Portable air compressors are essential tools for businesses of all kinds. Whether you run a workshop, have an art studio, or own a company, chances are good that you’ve got one around. A portable compressed air tank is a pressure vessel that holds air under pressure, which can be released on demand through a valve.

This makes them a useful tool for fields requiring instant air capacity and pressure. However, it is important to note the features of a portable air tank before getting one for use in the field. While they’re useful in their own right, many people also use them to fill tanks and cylinders for different purposes. We’ll talk about how to use air compressor tanks and the benefits of doing so. Let’s get into it.

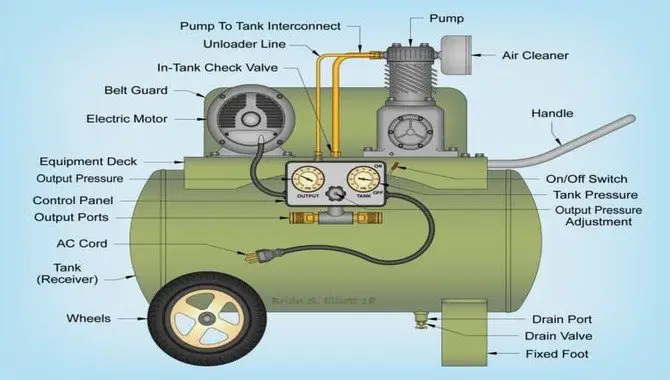

Parts Of A Portable Compressed Air Tank

A portable air tank is often lightweight and comes in 5 or 10-gallon sizes. They are also convenient to carry and store as they can be easily stored in a backpack or binocular case. The size of the portable air tank depends on the job requirement, with smaller ones being more suitable for quick operations.

In addition to being multipurpose, portable air tanks also come with multipurpose air hoses, quick-connect fittings, and pressure gauges. These make it easy to use the tanks with different types of air compressors and allow you to read the tank’s pressure in accordance with your needs.

1. Air Fill Valve

An air fill valve is a component of a portable air compressor tank and is used to fill the tank with compressed air. The air fill valve typically connects to a compressor when filling the tank and may be found on portable air compressor tanks.

Universal quick-connect fittings allow for easy changes of hose types, making it possible to switch from one type of hose to another depending on the job at hand. Air shutoff valves are knobs that prevent air from leaking out of the tank when it is not in use, while an air vent allows excess air to escape.

2. Air Shutoff Valve

An air shutoff valve is a component of a portable compressed air tank that is used to prevent air from leaking out of the tank when it is not in use. The air shutoff valve is typically a knob that can be turned off and on, allowing the user to adjust the flow rate of air into the tank or to shut it off completely.

It is essential to have a properly sized air shutoff valve for a portable air compressor tank to minimize maintenance costs and maximize efficiency. An air shutoff valve can be attached to the tank with a threaded fitting or a quick-connect fitting, depending on the type of tank being used.

3. Air Pressure Gauge

A portable air tank typically has a maximum pressure rating of 125-150 psi. This means that it is important to not fill the tank to its maximum pressure level. Filling a portable air tank to its maximum pressure can cause harm and damage to the compressed air system.

Instead, it is best to work within the pressure range specified by the tank. The PSI, or “working pressure” of a portable air tank, is often displayed on its side. A compressed air tank is a pressure vessel that stores air compressed under pressure and releases it on an on-demand basis.

4. Pressure Tank

Compressed air tanks are pressure vessels that hold air compressed under pressure, releasing it on demand through a valve. They are useful for remote jobs when it is not feasible to move the air compressor to the job site. These tanks can be used in combination with a portable air compressor to increase air capacity and pressure.

They are typically made of steel or aluminum, and vary in size depending on the air compressor they are used with. Portable air compressor tanks are too small to operate air tools for extended periods; they should only be used as backup storage for short-term use.

5. Flexible Hose

A flexible hose is commonly used with portable compressed air tanks to transport air from the tank to another location. The air hose can be connected to the tank with a quick connect fitting, allowing for secure attachment and easy airflow. The size of the air hose, as well as its length and diameter, determines how much air can be transported at once.

Pressure gauges attached to the tanks allow users to monitor the pressure inside the tank while ensuring safety. These tanks often come with pressure relief valves for safety and overall safety. They are lightweight, compact, and designed for high-volume use. Overall, a flexible hose is essential for safely transporting compressed air from one location to another.

6. Universal Fitting

A portable compressed air tank is a pressure vessel that stores air under pressure and releases it when needed. It is typically lightweight, with a range of uses, such as in workshops, technical work areas, and other places where compressed air is frequently needed.

The portability of portable air tanks makes them useful for large workspaces. They are available in various sizes, from 5 gallons to 10 gallons. Universal fitting options, such as air hoses, quick-connect fittings, and pressure gauges, can be used with these tanks to ensure that they are properly connected.

These tanks are beneficial for their portability and versatility. They can be used in large workspaces without taking up much space or requiring complicated setup procedures.

4 Tips To Use Portable Air Compressor Tanks

When it comes to air compressor tanks, there are a few tips you can follow to ensure you get the most out of your tank. Firstly, it’s vital to size the tank correctly so that it doesn’t overfill and damage the air compressor.

This will help save on maintenance costs. Additionally, you should consider horizontal or vertical alignment tanks with pressure ratings of 137 PSI, 150 PSI, 165 PSI, and 200 PSI. These should be durable and capable of withstanding high pressures without breaking down easily.

1. Understand The Sizes

Air compressor portable tanks come in a variety of sizes, with capacities ranging from 5 to 20 gallons. Common sizes for these tanks include 5, 7, 9, and 11 gallons. Portable air tanks are available in small 5- or 7-gallon sizes, which are highly portable and take up less space.

They are great for little remote jobs when moving your air compressor to the job is not feasible. Understanding the various sizes of air compressor tanks can help you choose the right tank for your application.

2. Estimate What Size You Need

When choosing the size of a portable air tank, it is important to consider the capacity and work that is to be done with the tank. The size of the tank should be based on the amount of air required for a specific application.

For example, a 10-gallon tank would be more suitable for filling tires than a 5-gallon tank. Another factor to consider is the type of air tank being used. Some air tanks are made up of multiple pieces, such as a plastic carrying case and pressure gauge valve.

Other tanks are portable and can be assembled or disassembled in seconds. If a specific size or type of tank is not available, it may be necessary to combine several different sizes to achieve the desired capacity. In addition, quality portable air tanks come with features such as pressure gauges and protective covers to ensure safety while using them.

3. Consider The Rating

A portable air compressor tank is an essential tool for any DIY or professional air job. These tanks are designed to store and supply air for various tools, such as nailers and paint sprayers. They come in different sizes and pressure ratings, ranging from 125 PSI to 150 PSI.

It’s important to use the correct tank type, size, and working pressure (PSI) to ensure the best performance for the application. Selecting a portable air compressor that matches the specific needs of your job can save time and money. For example, a pressurized air system with a 60-PSI working pressure may be more suitable for finishing projects than one with 40-PSI working pressure.

4. Choose And Fill Your Compressor

A compressor tank is a pressure vessel that holds compressed air and releases it on an on-demand basis. It is vital to choose the right size for your compressor tank as this will affect the amount of air that you can store in it and the efficiency of your compressor.

Compressor tanks can be filled up by attaching the fill nipple to the tank and using a compressor. If you are filling up an air tank at home or at a gas station or hardware store, it is important to watch the pressure gauge to make sure the pressure does not rise too quickly or too high. This can cause damage to your air tank or air compressor.

Benefits Of Using A Portable Air Compressor Tank

A portable compressed air tank is a great option for jobs where it isn’t feasible to move a compressor to the job site. They provide a large capacity and pressure for certain air tool applications, such as sanders and drills, when used in conjunction with a portable air compressor.

They’re also lightweight and easy to transport, making them essential for storing compressed air in workshops, job sites and other places where compressed air is needed.

Most portable air tanks have a capacity of 5-10 gallons, depending on the size. This provides enough air for small jobs without requiring an always-on source of power. Moreover, they’re easy to use and maintain, making them a popular choice among professionals and hobbyists alike.

Safety Tips For Working With Portable Air Compressor Tanks

When working with a portable air compressor tank, it’s important to follow the manufacturer’s safety guidelines and instructions. Always watch the pressure gauge carefully when filling a tank to ensure that pressure doesn’t exceed the recommendation. Additionally, portable tanks come in a range of pressure ratings, so be sure to use the appropriate size for the job.

Underfill the tank just enough to allow air to expand with the heat. This will help prevent the tank from bursting under pressure. Also, be sure to use the necessary tools and supplies when working with air compressor tanks, such as a screwdriver, adjustable wrench, teflon tape, cleaning solvent, brass wire brush, old air compressor, relief valve, and Schrader/sniffer valve. These tools can help ensure safe and efficient completion of any air compressor task.

Conclusion

If you are looking for a portable air compressor tank that is durable, efficient, and affordable, then look no further. The above-mentioned portable air compressor tanks have all the benefits of using them. Besides being user-friendly, they are also easy to refill and transport. They have helped countless individuals in various industries. Diverse uses include industry professionals working on-site or in their vehicles, home workshops, and more.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-35db27d6-559e-4a76-a81e-fac40d66af79″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.