An impact wrench is a powerful tool to tighten or loosen nuts and bolts quickly and efficiently. It uses a combination of rotational force and impact force to apply high torque output to the fastener.

Impact wrenches are commonly used in automotive repair, construction, and manufacturing industries due to their ability to loosen even the most stubborn bolts. They come in various chuck sizes and power levels, ranging from cordless models for light use at home to heavy-duty pneumatic premium models for industrial applications.

Impact wrenches are essential tools for any mechanic or DIY enthusiast. They’re versatile and can be used for various tasks, but many users find them too weak for some functions. We’ll show you how to make impact wrench more powerful and perfect for your needs. We’ll also provide tips on using impact wrenches safely and effectively so you can get the most out of this essential tool.

6 Easy Steps On How To Make Impact Wrench More Powerful

Regarding using a wrench, having a powerful tool can make all the difference. Making your wrench more powerful can help you tackle tough jobs with ease and efficiency. There are several ways to achieve this, such as selecting a wrench with a longer handle for increased leverage or opting for a wrench with a higher torque output rating.

Additionally, using lubrication on rusted or tight bolts can help reduce friction and make it easier to loosen or tighten them. Another option is to invest in an electric or pneumatic wrench, which can provide even more power and speed. By making your wrench more powerful, you can save time and effort while getting the job done effectively. Below, we provid 6 easy steps on how to make impact tool wrench more powerful.

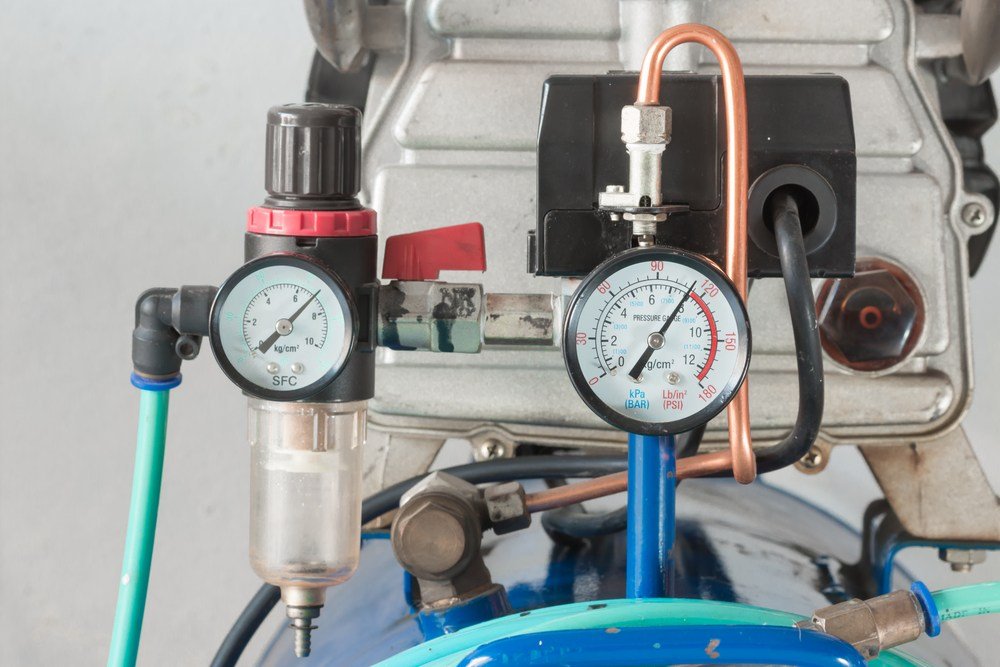

1.Use A Higher-Rated Air Compressor

Ensure that your air compressor can deliver sufficient air pressure and volume to meet the requirements of your impact drivers wrench. A higher-rated compressor will provide more power to the impact tool.

To achieve a more powerful impact wrench, one of the key steps is to use a higher-rated air compressor. By upgrading to a compressor with a higher cubic feet per minute (CFM) rating, you can ensure a steady and consistent airflow to the impact wrench, enabling it to operate at its full potential.

A higher CFM rating means that the compressor can deliver a greater volume of air, which is crucial for generating the necessary torque and power required for heavy-duty applications. Furthermore, a higher-rated air compressor often comes with a larger tank size.

2.Upgrade To A Larger Diameter Air Hose

A larger diameter air hose allows for better airflow, reducing restriction and increasing the power delivered to the impact wrench. This can enhance its performance. In order to harness the full power of your impact wrench, it is essential to take another crucial step: upgrading to a larger diameter air hose.

While a standard air hose may suffice for many applications, a larger diameter hose allows for increased airflow, resulting in enhanced performance and efficiency. By upgrading to a larger diameter air hose, you can ensure that your impact wrench receives a consistent and sufficient supply of compressed air.

This not only MAX Torque the power output of the tool but also minimizes the risk of air pressure loss or drop-offs during operation.

3.Adjust The Air Pressure

Check the manufacturer’s specifications for your impact wrench and adjust the air pressure accordingly. Increasing the pressure within the recommended range can provide more power to the tool.

Once you have connected the air hose to the tool, it is important to ensure that the air pressure is set correctly for maximum power. Refer to the manufacturer’s instructions or the recommended air pressure range for your specific impact wrench model.

To adjust the air pressure, locate the pressure regulator on the pressure drop. Rotate the knob or adjust the dial to increase or decrease the pressure, depending on your needs. Be cautious not to exceed the maximum pressure limit recommended for your impact wrench, as this can cause damage to the tool or compromise its performance.

4.Lubricate The Impact Mechanism

Regularly lubricate the impact mechanism of your wrench to reduce friction and increase efficiency. This can help to maximize the power output. The lubrication process helps to reduce friction and wear, ensuring smooth operation and prolonging the lifespan of your tool.

To lubricate the impact mechanism, start by locating the oil port on the tool. This is usually located near the base of the handle or on the side of the wrench. Once you have identified the oil port, use a small, pointed oil can or a designated lubrication tool to apply a few drops of high-quality lubricating oil into the port.

Be careful not to overfill or spill any oil onto other parts of the tool. After applying the lubricating oil, engage the impact mechanism by pulling the trigger or pressing the activation pressure switch a few times.

5.Use High-Quality Impact Sockets

Choose impact sockets specifically designed for use with impact wrenches. These sockets have a higher torque capacity, allowing the wrench to transfer more power to the fastener. These sockets are specifically designed to withstand the high noise levels of torque generated by the impact wrench, ensuring a secure and reliable connection between the wrench and the fastener.

When using low-quality or regular sockets with an impact wrench, there is a higher risk of the socket adapter breaking or shattering under intense pressure. This not only poses a safety hazard but can also damage the fastener or the wrench itself.

High-quality impact standard sockets, on the other hand, are constructed from durable materials such as chrome molybdenum steel or heat-treated alloy steel. These materials provide the necessary strength and resilience to handle the powerful impacts delivered by the wrench.

6.Increase The Stroke Size Of Your Impact Wrench

There are a few important factors to consider. The stroke size refers to the distance that the impact mechanism travels back and forth within the wrench. Increasing the stroke size can enhance the wrench’s power and torque, allowing it to tackle tougher tasks with ease.

One way to increase the stroke size is by adjusting the air pressure applied to the impact wrench. Higher air pressure leads to a longer stroke, resulting in more force when the wrench strikes the fastener. To increase the stroke size of your impact wrench, you can follow these steps:

- Check The Manufacturer’s Instructions: Consult the user manual or guide provided by the manufacturer of your impact wrench. They may have specific recommendations or limitations for adjusting the stroke size.

- Locate The Stroke Adjustment Mechanism: Look for a knob, dial, or lever on your impact wrench that is specifically designed for adjusting the stroke size. It may be located near the front or rear of the tool.

- Adjust The Stroke Size: Use the stroke adjustment mechanism to increase the stroke size. This may involve turning a knob clockwise or counterclockwise, sliding a lever, or using a specific tool provided by the manufacturer.

- Test And Fine-Tune: After adjusting, test the impact wrench on a suitable surface or object to see if the stroke size has increased as desired. If necessary, continue to fine-tune the adjustment until you achieve the desired stroke size.

7.Ensuring Proper Lubrication For Optimal Performance

Ensuring proper maintenance and lubrication is essential for maintaining optimal performance in any machinery or equipment. Neglecting these crucial aspects can result in decreased efficiency, increased wear and tear, and even potential breakdowns.

Therefore, it is imperative to establish a comprehensive maintenance routine that incorporates regular inspections, cleaning, and lubrication. To ensure proper maintenance and lubrication for optimal performance of an impact wrench, follow these guidelines:

- Regular Cleaning: Clean the impact wrench after each use to remove dirt, debris, and dust that can accumulate over time. Use a soft cloth or brush to wipe off any residue.

- Lubrication: Lubricate the impact wrench regularly to prevent friction and ensure smooth operation. Use a high-quality impact wrench lubricant recommended by the manufacturer. Apply the lubricant to the designated points as instructed in the user manual.

- Check Air Supply: If you have an air-powered impact type of impact wrench, ensure a clean and consistent air supply. Check the air filter regularly and clean or replace it if necessary. Ensure that the air pressure is within the recommended range.

- Inspect For Wear And Damage: Periodically inspect the impact wrench for any signs of wear or damage. Check the housing, trigger, anvil, and other components for cracks, corrosion, or any abnormalities. Replace any worn-out or damaged parts immediately.

- Adjust Torque Settings: Depending on the application, adjust the torque settings accordingly. Using excessive torque can strain the impact wrench and lead to premature wear. Refer to the manufacturer’s recommendations for the appropriate torque settings.

- Store Properly: When not in use, store the impact wrench in a clean and dry place. Avoid exposing it to extreme temperatures or moisture, as these can damage the internal components.

What Are The Benefits Of Upgrading Your Impact Wrench?

One cannot underestimate the importance of having a reliable and efficient impact wrench. This versatile tool has revolutionized the way professionals and DIY enthusiasts tackle various tasks, making it an indispensable asset in the toolbox.

What sets an impact wrench apart from other tools is its incredible power and torque capabilities, making it more powerful than traditional wrenches or drills. Here are some benefits of upgrading your impact wrench:

- Increased Power: Upgrading to a newer model of impact wrench often means getting more power. This can help you tackle tougher jobs and handle more demanding tasks with ease.

- Improved Efficiency: Newer impact wrenches often come with better technology and features that enhance efficiency. This can result in faster and more effective work, saving you time and effort.

- Enhanced Durability: Upgrading to a higher-quality impact wrench can lead to improved durability. This means that it will last longer and withstand more wear and tear, reducing the need for frequent replacements.

- Better Ergonomics: Newer models often come with ergonomic designs that prioritize user comfort. This can help reduce fatigue and strain during extended use, allowing you to work for longer periods without discomfort.

- Advanced Features: Upgraded impact wrenches may offer additional features like adjustable torque settings, LED lights for better visibility, and improved control mechanisms. These features can improve the overall performance and versatility of the tool.

- Compatibility With Newer Fasteners: As technology advances, new fasteners and fastening systems may be introduced. Upgrading your impact wrench ensures that you have a tool capable of handling these newer fasteners, allowing you to stay up to date with industry trends.

Conclusion

An impact wrench is a powerful tool that can make many jobs easier and more efficient. When choosing the right impact wrench, power is a crucial consideration. A more powerful impact wrench will be able to handle tougher jobs and make quicker work of them. To ensure you get a more powerful impact wrench, look for one with a higher torque rating.

Torque refers to the amount of rotational force that the wrench can generate, and a higher torque specification rating means that the wrench can apply more force to fasteners. If you want to increase the power of your impact wrench, you can do a few things to achieve this goal. Following the step on how to make impact wrench more powerful and efficient may benefit you.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-fe16a246-ea85-49d2-a7a6-39b358f2d06a”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.