Air compressors play an important role in various industries, from automotive to construction. These machines provide high-pressure compressed air, which is used for powering various tools and equipment.

However, sometimes, you may notice water coming out of the air compressor hose, which can cause concern. This issue can lead to various problems, such as rusting of the tools, equipment, and pipes, reducing the compressor’s lifespan. And even causing accidents due to moisture buildup in the compressed air.

The presence of water in the compressed air can be attributed to various factors, such as high humidity levels, incorrect installation of the compressor, or a malfunctioning drainage system. Therefore, it is crucial to understand the causes and solutions to the water coming out of the air compressor hose. We will provide a comprehensive guide on the water coming out of air compressor hose.

Causes Of Water In Air Compressor Hose

Water from an air compressor hose can be a common issue many people experience. If you are experiencing water coming out of your air compressor hose, it is important to address the issue promptly. Excess moisture can damage tools and affect the performance of your air compressor.

Consider implementing measures such as using a water separator or installing a proper drainage system to prevent further problems with water accumulation in your air compressor hose. There are several possible causes for this problem:

1.Condensation: Air compressors generate heat during operation, and when the compressed air cools down, it can cause condensation to form. This condensation collects in the hose and eventually comes out.

2.Humid environment: If you are working in a humid environment, there is more moisture in the air, which can result in more water accumulating in the hose.

3.Incorrect pressure settings: If the pressure settings on your air compressor are too high, it can cause excess moisture to build up in the hose.

4.Inadequate drainage system: Some air compressors have built-in drainage systems to remove excess moisture from the tank. If this system is not functioning properly or is not installed, it can lead to water being released through the hose.

5.Faulty or damaged equipment: It is also possible that there may be an issue with your air compressor or hose itself. Inspect your equipment for any leaks or damage that could be causing the water to escape.

Water Coming Out Of Air Compressor Hose – The Best Solution

It is crucial to be aware of the water coming out of air compressor hose because it can cause significant damage to your tools and equipment. When an air compressor releases compressed air, compression tends to produce moisture. This moisture can accumulate within the hose and eventually reach your tools.

Water in your equipment can cause rust, corrosion, and other damage that may affect its performance and lifespan. It could also lead to malfunctioning or breakdown of your machinery, resulting in costly repairs or replacement. Moreover, the water that comes out of an air compressor hose can also be harmful to your health.

When moisture accumulates within the hose, it can create a breeding ground for bacteria and other harmful microorganisms. If inhaled, these bacteria can cause respiratory problems and other health issues. Here the best solution for it.

Option 1: Installing A Water Separator

Installing a water separator is an important step in maintaining the quality of your compressed air system. A water separator is designed to remove moisture and other impurities from the compressed air before it enters the system. This is crucial because moisture can cause damage to your machinery, reduce efficiency, and even compromise the quality of your products.

First, identify the location where you will install the water separator. This is typically when the compressed air enters the system, such as the compressor or the air receiver tank. Once you have identified the location. You must shut off the power to the system and release any pressure in the lines. Then, you can install the water separator according to the manufacturer’s instructions.

Option 2: Regular Draining Of The Air Compressor Tank

Regular draining of the air compressor tank is an essential maintenance task that should not be overlooked. The accumulation of moisture and debris within the tank can lead to corrosion and reduced compressor performance. You should do drainage after every use or at least once a week, depending on the frequency of use. First, drain the tank, turn off the compressor, and release all the pressure from the tank.

Then, locate the drainage valve at the bottom of the tank and attach a hose to the valve. Open the valve and let the water and debris drain from the tank. Ensure that you completely drain the tank before closing the valve. Failure to do so can result in the formation of rust and other contaminants, which can damage the compressor.

Option 3: Using An Aftercooler System

Using an aftercooler system has been a game-changer for many industries, as it helps reduce compressed air’s temperature and moisture content. However, despite its benefits, there are still instances where water can come out of the air compressor hose. This is particularly true when the aftercooler is not working effectively or when the temperature and humidity levels are too high.

When this happens, it is important to take immediate action to prevent any damage to the equipment or the products being produced. One way to do this is by installing a water separator. This can help remove excess moisture from the air before it reaches the compressed air system.

Option 4: Employing A Desiccant Dryer

Employing a desiccant dryer is an essential part of any compressed air system as it helps to remove moisture and contaminants from the compressed air. This is crucial, especially in industrial and manufacturing settings.

Where the quality and purity of compressed air can significantly impact the final product. Without a desiccant dryer, water coming out of the air compressor hose is a common problem that can cause damage to the equipment and affect the quality of the end product.

A desiccant dryer removes water vapour from the compressed air, ensuring that the air is dry and free from any impurities. The dryer uses a desiccant material, such as silica gel, to absorb moisture from the air before it enters the distribution system. Regularly replacing or regenerating the desiccant material ensures its effectiveness in removing moisture.

How Do I Stop Water From Coming Out Of My Air Compressor?

Water coming out of an air compressor hose can be a frustrating issue to deal with. Fortunately, there are several steps you can take to prevent this from happening. Firstly, ensure the air compressor is properly drained after each use.

This will help to remove any excess moisture that may have accumulated in the tank. Secondly, consider using a water separator or filter on your air compressor system. These devices trap and remove water vapour from the compressed air before reaching your tools or equipment.

Finally, if you are working in a humid environment, consider using a desiccant or refrigerated dryer to reduce the moisture content in the compressed air. By taking these preventative measures, you can minimize the amount of water coming out of your air compressor hose and ensure optimal performance of your tools and equipment.

Effects Of Water In The Compressed Air

Water in the compressed air can have several negative effects on the performance and longevity of an air compressor system. Firstly, water can cause corrosion and damage to the compressor’s internal components, leading to decreased efficiency and potential breakdowns.

Additionally, water can mix with oil in the system, resulting in a contaminated lubricant that may not adequately protect the compressor’s moving parts. This can lead to increased wear and tear and reduced overall lifespan of the equipment.

Furthermore, water in the compressed air can also affect the quality of the end product or process. In industries such as painting or food production, moisture in the compressed air can cause issues like uneven coating or contamination. It is important to implement proper moisture removal techniques to mitigate these effects. Such as using air dryers or filters to ensure dry and clean compressed air for optimal performance and reliability.

DIY Tips For Compressor Maintenance

Proper air compressor maintenance is essential to ensure its optimal performance and longevity. One common issue that people may encounter is water coming out of the air compressor hose. This can be caused by condensation inside the tank, which then gets carried along with the compressed air. To prevent this, there are a few DIY tips you can follow:

1.Drain the tank regularly: You can remove any accumulated moisture by draining the tank regularly. This can help prevent water from entering the air compressor hose.

2.Install a moisture trap/filter: Adding a moisture trap or filter to your air compressor setup can help remove excess moisture from the compressed air before it reaches the hose. This can be particularly useful in humid environments or colder seasons when condensation is more likely to occur.

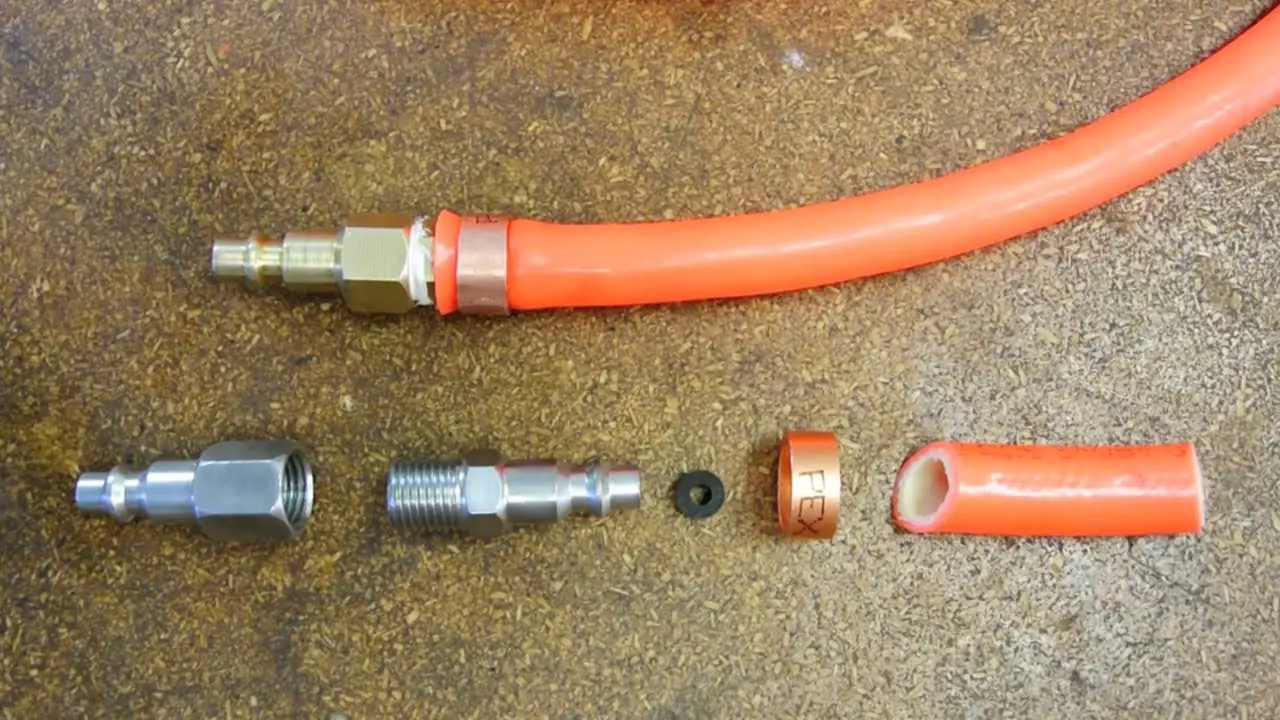

3.Check for leaks: Any leaks in your air compressor system can allow moisture to enter and be carried through the hose. Inspect all connections, fittings, and hoses for any signs of leakage and repair them promptly.

4.Use an air dryer: If you frequently experience water coming out of the hose, investing in an air dryer may be beneficial. Air dryers help remove moisture from the compressed air, preventing water buildup in the system.

5.Store your compressor properly: When not in use, store your compressor in a clean and dry area. Moisture and dust can contribute to issues with water in the hose.

By following these DIY maintenance tips, you can help reduce the likelihood of water coming out of your air compressor hose and ensure that your equipment operates smoothly and efficiently.

DIY Fixes For Water In Air Compressor Hoses

Water coming out of your air compressor hose is a common issue that can affect the quality and efficiency of your compressed air system. Fortunately, several DIY fixes can help you resolve this problem. One of the most effective solutions is to install a water separator or filter in your air compressor system. This can help remove excess moisture from the air and prevent water from accumulating in the hoses.

Another option is to drain the water from your compressor tank regularly. This can help prevent water from accumulating in the hoses and causing damage to your tools and equipment. In addition, you can also use a desiccant dryer or moisture trap to remove moisture from the air before it enters the hoses. Finally, you can also consider insulating your hoses or using heat tape to prevent condensation from forming inside the hoses.

Conclusion

Water coming out of air compressor hose can be a concerning issue, but it can be effectively managed through proper preventive measures and maintenance. The presence of water in the hose is often a result of condensation inside the air tank or drawing in moisture from a humid environment.

However, by regularly draining the air tank, using water separators and filters, and ensuring proper compressor maintenance, users can prevent water-related complications and ensure a consistent supply of dry, compressed air.

Maintaining a dry and efficient compressed air system maximises productivity, extends equipment lifespan, and ensures safe and reliable operations across various industrial and commercial applications.

FAQs

[rank_math_rich_snippet id=”s-1f1383cf-fc49-46a7-bbb8-4fb0deea4b78″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.