when needed, you can extend its lifespan and maximize its performance.

Regular maintenance and cleaning are crucial for keeping your old champion-air compressor in shape. If you ever need replacement parts, there are reliable sources where you can find them. Don’t let your old champion-air compressor go to waste – unleash its power and make the most of it.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-37ed0e9d-996d-424f-8ad4-ceb8a815d210″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.