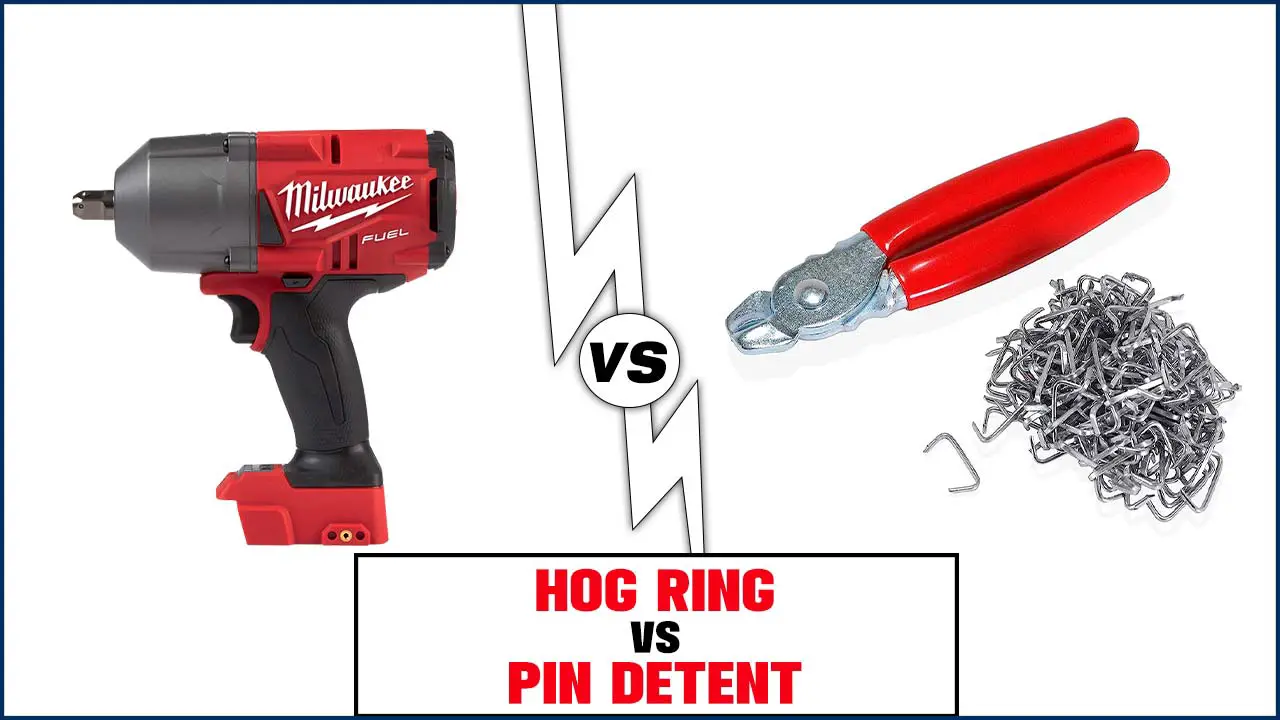

As a professional tradesperson or DIY enthusiast, choosing the right tool for the job is crucial. One tool that often causes confusion among users is the hog ring anvil vs detent pin.

Both are handy in impact wrenches to hold sockets securely in place. However, these two types of anvil have different mechanisms and advantages. Hog ring anvils use a circular ring to hold the socket, while detent pin anvils use a spring-loaded ball bearing to secure the socket.

The debate over which is better has raged on for years, with professionals and enthusiasts chiming in with their preferences. Some swear by hog ring anvils for convenience and ease of use, while others prefer detent pin anvils for their superior grip and reliability.

We’ll explore the differences between these two types of anvil, their advantages and disadvantages, and ultimately, help you determine which is better for your specific needs.

What Is A Hog Ring Anvil?

Power tools like impact wrenches and impact drivers use hog ring anvils as a type of anvil. They named it after the hog rings, small metal rings used to secure materials together. The hog ring anvil holds the hog rings securely in place by having a groove or channel for insertion.

This anvil type is commonly used in applications where a strong and secure connection is needed, such as in construction or automotive work. The hog ring anvil provides a reliable and efficient way to fasten materials together, making it a popular choice among professionals in various industries.

What Is A Detent Pin Anvil?

A detent pin anvil is a tool handy in construction and mechanical work. It is a component of impact wrenches and drills that helps secure the socket or drill bit in place, preventing it from slipping during use. The detent pin anvil features a small metal pin that locks into corresponding holes on the socket or drill bit, creating a secure connection.

This ensures the tool remains stable and allows for efficient and precise work. Detent pin anvils are commonly handy in automotive repair, construction, and other industries requiring high torque and stability.

Head To Head Difference Between Hog Ring Anvil Vs Detent Pin

Choosing between a hog ring anvil vs detent pin, it’s important to understand the differences and advantages of each. A hog ring anvil is popular for its secure hold, using a series of metal rings to fasten materials together. This makes it ideal for applications where the connection needs to be strong and long-lasting, such as in construction or fencing.

On the other hand, a detent pin offers quick and easy tool changes, as it uses a spring-loaded ball-bearing mechanism to secure attachments in place. This makes it more convenient for tasks requiring frequent switching between tools or accessories, such as automotive repairs or woodworking. Ultimately, the choice between a hog ring anvil and a detent pin will depend on the specific needs of your project and personal preferences.

People know a hog ring anvil for its durability and ability to hold fasteners securely. This makes it a popular choice for applications that require a strong grip, such as fencing or upholstery work. On the other hand, a detent pin anvil offers quick and easy socket changes, making it ideal for tasks that require frequent switching between different sizes of fasteners.

It’s also worth noting that hog ring anvils are typically more difficult to remove once installed. While detent pin anvils can be easily swapped out when needed. Ultimately, the decision between these two types of anvils will depend on the specific needs of your project and personal preferences.

Pros And Cons

When choosing between a hog ring anvil and a detent pin anvil, there are pros and cons to consider for each option.

Hog ring anvils are known for their durability and strength. They securely hold the socket in place, preventing it from accidentally disconnecting during use. This makes them particularly useful in high-impact applications where stability is crucial. However, one drawback of hog ring anvils is that it can be more difficult to change out the sockets compared to detent pin anvils.

Detent pin anvils, on the other hand, offer quick and easy socket changes. The pins on the anvil provide a secure hold while still allowing for easy removal when needed. This makes detent pin anvils more convenient for users who frequently switch between socket sizes. However, detent pin anvils may not be as reliable as hog ring anvils in heavy-duty applications, as they can be prone to accidental disconnections.

Choosing between a hog ring anvil and a detent pin anvil will depend on your specific needs and preferences. Consider the type of work you will be doing, the frequency of socket changes. And the level of stability required to make an informed decision.

When Should You Use A Hog Ring Anvil Vs A Detent Pin Anvil?

Choosing between a hog ring anvil and a detent pin anvil depends on the specific needs of your project. A hog ring anvil is typically handy for applications that require quick and easy tool-free socket changes, such as construction or automotive work. The hog ring design securely holds the socket, preventing accidental detachment.

On the other hand, a detent pin anvil is better suited for heavy-duty applications that require maximum stability and security. The detent pin mechanism provides a strong grip on the socket. Ensuring it stays firmly in place even under high torque. Ultimately, the decision between a hog ring and detent pin anvil should be based on the specific requirements of your job. And your personal preference for convenience versus stability.

Installing, Replacing, And Maintaining Hog Ring And Detent Pin Anvils

When installing, replacing, and maintaining hog ring and detent pin anvils, there are a few key differences to consider. Hog ring anvils are commonly handy in upholstery work and fencing. Providing a secure hold on materials like fabric or wire mesh.

To install or replace a hog ring anvil, simply slide it onto the corresponding tool and ensure it is securely in place. To maintain a hog ring anvil, regularly inspect it for any signs of wear or damage and replace as needed.

On the other hand, detent pin anvils are often found in power tools such as impact wrenches or drills. They use a spring-loaded pin mechanism to hold the socket or attachment. When installing or replacing a detent pin anvil, ensure that the pin is properly aligned with the corresponding hole in the tool. To maintain a detent pin anvil, periodically clean any debris from the pin mechanism and lubricate if necessary.

How To Choose The Best Hog Ring Anvil Or Detent Pin For Your Needs?

When choosing between a hog ring anvil and a detent pin, there are a few factors to consider. First, you’ll want to think about the type of work you’ll be doing. A hog ring anvil is typically handy for applications that require a stronger grip, such as fencing or upholstery work. On the other hand, a person can use a detent pin for tasks that require quick and easy tool changes, like automotive repairs.

You’ll also want to consider the compatibility of the anvil or pin with your specific tool. Some tools may only accept one type of anvil or pin, so checking the specifications before purchasing is important.

Finally, the budget may also play a role in your decision-making process. Hog ring anvils tend to be more expensive than detent pins, so you may lean towards the detent pin option if cost is a concern.

Choosing between a hog ring anvil and a detent pin comes down to your specific needs and preferences. By considering the type of work you’ll be doing, tool compatibility is important. And your budget, you can make an informed decision that will help you get the job done effectively and efficiently.

Conclusion

Choosing between a hog ring anvil vs detent pin ultimately depends on your specific needs and preferences. Both options have their pros and cons, so it’s essential to consider things like ease of use, security, and versatility.

Whether you’re a professional or a DIY enthusiast, understanding the difference between these two types of anvils will help you make an informed decision. Learn more about the pros and cons of hog ring and detent pin anvils and when to use each type. It will give you all the information you need to choose the best project option.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-cd9ba624-fd98-41cd-8b99-e6f7879377a0″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.