An air compressor is a mechanical device that compresses air and delivers it at high pressure. It is commonly used to power tools and machinery in industrial and commercial applications.

We will dive deep into the world of air compressor-condensers and provide you with expert tips and tricks to optimize their performance. From understanding an air compressor condenser and its benefits to learning how to install and maintain it, we’ve got you covered.

We will also discuss common issues that can arise with air compressor-condensers and provide troubleshooting techniques to keep them running smoothly. Whether you’re a DIY enthusiast or a professional in the industry, this blog will help you boost efficiency and get the most out of your air compressor-condenser.

Mastering Air Compressor Condenser: Expert Tips And Tricks

To fully utilize your air compressor condenser, it is essential to grasp its function within your system. Maintaining the condenser through regular cleaning guarantees optimal performance. Upgrading to a more efficient model can lead to increased energy savings.

Monitoring and adjusting the condenser settings based on operating conditions and load requirements is critical. Implementing proper insulation and ventilation techniques can further enhance condenser efficiency. By following these expert tips and tricks, you can significantly improve the efficiency of your air compressor-condenser, resulting in maximized performance.

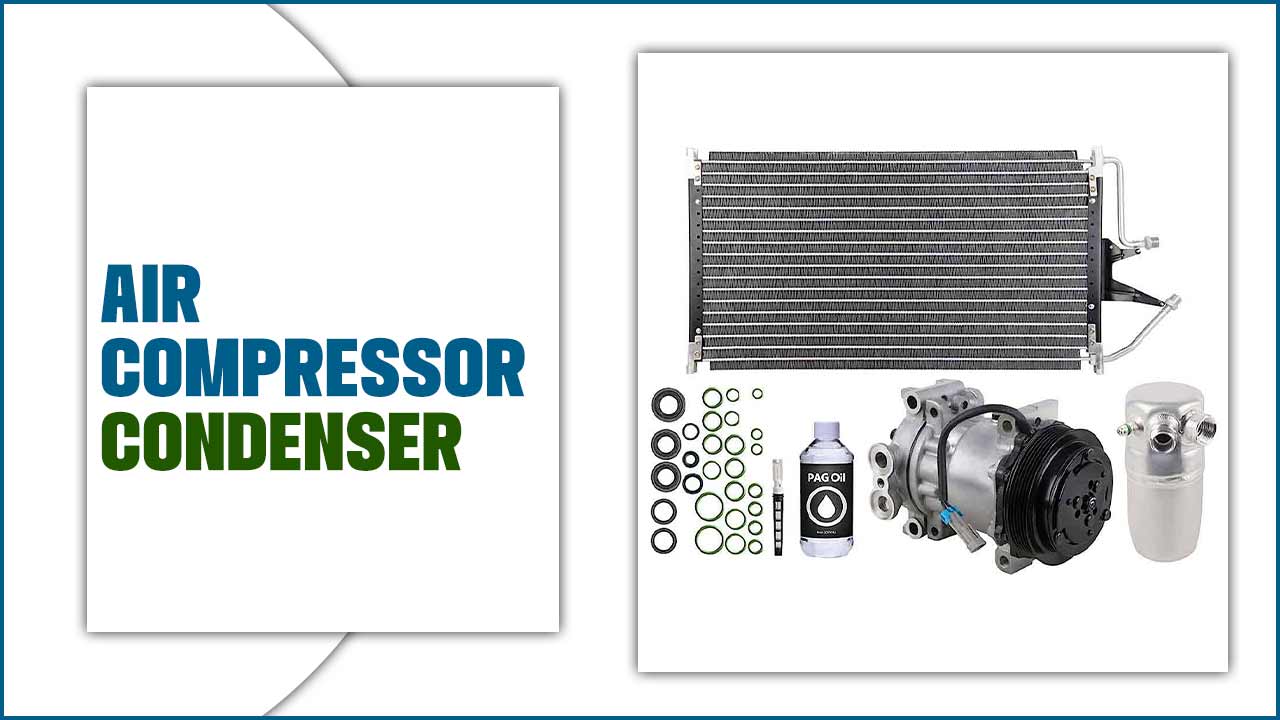

What Is An Air Compressor-Condenser?

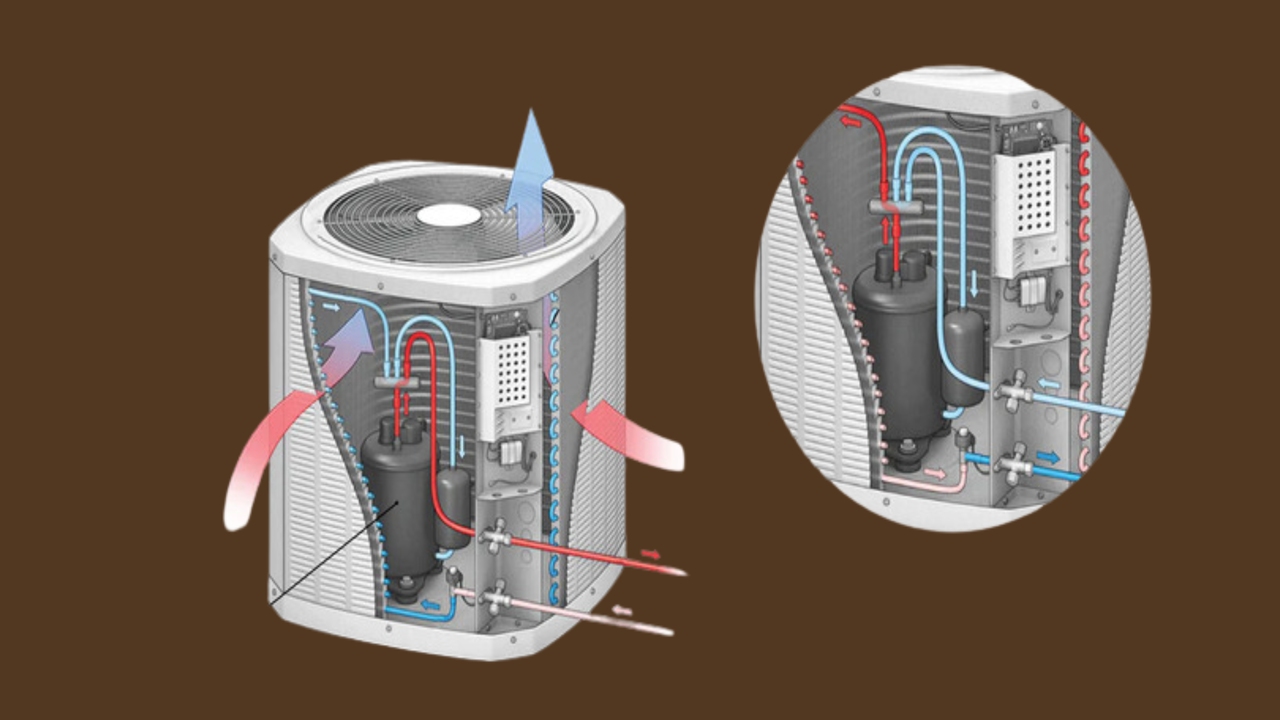

An air compressor-condenser is an essential element of an air compressor system as it plays a vital role in cooling the compressed air before it enters the distribution system. This process involves removing moisture and heat from the air, enhancing the compressed air’s quality, and improving its overall efficiency.

Various types of condensers are available, including air-cooled and water-cooled options. The choice between these two types depends on factors such as available space, environmental conditions, and specific requirements of the compressed air system.

Benefits Of An Air Compressor-Condenser

The air compressor-condenser is a vital component that significantly contributes to the overall efficiency of an air compressor system. Its primary function is to cool and condense the compressed air, improving its quality and performance. Optimizing the condenser can reduce energy consumption and operating costs, making it a cost-effective solution for businesses.

Furthermore, a well-maintained and clean condenser helps prevent overheating, ensuring the longevity of the air compressor. Regular maintenance and cleaning are essential to guarantee optimal efficiency and prevent potential breakdowns. Investing in an air compressor-condenser includes enhanced efficiency, significant cost savings, and increased durability for your air compressor system.

How To Install An Air Compressor-Condenser

To maximize the performance of your air compressor, it is essential to install the condenser correctly. Start by choosing the appropriate size and type of condenser for your specific compressor system. Place the condenser in a well-ventilated area, away from direct sunlight or any heat sources that could affect its operation.

It is important to insulate the condenser properly to prevent heat loss and minimize condensation buildup. Regular maintenance and cleaning are also crucial to ensure optimal efficiency and prolong the lifespan of your air compressor system. Following these installation guidelines can enhance the cooling process and improve overall efficiency.

Common Air Compressor-Condenser Issues

Air compressor-condensers are crucial components of cooling systems, but they can experience several common issues. One such issue is clogging when dirt, debris, or mineral deposits accumulate, restricting airflow. This leads to a decrease in cooling efficiency. Additionally, leaks can occur, resulting in refrigerant loss and reduced cooling capacity. Another problem is inefficient heat transfer caused by dirt or scale buildup on the condenser coils, decreasing overall efficiency.

Cleaning and maintaining the condenser regularly is essential to prevent these issues and optimize performance. This includes cleaning the condenser coils to remove any dirt or debris that may have accumulated. It is also important to promptly address any clogging or leaks to ensure efficient cooling and proper functioning of your air compressor-condenser.

Regular maintenance and cleaning will not only extend the lifespan of your condenser but also help you avoid costly repairs or replacements in the future. By taking proactive measures to keep your condenser in good condition, you can ensure that your cooling system operates at its best performance and provides optimal cooling for your air compressor.

Air Compressor-Condenser Maintenance Tips

Regular maintenance and cleaning of the air compressor-condenser ensure optimal efficiency. To achieve this, it is important to keep the condenser coils free from dirt, dust, and debris by using a soft brush or compressed air for cleaning. Additionally, regularly inspect the condenser coils for any signs of damage or leaks and promptly repair or replace them as needed.

Maintaining clear space around the condenser is also necessary for proper airflow. Monitoring the pressure and temperature levels of the air compressor is recommended to ensure it operates within the recommended range. Another consideration for optimizing airflow and reducing energy consumption is installing a condenser fan speed controller.

How To Troubleshoot An Air Compressor-Condenser

The air compressor-condenser plays a crucial role in the efficiency of an air compressor system. To ensure optimal performance, promptly addressing any issues with the condenser is important. Common problems that may arise include clogged filters, refrigerant leaks, or faulty fan motors.

Regular maintenance and cleaning of the condenser can help prevent these issues and keep the system running smoothly. Maintaining airflow around the condenser is essential to clearing debris and ensuring adequate ventilation.

If troubleshooting efforts do not resolve the problem, it is advisable to seek the expertise of a professional technician for further diagnosis and repair. Their specialized knowledge and experience can help identify and rectify underlying issues more effectively.

Choosing The Right Air Compressor-Condenser

When selecting an air compressor-condenser, there are several factors to consider. The condenser plays a crucial role in the efficiency of the air compressor system. Choosing a condenser that is the right size for the system and can effectively transfer heat is important.

Material choices like copper, aluminum, or stainless steel can impact durability and performance. Additionally, the design of the condenser should allow for efficient airflow. Consulting with an expert or conducting thorough research can help ensure that the right condenser is chosen for specific needs and applications.

Conclusion

Optimizing the condenser is crucial to maximize the efficiency and performance of your air compressor. An air compressor-condenser is vital in maintaining proper heat transfer and preventing overheating. By understanding what an air compressor condenser is, its benefits, installation process, common issues, maintenance tips, troubleshooting techniques, and how to choose the right one for your needs, you can ensure your air compressor operates at its best.

Regular maintenance of your air compressor-condenser is key to ensuring optimal performance. From cleaning the coils to checking for leaks and maintaining proper airflow, these maintenance tips will help extend the lifespan of your condenser and prevent costly repairs.

Frequently Asked Questions

[rank_math_rich_snippet id=”s-9dbae6be-596f-420d-b8ce-f773c750c976″]

I am passionate about home engineering. I specialize in designing, installing, and maintaining heating, ventilation, and air conditioning systems. My goal is to help people stay comfortable in their homes all year long.