Sanborn 5HP air compressor is a powerful tool designed for heavy-duty applications. Various industries use it, such as automotive, construction, and manufacturing. This compressor can deliver high-pressure air for powering pneumatic tools and equipment, such as paint sprayers, impact wrenches, and sanders.

This air compressor is highly reliable and durable, making it a popular choice for professionals who require a consistent and efficient compressed air source. The compressor has a powerful motor and a large air tank, ensuring it can deliver the required air pressure for extended periods.

The feasibility of the air compressor lies in its ability to provide a reliable and energy-efficient source of compressed air. Its design enables it to operate at peak performance levels, easily handling the most demanding tasks.

Types Of Tasks That The Air Compressor Can Handle

This air compressor is a versatile machine capable of handling various tasks. It is suitable for industrial, commercial, and DIY applications. Here are Some details and a listing of the types of tasks it can handle:

- Inflating tires and sports equipment.

- Operating pneumatic tools like nail guns and staplers.

- Powering paint sprayers for large-scale painting projects.

- Running airbrush kits for intricate artwork.

- Supplying air to sandblasters for surface preparation.

- Assisting in automotive repairs and maintenance.

- Operating impact wrenches for loosening tight bolts.

- Powering drills and screwdrivers.

- Running air-powered saws and grinders.

Cost Analysis And Value For Money Of This Air Compressor

The air compressor is a single-stage, belt drive, electric air compressor that can deliver up to 155 PSI of maximum pressure and 15.6 CFM of airflow at 90 PSI. It has a 60-gallon vertical tank and a heavy-duty induction motor with 230V power.

The cost of this compressor varies depending on the retailer, but it is generally around $800-$900. Compared to similar models, this compressor offers good value for money as it has a durable cast iron pump, a large capacity tank, and reliable performance.

The Installation Process Of The Sanborn 5hp Air Compressor

You can use this air compressor, a high-quality tool, for various applications. Its 5-horsepower motor provides plenty of power to run air tools, inflate tires, and power other pneumatic equipment. The manufacturer designed the compressor to be durable and long-lasting using a cast iron pump that can withstand heavy use.

Additionally, the compressor has a large, 60-gallon tank that allows for longer periods of use before needing to refill. Here are some steps to the Sanborn 5hp air compressor installation process.

1.Selecting A Suitable Location For The Compressor

When selecting a suitable location for a compressor, consider the surrounding environment. Ensure adequate ventilation to avoid overheating and that the area is free of flammable materials.

The location should also be easily accessible for maintenance and repairs. You should also consider the noise and vibration levels and the distance between the compressor and the point of use. Finally, consider whether the power source adequately supports the compressor’s needs.

2.Preparing The Foundation And Mounting Surface

The foundation and mounting surface for the compressor should be strong enough to support the weight and vibration of the compressor. The recommended foundation is a concrete slab at least 4 inches thick and extends 6 inches beyond the compressor’s base.

The mounting surface should be flat and smooth, with no cracks or holes. Secure the compressor to the foundation with anchor bolts at least 1/2 inch in diameter and 4 inches long.

3.Assembling The Compressor And Accessories

Assembling the compressor and accessories involves several steps. First, ensure all parts are present and in good condition. Then, mount the compressor onto a stable surface and connect the air inlet and outlet. Install the pressure switch and regulator, and connect the hoses and fittings. Finally, add oil to the compressor and test for proper operation. Follow the manufacturer’s instructions carefully and use appropriate safety gear.

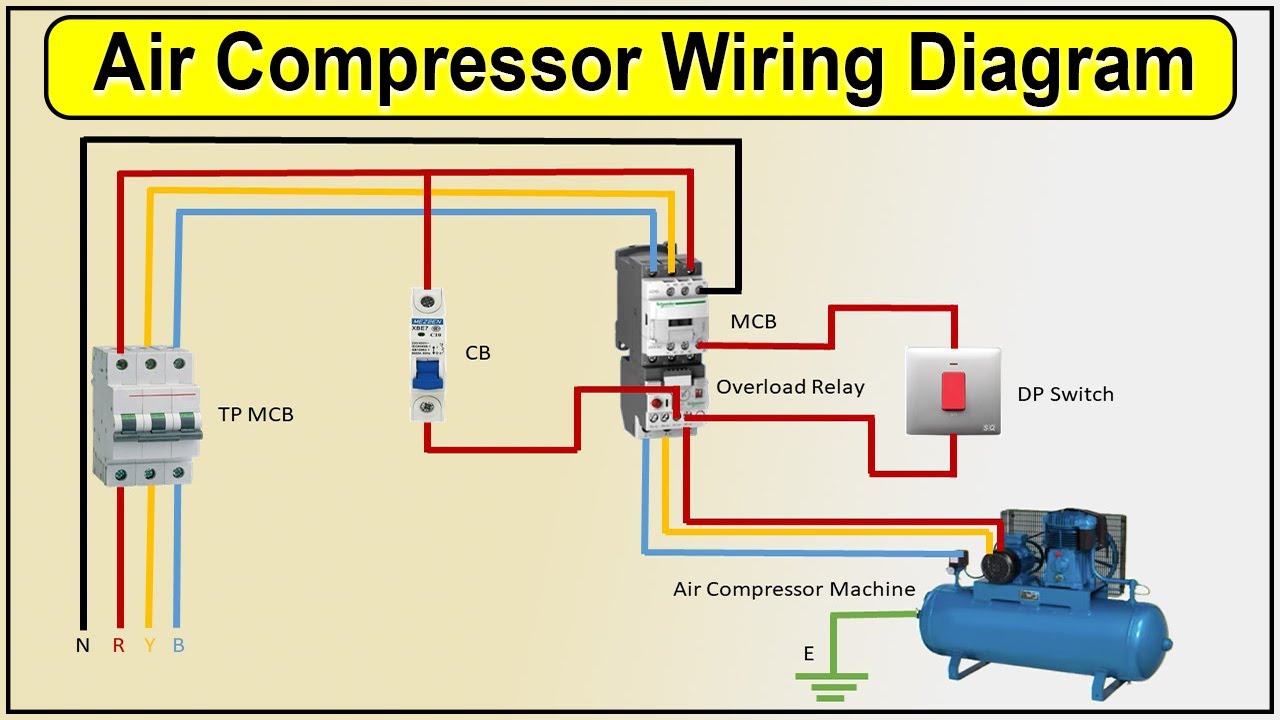

4.Connecting The Electrical Supply

A dedicated circuit breaker should provide the electrical supply for the compressor with enough amperage to handle the load of the compressor. You should rate the circuit breaker for at least 30 amps for a single-phase motor or 20 amps for a three-phase motor.

A qualified electrician should do the wiring following all local codes and regulations. The wiring should match the voltage and frequency of the motor as indicated on its nameplate. The wiring should also have a proper grounding connection.

5.Adding Lubricant To The Compressor

The compressor requires lubricant to operate smoothly and prevent wear and tear on its parts. Use non-detergent synthetic oil specially designed for air compressors as a lubricant. Before each use, you should check the lubricant level and maintain it between the minimum and maximum marks on the oil sight glass. You should change the lubricant every 500 hours of operation or once a year, whichever comes first.

6.Checking And Adjusting The Belt Tension

You should check and adjust the belt tension of the compressor periodically to ensure optimal performance and efficiency. The belt tension should be such that there is about 1/2 inch of deflection when pressed firmly with a finger at the centre of the belt span. Adjust the belt tension by moving the motor forward or backwards and loosening the mounting bolts until the desired tension is achieved. Then tighten the bolts securely.

Bleeding The Air Tank

The compressor’s air tank should be bled regularly to remove any moisture or condensation that may accumulate inside it. Moisture can cause rust and corrosion on the tank and its components, reducing the life and safety of the compressor. To bleed the air tank, open the drain valve at the bottom and let the air and water escape until only air comes out. Then close the valve tightly.

Testing The System For Leaks

You should test the compressor system for leaks before each use to ensure proper operation and safety. To test the system for leaks, plug the compressor into the power source and turn it on. Let the compressor run until it reaches its cut-out pressure and shuts off automatically.

Then disconnect the power cord and listen for any hissing or bubbling sounds that may indicate a leak. If a leak is detected, locate its source and repair it using thread sealant tape or pipe dope.

Maintenance Requirements For The Air Compressor

Regular maintenance is necessary to keep the air compressor in good working condition. This includes checking and changing the oil regularly, inspecting and replacing air filters as needed, and checking for any leaks or damage to the hoses and fittings.

It’s also important to drain the moisture from the tank regularly to prevent corrosion and ensure proper operation. Additionally, it’s recommended to have the compressor serviced by a professional on a regular basis to address any potential issues before they become more serious problems.

Troubleshoot Common Issues

When troubleshooting common issues with the air compressor, there are a few things to remember. Firstly, ensure that the compressor is properly plugged in and receiving power. Check the pressure switch to ensure it is properly set to the correct level.

If the compressor isn’t building pressure, check for airlines or fittings leaks. Also, check the compressor’s oil level and replace it if necessary. Finally, if the motor is overheating or making unusual noises, it may be a sign of a more serious issue and should be inspected by a professional.

Conclusion

The air compressor is a reliable and efficient tool for various applications. Its specific features and capabilities make it a dependable choice for professional and personal use. The compressor’s 5HP motor provides enough power to handle even the most demanding tasks, ensuring successful and satisfactory results.

Its durability, portability, and ease of use make it an ideal choice for those needing a dependable air compressor that can withstand heavy use and transport. The importance of having a dependable air compressor cannot be overstated, and the Sanborn 5HP air compressor proves to be just that.

Its success in various industries speaks to its specificity and ability to meet the needs of various users. The air compressor is a valuable investment for anyone needing a reliable and efficient air compressor.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-79f40a27-a844-40bc-8bab-f4eb1760a2bd”]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.