Air compressors are essential equipment in many industrial and commercial applications. They are used for various tasks, from powering tools to operating machinery.

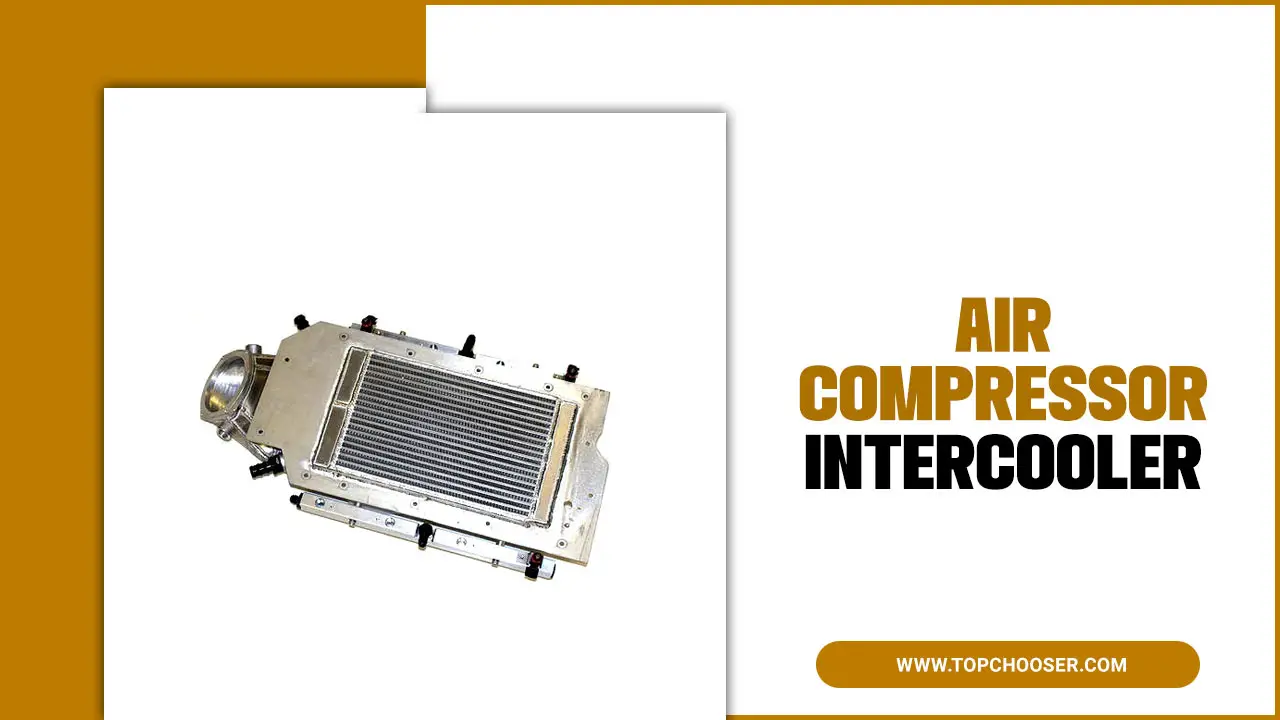

However, air compressors require proper maintenance and care to perform optimally like any equipment. One critical component that plays a significant role in the performance of an air compressor is the intercooler. An intercooler is a device that cools the compressed air before it enters the next compression stage.

Here we will explore the importance of the air compressor intercooler. And how it can impact the overall performance of your compressed air system. We will delve into the key functions of the intercooler, the factors that affect its efficiency, and the steps you can take to optimize its performance. Whether you are an industrial facility manager, a compressor operator, or a maintenance professional.

How To Optimize Your Air Compressor Intercooler Performance

To optimize the performance of your air compressor intercooler, you can take a few key steps. First and foremost, it is important to ensure that your intercooler is properly sized for your specific air compressor system. This will help to maximize heat transfer and prevent any potential bottlenecks in airflow.

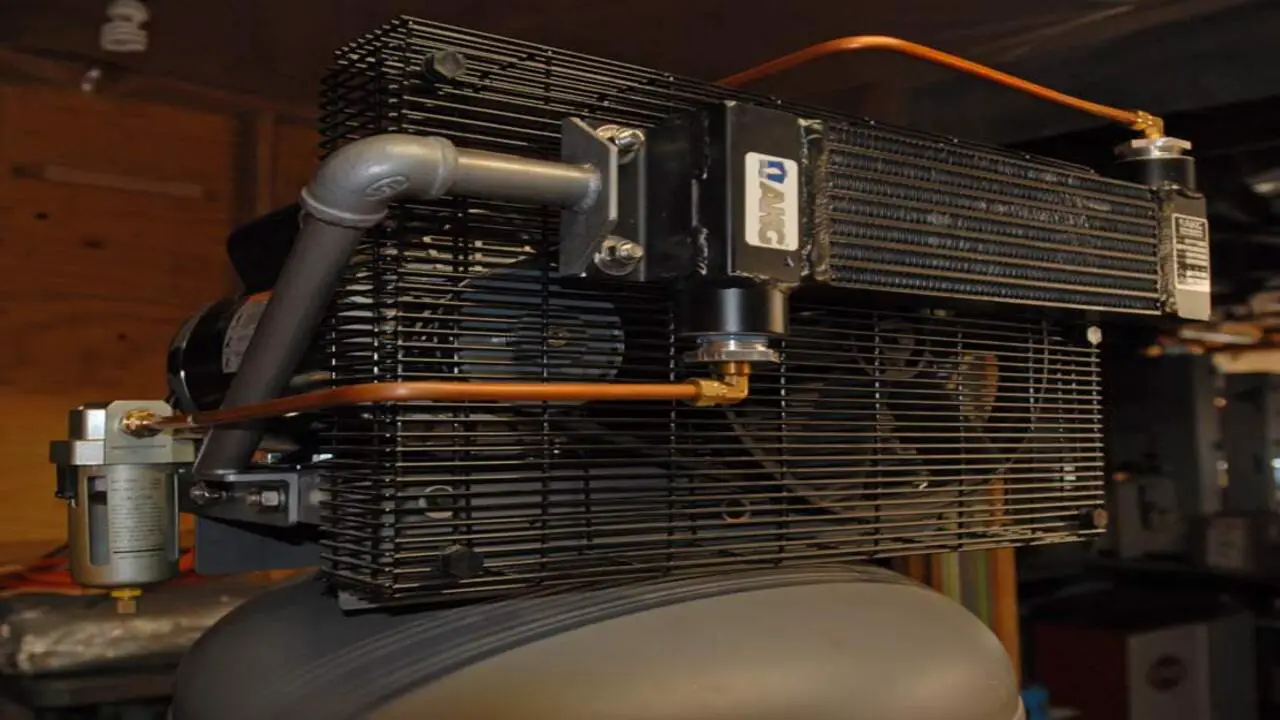

Additionally, regular maintenance and cleaning of the intercooler is crucial to maintain its efficiency. Over time, dust, dirt, and other debris can accumulate on the intercooler’s fins. Reducing its ability to cool the compressed air effectively. Regularly inspecting and cleaning the intercooler will help to keep it operating at peak performance.

Lastly, consider installing additional cooling mechanisms such as fans or water-cooling systems to enhance the performance of your intercooler. These additional measures can help to further reduce the temperature of the compressed air and optimize overall system efficiency.

By following these steps, you can ensure that your air compressor-intercooler operates at its best, providing reliable and efficient compressed air for your applications.

Understanding The Importance Of Optimizing Intercooler Performance

The intercooler plays a crucial role in optimizing the performance of an air compressor. It is responsible for cooling the compressed air before it enters the next compression stage. Ensuring that the air remains at a suitable temperature for efficient operation. By reducing the compressed air temperature, the intercooler helps increase its density. Resulting in improved overall compressor efficiency and performance.

In addition to cooling the compressed air. The intercooler also helps to remove any moisture or condensation that may have formed during compression. This is important because moisture can negatively impact the quality and reliability of the compressed air. Leading to potential issues such as corrosion or damage to downstream equipment.

To ensure optimal performance, choosing an intercooler that is properly sized and designed for your specific air compressor system is essential. When selecting an intercooler, factors such as pressure, airflow, and ambient conditions should be considered. Regular maintenance and cleaning of the intercooler are also important to prevent any buildup of dirt or debris that could hinder its effectiveness.

Factors That Can Affect Intercooler Performance

Several factors can affect the performance of an air compressor-intercooler. One of the most important factors is the size and design of the intercooler. A larger intercooler with a more efficient design will be able to cool the compressed air more effectively, resulting in better overall performance. Another factor to consider is the air flow rate through the intercooler.

If the flow rate is too high, it can reduce the time the air has to cool, leading to less effective cooling. Additionally, ambient temperature can also impact intercooler performance. In hotter climates, it may be necessary to use a larger or more efficient intercooler to maintain optimal performance.

Finally, proper maintenance and cleaning of the intercooler is crucial for ensuring its longevity and effectiveness. Regularly checking and cleaning any dirt or debris accumulating on the intercooler can help prevent clogs and maintain optimal cooling performance.

Proper Maintenance And Cleaning Of The Intercooler

Proper maintenance and cleaning of the air compressor-intercooler is essential to ensure optimal performance and longevity of the equipment. The intercooler plays a crucial role in cooling down the compressed air before it enters the next stage of the compression process.

Over time, dust, dirt, and other contaminants can accumulate on the intercooler fins, hindering its ability to cool the air effectively. Inspecting and cleaning the intercooler is recommended to prevent blockages or airflow restrictions. This can be done using compressed air or a soft brush to remove debris from the fins.

Additionally, it is important to check for any signs of corrosion or damage and address them promptly to maintain the efficiency of the air compressor-intercooler. By taking these maintenance steps, you can ensure that your air compressor operates at its best and avoids any potential issues caused by a neglected intercooler.

Upgrading To A Larger Or More Efficient Intercooler

Upgrading to a larger or more efficient intercooler for your air compressor can have several benefits. An intercooler helps to cool down the compressed air before it enters the next stage of the compression process, which can help improve efficiency and performance. By upgrading to a larger intercooler, you can increase the cooling capacity and reduce the compressed air temperature even further.

This can result in lower energy consumption, reduced wear and tear on equipment, and improved overall productivity. Additionally, a more efficient intercooler can help prevent heat-related issues such as moisture buildup and condensation, which can negatively impact the compressed air quality. So, if you want to optimize your air compressor’s performance, upgrading to a larger or more efficient intercooler may be a wise investment.

Installing Additional Cooling Mechanisms For Improved Performance

Installing an intercooler can be beneficial to an air compressor system, especially if you want to improve its cooling capabilities. An intercooler works by reducing the temperature of the compressed air before it enters the next stage of the compression process. This helps to prevent overheating and allows for more efficient and reliable operation of the compressor.

By installing an intercooler, you can help extend your compressor’s lifespan and ensure that it continues to perform at optimal levels. An intercooler can also help reduce energy consumption, as cooler air requires less energy to compress. Investing in an air compressor-intercooler can be a smart choice for those looking to enhance their system’s cooling capabilities and improve overall performance.

Monitoring Intercooler Temperatures And Pressures

Monitoring intercooler temperatures and pressures is essential for the proper functioning of an air compressor. The intercooler plays a crucial role in cooling the compressed air before it enters the next compression stage. By monitoring intercooler temperatures and pressures, you can ensure the compressor operates within safe limits and avoid potential damage or overheating.

Regularly checking and maintaining the intercooler can help optimize performance, increase efficiency, and extend the lifespan of your air compressor. It is recommended to refer to the manufacturer’s guidelines for specific monitoring procedures and to consult with a professional if you have any concerns about your air compressor’s intercooler.

Benefits Of Optimizing Intercooler Performance

Optimizing the performance of an air compressor-intercooler can provide several benefits. The intercooler plays a crucial role in the cooling process of compressed air, allowing it to be more efficiently and effectively cooled before entering the next compression stage. By optimizing the intercooler performance, you can enhance the overall efficiency and productivity of your air compressor system.

This can reduce energy consumption, lower operating costs, and increase reliability. Additionally, a well-functioning intercooler can help prevent overheating and potential damage to the compressor components, extending its lifespan and reducing maintenance needs. Overall, investing in optimizing your air compressor-intercooler performance is a smart choice that can significantly impact your operations.

Extended Lifespan Of The Intercooler And Other Components

The intercooler is an essential component of an air compressor, as it helps to cool down the compressed air before entering the process’s next stage. This cooling effect not only improves the efficiency of the compressor but also extends the lifespan of the intercooler and other components.

By reducing the compressed air temperature, the intercooler prevents excessive heat buildup, which can lead to damage or failure of the compressor. It also helps remove moisture from the air, preventing corrosion and ensuring the compressed air remains clean and dry. Regular maintenance and cleaning of the intercooler are crucial to ensure its optimal performance and longevity.

Conclusion

Optimizing the performance of your air compressor-intercooler is crucial for ensuring efficient and reliable operation. By understanding the importance of intercooler performance and taking necessary steps such as proper maintenance, cleaning, and upgrading to a larger or more efficient intercooler, you can enhance your air compressor’s overall performance and lifespan.

Additionally, monitoring intercooler temperatures and pressures and installing additional cooling mechanisms can further improve the efficiency and effectiveness of your intercooler. By optimizing your intercooler performance, you can experience benefits such as increased productivity, reduced energy consumption, and minimized risk of component failure. Don’t overlook the significance of your air compressor intercooler in achieving optimal performance.

Frequently Asked Questions

What Does An Intercooler Do On An Air Compressor?

An intercooler on an air compressor plays a crucial role in optimizing its performance. It cools down the compressed air, improving efficiency and reducing moisture. This helps prevent equipment damage and enhances air quality. Understanding the importance of the intercooler is vital for maximizing the compressor’s lifespan and components.

What Is The Intercooler Between Compressor Stages?

Located between the stages of an air compressor, the intercooler serves as a heat exchanger. Its primary role is to cool the compressed air, reducing its temperature and increasing density. This results in more efficient compression and improved overall performance, preventing overheating and extending component lifespan.

How Is The Intercooler Used To Reduce The Power Consumption Of Compressor?

The intercooler plays a crucial role in reducing the power consumption of an air compressor. C cooling the compressed air between stages lowers its temperature and increases density. This results in less energy required for compression, optimizing performance and reducing power consumption.

What Type Of Air Compressors Have An Intercooler?

Most rotary screw air compressors have an intercooler, while some high-performance reciprocating air compressors also feature this component. Intercoolers are crucial in reducing compressed air temperatures, improving efficiency and overall performance. When choosing an air compressor, selecting one with an intercooler is important for optimal performance and longevity.

What Are The Advantages Of Inter-Cooling Of The Air Compressor?

Inter-cooling of the air compressor offers several advantages. It helps reduce the compressed air temperature, resulting in improved efficiency and performance. Additionally, the intercooler helps remove moisture from the compressed air, reducing the risk of corrosion and damage to equipment. This can also extend the lifespan of the air compressor by minimizing wear and tear on components.

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.