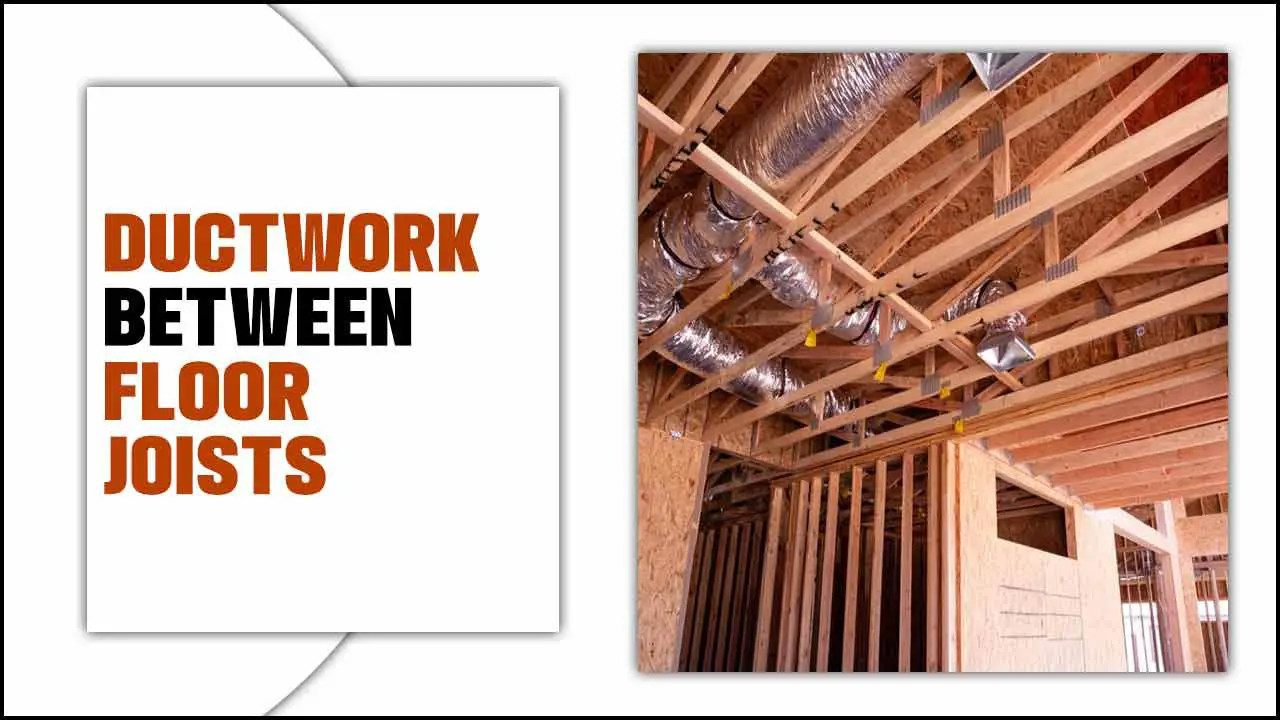

Ductwork is an essential component of any HVAC system, responsible for circulating heated or cooled air throughout a building. In most cases, ductwork is located in attics, basements, or crawl spaces, but there are situations where it may need to be installed in between the floor joists.

This method of installation, known as “ductwork between floor joists,” is a popular choice among homeowners and contractors alike due to its space-saving and cost-effective advantages.

However, this method also comes with its own set of challenges and considerations, making it crucial to understand the intricacies of this type of installation. Here, we will delve into the world of ductwork between floors, discussing its benefits, potential issues, and best practices for proper installation.

Tools And Materials Needed For The Installation Process

Floor joists are an integral component of any building structure, providing essential support and stability to the flooring system. These horizontal beams, typically made of wood or steel, distribute the weight of the structure and any applied loads evenly across the foundation or supporting walls.

Understanding the importance of floor joists is crucial for architects, engineers, and construction professionals alike. Tools and materials needed for the installation process of floor joists may include:

- Measuring tape or ruler

- Circular saw or reciprocating saw

- Hammer or nail gun

- Drill and screws

- Level

- Joist hangers

- Sizes of lumber

- Safety equipment

- Building code requirements

6 Steps On Installing Ductwork Between Floor Joists

Measure and plan carefully before cutting into the joists. Use appropriate tools and techniques for cutting openings. Install support brackets to secure the ductwork. Seal all joints and connections to prevent air leaks. Insulate the ductwork for improved energy efficiency.

Consider hiring a professional if unsure about any step. Installing ductwork between floors can be challenging, but it can be done effectively with the right tips and techniques. Here are six tips to help you successfully install ductwork between floors. Below we provide 6 steps to install ductwork between floor joists in detail.

1.Choosing The Right Ductwork For Your Project

When choosing ductwork for your project, it’s important to consider the size and shape that best suits your needs. Whether round or rectangular, accurate measurements ensure a proper fit between floor joists. Selecting the right material, such as galvanized steel or flexible aluminium, is crucial for durability.

Additionally, insulating the ductwork prevents condensation and energy loss. Always follow local building codes and regulations to ensure compliance and safety. The right choice of ductwork ensures optimal airflow and efficiency for your HVAC system.

2.Measuring And Cutting The Ductwork

To ensure a proper fit, accurate measurements of the space between the floor joists are crucial before installing the ductwork. Use a tape measure to mark the measurements on the ductwork using a permanent marker or pencil.

Tin snips or a metal duct cutting saw can carefully cut the ductwork following the marked measurements. It’s important to wear protective gloves and goggles when cutting to avoid injury. Smooth rough edges with a file or sandpaper to prevent excess insulation or air leakage damage. Test fit the cut ductwork between the floor joists before securing it in place.

3.Preparing The Floor Joists For Installation

Before starting the installation process, it is crucial to measure and mark the locations of the ductwork on the floor joists. Using a reciprocating saw or similar tool. Cut notches in the floor joists to install the ductwork while ensuring compliance with local building codes.

Secure the ductwork between the floor joists using appropriate support brackets or hangers. To prevent leaks and ensure proper airflow, seal any gaps or seams in the ductwork with foil tape or mastic. Additionally, consider insulating the ductwork to enhance energy efficiency and reduce noise transmission between floors.

4.Installing The Ductwork Between Floors

Careful measurement and planning are crucial to ensure a proper fit and alignment before starting the installation process. Use appropriate tools, such as a reciprocating saw or tin snips, to cut openings in the floor joists. Consider using flex ducts for easier maneuverability in tight spaces.

Properly securing the ductwork will prevent sagging or movement over time. Insulating the ductwork improves energy efficiency and reduces noise transmission. Test the airflow and make any necessary adjustments before completing the installation for optimal performance.

5.Sealing And Insulating The Ductwork

Properly sealing and insulating ductwork is crucial for efficient heating and cooling. Use foil-backed duct tape or mastic sealant for joints and connections. Insulate the ductwork with sleeves or wrap to prevent heat loss or gain.

Please pay attention to areas where ductwork passes through walls, floors, or ceilings, as they are prone to leaks. Consider using flexible ducting for easier installation and better airflow. Consult an HVAC technician for assistance.

6.Testing And Balancing The Airflow

Properly testing and balancing the airflow in your HVAC system is essential before installing ductwork between floors. This ensures balanced airflow throughout your home, preventing hot or cold spots.

You can measure the airflow at each supply ducts and return register using a handheld anemometer or consult with a professional HVAC technician. You may need to adjust the ductwork or dampers if there are imbalances. Testing and balancing the airflow will ensure your HVAC system’s efficient and effective operation.

Common Mistakes To Avoid While Installing Ductwork

When installing ductwork between floors, it is important to avoid common mistakes that can compromise the effectiveness and efficiency of your HVAC system. One common mistake is using improper sizing for the ducts. Ensuring that the ducts are properly sized is crucial.

To match the airflow requirements of your heating and cooling system. Another mistake to avoid is improper sealing of the duct joints. Air leaks can lead to energy loss and reduced performance, so sealing all joints tightly using methods such as mastic or foil tape is essential.

Additionally, ensure adequate support for the ductwork by using hangers or straps to prevent sagging or damage over time. By avoiding these common mistakes, you can ensure that your ductwork installation is successful and contributes to a comfortable and efficient indoor environment.

Benefits Of Installing Ductwork Between Floor-Joists

Floor joists are an integral component of any building’s structural framework. These horizontal beams provide critical support and stability to the flooring system, playing a crucial role in distributing the weight of the structure evenly.

Whether it is a residential home, commercial establishment, or industrial facility, the proper installation and maintenance of floor joists are paramount to ensure safety and longevity. Installing ductwork between floors offers several benefits:

- Space Efficiency: By utilizing the space between floor joists, you can maximize the available area in your home. This is particularly useful in areas where ceiling height is limited or when there is no attic or basement to accommodate traditional ductwork.

- Improved Aesthetics: By hiding the ductwork between floors, you can maintain a clean and uncluttered look in your living space. This can be especially desirable in areas such as finished basements or open-concept floor plans.

- Energy Efficiency: Ductwork installed between floor joists can help improve energy efficiency by reducing the length of duct runs. Shorter duct runs mean less energy loss due to heat transfer, resulting in lower energy bills and improved HVAC system performance.

- Noise Reduction: Placing ductwork between floors can help minimize noise transmission between different areas of your home. This can be particularly advantageous in multi-story homes or situations where noise control is a priority.

- Flexibility: Installing ductwork between floors provides flexibility in terms of HVAC system design and layout. It allows for customized duct routing and easier access for maintenance and repairs.

How Does The International Residential Code (Irc) Affect Ductwork Installation?

The International Residential Code (IRC) sets guidelines and regulations for the construction of residential buildings, including installing ductwork. When installing ductwork between floors, you must follow the requirements specified by the IRC.

These requirements ensure supporting the ductwork is properly and does not compromise the structural integrity of the building. For example, the IRC may specify the type and size of hangers or supports that must be used to secure the ductwork to the floor joists.

The IRC may also dictate minimum clearances that must be maintained between the ductwork and other components, such as electrical wiring or plumbing pipes. It is important to consult the IRC and work with a qualified HVAC professional to ensure your ductwork installation meets all necessary code requirements.

Maintaining Your Ductwork Post-Installation

Once your ductwork has been installed between the floor joists, it is important to maintain it to ensure optimal performance and efficiency. Regular maintenance can help prevent leaks, blockages, and poor airflow.

Here are some tips for maintaining your ductwork post-installation. By following these maintenance steps, you can prolong the lifespan of your ductwork and ensure optimal performance from your HVAC system.

- Inspect For Any Signs Of Damage Or Wear: Regularly check your ductwork for any signs of damage, such as cracks, holes, or loose connections. Addressing these issues promptly can prevent air leakage and improve the overall efficiency of your HVAC system.

- Clean Regularly: Dust, dirt, and debris can accumulate in your ducts over time, impacting the quality of the air circulating in your home. It would be best if you regularly cleaned your ductwork to remove any build-up and ensure clean air is distributed throughout your living space.

- Schedule Professional Inspections: A professional HVAC technician should inspect your ductwork on a regular basis. They can identify any potential issues or areas needing repair and provide necessary maintenance or repairs.

How Can Proper Ductwork Installation Improve Energy Efficiency?

Proper ductwork installation between floor joists can have a significant impact on energy efficiency in a building. When ducts are improperly installed or not sealed correctly, air leaks can occur, causing conditioned air to escape and unconditioned spaces air to enter the duct system.

This can result in wasted energy and higher utility bills. Ensure that ducts are properly installed and sealed. You can minimize air leaks and improve the overall efficiency of your HVAC system. This allows for better control of indoor temperatures, reduces energy waste, and ultimately leads to cost savings.

Additionally, proper ductwork installation can help improve indoor air quality by preventing the entry of dust, allergens, and other contaminants into the duct system. Proper ductwork installation is a smart choice for energy efficiency and indoor comfort.

Conclusion

Installing ductwork between floor joists can be an effective solution for heating and cooling your home. Utilizing the space between the floor joists can save valuable square foot footage and maintain a clean aesthetic in your living spaces. However, it is important to consider the structural integrity of your home and consult with a professional to ensure the installation is done correctly.

Proper ductwork installation between floors is crucial for maintaining a comfortable and energy-efficient home. You can ensure that your ductwork installation is done correctly by following the tips, such as choosing the right ductwork, measuring and cutting accurately, and sealing and insulating properly. This will improve your home’s airflow and help reduce energy waste and utility bills.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-b65dbc87-37bb-4b7a-bcf3-102a7e61d97f”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.