Having a functional air compressor is essential for many home and professional tasks. Regarding reliability and durability, Sanborn air compressors are among the top choices in the market.

However, like any other machinery, these air compressors may encounter issues and require maintenance and repairs over time. As a responsible owner, knowing how to repair your Sanborn air compressor can save you time and money in the long run.

Here, we’ll take you through the basics of understanding your Sanborn air compressor, common problems that can arise, and the essential tools needed for repair. We will also provide a step-by-step guide on how to repair sanborn air compressor and how to repair your Sanborn air compressor and give you some tips on preventative maintenance to keep your machine running smoothly for years to come.

The Basics Of A Sanborn Air Compressor

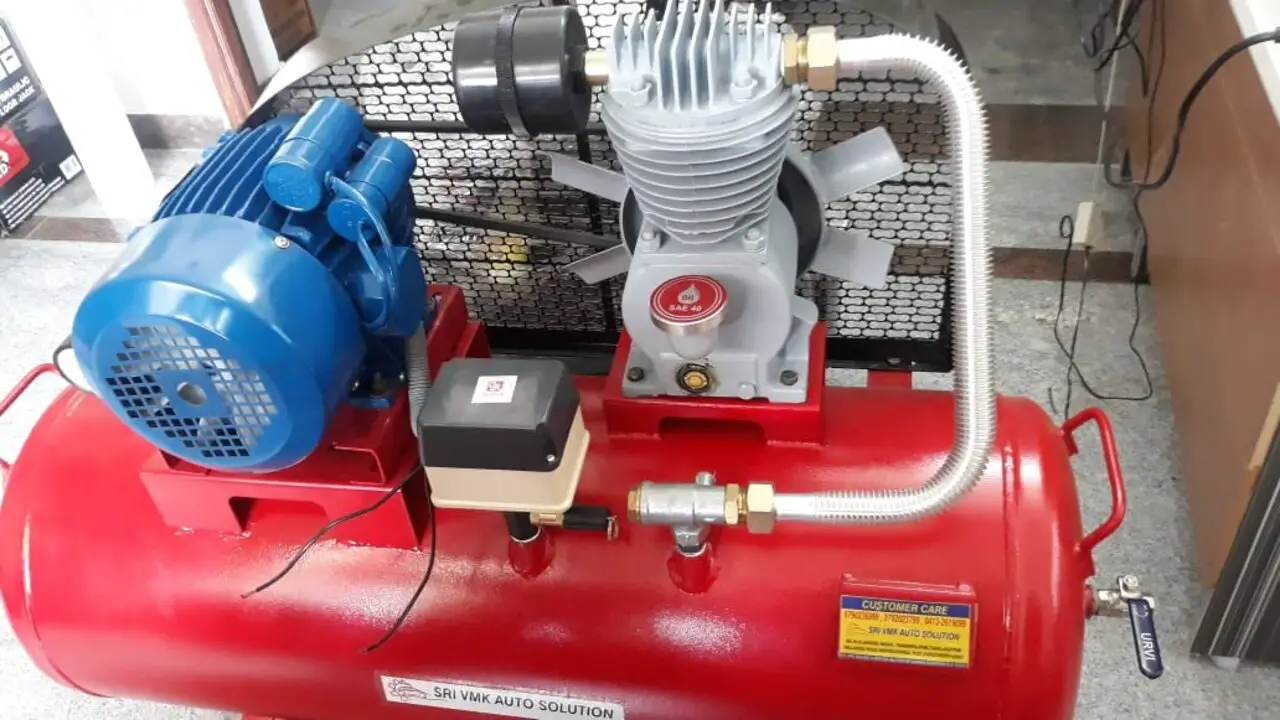

Before attempting to repair a Sanborn air compressor, it is important to understand its basics. A Sanborn air compressor comprises several key components, including a motor, tank, pressure switch, and regulator. The motor powers the compressor and drives the pump, compressing air and storing it in the tank.

The pressure switch controls when the compressor turns on and off based on the desired pressure level. The regulator allows you to adjust the pressure at which the compressed air is released. Understanding these basic components will help you diagnose and troubleshoot any issues that may arise with your Sanborn air compressor.

Identifying Common Problems With Your Sanborn Air Compressor

If your Sanborn air compressor is not functioning properly, it can be helpful to identify common problems that may be causing the issue. One common problem is a leak in the air hose or fittings. This can result in a loss of pressure and decreased performance. Another common issue is a faulty pressure switch, which can prevent the compressor from turning on or off at the appropriate times.

Additionally, a clogged air filter or dirty intake valve can restrict airflow and decrease efficiency. By identifying these common problems, you can troubleshoot and repair your Sanborn air compressor to ensure it operates at its best.

Issues Related To The Valve

When repairing a Sanborn air compressor, issues related to the valve can be a common problem. Suppose you are experiencing issues with your compressor’s valve, such as leaks or difficulty in maintaining pressure. In that case, there are a few steps you can take to troubleshoot and resolve the issue. First, check the valve for any signs of damage or wear. If you notice any cracks or broken parts, it may be necessary to replace the valve altogether.

Additionally, make sure that the valve is properly lubricated and functioning correctly. Clean any dirt or debris that may be affecting its performance. If these steps do not resolve the issue, it may be necessary to seek professional assistance or contact the manufacturer for further guidance.

Compressor Not Building Pressure

If your Sanborn air compressor is not building pressure, there are a few possible causes that you can check. First, ensure that the air intake filter is clean and free from any debris blocking airflow. Next, check for any leaks in the air hose or fittings. Even a small leak can prevent the compressor from building pressure.

Additionally, check the drain valve to ensure it is closed tightly and prevents air from escaping. If none of these solutions resolves the issue, it may be necessary to consult the manufacturer’s manual or contact a professional for further assistance with repairing your Sanborn air compressor.

Essential Tools For Sanborn Air Compressor Repair

When repairing a Sanborn air compressor, having the right tools is essential. With these essential tools readily available, you will be well-equipped to tackle any repair needs that may arise with your Sanborn air compressor. Here are some of the essential tools you will need for Sanborn air compressor repair:

- Wrench set: Wrenches in different sizes will be necessary for loosening and tightening bolts and fittings.

- Screwdriver set: A set of screwdrivers with different types and sizes of heads will be needed for removing screws and accessing internal components.

- Socket set: A socket set of various sizes will be required to remove nuts and bolts.

- Pliers: A pair of pliers, such as slip-joint pliers or needle-nose pliers, can be useful for gripping and manipulating small parts.

- Air pressure gauge: An air pressure gauge will allow you to measure the pressure output of the compressor accurately.

- Multimeter: A multimeter is an indispensable tool for troubleshooting electrical issues in the compressor.

- Lubricant: Having lubricant on hand is important for maintaining the smooth operation of moving parts in the compressor.

How To Repair Sanborn Air Compressor: Tips And Tricks

Repairing a Sanborn air compressor can seem daunting, but with the right tools and knowledge, it can be a straightforward process. Remember, if you are unsure about repairing your Sanborn air compressor, it is always best to consult a professional or contact the manufacturer for assistance. Here is a step-by-step guide on how to repair Sanborn air compressor.

- Safety first: Before starting any repairs, disconnect the power source and release any built-up pressure in the compressor.

- Identify the problem: Determine what is causing the issue with your air compressor. Common problems include leaks, low pressure, or motor failure.

- Gather necessary tools: Depending on the specific problem, you may need tools such as wrenches, screwdrivers, multimeters, and replacement parts.

- Replace faulty parts: If you have identified a specific part that needs to be replaced, carefully remove the old part and install the new one according to manufacturer instructions.

- Check for leaks: If your air compressor is experiencing leaks, inspect all connections and fittings for damage or looseness. Use thread sealant or Teflon tape to ensure a tight seal.

- Test the compressor: Once all repairs have been made, reconnect the power source and test the compressor to ensure it is functioning properly.

Preventative Maintenance For Your Sanborn Air Compressor

Preventative maintenance is crucial for keeping your Sanborn air compressor in optimal working condition. Regularly inspecting and maintaining your compressor can extend its lifespan and avoid costly repairs. Following these preventative maintenance steps, you can keep your Sanborn air compressor running smoothly and avoid unexpected breakdowns. Here are some preventative maintenance steps you can take:

Check the oil levels: Regularly check the oil levels in your compressor and top it up if necessary. Dirty or low oil levels can cause damage to the compressor’s internal components.

Clean or replace the air filter: The air filter prevents dust and debris from entering the compressor. Clean or replace the air filter regularly to ensure proper airflow and prevent clogs.

Inspect for leaks: Check all connections, hoses, and fittings for any signs of leaks. Leaks can lead to reduced performance and increased energy consumption.

Drain moisture from the tank: Moisture can accumulate over time, leading to rust and corrosion. Regularly drain the moisture from the tank to prevent damage.

Lubricate moving parts: Apply lubricant to moving parts such as pistons, cylinders, and valves to reduce friction and ensure smooth operation.

Regular Check-Ups And Their Importance

Regular check-ups are an important part of maintaining the performance and longevity of your Sanborn air compressor. By conducting regular inspections and maintenance tasks, you can catch any potential issues early on and prevent them from becoming major problems. Some key areas to focus on during check-ups include inspecting the air filter, checking for leaks, monitoring oil levels, and examining the belt and pulley system.

Regular check-ups also allow you to ensure that your compressor is operating at optimal efficiency, which can help save energy and reduce operating costs. Overall, making regular check-ups a priority will help extend the lifespan of your Sanborn air compressor and keep it running smoothly for years to come.

Cleaning And Lubrication: Key To Longevity

Cleaning and lubrication are key factors in maintaining the longevity of your Sanborn air compressor. Over time, dust, debris, and moisture can accumulate in the compressor, causing it to work less efficiently and potentially leading to malfunctions. Regularly cleaning the exterior of the compressor with a damp cloth can help remove any dirt or grime that has built up.

Additionally, lubricating the compressor’s moving parts according to the manufacturer’s instructions is crucial for smooth operation and preventing excessive wear and tear. By incorporating these maintenance tasks into your routine, you can ensure that your Sanborn air compressor remains in optimal condition for years.

Is It Worth Repairing Your Sanborn Air Compressor?

Deciding whether it is worth repairing your Sanborn Air Compressor depends on a few factors. First, you should assess the extent of the damage or issue with your compressor. It may be worth repairing if it is a minor repair that can be fixed easily and inexpensively. However, if the repair is more extensive and costly, investing in a new air compressor may be more cost-effective.

Additionally, consider the age and overall condition of your Sanborn Air Compressor. If it is an older model or has had multiple repairs in the past, it may be a sign that it is reaching the end of its lifespan, and a new compressor would be a better long-term investment. Ultimately, weigh the cost of repairs against purchasing a new compressor to determine which option makes the most sense for your situation.

Where Can You Find Replacement Parts For Your Sanborn Air Compressor?

Finding replacement parts for your Sanborn Air Compressor can be crucial in repairing and maintaining your equipment. Several options are available to help you locate the necessary parts for your specific model. One option is to contact the manufacturer directly. Sanborn may have an official website or customer service line where you can inquire about purchasing replacement parts.

Another option is to visit local hardware stores or speciality tool retailers that carry Sanborn products. They may have a selection of commonly needed parts in stock or be able to order them for you. Additionally, online marketplaces and auction websites can be a valuable resource for finding replacement parts at competitive prices. Just be sure to verify the authenticity and compatibility of the parts before making a purchase.

Conclusion

How to repair sanborn air compressor can save you time and money. By understanding the basics of your compressor, identifying common problems, and having the essential tools on hand, you can easily troubleshoot and repair any issues. Regular preventative maintenance, such as regular check-ups, cleaning, and lubrication, is crucial to ensuring the longev ity of your compressor.

However, it’s also important to assess whether it’s worth repairing your compressor or if it’s more cost-effective to invest in a new one. If you decide to repair, finding replacement parts for your Sanborn Air Compressor is relatively easy with various online retailers and authorized service centres. So go ahead and get your compressor back up and running efficiently.

Frequently Asked Questions

Can An Air Compressor Be Repaired?

Yes, air compressors can be repaired. The extent of the repair depends on the specific issue with the compressor. Common repairs include fixing leaks, replacing faulty parts, and cleaning or replacing filters. It is important to follow proper safety measures when repairing an air compressor.

What Happened To Sanborn Air Compressor?

MAT Industries LLC previously manufactured sanborn air compressors. However, in 2017, the company filed for bankruptcy and ceased operations. While parts for Sanborn air compressors may still be available through third-party vendors, consulting a professional before attempting any repairs is advisable.

What Causes An Air Compressor To Stop Working?

When an air compressor stops working, it is often due to a lack of power or pressure. Other possible causes include a faulty pressure switch, worn-out parts, or a clogged air filter. Regular maintenance and cleaning can help prevent these issues. If unsure, consult a professional.

What Are Common Issues That Can Occur With A Sanborn Air Compressor?

Common issues with a Sanborn air compressor include leaks, low pressure, and overheating. Damaged hoses or fittings often cause leaks, while low pressure can be due to a faulty regulator or valve. Overheating may occur if the compressor is overworked or the oil level is too low. Regular maintenance and inspection can help prevent these issues.

What Tools Do You Need To Repair A Sanborn Air Compressor?

When repairing a Sanborn air compressor, the necessary tools will depend on the specific issue. Common tools include wrenches, pliers, screwdrivers, and an air compressor repair kit. It’s essential to have the correct replacement parts and follow the manufacturer’s instructions and safety guidelines.

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.