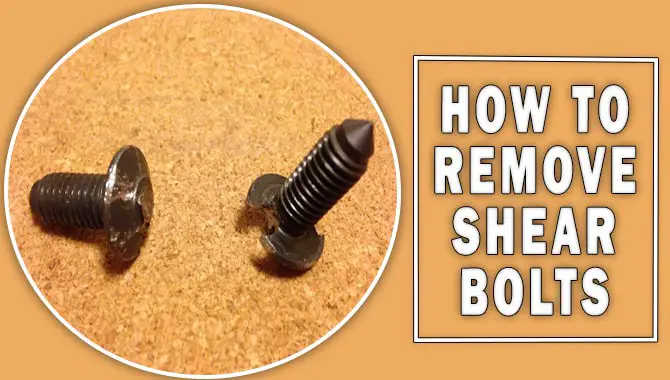

Shear bolts bolts used to attach two pieces of metal. They are also known as self-retaining bolts because they hold their own against the forces of shear (a type of stress). There are a few ways to remove shear bolts, but a bolt extractor is the most common.

This metal tool has a series of hooks that can grab onto the shear bolts and pull them out. If you’re dealing with a shear bolt that’s not budging, you can do a few things to try and remove it.

Here we’ll walk you through removing shear bolts step by step so that you can get back to work in no time. We’ve got you covered, from the tools you’ll need to the best techniques. So grab your wrench, and let’s get those shear bolts out once and for all.

What Are Shear Bolts?

Shear bolts are a type of fastener that attaches two pieces of material. They are made up of two parts: a head and a nut. The head design is to shear off when the bolt is tightened. Allowing the nut to hold the two pieces of material together securely.

Shear bolts are typically used in construction and manufacturing because they make connecting two pieces of metal or other materials easy. They’re also popular for outdoor applications, like decking and fencing, because they offer extra durability and security.

Tools Needed To Remove Shear Bolts

When removing shear bolts, having the right tools is essential. Shear bolts are designed to break under excessive force, making them difficult to remove without the proper equipment. Using the wrong tools can damage the bolt or surrounding components, making removal even more challenging. Here are some tools needed to remove shear bolts:

- Wrench

- Hammer

- Protective gloves

5 Effective Steps To Remove Shear Bolts

To remove shear bolts, start by identifying the bolt heads and using a centre punch to create a small indentation in the centre of the head. Then, clamp a pair of locking pliers onto the shear bolt head and turn it counterclockwise to loosen it. If the bolt is too tight or damaged, you can use bolt cutters to cut through it carefully. Avoid damaging surrounding parts or threads while removing the shear bolts.

Terminate Shear Bolts Operating A Hex Key

When removing shear bolts, there are several effective steps you can take. One option is to use a hex key or Allen wrench to terminate the shear bolts. You can loosen and remove the bolt by inserting the hex key into the bolt head and turning it counterclockwise.

Another method is using a rotary tool with a metal cutting disc to carefully cut through the shear bolt. Alternatively, you can use a specialized tool designed specifically for removing shear bolts, providing added precision and ease in the removal process.

Remove Shear Bolts Using Lubricant

To remove shear bolts using lubricant, start by applying a penetrating lubricant to the bolt and allowing it to sit for several minutes. This will help to loosen any rust or debris causing the bolt to stick. Next, use a drill bit slightly smaller than the diameter of the bolt to drill into the centre of the bolt head.

This will create a starting point for removing the bolt. Then, use a pair of vice grips or pliers to grip onto the exposed portion of the bolt and turn it counterclockwise to unscrew it. You can also use a strong clamp to hold the steering column or drive shaft in place while removing the bolt.

Remove Shear Bolts Using Torque Wrench

Using a torque wrench can be an effective method. First, make sure to apply grease to the threads of the bolt to help reduce friction. This will make it easier to loosen and remove the bolt.

Taking proper safety precautions, such as gloves and safety goggles, is also important to protect yourself from any potential injuries. Mechanics rely on shear bolts for their high strength but can efficiently and safely remove them with the right tools and precautions.

Remove Shear Bolts Using a Bolt Extractor

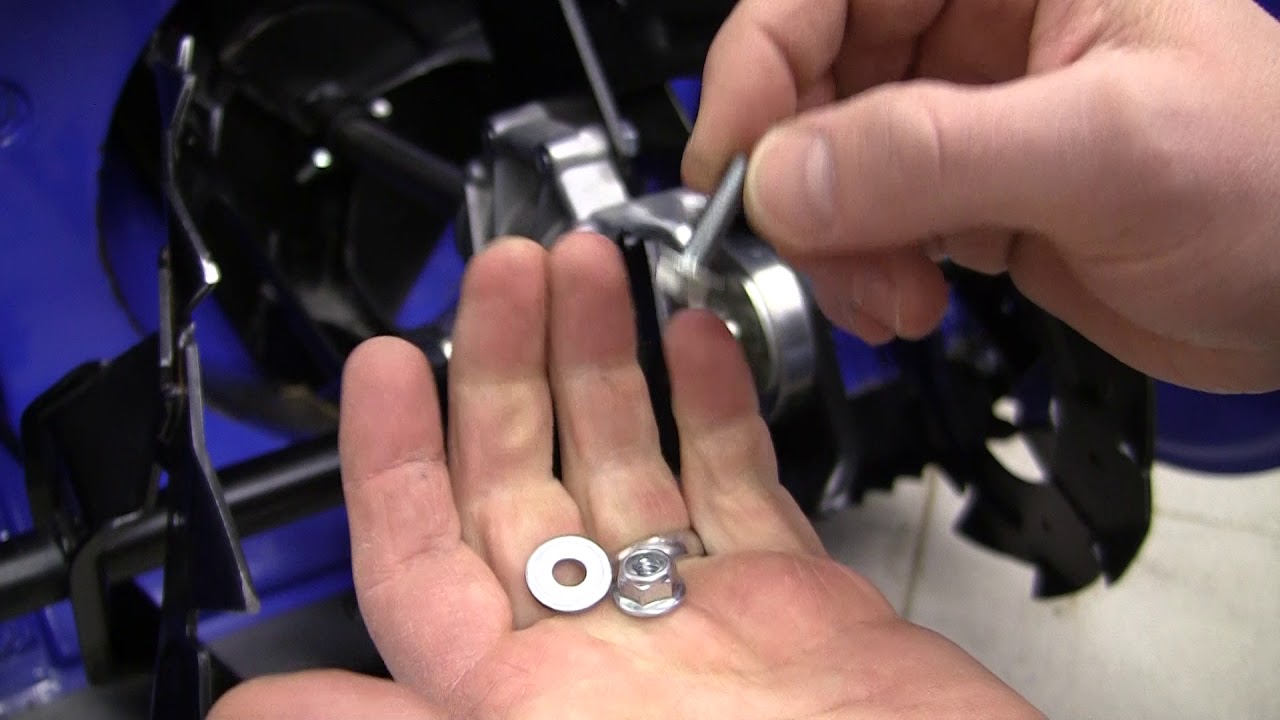

A bolt extractor can be a valuable tool when removing shear bolts in the automotive industry. A bolt extractor with its specialized design grips onto the broken bolt fragment and provides the necessary leverage to remove it. To use a bolt extractor, simply select the appropriate size for your shear bolt.

Insert it into the broken bolt fragment, and turn it counterclockwise with a wrench or socket. The unique spiral flutes of the extractor will bite into the bolt, allowing you to easily remove it without damaging the surrounding components.

Precautions That Need To Be Taken While Removing Shear Bolts

Shear bolts are commonly handy in construction to connect two pieces of timber or metal. You insert them into the joint and tighten them using a wrench so the two pieces of wood or metal can move together without breaking. When removing shear bolts, it’s important to take all the appropriate precautions to avoid accidents. Here are some tips:

- Always use proper safety equipment, like safety goggles and a dust mask.

- Wear gloves and work in a well-ventilated area.

- Use a powered screwdriver to remove the bolt instead of a wrench.

- Make sure you have enough torque when tightening the bolt.

How Much Does It Cost To Replace Shear Bolts?

The cost to replace shear bolts can vary depending on the size and type of bolt, as well as the specific circumstances of the job. In general, shear bolts are relatively inexpensive and range from a few dollars to around $20 each. However, one should note that replacing shear bolts requires caution and precision to ensure the correct bolt size and proper installation.

Using the wrong size or incorrectly installing a shear bolt can result in damage or failure of the equipment, leading to more costly repairs or replacements. Professionals or manufacturer guidelines recommend consulting and referring them for guidance on selecting and replacing shear bolts.

How Do I Know If My Shear Bolts Are In Good Condition?

To ensure that your shear bolts are in good condition, there are a few key factors to consider. First, inspect the entire bolt for any signs of damage or wear, such as rust, cracks, or bent edges. Next, check the hex bolt for tightness and make sure it is securely fastened.

Finally, you should examine the column pinch bolt to ensure that it is properly aligned and not loose. It is important to regularly inspect your shear bolts to prevent any potential failures or malfunctions. If you notice any issues with your shear bolts, we recommend replacing them promptly to maintain the safety and functionality of your equipment.

How To Remove Shear Bolts By Using A Drill?

You can remove shear bolts effectively with the right tools and techniques, even though it can be challenging. One method to remove shear bolts is by using a drill. Always wear safety goggles and gloves when working with power tools and sharp objects. If you’re not confident in your abilities, it’s best to consult a professional for assistance with shear bolt removal. Here are the steps to follow:

- Choose The Right Drill Bit: Select a drill bit that matches the size of the shear bolt head. Make sure it fits securely in the chuck of your drill.

- Mark The Centre: Use a centre punch or a nail to create a small indentation in the centre of the bolt head. This will help guide your drill bit and prevent it from slipping.

- Drill Slowly: Start drilling at a low speed and apply gentle pressure on the bolt head. Gradually increase the speed as you penetrate the bolt.

- Reverse direction: Once you have drilled deep enough, switch your drill to reverse mode and slowly back out the bolt.

- Use Lubricant If Needed: If you encounter resistance while drilling, apply a small amount of lubricant, such as penetrating oil, to loosen up any rust or debris.

- Clean Up: After removing the shear bolt, check for any remaining debris or damage in the hole. Use a wire brush or compressed air to clean out any leftover material.

Conclusion

Removing shear bolts can be daunting, but following these effective steps to remove shear bolts can make the process much easier. Start by ensuring you have the right tools and safety equipment. Then, carefully assess the situation and determine the best approach to remove the shear bolt.

Each step should be taken cautiously and precisely, whether using heat, lubrication, or a specialized removal tool. Remember to take your time and apply steady pressure to avoid damaging the surrounding components. You can successfully remove shear bolts and complete your project with patience and a methodical approach.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-7b5f2e40-aa4d-453a-8d56-201bc195e2ca”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.