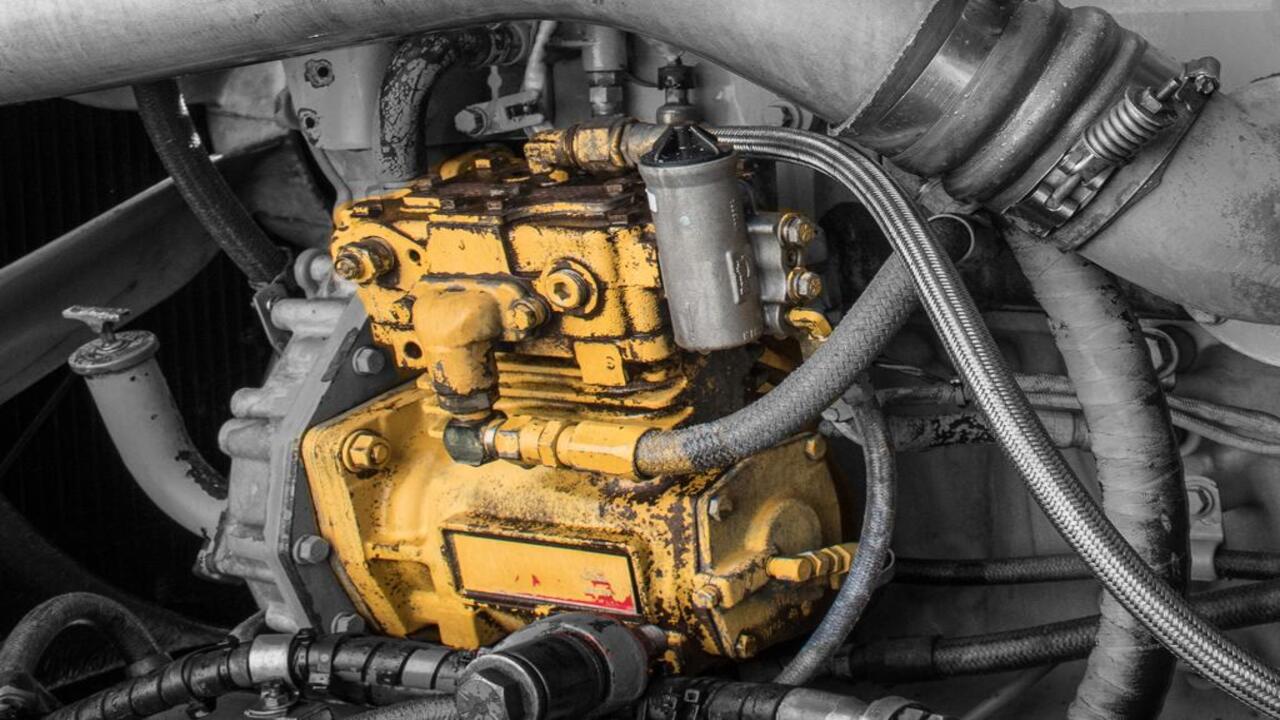

The truck air compressor unloader valve is an essential part of the air compressor system as it plays a crucial role in regulating pressure. When the pressure reaches a certain level.

The valve releases the excess pressure, ensuring the compressor can start and stop smoothly. This prevents damage to the compressor and reduces wear and tear on other system components. By maintaining optimal pressure levels, the unloader valve helps to prolong the lifespan of the entire air compressor system.

Here we will delve into the intricate workings of this valve and explore its significance in a truck’s air system. We will begin by explaining what exactly a truck air compressor unloader valve is and how it operates within the larger system. We will also discuss the importance of maintaining a properly functioning unloader valve and highlight common signs of a faulty or malfunctioning valve.

How Does The Truck Air Compressor Unloader Valve Work?

The truck air compressor unloader valve is a critical component that ensures the proper functioning of the air compressor system. Its main function is to release excess pressure from the system when the compressor reaches its maximum capacity. Opening the valve allows the compressed air to escape, preventing any potential damage to the compressor and other related components.

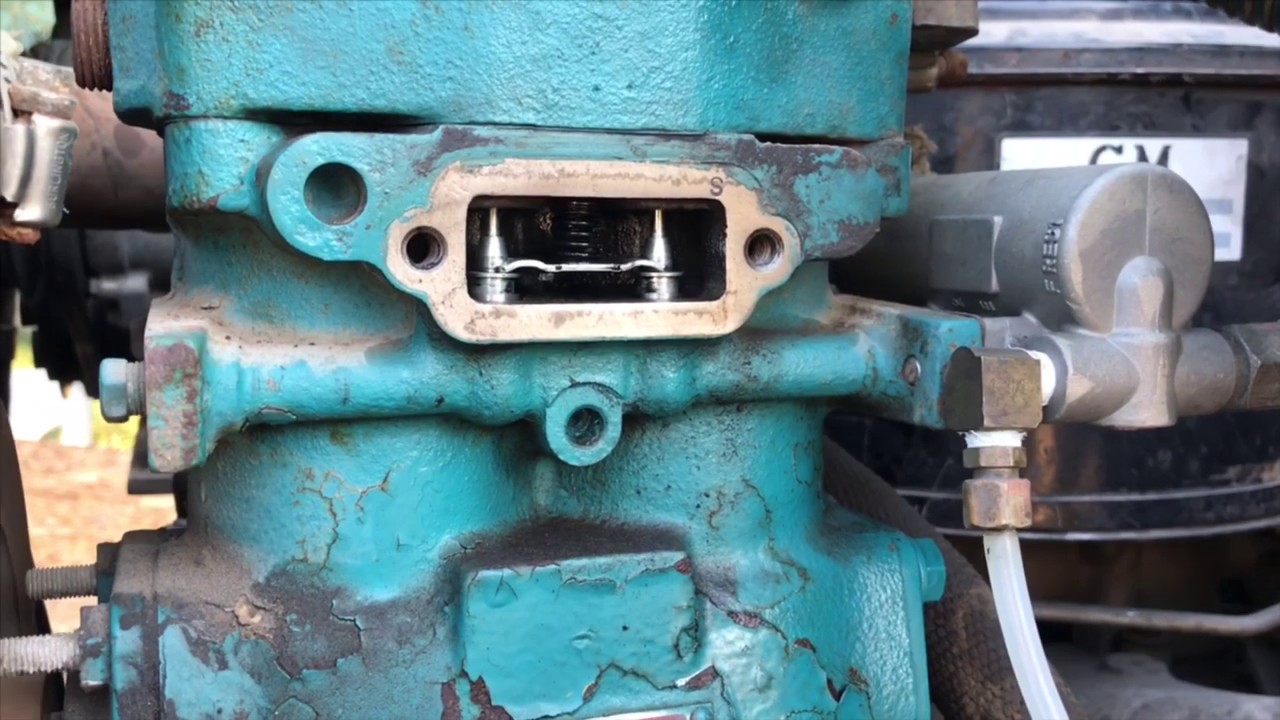

Two common types of unloader valves are used in truck air compressors – mechanical and pneumatic. Mechanical unloader valves operate using a spring-loaded mechanism that opens and closes the valve based on pressure levels. On the other hand, pneumatic unloader valves utilize air pressure to control the opening and closing of the valve.

Overall, the air compressor unloader valve plays a crucial role in maintaining the efficiency and safety of the air compression system by regulating pressure levels and preventing overloading. It is important to regularly inspect and maintain this valve to ensure optimal performance and extend its lifespan.

The Truck Air Compressor Unloader Valve Functions

The air compressor unloader valve is essential in maintaining the compressor’s optimal pressure. Its primary function is to open when the desired pressure is achieved, releasing the trapped air and preventing the compressor from operating at excessively high pressures. This prevents damage to the compressor and reduces wear and tear on its components.

Conversely, when the pressure drops, the unloader valve closes, allowing the compressor to restart its process of building pressure. Some unloader valves have a governor feature that regulates the compressor’s speed, ensuring efficient operation and prolonging its lifespan.

The Importance Of The Unloader Valve In A Truck’s Air System

The unloader valve is an essential component of a truck’s air system as it safely releases excess pressure from the compressor. Doing so prevents potential damage to the system and ensures its longevity. Additionally, the unloader valve plays a key role in preventing the compressor from starting under load, which helps reduce strain on the engine and improve overall performance.

Regular maintenance and inspection of the unloader valve are highly recommended to ensure optimal functioning and prevent any air system issues. This includes checking for signs of wear or damage, cleaning or replacing parts as needed, and ensuring proper lubrication.

Signs Of A Faulty Or Malfunctioning Unloader Valve

Loss of air pressure, excessive noise, vibration, difficulty building up air pressure, or frequent air leaks all indicate a malfunctioning or faulty unloader valve. To prevent potential problems and ensure proper functioning, inspecting and maintaining the valve regularly is essential.

This includes checking for signs of wear or damage, cleaning or replacing clogged components, and lubricating moving parts as needed. Maintaining the unloader valve in good condition can avoid costly repairs and downtime in your pneumatic system.

How To Diagnose And Troubleshoot Issues With The Unloader Valve

When facing issues with the unloader valve, diagnosing and troubleshooting the problem effectively is important. Begin by thoroughly inspecting the valve components and checking for any air leaks. Testing pressure readings can help identify any abnormalities affecting the valve’s performance.

Depending on the issue, troubleshooting methods can include cleaning or replacing faulty parts, adjusting settings, or seeking professional assistance. Regular maintenance and inspections are crucial for the unloader valve to prevent costly repairs and maintain optimal performance.

Steps To Replace Or Repair A Faulty Unloader Valve

To replace or repair a faulty unloader valve, first, identify the issue by listening for air leaks or observing insufficient pressure. Then turn off the truck’s engine and disconnect the air compressor. Unscrew the old valve and securely install the new one. Finally, reconnect the compressor and test for proper functioning.

Proper Maintenance And Care For The Air Compressor Unloader Valve

Regular maintenance and cleaning are essential to prevent buildup on the unloader valve, which can impede its smooth operation. It is also important to properly adjust the valve to maintain optimal pressure and prevent unnecessary strain on the compressor.

Repairing or replacing any damaged valve components can significantly extend its lifespan and ensure its continued functionality. Regular inspection is necessary to detect any air leakage and ensure efficient performance. Finally, following the manufacturer’s guidelines for maintenance and operation is crucial in maintaining the reliability of the unloader valve.

Benefits Of A Properly Functioning Unloader Valve In A Truck’s Air System

The unloader valve in a truck’s air system plays a vital role in regulating air pressure to prevent component damage. Efficiently controlling air flow ensures the proper operation of air-powered devices and minimizes the risk of air leaks. This not only improves safety but also enhances overall performance.

Regular maintenance and inspection are essential to ensure the unloader valve functions correctly. This includes checking for any signs of wear or damage and promptly addressing any issues that may arise. By prioritizing the upkeep of this critical component, truck owners can maintain optimal functionality and extend the lifespan of their vehicles.

Common Misconceptions And Myths About The Unloader Valve

There are common misconceptions and myths about the air compressor unloader valve. First, it’s important to note that the unloader valve does not regulate the pressure in the air system. Rather, it is a safety device that releases excess air from the compressor when it reaches a certain pressure.

Some people mistakenly believe that the unloader valve controls the compressor’s speed, but its main function is to prevent the compressor from stalling or overheating by relieving pressure. Additionally, the unloader valve works with the governor to regulate the compressor’s operation.

Conclusion

To ensure that your truck’s air system operates smoothly and efficiently, it is crucial to understand how the truck air compressor unloader valve works. This valve plays a vital role in relieving pressure within the compressor and preventing the engine from stalling during startup. By releasing excess air trapped in the compressor, the unloader valve allows for seamless operation and optimal performance of the air system.

Regular maintenance and care of the unloader valve are essential to avoid any malfunctions or faults that may disrupt the functioning of your truck’s air system. It is crucial to diagnose and troubleshoot any issues promptly and replace or repair the unloader valve as needed.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-ca19c1ee-4dd9-41ae-aba4-5df4d8c55012″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.