Air compressors are essential in almost every garage setting. They are handy to power tools, inflate tires, and even paint cars. However, their performance and efficiency depend on a well-designed air compressor piping system.

Installing and maintaining an air compressor piping system can be challenging, but with the right planning, it can be a success. In this blog post titled “Essential Tips for Air Compressor Piping in Garage Success,” we will provide you with crucial information and tips on achieving optimal efficiency and performance from your air compressor piping system.

The blog post will cover the ideal piping material, routing, and sizing topics. We will also discuss the importance of proper installation, including using fittings, valves, and elbows. Furthermore, we will highlight the significance of regular maintenance on your air compressor piping system to ensure its longevity and prevent costly repairs.

Types Of Pipes Suitable For Air Compressor Systems

When installing air compressor piping in your garage, choosing the right type of pipes for your system is important. There are several options available, each with its own advantages and considerations.

- One commonly used type of pipe for air compressor systems is copper. Copper pipes are durable, corrosion-resistant, and can handle high pressures. They are also easy to install and can be soldered or brazed together. However, copper pipes can be more expensive than other options and may require additional insulation to prevent condensation.

- Another option is galvanized steel pipes. These pipes are strong and durable, making them suitable for high-pressure applications. They are also resistant to corrosion and can withstand extreme temperatures. However, galvanized steel pipes can be more difficult to work with and may require threading or welding during installation.

- For a more cost-effective option, you may consider using PVC pipes. PVC pipes are lightweight, easy to install, and resistant to corrosion. They are also less expensive than copper or steel pipes. However, PVC pipes have lower pressure ratings than metal pipes and may not be suitable for all air compressor systems.

Ultimately, the choice of piping material will depend on your specific needs and budget.

Recommended Tools And Equipment For Installation

Regarding installing air compressor piping in-garages, there are several recommended tools and equipment that can make the process smoother and more efficient. Consider using durable copper pipes, which are resistant to corrosion and can withstand the demands of compressed air systems.

Having the necessary fittings and connectors on hand is important to ensure a secure and leak-free installation. A pipe cutter and deburring tool are essential to achieve clean and smooth pipe cuts. Using Teflon tape or pipe sealant can also help prevent air leaks at connections. Lastly, prioritize safety by wearing protective gear such as gloves and safety glasses throughout the installation.

Tips For Installing And Maintaining Air Compressor Piping In Garage

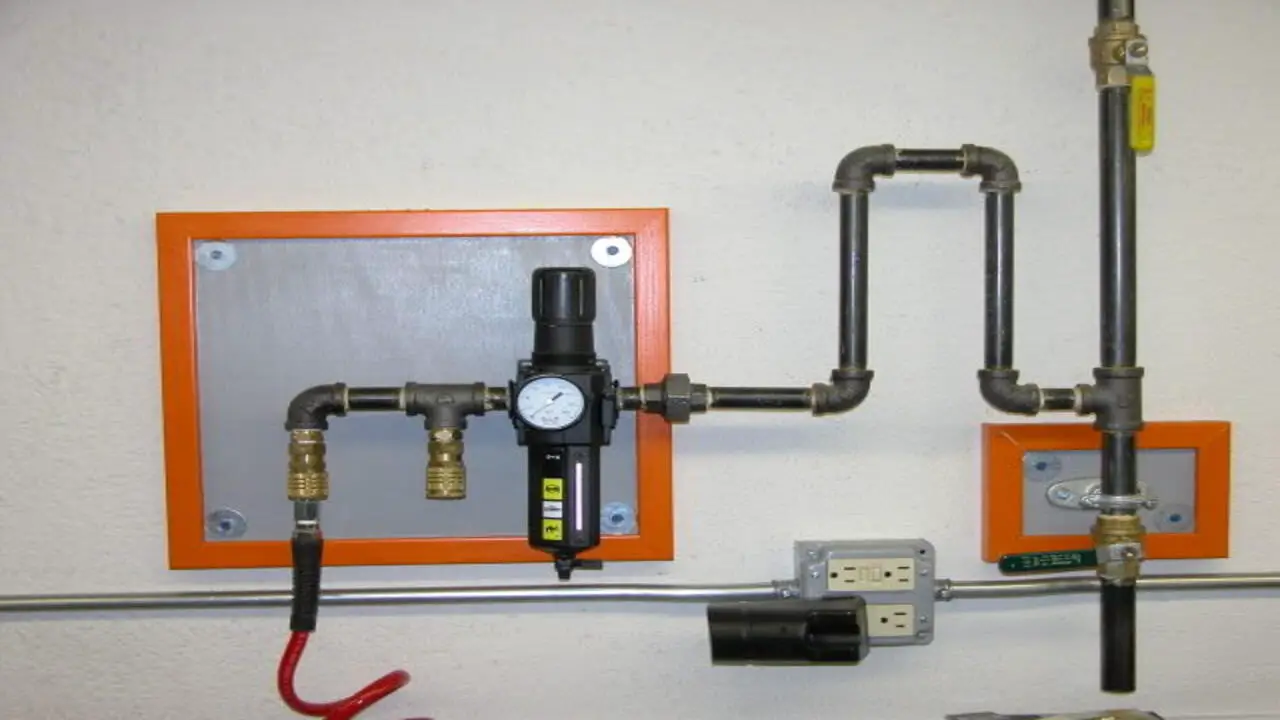

Air compressor piping in garage is typically used to route compressed air from the air compressor to the garage. It can be used for various purposes, such as powering pneumatic tools and equipment. Providing water for automotive cleaning, and providing ventilation for the garage. Installing and maintaining air compressor piping in your garage ensures efficient operation and prevents potential issues. Here are some tips to help you with the process:

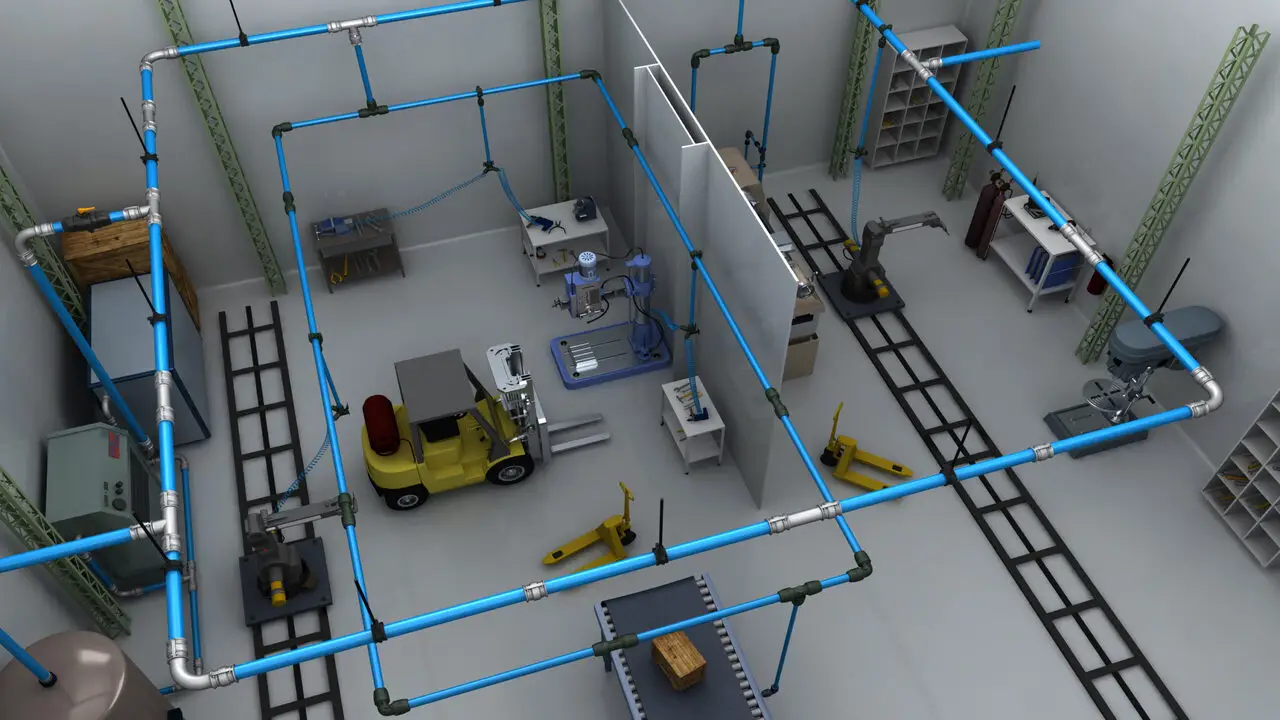

Plan the layout: Before installing the piping, carefully plan the layout to optimize airflow and minimize pressure drops. Consider factors such as the location of the compressor, the length of piping required, and any obstacles that may affect airflow.

Choose the right materials: The appropriate piping material is crucial for durability and performance. Common options include copper, aluminum, and PVC. Each has its own advantages, so research and choose based on your specific needs.

Size the pipes correctly: Properly sizing the pipes is critical for maintaining consistent airflow throughout your system. Consult a professional or refer to industry guidelines to determine the correct pipe diameter for your compressor’s CFM (cubic feet per minute) requirements.

Use proper fittings and connectors: Ensure you use high-quality fittings and connectors compatible with your chosen piping material. This will help prevent leaks and ensure a secure connection between components.

Install a moisture separator and filters: To protect your compressor from moisture and debris, install a moisture separator and filters in your system. This will help extend the lifespan of your equipment and maintain optimal performance.

By following these tips, you can effectively install and maintain air compressor piping in your garage, ensuring reliable performance and longevity for your equipment.

How To Choose The Right Pipe For Your Air Compressor Piping

Air compressor piping in a garage is a pipe handy to transport air from the air compressor to a distribution point in the garage. When installing air compressor piping in your garage, choosing the right pipe material for your needs is important. Several options are available, including copper, stainless steel, and various types of plastic. Each material has its own advantages and considerations to keep in mind.

- Copper piping is popular for its durability and resistance to corrosion, making it a popular choice for air compressor systems. It is also relatively easy to install and can handle high-pressure applications. However, copper piping can be more expensive compared to other materials.

- Stainless steel piping is another option that offers excellent corrosion resistance and durability. It can withstand high temperatures and is often used in industrial settings. However, stainless steel pipes can be more costly and require specialized tools for installation.

- Plastic piping, such as PVC or polyethylene, is more affordable, lightweight, and easy to install. However, it may not be suitable for high-pressure applications or extreme temperatures.

When choosing the right pipe for your air compressor system, consider factors such as the required pressure rating, compatibility with your compressor and other components, cost-effectiveness, and ease of installation. Consulting with a professional or doing thorough research can help you make an informed decision based on your needs.

Importance Of Proper Air Compressor Piping In A Garage

Proper air compressor piping is essential for maintaining optimal airflow and pressure in your garage. Choosing the right pipe material, such as copper or PVC, can prevent corrosion and leaks. It’s important to have properly sized pipes to ensure efficient airflow and minimize pressure drop.

Installing a moisture separator and filter can help prevent damage to tools and equipment. Regular maintenance, including checking for leaks and cleaning filters, will prolong the life of your air compressor system. You can create a reliable and efficient workspace for all your projects by prioritizing proper air compressor piping.

Conclusion

To ensure the success of your air compressor piping in the garage, choosing the right pipe that suits your needs is crucial. Proper air compressor piping is essential for optimal performance and efficiency in your garage. Consider factors such as the size and capacity of your air compressor system, layout and space constraints, compatibility with other equipment and fittings, and future expansion or modifications.

Additionally, pay attention to proper sealing and insulation techniques, regular inspections, and maintenance to prevent leaks or damage. With the right pipe and proper installation and maintenance, you can ensure that your air compressor system operates smoothly and effectively in your garage, making your work easier and more efficient. We have provided bulk information for air compressor piping in garage and hope our information was helpful from your perspective.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-0c44af67-3633-43b0-bc27-5d8971f36d64″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.